Surface treatment method of aluminum alloy piston and precision friction pair

A technology of surface treatment and friction pairs, applied in nanotechnology for materials and surface science, metal material coating technology, nanotechnology, etc., can solve problems such as increased friction coefficient, loose and rough surface layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

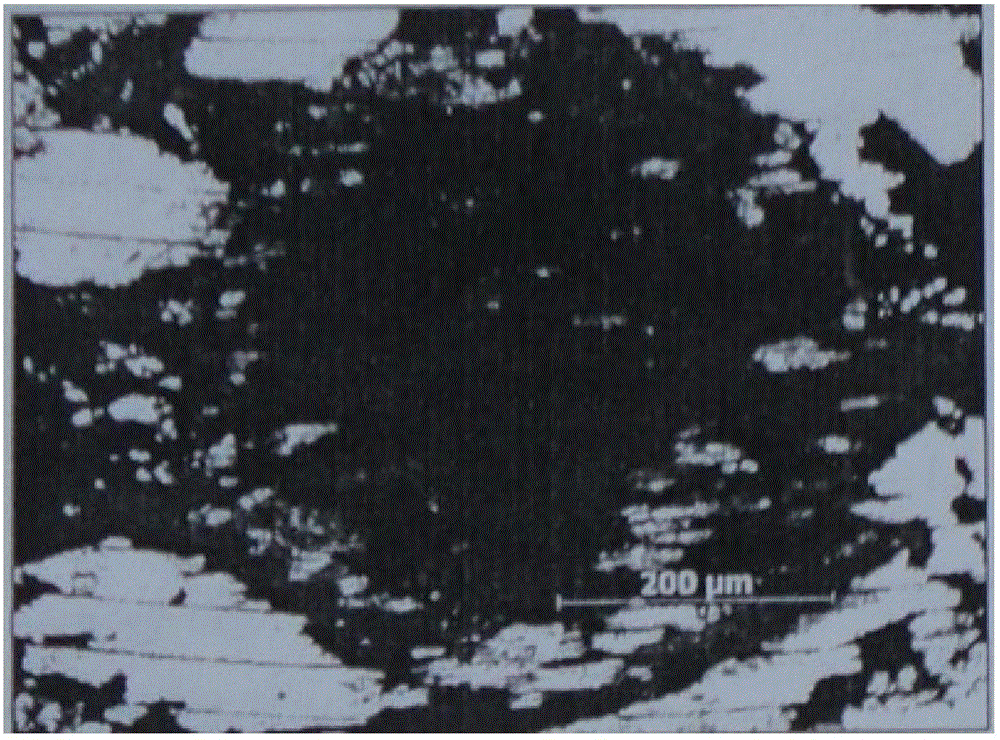

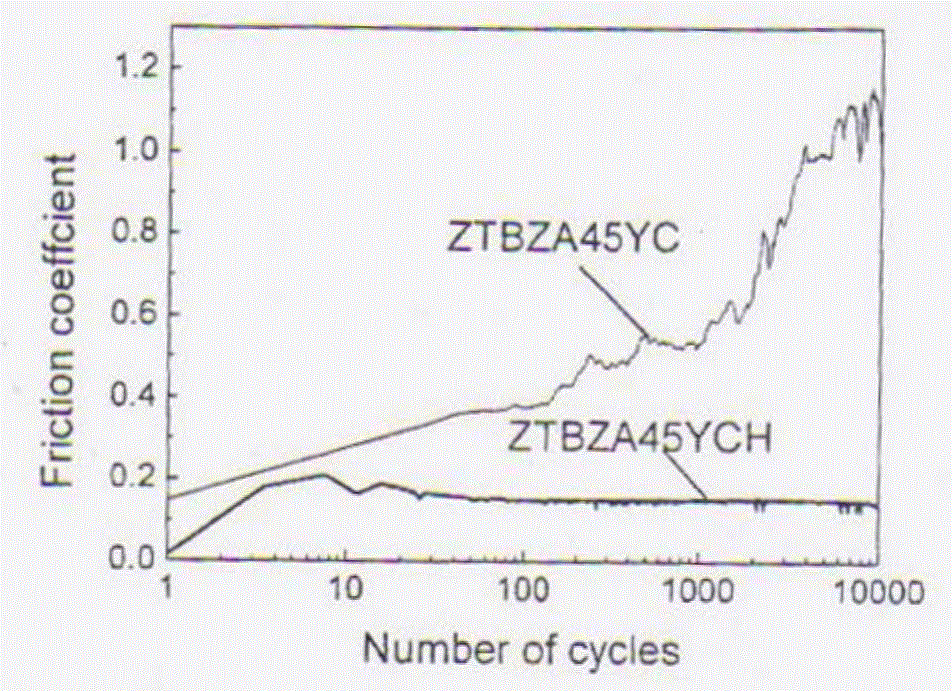

[0067] Clean and dry the ZTBZA45YC aluminum-based wear-resistant alloy precision worm gear. Put it into the multi-component composite oxidation solution, and the oxidation solution submerges the tooth surface. The multi-component composite oxidation solution contains: sodium silicate 11.3g / L, potassium hydroxide 1.3g / L, zirconium dioxide 0.3g / L, EDTA disodium salt 1.2g / L, adjust pH=11-13 with NOH .

[0068] The power of the equipment is 100Kw, and the power limit surface area is 25dm 2 / time, adjust the positive pulse width and negative pulse width to 0.5-1.5 range for compound changes, adjust the pulse frequency to 37.5-75Hz for compound changes, adjust the positive voltage to 180-320V for compound changes, and adjust the negative voltage to 10-30V range Compound change, the current density is controlled at 2-6A / dm 2 , oxidized for 20 minutes.

[0069] Then, adjust the positive pulse width and negative pulse width to 2-3 intervals for compound changes, adjust the pulse f...

Embodiment 2

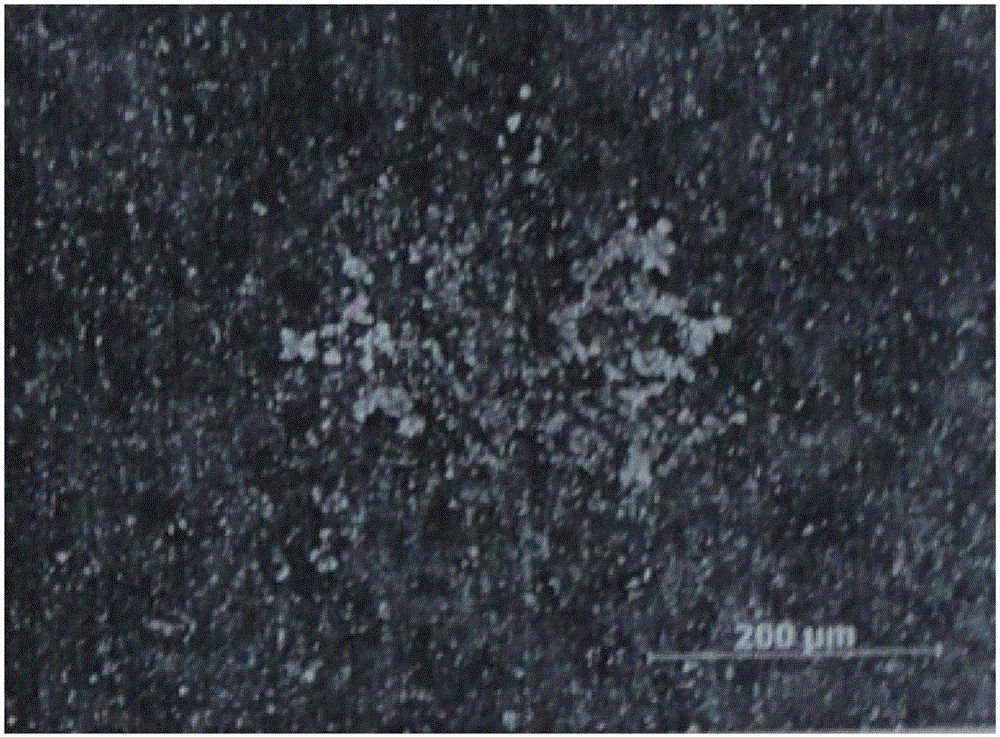

[0073] Clean the ZTBZA31YB aluminum-based wear-resistant alloy nuts and shaft sleeves, and dry them at a constant temperature of 80°C for 30 minutes. Put it into the multi-component composite oxidation solution, and the oxidation solution submerges the aluminum alloy nut and shaft sleeve. The multi-component composite oxidation solution contains: sodium silicate 10g / L, potassium hydroxide 0.8g / L, sodium hydroxide 0.6g / L, zirconium dioxide 0.2g / L, EDTA disodium salt 1.3g / L, with NOH adjusts pH=11-13.

[0074] The power of the equipment is 100Kw, and the power limits the surface treatment area to 25dm 2 / time, adjust the positive pulse width and negative pulse width to 0.5-1.5 range compound change, pulse frequency to 37.5-75Hz compound change, positive voltage to 180-380V range compound change, negative voltage to 10-30V range Compound change, the current density is controlled at 3-5A / dm 2 , oxidized for 30 minutes.

[0075] Then, adjust the positive pulse width and negati...

Embodiment 3

[0079] Clean the top of the aluminum alloy piston, the first ring groove and the ring bank used in the ZS156FMI engine, and dry them at a constant temperature of 80°C for 20 minutes. Put it into the multi-component composite oxidation solution, and the oxidation solution submerges the treated surface of the piston. The multi-component composite oxidation solution contains: sodium silicate 14g / L, sodium hydroxide 1.3g / L, zirconium dioxide 0.25g / L, EDTA disodium salt 1.0g / L, and NOH is used to adjust the pH=11-13.

[0080] The power of the equipment is 100Kw, and the power limit surface area is 25dm 2 / time, adjust the positive pulse width and negative pulse width to 0.5-1.5 range for compound changes, adjust the pulse frequency to 37.5-75Hz for compound changes, adjust the positive voltage to 180-320V for compound changes, and adjust the negative voltage to 10-30V range Compound change, the current density is controlled at 2~5A / dm 2 , oxidized for 10 minutes.

[0081] Then,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com