Dedusting and phosphorus collecting system and dedusting and phosphorus collecting method

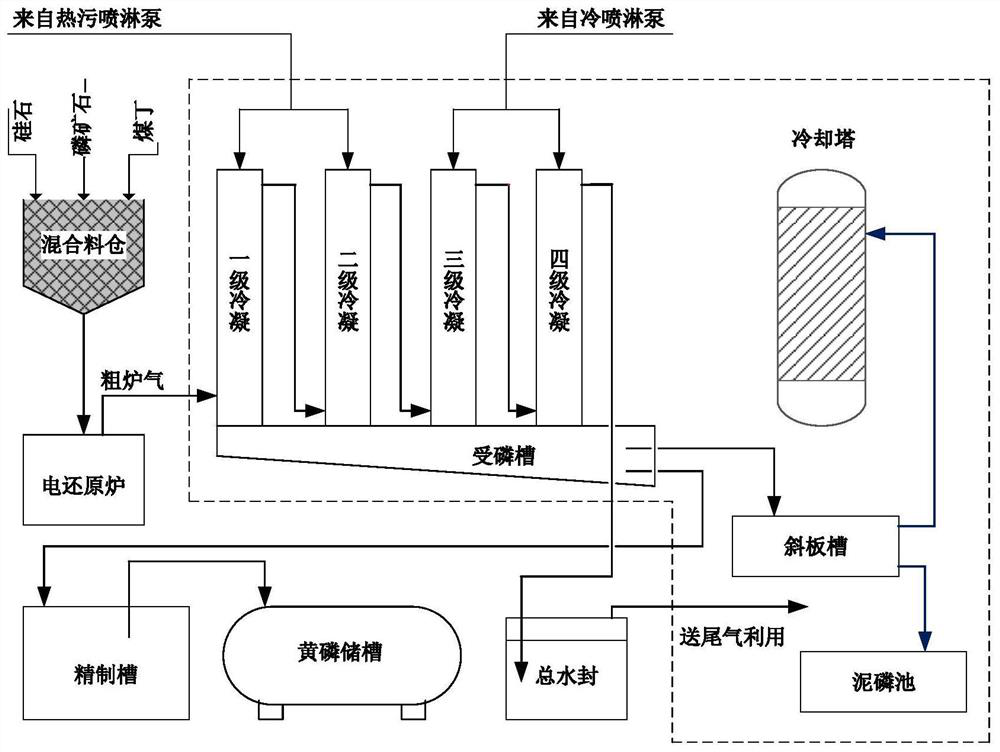

A technology of high-temperature dust collector and yellow phosphorus, which is applied in separation methods, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low quality and yield of yellow phosphorus, large amount of sludge phosphorus treatment, difficulty in phosphorus purification, etc., and achieve huge Energy saving and environmental protection benefits, increase in yellow phosphorus production, and the effect of reducing the amount of recycled sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

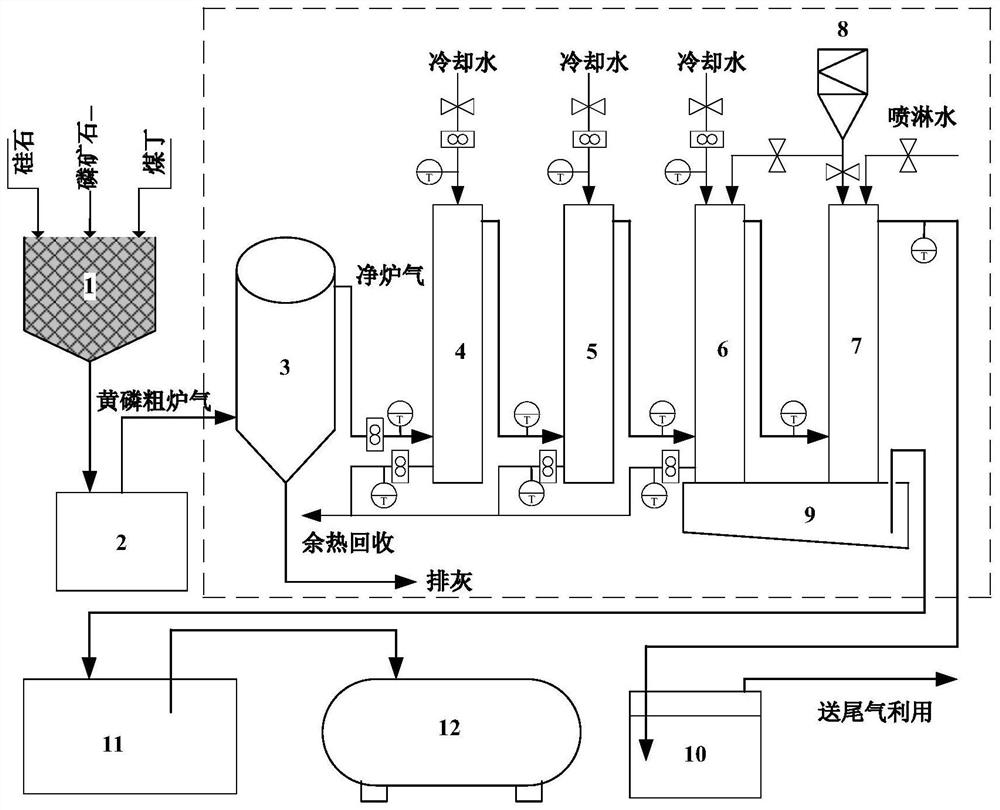

[0041] like figure 2 As shown, a dust removal and phosphorus collection system includes a high temperature dust collector 3, a three-stage heat exchanger, an atomizing spray device 8, a spray condenser 7 and a phosphorus receiving tank 9;

[0042] The mixture in the mixing bin 1 enters the electric furnace 2, and the yellow phosphorus rough furnace gas obtained by the electric furnace 2 is sent to the high temperature dust collector 3 through the yellow phosphorus rough furnace gas conveying pipe, and the air inlet of the high temperature dust collector 3 is connected to the yellow phosphorus rough furnace gas transmission. The bottom of the high-temperature dust collector 3 is provided with an ash discharge port, and the air outlet of the high-temperature dust collector 3 is connected to the air inlet of the first-stage heat exchanger 4; the first-stage heat exchanger 4 and the second-stage heat exchange A series connection is adopted between the heat exchanger 5 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com