Mechanical transmission-free jet flow spray-adjustable cooling method and device

A cooling device, spray cooling technology, applied in the direction of mechanical equipment, heating methods, air conditioning systems, etc., can solve problems such as the overwhelmed maintenance costs of ventilation components, failure of operation balance, wear and tear of rotating bearing components, etc., to eliminate backflow sinking pressure Effects of wind damage, removal of performance limitations, and enhancement of cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

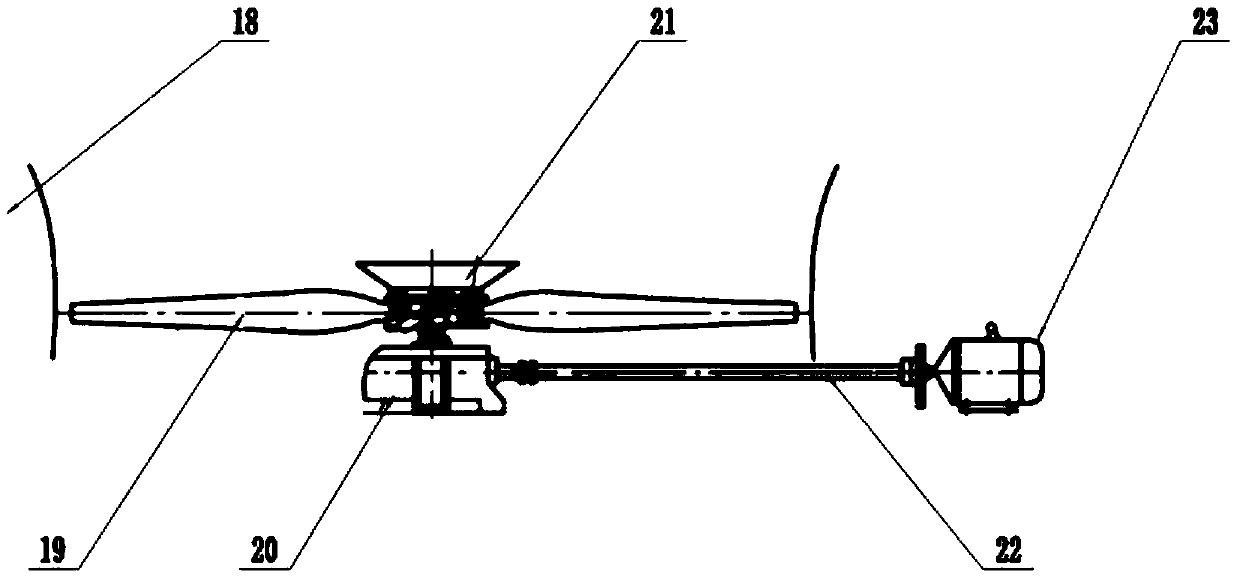

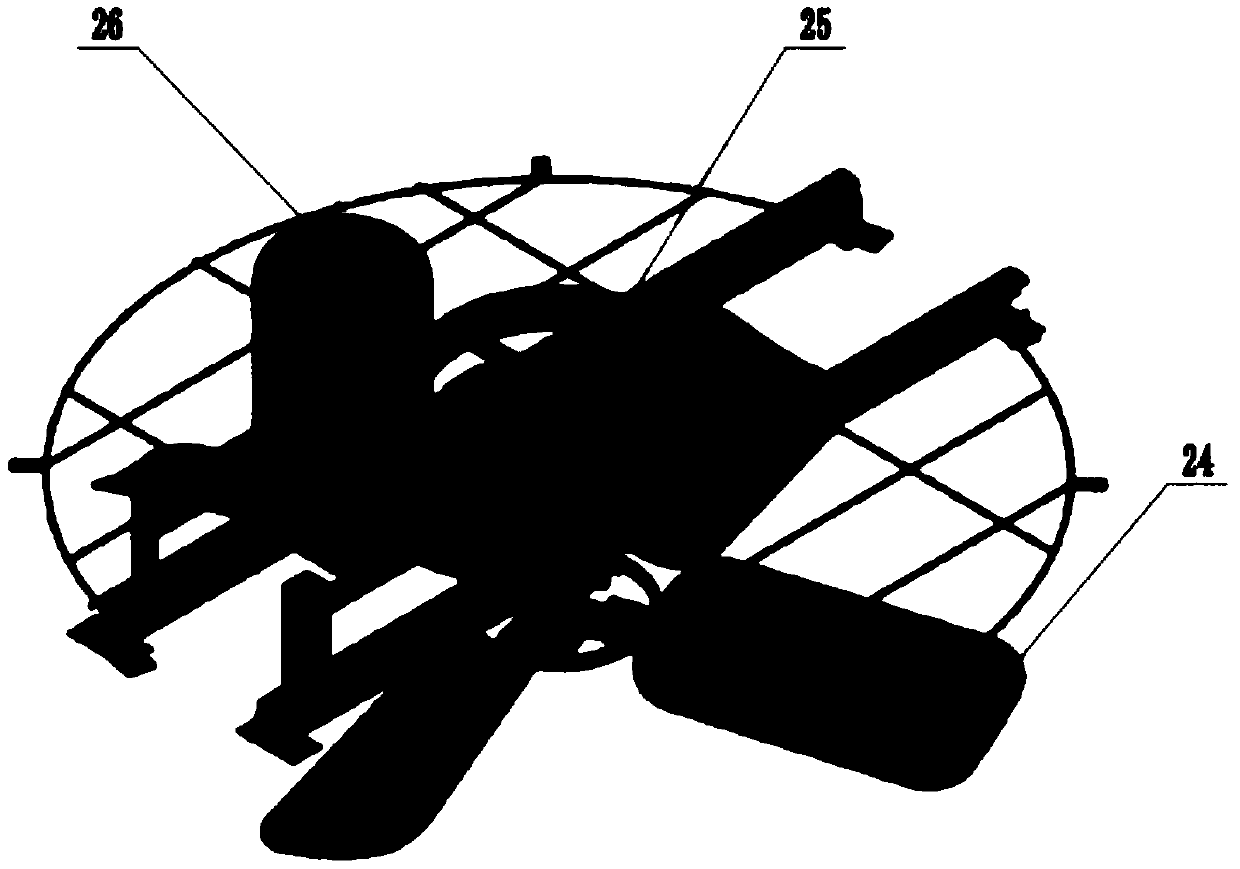

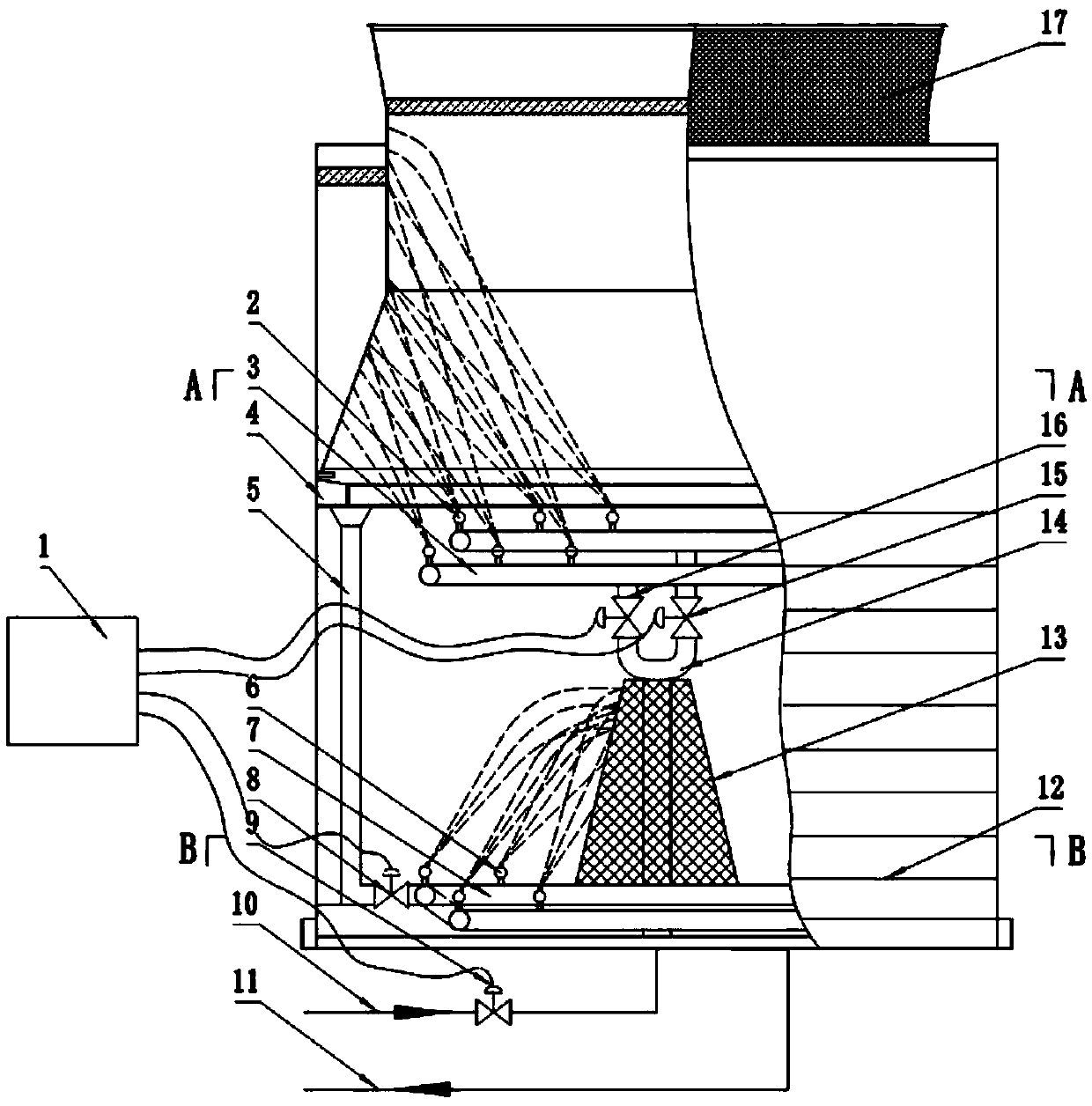

[0043] In order to solve the problems existing in the prior art, the embodiments of the present invention are as image 3 , attached Figure 4 And attached Figure 5 Shown: including the tower body, hot water inlet 10 pipes and cooling water outlet 11 pipes, the tower body is arranged in sequence from high to low with the top water distribution pipeline 3 in the middle and the top water distribution pipeline 7 in the bottom, and the top water distribution pipeline in the middle Road 3 is connected with a circumferentially distributed first-level multi-layer non-mechanical transmission fixed jet spray cooling nozzle group, and the bottom water distribution topological pipeline 7 is connected with a second-level multi-layer non-mechanical transmission fixed jet spray cooling nozzle group. There are 14 main water inlet pipes in communication between the water topology pipeline 3 and the bottom water distribution topology pipeline 7 . The hot water inlet 10 pipeline and the cool...

Embodiment 2

[0051] as attached Image 6 As shown, the difference between this embodiment and Embodiment 1 is that: the central water distribution topological pipeline 3 includes an inner ring and an outer ring, and the height of the inner ring is higher than that of the outer ring, and the height difference between the inner ring and the outer ring water distribution pipeline is designed by H1 The value is 600mm, and the water distribution pipelines of the inner ring and the outer ring adopt double-circuit four-channel water pipes.

[0052] The distance between any adjacent one-level multi-layer non-mechanical transmission fixed-jet spray cooling nozzles is L1, and the design of L1 is 800mm. is θ1, the design of θ1 is 85°, the angle between the one-level multi-layer non-mechanical transmission fixed jet spray cooling nozzle group and the horizontal direction is α, and the design of α is 30°.

[0053] The specific implementation process is as follows: due to the dual-circuit four-channel ...

Embodiment 3

[0055] as attached Figure 7As shown, the difference between this embodiment and the previous embodiment is that the bottom water distribution topological pipeline 7 includes an inner ring and an outer ring, and the height of the inner ring is higher than that of the outer ring, and the height difference H between the inner ring and the outer ring water distribution pipeline is 2 The design value is 300mm, and at the same time, the pipeline is arranged in a dual-circuit eight-channel uniform water inlet topology. The distance between any adjacent two-level multi-layer non-mechanical transmission fixed-jet spray cooling nozzle group is L2, and the design of L2 is 700mm. The angle between the first-level multi-layer non-mechanical transmission fixed-jet spray cooling nozzle group and the vertical direction is θ2 and θ2 are designed to be 80°, and the angle between the first-stage multi-layer non-mechanical transmission fixed jet spray cooling nozzle group and the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com