Patents

Literature

92 results about "Collision checking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

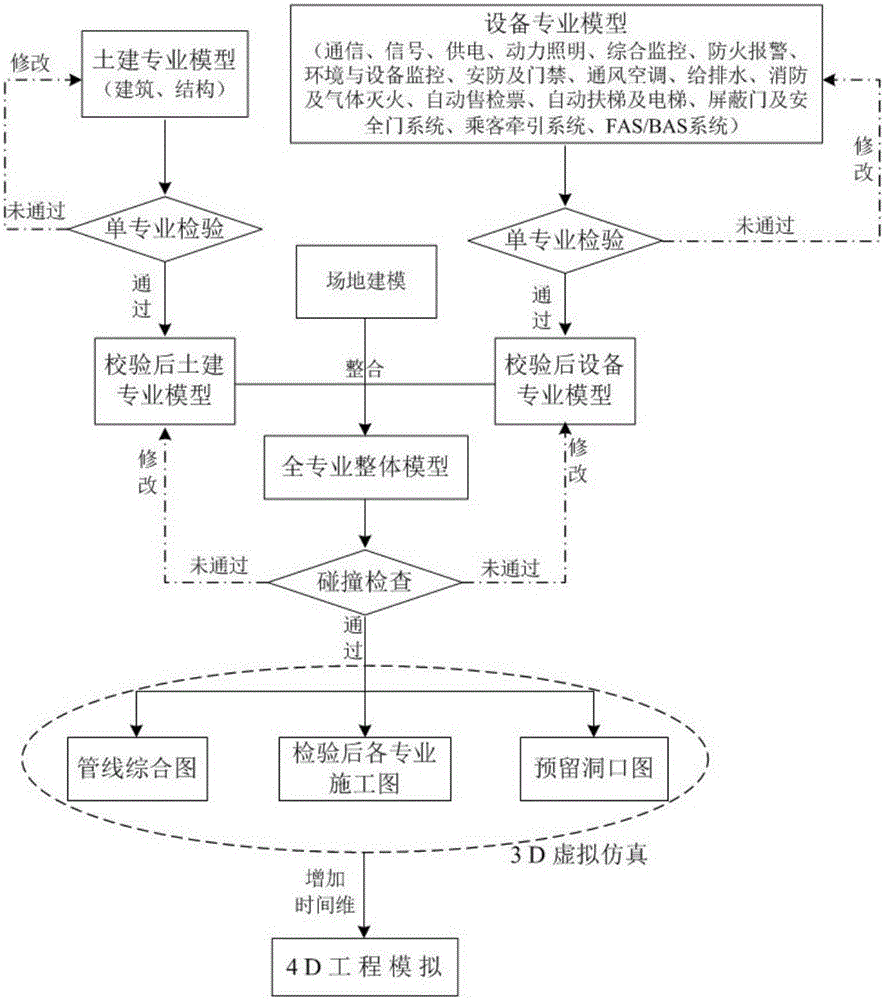

BIMbased metro construction method

InactiveCN106202723AImprove systematizationImprove standardizationGeometric CADSpecial data processing applicationsData informationManagement efficiency

A BIM based metro constructiontechnique method comprises the implementing process that a metro construction site three-dimensional model is established, comprehensive pipeline collision checking is conducted, local complicated structures are visually analyzed, 4D dynamic simulation and analysis optimization are performed, model data information is extracted, and site layout and simulation are performed. By the adoption of the method, a metro engineering construction organization model in a complicated environment is established, the dynamic relation of progress, resources and site factors in the construction process is comprehensive considered, the complexity, uncertainty and randomness in construction can be well expressed, and the intuition,feasibility and scientificity of construction organization can be strengthened. The method is based on construction and endures in a whole metro construction life cycle. Due to the fact that the metro engineering BIM model used during implementation of the technique method provides accurate construction information for operation and maintenance of metro engineering, the management efficiency of the metro engineering is greatly improved by implementing the technique method, and a technical support is provided for achievement of scientific and technological metros and green metros.

Owner:BEIJING UNIV OF TECH +1

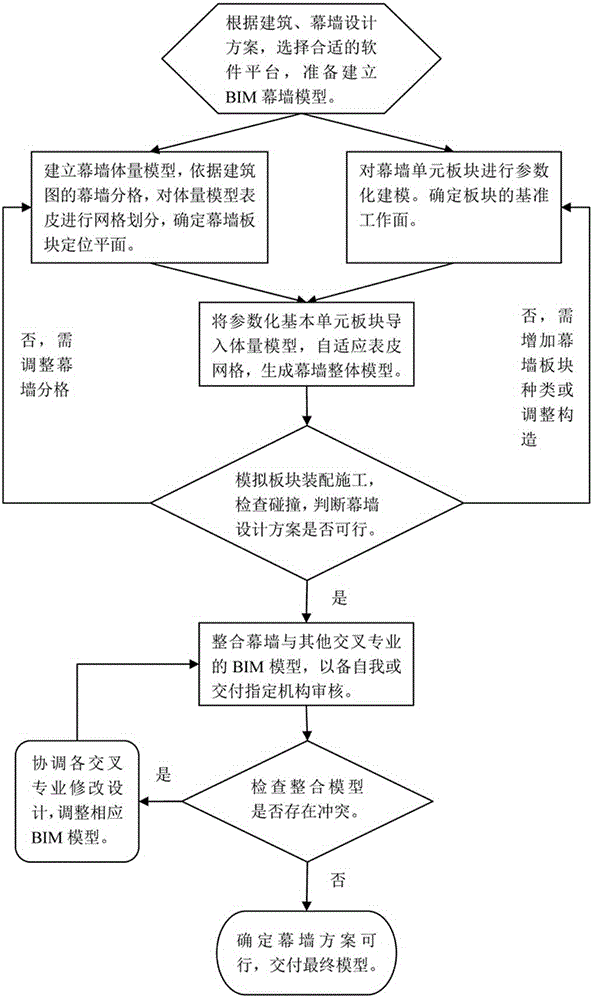

BIM (Building Information Modeling)-based curtain wall parametrization design method

InactiveCN104102765AImplement changesRealize monitoringImage data processingSpecial data processing applicationsDynamic managementDesign methods

The invention relates to a BIM (Building Information Modeling)-based curtain wall parametrization design method, which comprises the following steps: building a BIM mass model of a curtain wall; building multiple parametrization basic unit plate models; assembling each basic unit plate model to the BIM mass model in a simulating manner, checking collision, and judging the feasibility of the designing scheme according to the assembly situation; integrating the well-assembled BIM model with other crossed professional BIM model, and checking whether the integrated model conflicts or not. Through BIM, the parametrization design of a curtain wall project is realized, the problem of building a curved-surface curtain wall by using standard rectangular unit plates is handled, the parametrization dimension driven design and adjustment functions are integrated, so that the control dimension of the curtain wall units is amended at any time, thus the design efficiency is improved, the error rate is reduced, and a project delay risk is lowered; the collision checking function of the BIM technology is adopted, so the change, monitoring and dynamic management on the curtain wall design are realized. The BIM-based curtain wall parametrization design method can be used in the design of curtain walls.

Owner:GUANGDONG GOLDEN CURTAIN WALL ENGINEERING CO LTD

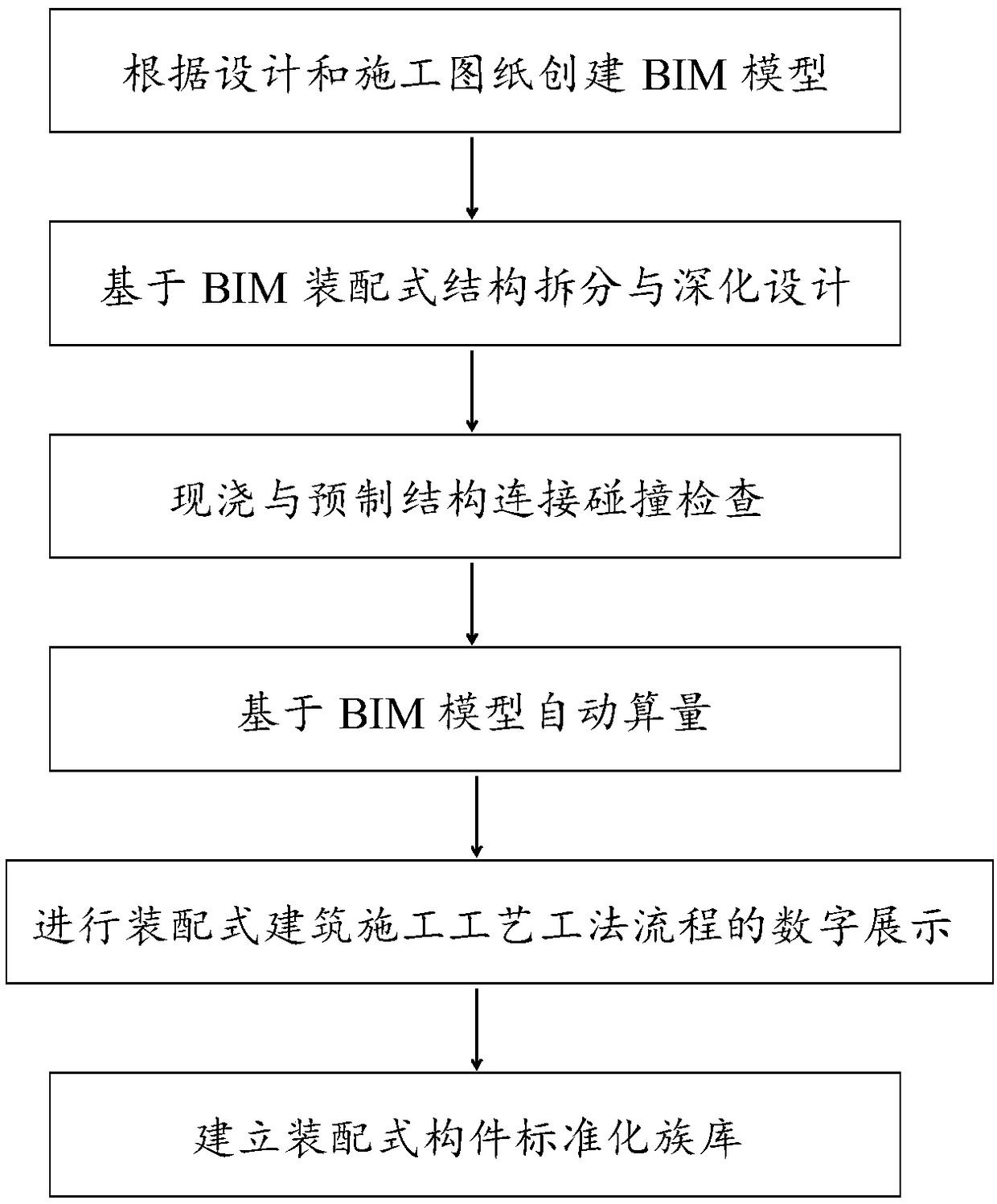

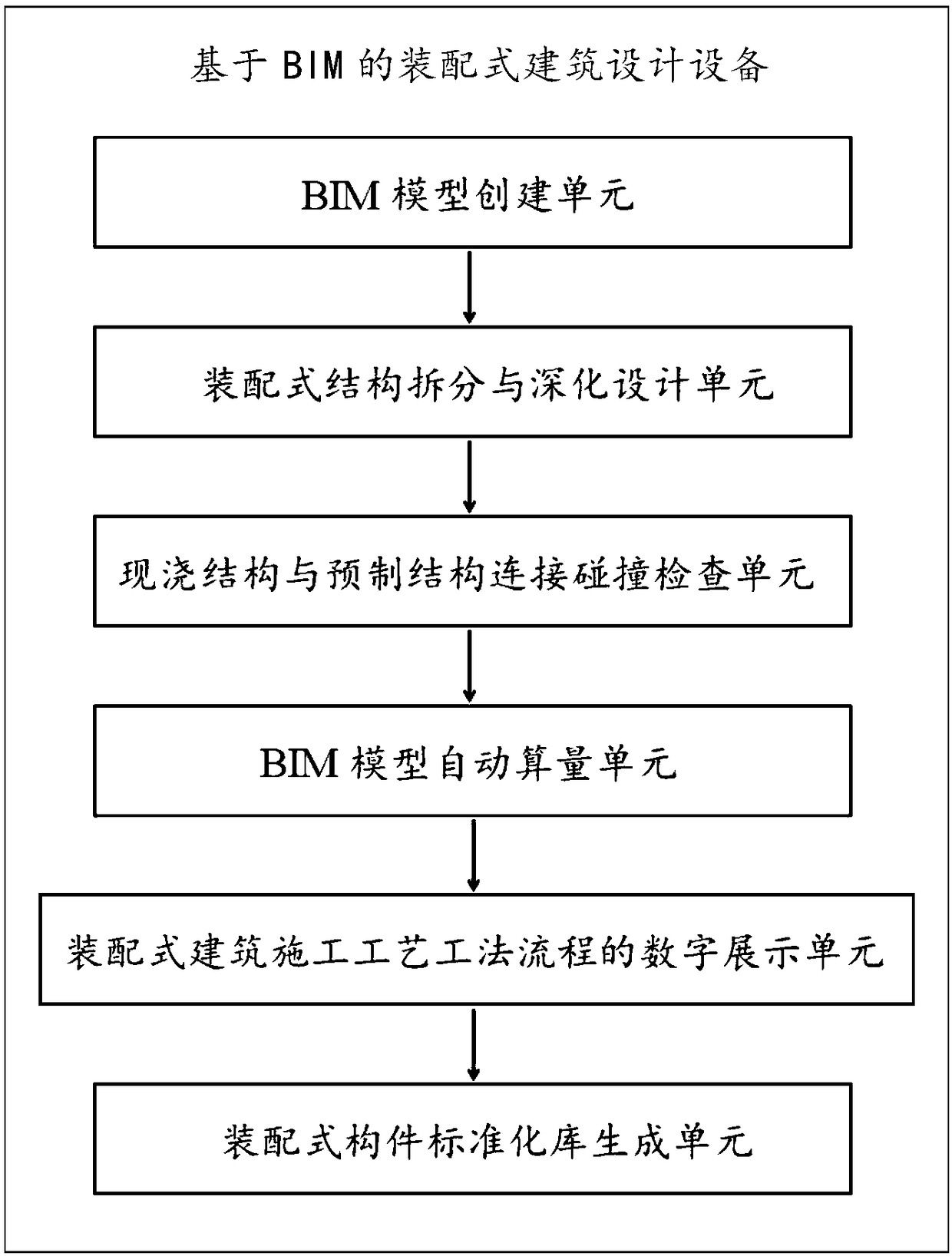

BIM-based fabricated building design method and device

PendingCN108108510ARealize integrationImprove efficiencyGeometric CADSpecial data processing applicationsEngineeringBuilding design

The invention relates to a BIM-based fabricated building design method and device. According to the method, by creating a BIM (building information model) according to a design and construction drawing, performing fabricated structure splitting and deepening design based on the BIM, performing cast-in-situ and prefabricated structure connection collision checking, performing automatic quantity calculation based on the BIM, performing digital display of a fabricated building construction technology, method and process and establishing a fabricated component standard family, a design scheme, a manufacturing demand and an installation demand are integrated in the BIM, integration of fabricated building design is realized, problems possibly generated in the actual manufacturing and installation process can be eliminated in advance, the overall efficiency of manufacturing and installation is improved, and the construction period is shortened.

Owner:广东星层建筑科技股份有限公司

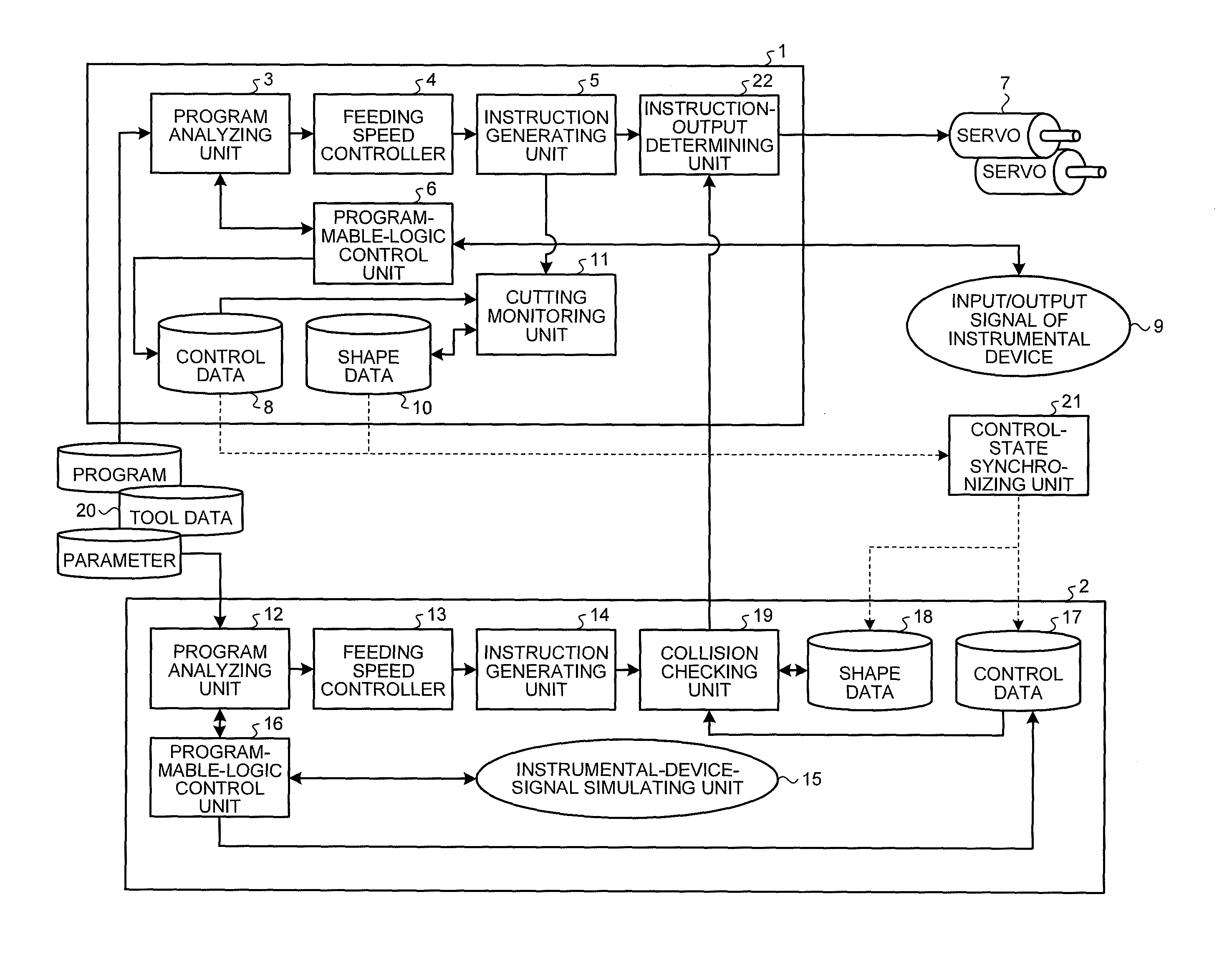

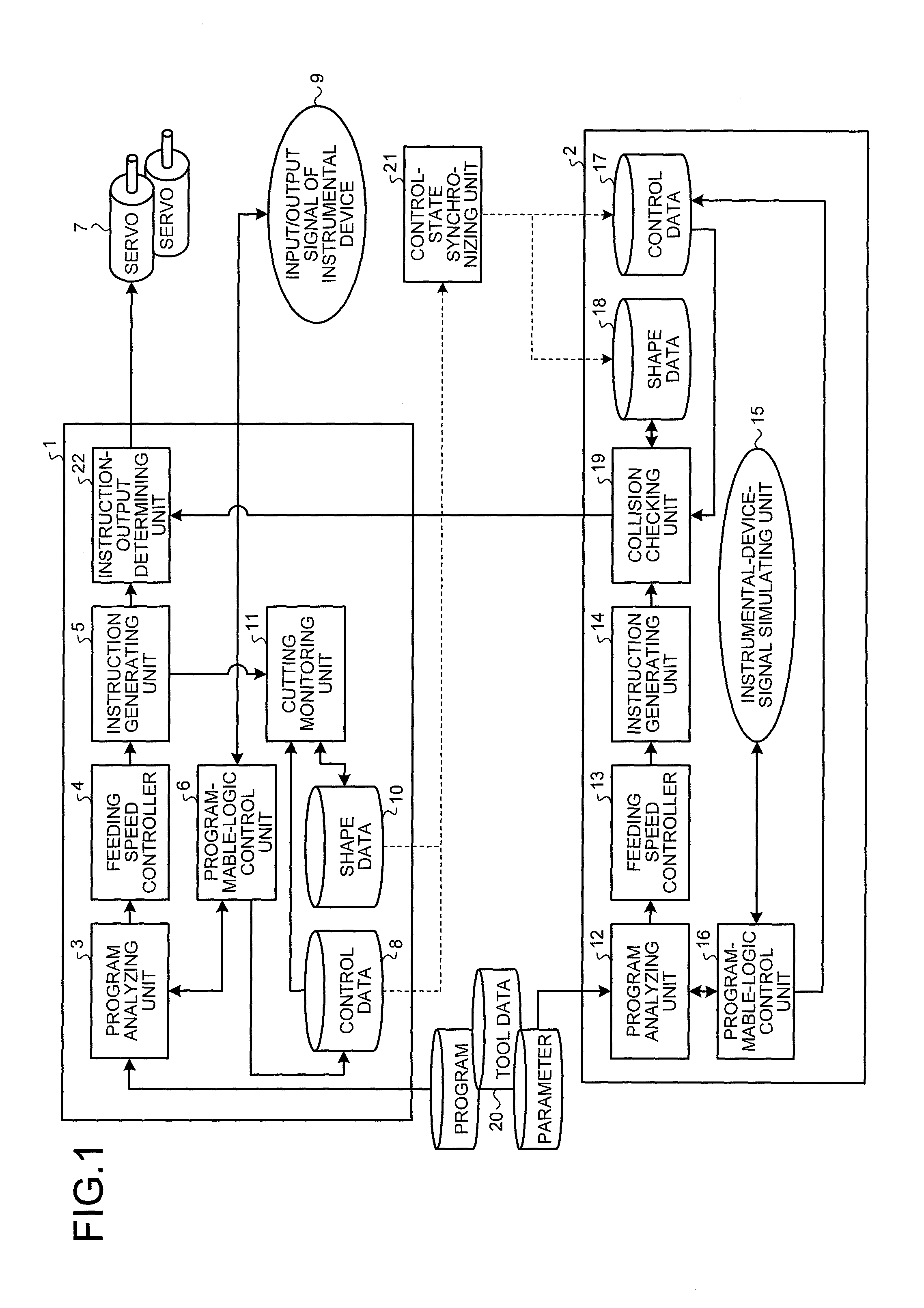

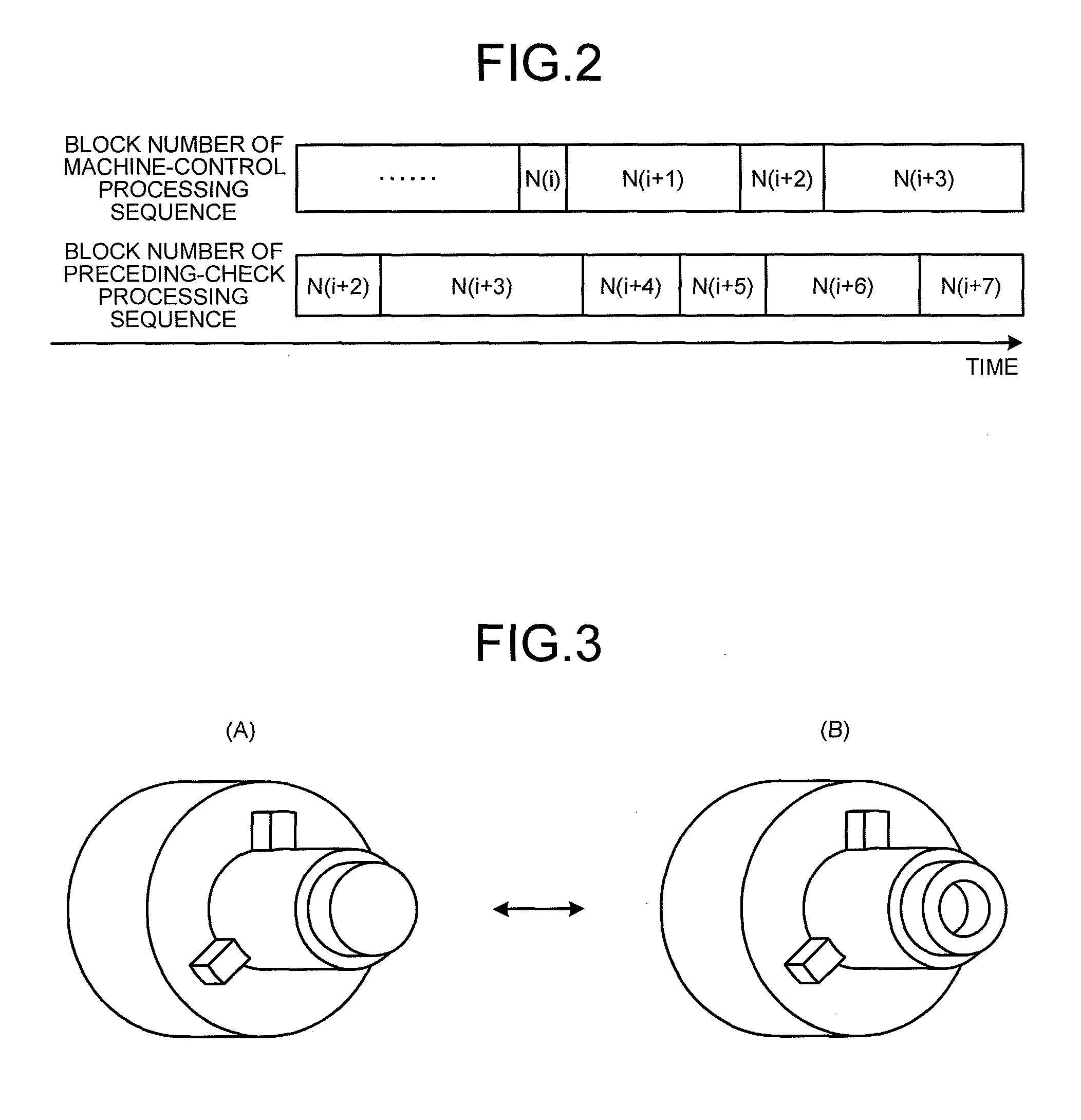

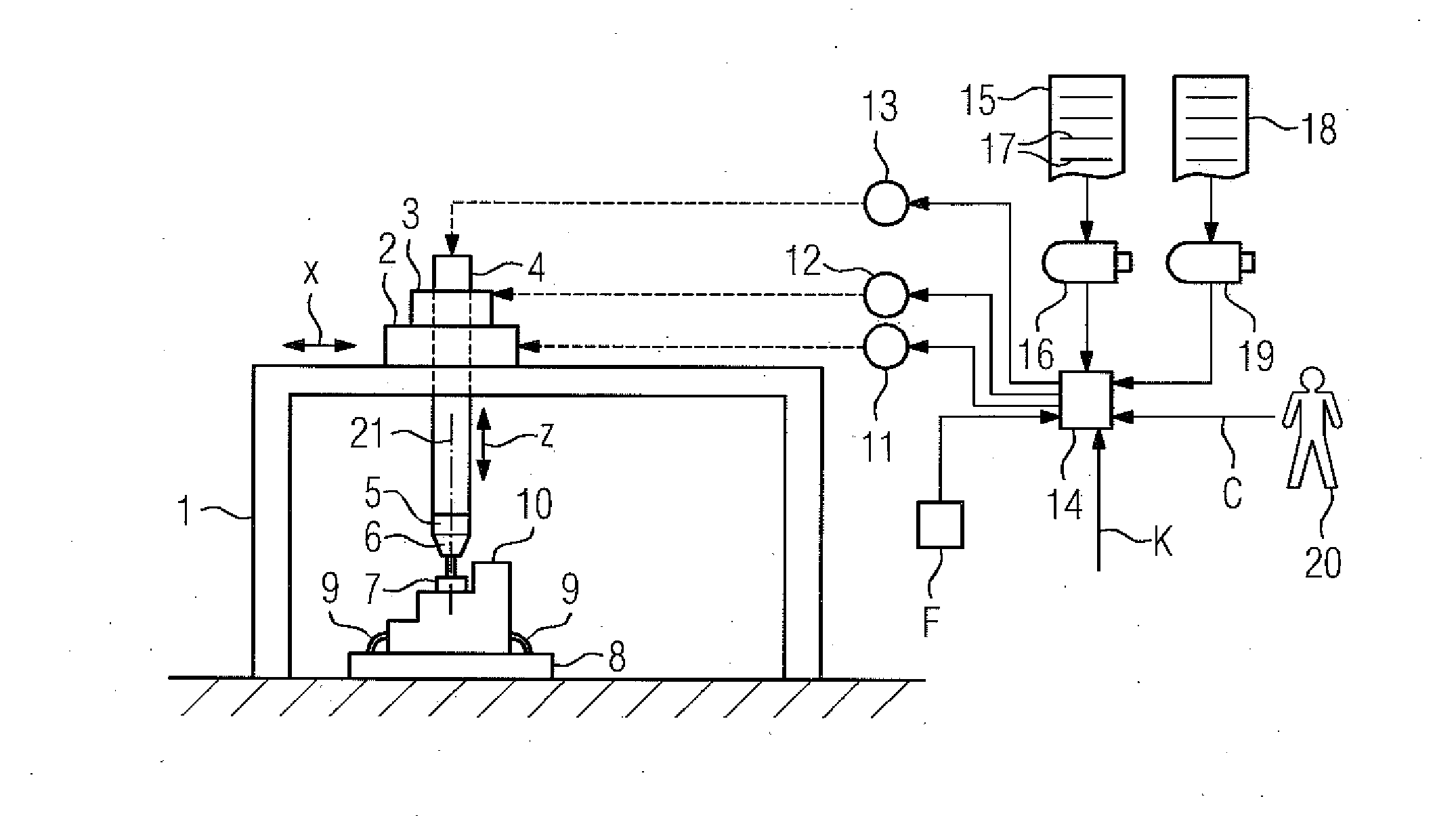

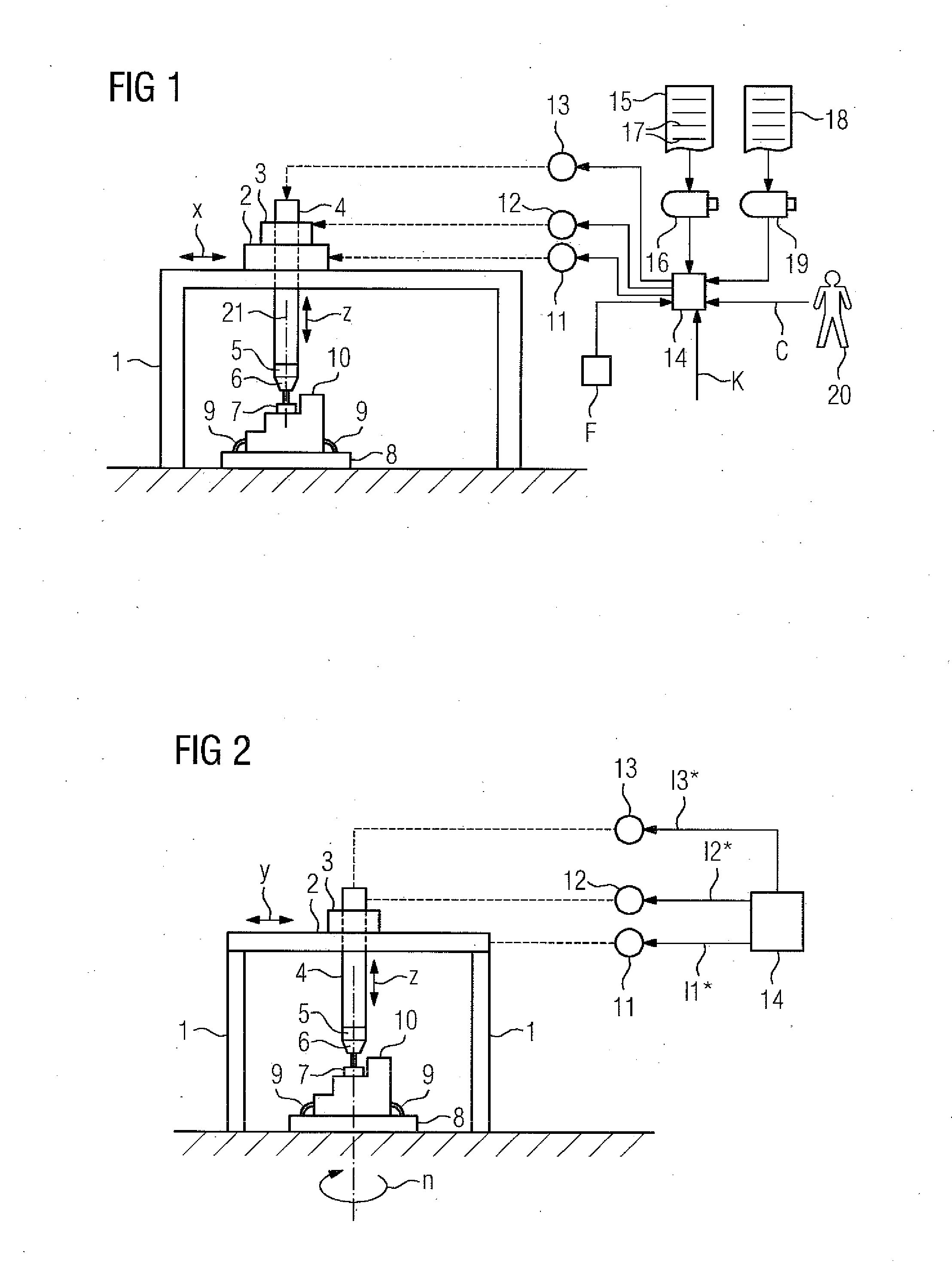

Numerical control method and apparatus therefor

ActiveUS20110035044A1Ensure correct executionHigh precisionComputer controlSimulator controlNumerical controlMachine control

A preceding-check processing sequence is provided separately from a machine-control processing sequence for an actual machine control, to make it possible to perform a collision check at an accurate position from an operation restart time of a machining program even when an operator interrupts an operation in the middle of the machining program or when the operator interrupts the operation as having detected a collision. This preceding-check processing sequence performs a collision possibility check ahead of an actual machine control. In this arrangement, there is provided a control-state synchronizing unit that matches a state of the preceding-check processing sequence with a state of the machine-control processing sequence during a period from when a machine stops until when the machine restarts an operation.

Owner:MITSUBISHI ELECTRIC CORP

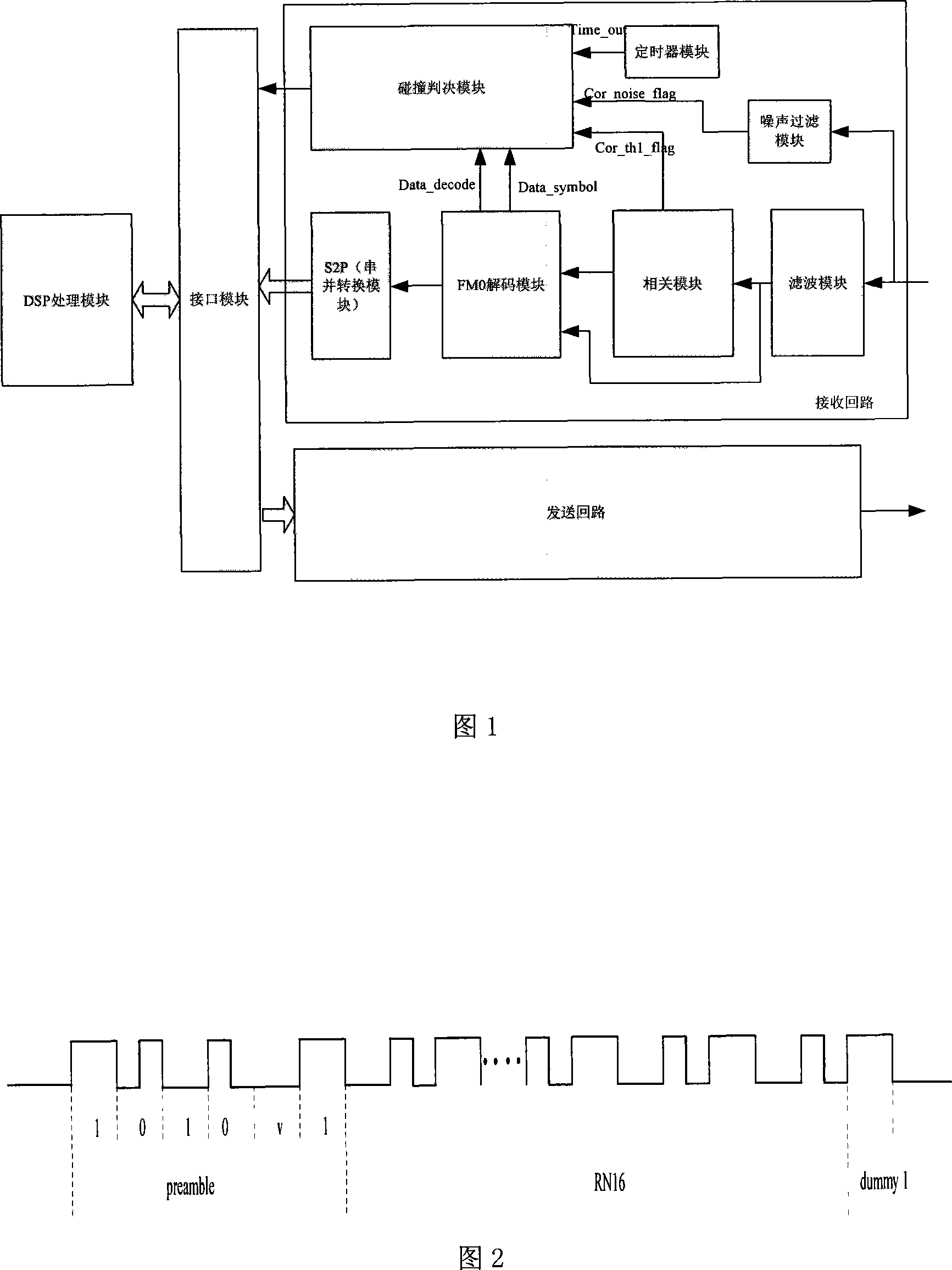

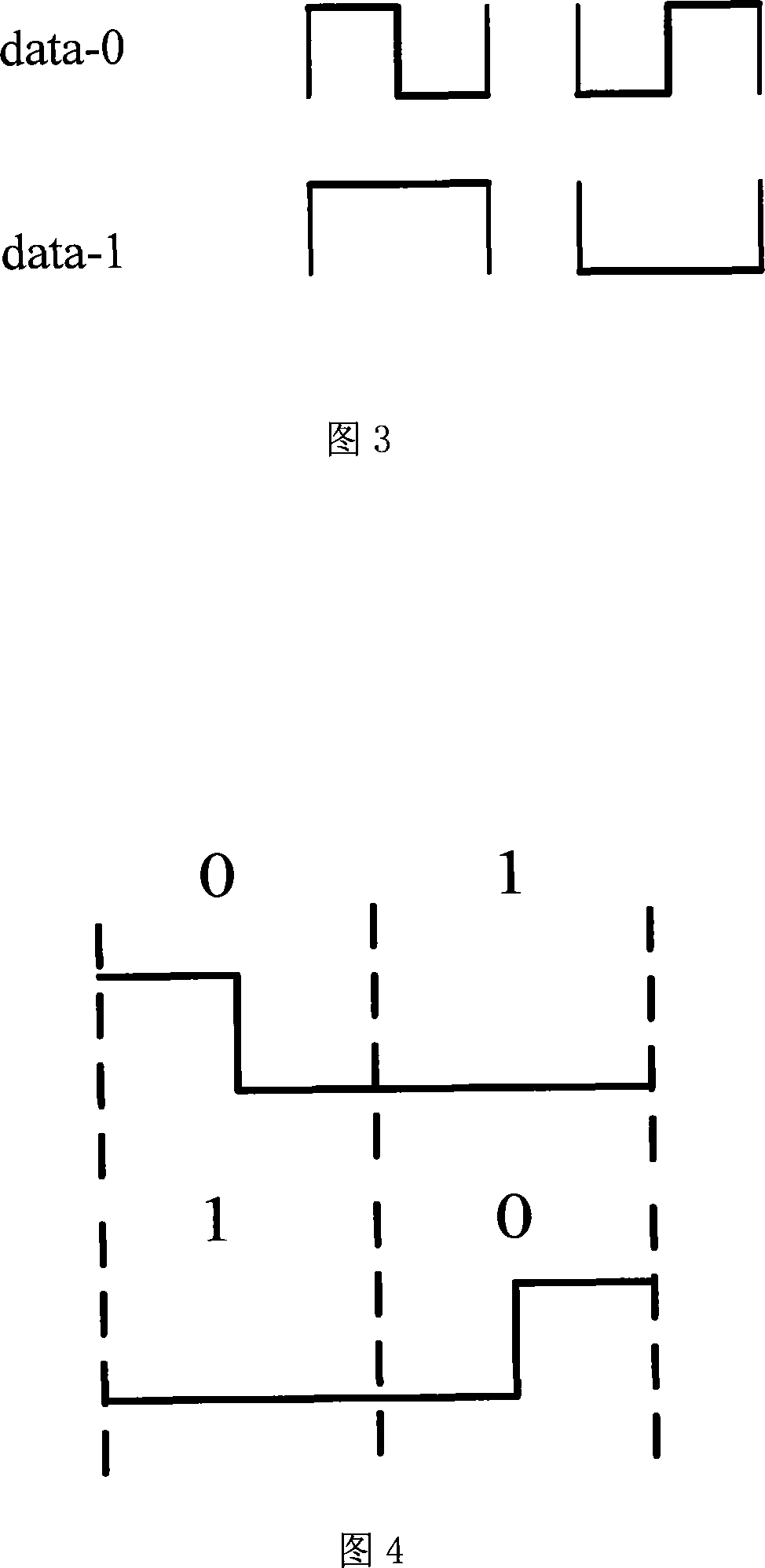

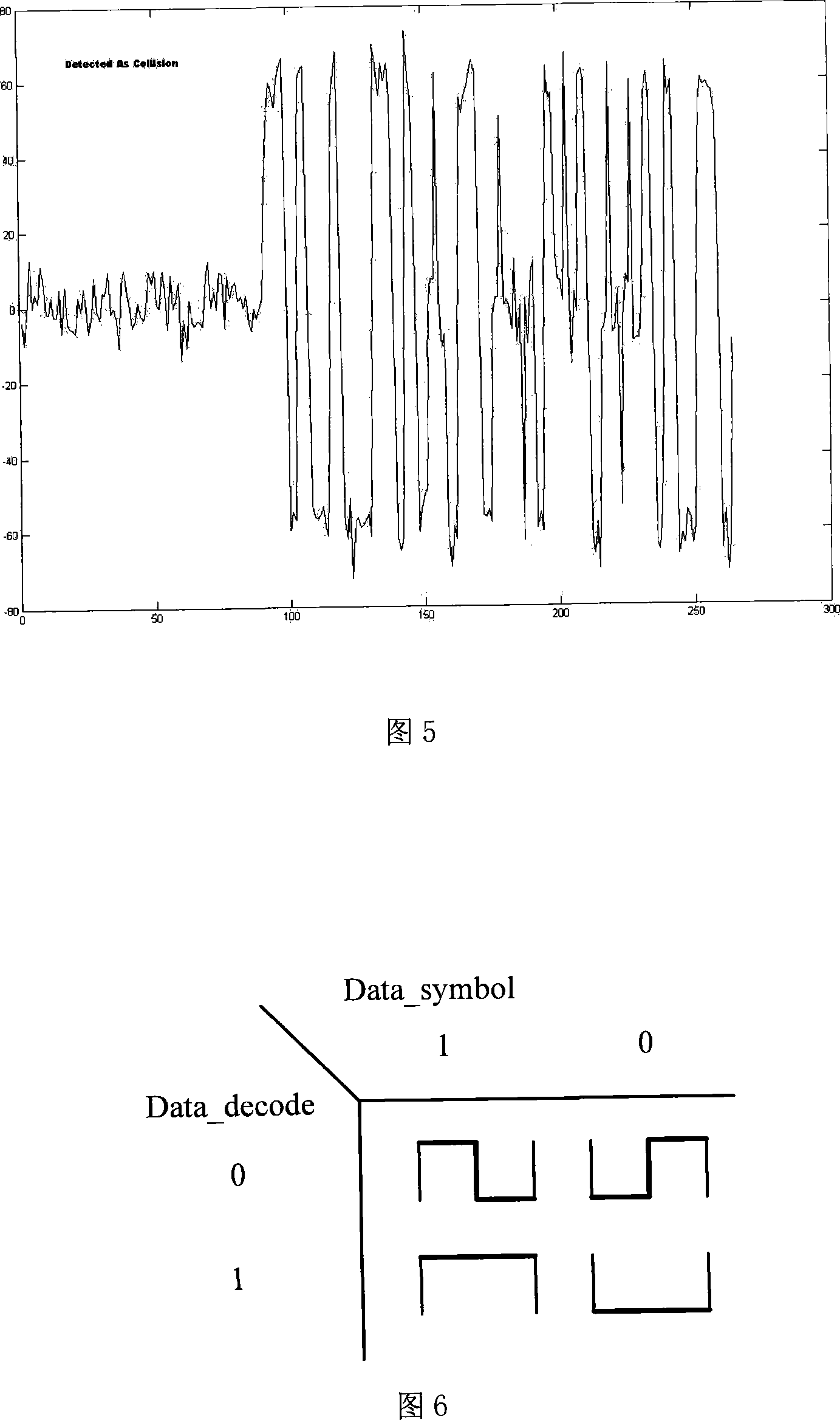

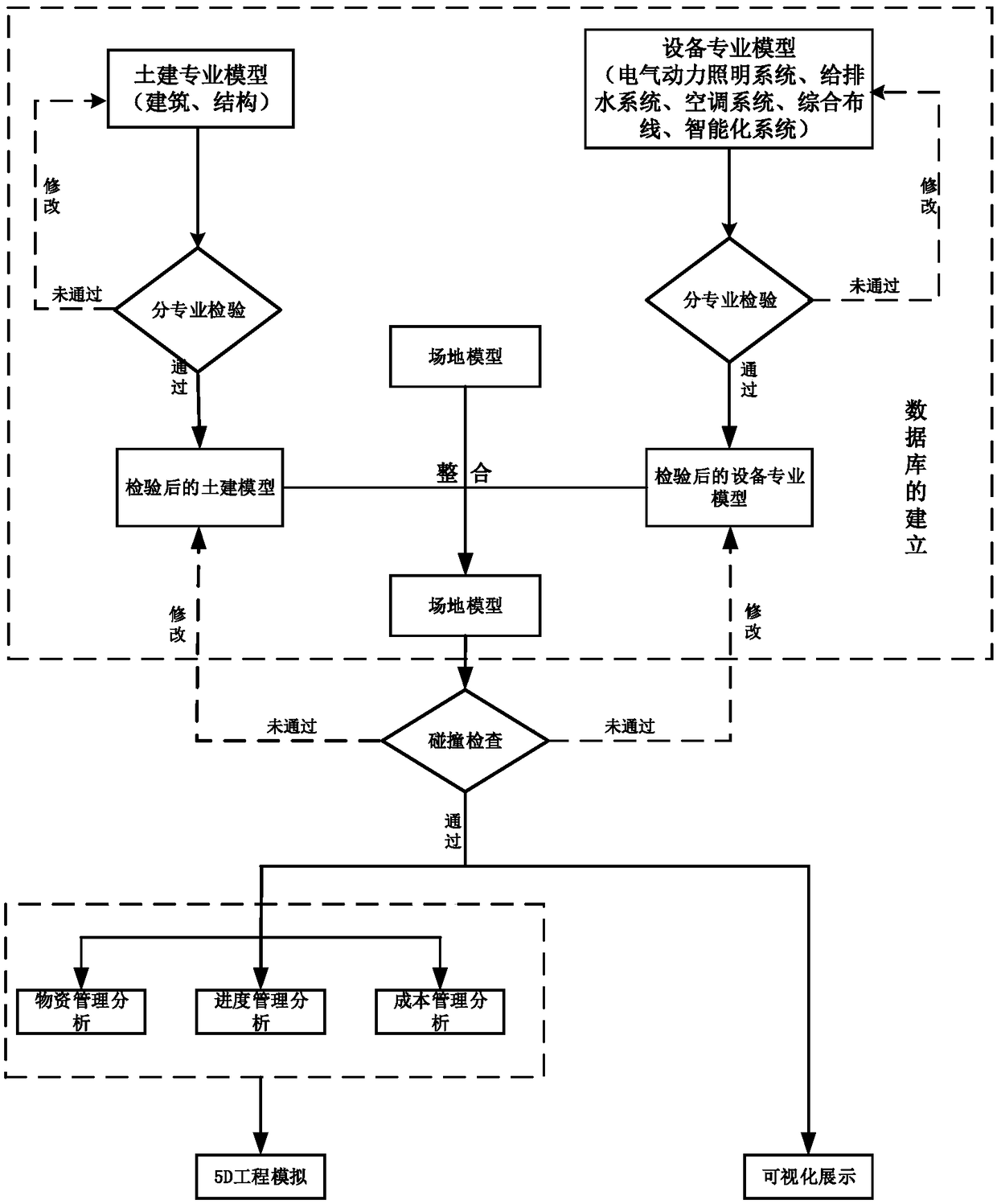

RFID read-writing device with collision checking function and its collision checking method

InactiveCN101122957AImprove recognition efficiencyImplement the collision detection functionCo-operative working arrangementsSensing record carriersThree levelData segment

The invention discloses an RFID interrogator with collide detection and a collide detection algorithm. When the interrogator receives the information returned from an electronic label, the interrogator firstly detects if the frame head data of the returned data are corrupted. If the data are corrupted, collision is considered to have occurred, and if not, data segments of the returned information are further detected for violation of the FMO coding rules. If one violation of the FMO coding rules is detected, collision is considered to have occurred, and if not, a further detection is carried out. The DSP sends an ACK command, and if the interrogator does not receive any information about the electronic lable within a time period T1max stipulated in the protocol, collision may be considered to have occurred, and if the interrogator receives return information from the electronic label, collision is considered to have not occurred, and the detection period is ended. The invention is used for detecting possible collision in three levels, and can thus increase accuracy of collision detection, provide supports to DSP module for realizing various anti-collision algorithms, and effectively increase efficiency of an interrogator of recognizing electronic labels.

Owner:FUDAN UNIV

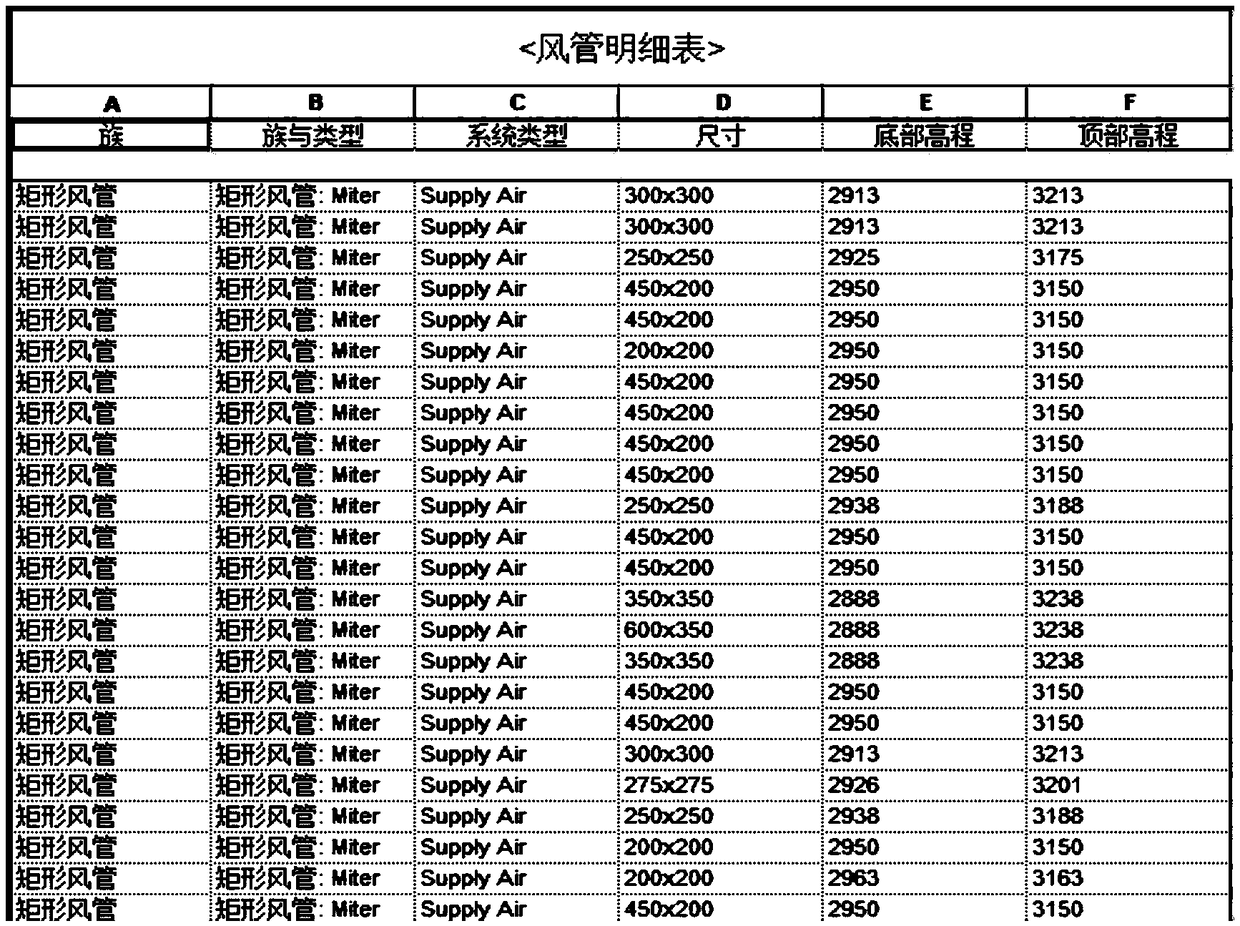

A construction method based on R-N5DL-BIM technology

PendingCN109190252AGuaranteed link 0 errorGuaranteed application guidanceGeometric CADSpecial data processing applicationsAnimationMaterials processing

A construction method based on R-N5DL-BIM technology belongs to the technical field of the construction method. The method includes: the construction of three-dimensional model of the building and comprehensive equipment collision inspection: the overall arrangement of construction progress and construction animation simulation; 5D construction dynamic simulation, analysis and optimization: material management and cost management of construction project effective control; material processing optimization of 3D model of construction site, visual animation display of simulation effect; The modelof construction organization system under different environment is established by this method, and the dynamic relationship among schedule, cost and construction flow process factors is considered comprehensively, so that the complexity, uncertainty and randomness in construction can be expressed more accurately, and the intuitionism, feasibility and scientificity of construction organization system can be enhanced. The invention provides accurate engineering information for the construction scheme establishment, maintenance and three-dimensional visual simulation effect experience of the project, and predicts and avoids unnecessary construction problems in the construction.

Owner:北京比目鱼信息科技有限责任公司

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

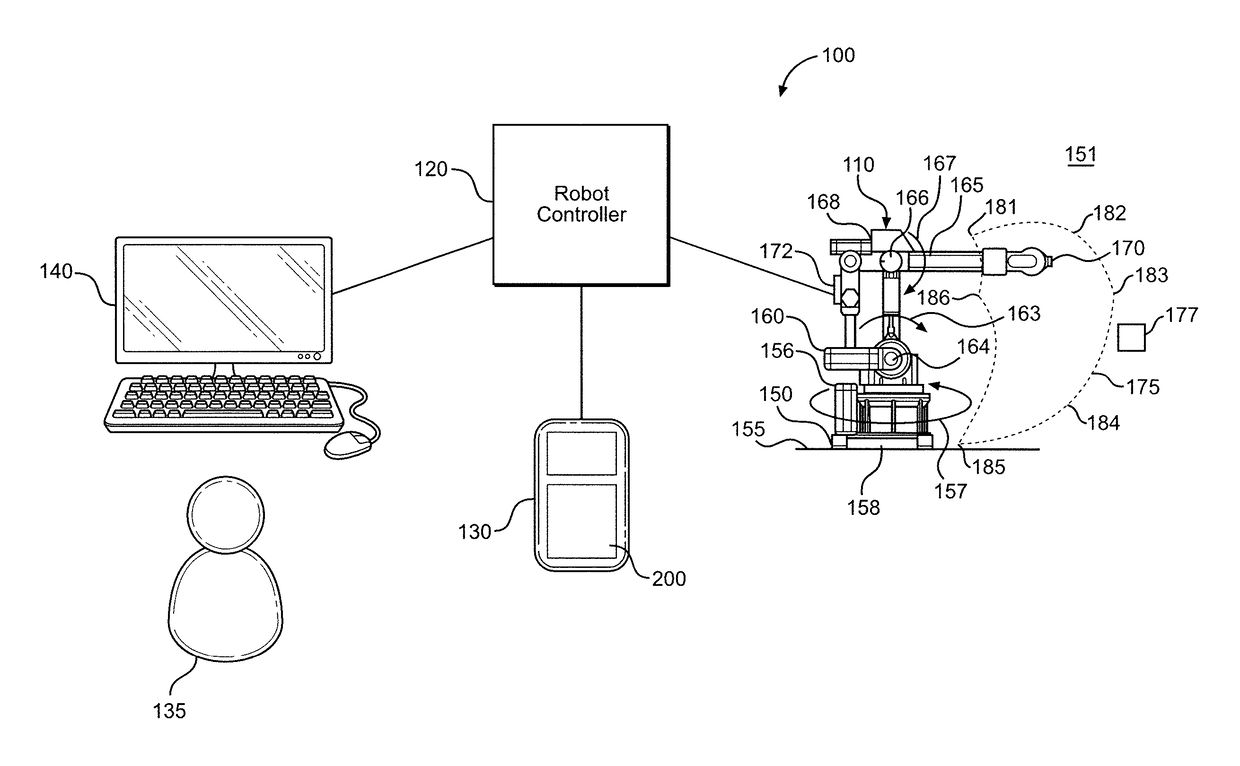

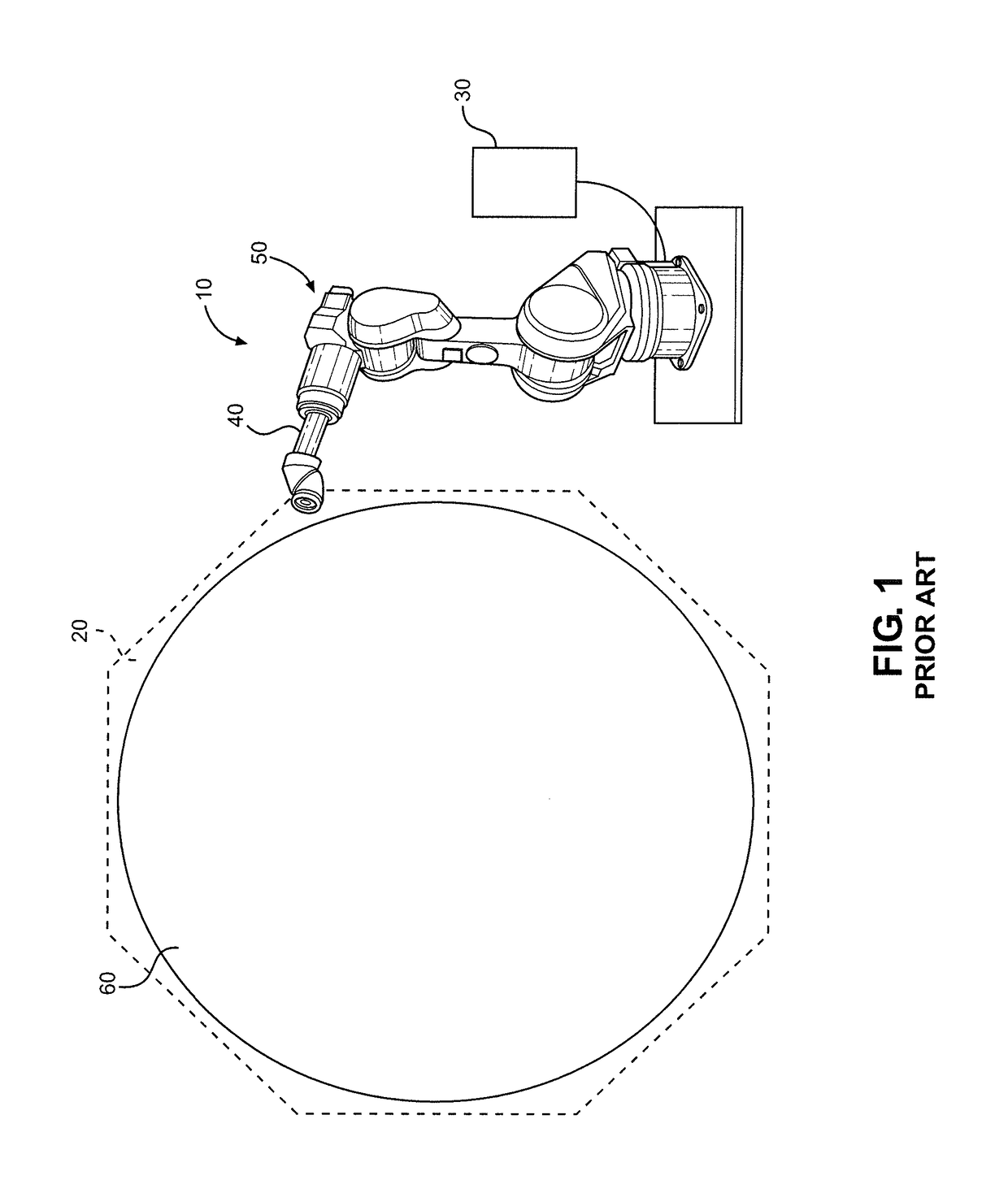

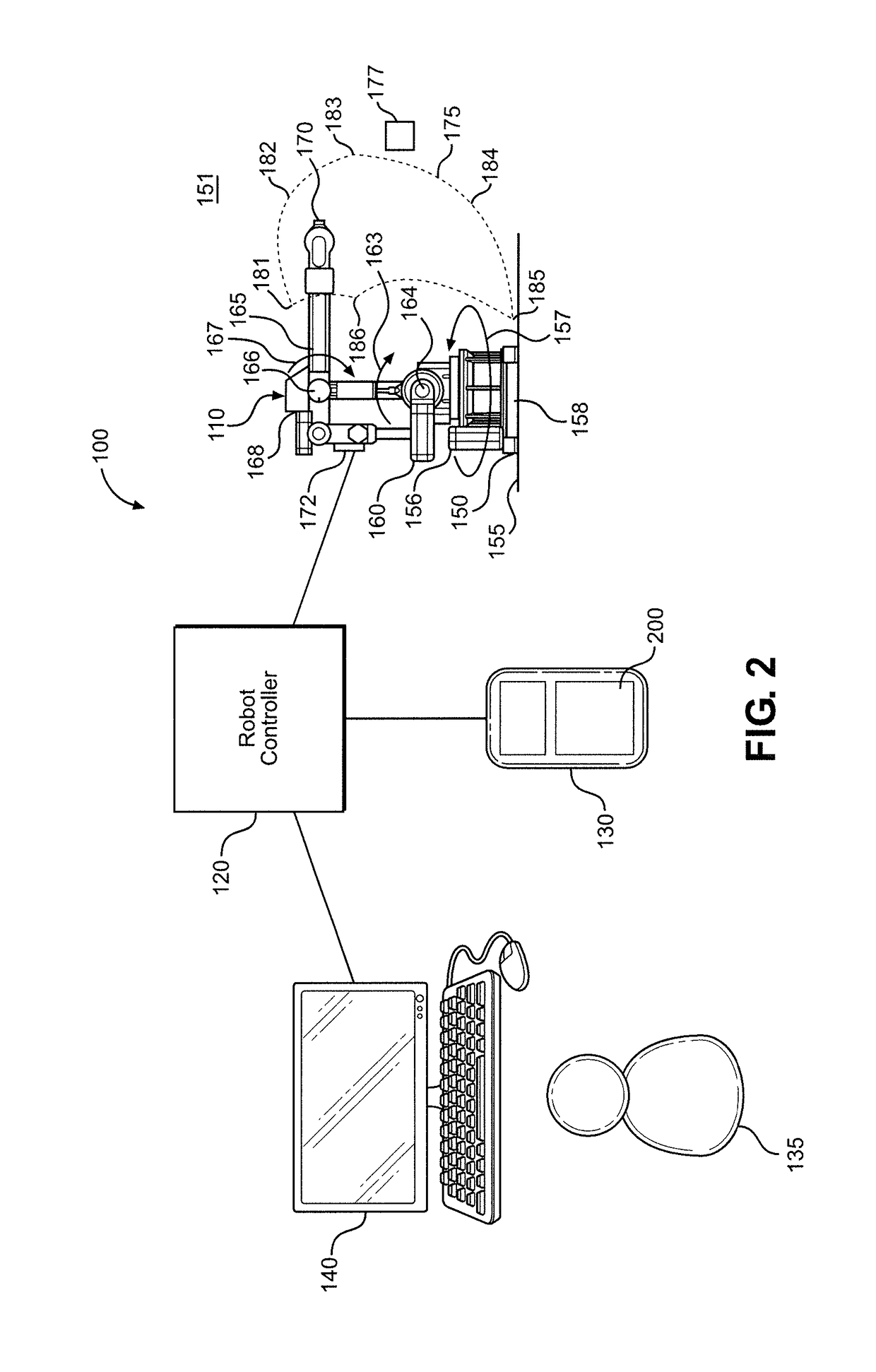

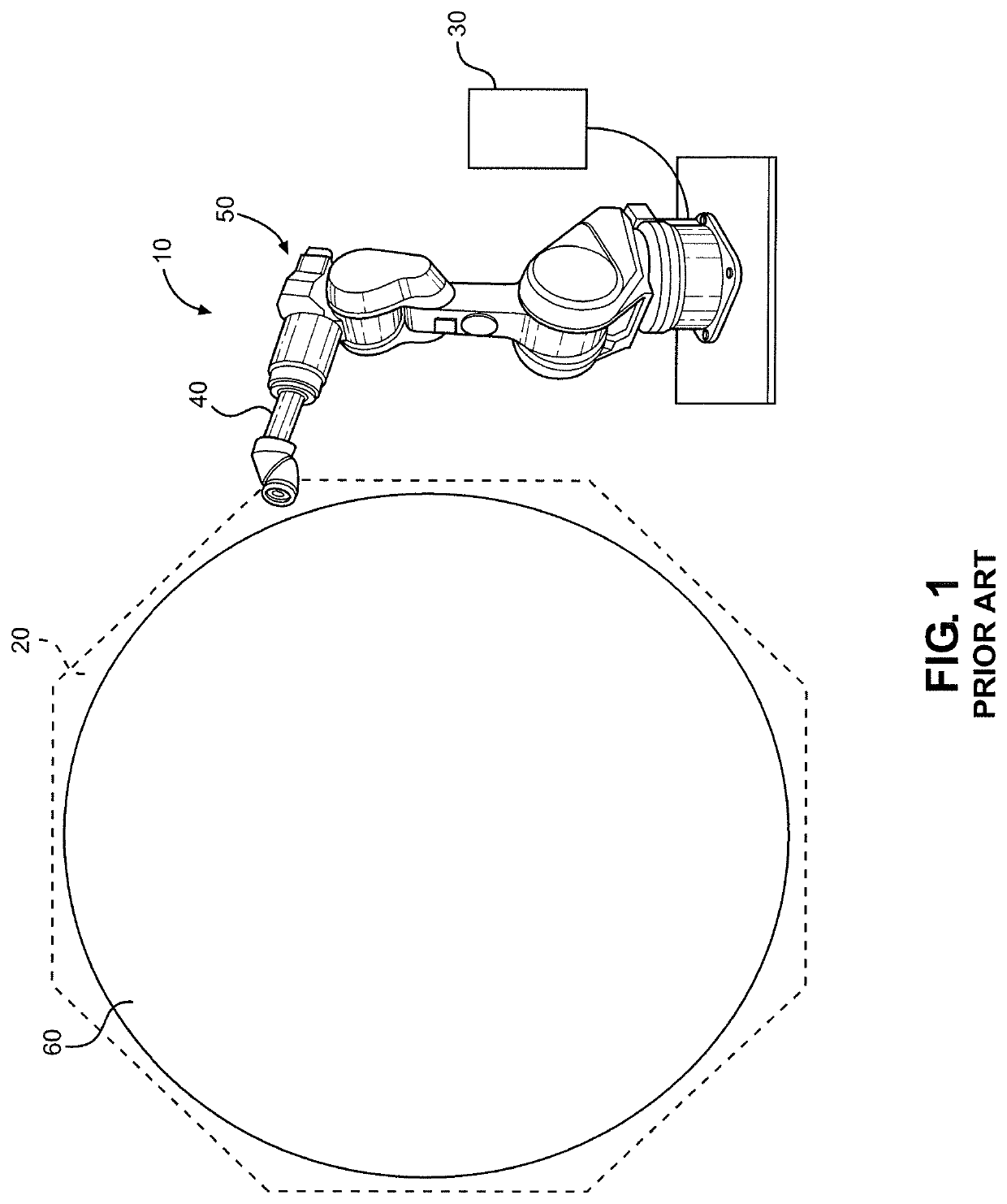

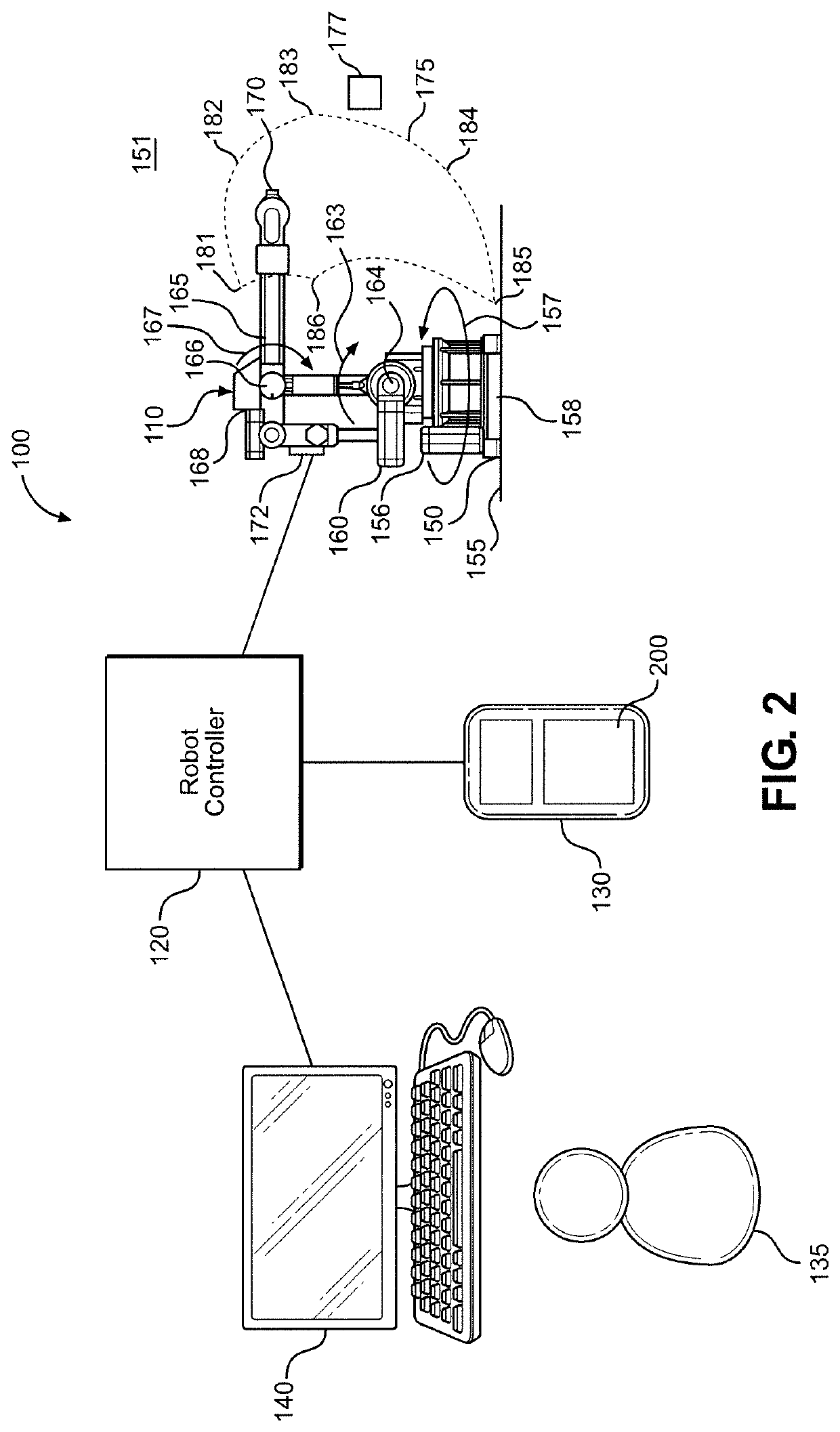

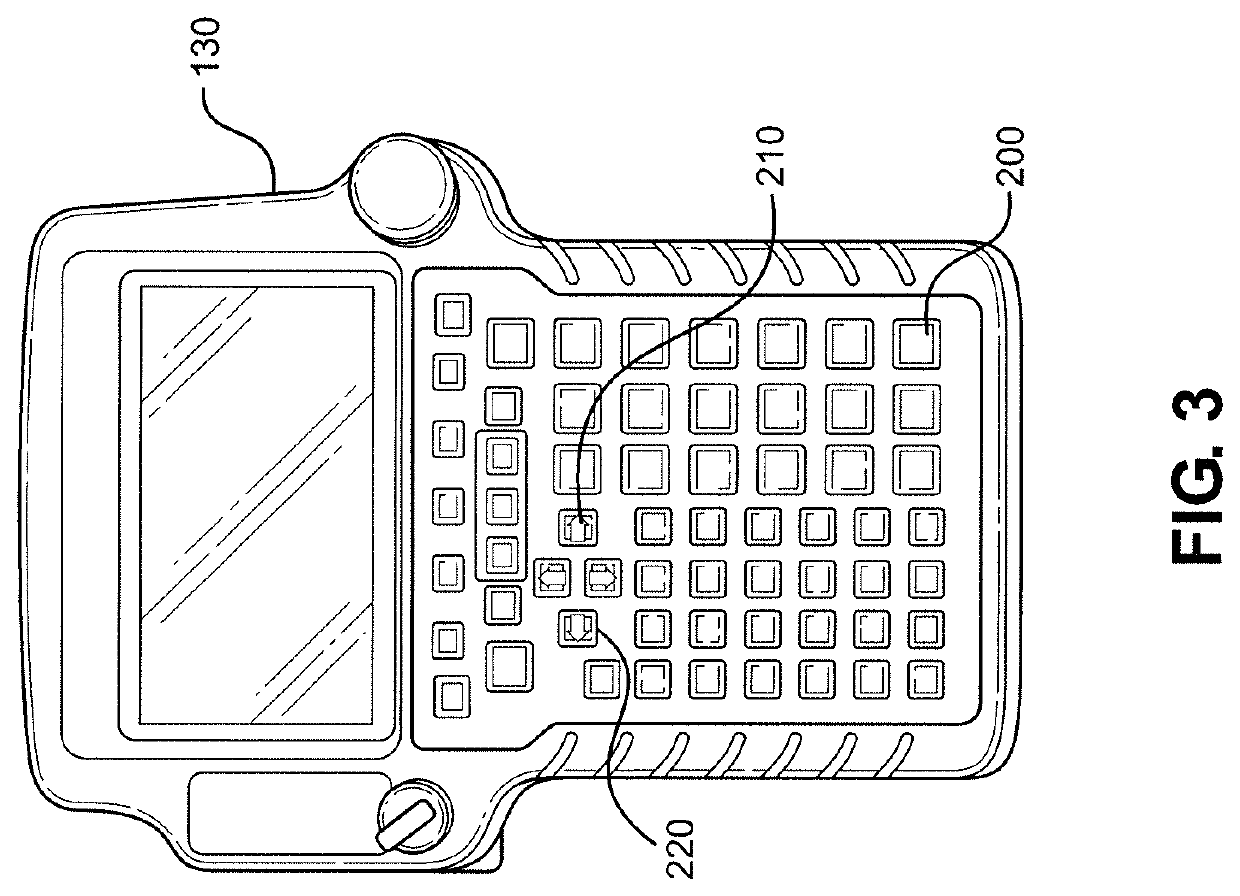

Teach Mode Collision Avoidance System and Method for Industrial Robotic Manipulators

ActiveUS20180297204A1Shorten speedAvoid collisionProgramme controlProgramme-controlled manipulatorOperator interfaceRobotic systems

A robot system includes a robot, a teach pendant having an operator interface, and a robot controller with a computer and associated hardware and software containing a virtual representation of the robot and the environment. The system employs a method for avoiding collisions including moving a manipulator arm along an actual path in an environment containing objects constituting collision geometry. Operator input is entered into the teach pendant, whereby the operator is able to directly control motion of the robot along the actual path. A recent history of the motion of the robot is recorded, and a predicted path of the robot is developed based on the input entered into the teach pendant and the recent history of the motion of the robot. Real-time collision checking between the predicted path and the collision geometry is performed while the operator manually controls the robot using the teach pendant.

Owner:BATTELLE MEMORIAL INST

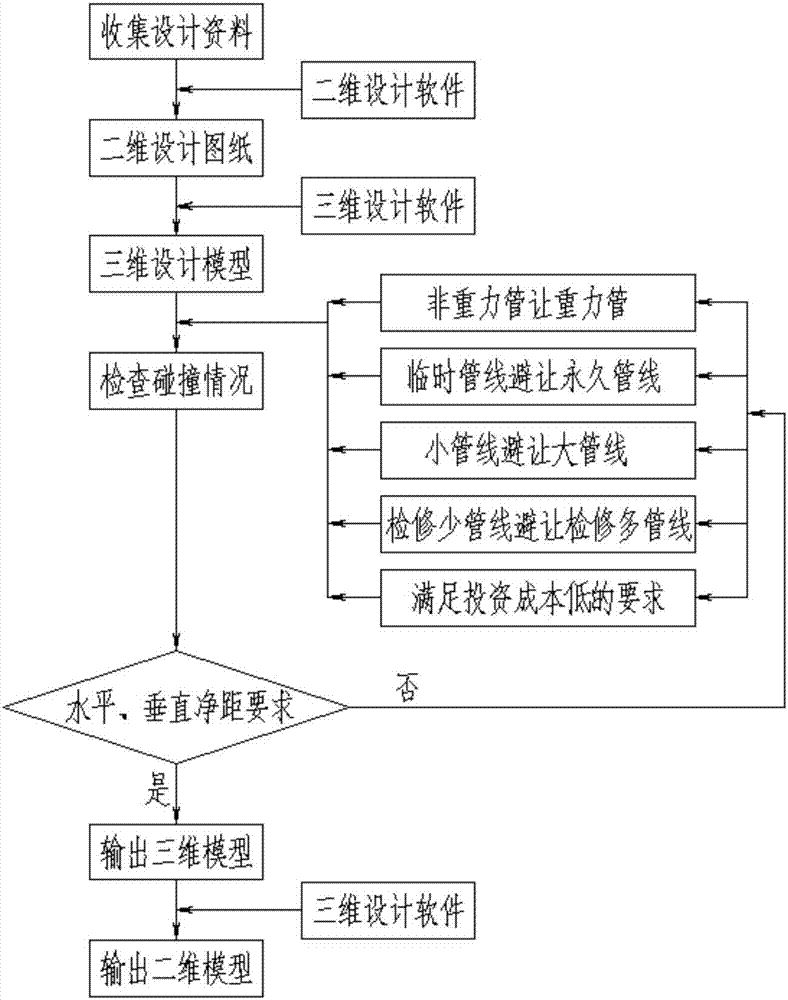

BIM based municipal administration road pipeline layout optimization method

InactiveCN107103115ALower investment budgetAchieve optimizationGeometric CADMulti-objective optimisationLine tubingDesign software

The invention discloses a BIM based municipal administration road pipeline layout optimization method. The method includes: (1) inputting all the pipeline information to two-dimensional design software; (2) establishing a three-dimensional model of the pipelines on the basis of BIM modeling; (3) using a collision checking algorithm of BIM modeling to check the collision situations of all the pipelines; (4) adjusting the pipelines on the basis of pipeline comprehensive standard requirement principle till all the pipelines meet the minimum horizontal and perpendicular clear distance demand of a municipal administration pipeline comprehensive standard; (5) outputting the three-dimensional model of the comprehensive pipelines; and (6) outputting a two-dimensional model and a drawing sheet through the output three-dimensional model. The method can solve the problem that construction cannot be performed due to collision of various comprehensive pipelines during a municipal construction process through the BIM technique, can perform reasonable planning and use on the municipal administration road pipelines through an optimization design, can reduce construction waste, can shorten the construction time, can greatly improve the working efficiency of sites, and can reduce investment.

Owner:中冶南方城市建设工程技术有限公司

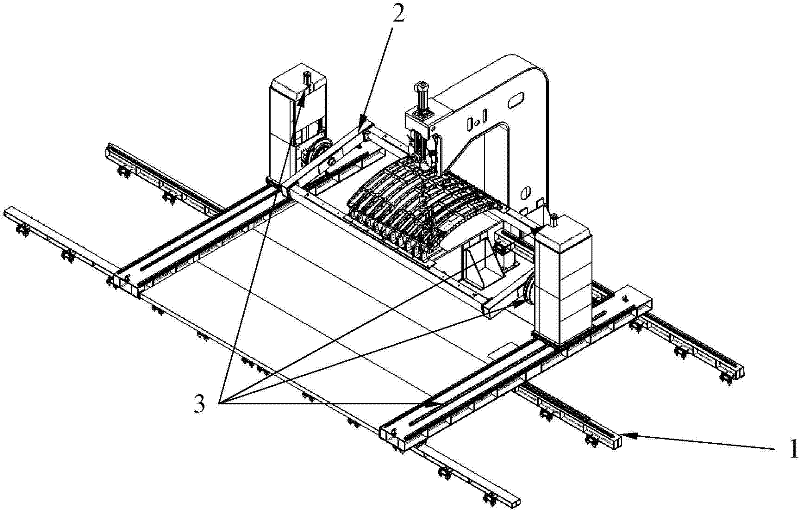

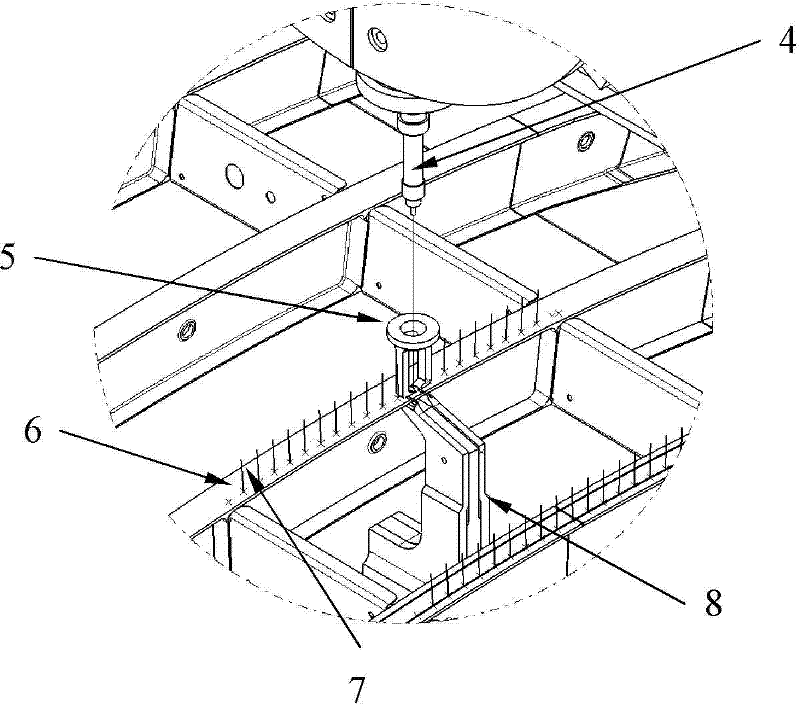

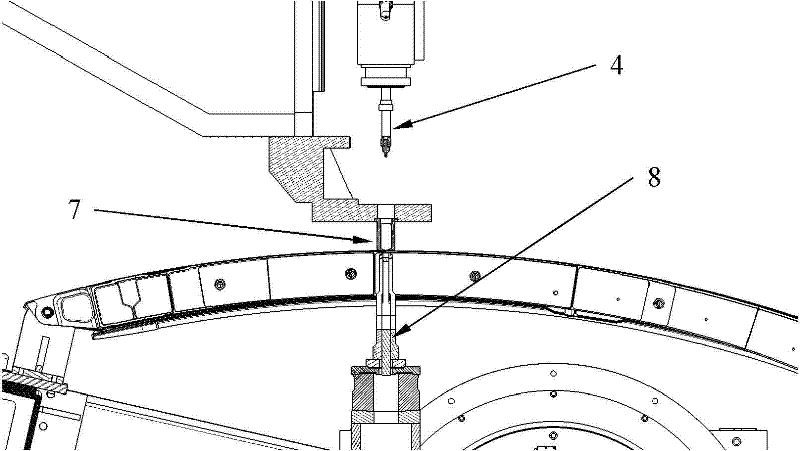

Space orientation computing method for numerical control bracket

InactiveCN102566439AWork quicklyContinuous operationSimulator controlSpatial positioningComputer science

The invention relates to a space orientation computing method for a numerical control bracket, which comprises the following steps of: 1, processing three-dimensional digital analogy of each part; 2, defining a fixed mechanism and a moving mechanism in each digital analogy; 3, setting a drive command for a multiple axis movements of a numerical control bracket; 4, simulating whether each axis movement accords with an actual condition; 5, correcting a movement zero point of the digital analogy of the numerical control bracket; 6, enabling a spindle axes of an automatic drilling and riveting machine to be coincident with a normal line of a riveting point and the riveting point to be coincident with the center of a pressure foot bush; 7, refreshing the digital analogy; 8, figuring out data of five axes of the numerical digital bracket and data of a lifting position and a rotating angle of a lower riveting head under the condition of automatic drilling and riveting on any point on the surface of an airplane; 9, carrying out collision checking and batch output on space orientation data; and 10, carrying out numerical control programming to ensure that the automatic drilling and riveting machine continuously operates. According to the space orientation computing method, the numerical control system can automatically operate according to the space orientation data, and the airplane on the numerical control bracket meets the working requirements of the automatic drilling and riveting machine on the space.

Owner:AVIC SAC COMML AIRCRAFT

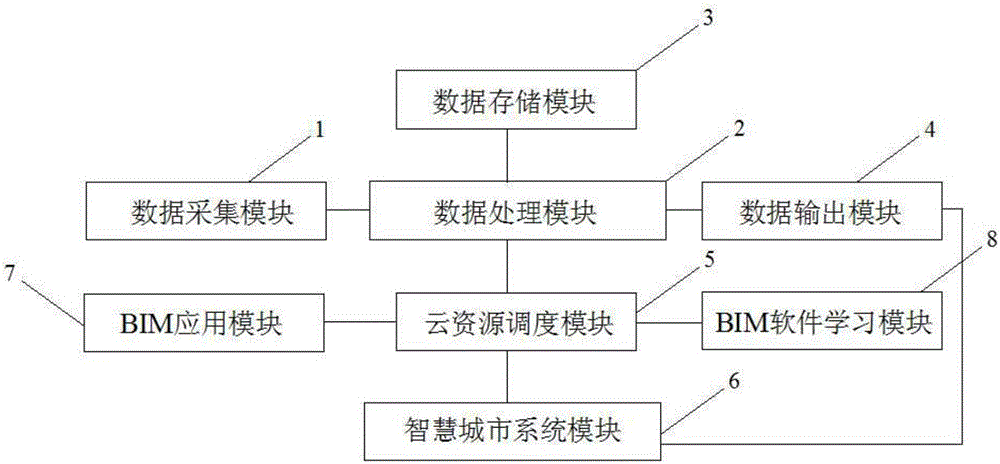

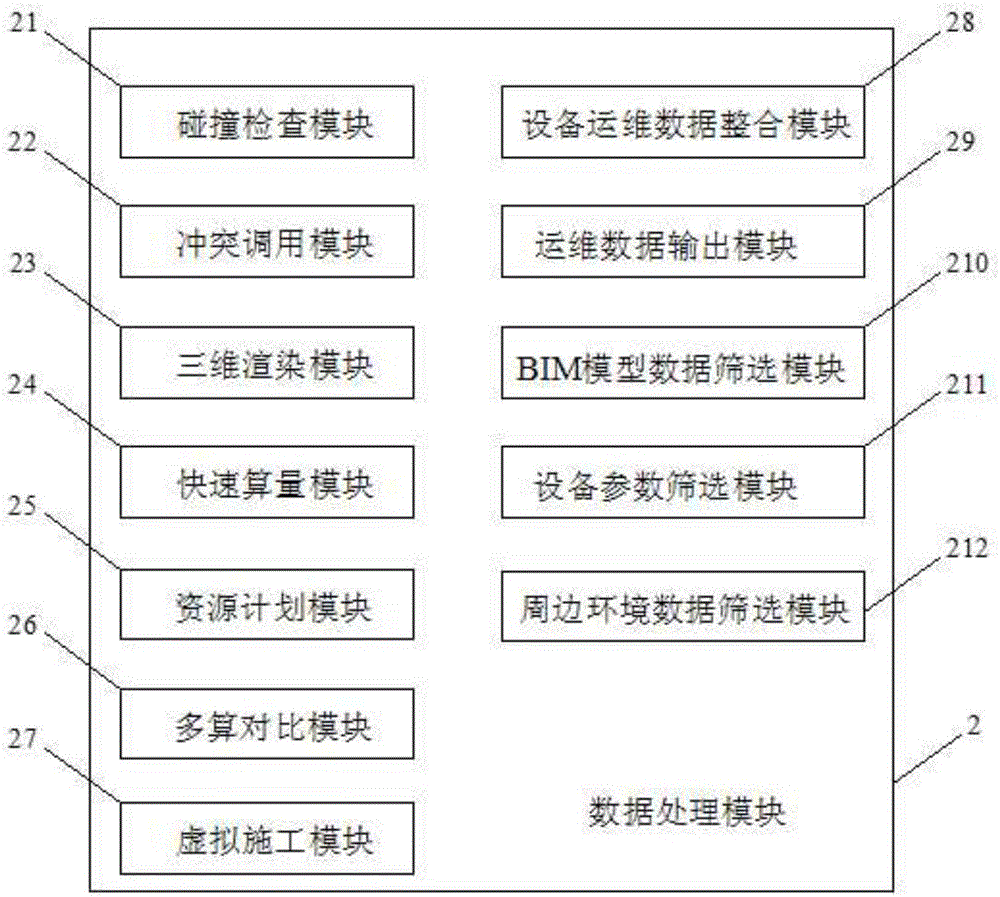

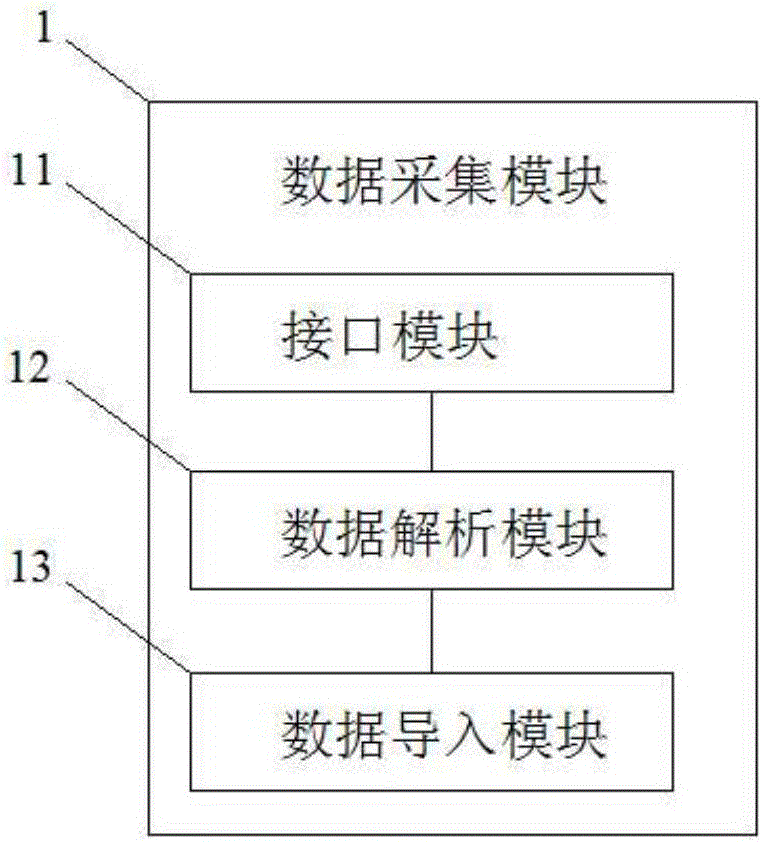

Intelligent building system based on BIM and management thereof

InactiveCN106203784AAutomate managementGuaranteed accuracyResources3D-image renderingData acquisitionApplication module

The invention provides an intelligent building system based on BIM and a management thereof, which belongs to the technical field of intelligent buildings. The system comprises a data acquisition module, a data processing module, a data storage module, a data output module, a cloud resource dispatching module, an intelligent city system module, a BIM application module and a BIM software learning module. The data processing module comprises a collision checking module, a collision calling module, a three-dimensional rendering module, a quick calculation module, a resource planning module, a multi-operation comparison module, a virtual construction module, a device operation and maintenance data integration module, an operation data output module, a BIM model data filtering module, a device parameter filtering module and a surrounding environment data filtering module. According to the invention, three-dimensional visualization display of a building is realized; all kinds of information of building operation and maintenance are highly integrated; information management automation is realized; and the cloud resource dispatching module retrieves intelligent city system data, BIM application data and BIM software learning data to realize function diversification.

Owner:JIANGSU SANLENG SMARTCITY&IOT SYST CO LTD

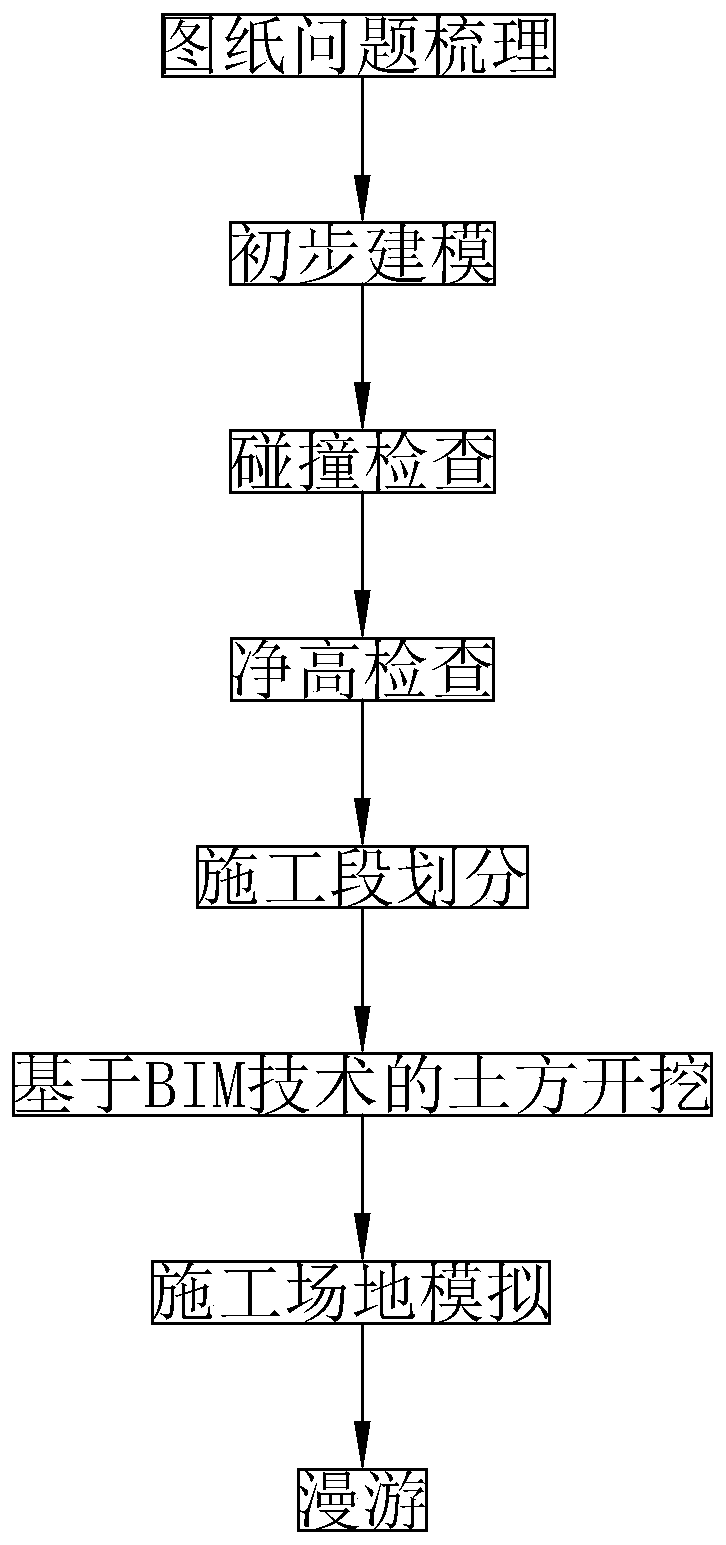

Comprehensive pipe gallery modeling method based on BIM

PendingCN110929325ALayout close to realityReasonable arrangementGeometric CADConstruction engineeringPipe

The invention relates to a comprehensive pipe gallery modeling method based on BIM, and belongs to the technical field of building modeling. The comprehensive pipe gallery modeling method comprises the following steps: step 1, drawing problem carding; step 2, preliminary modeling, wherein preliminary model design is conducted through Revit according to a two-dimensional construction drawing made through CAD and the stored data; step 3, collision inspection: discovering collision through Luban BIM Works and carrying out pipeline comprehensive optimization, wherein a pipeline avoidance principleis adopted during collision; step 4, net height and clearance inspection; 5, construction section division, wherein corresponding construction section organization construction is divided according to the underground structure distribution situation of the comprehensive pipe gallery; step 6, earth excavation based on the BIM technology; step 7, construction site simulation; and step 8, roaming. The comprehensive pipe gallery modeling method has the advantages that the comprehensive pipe gallery construction problem is estimated in advance, so that the project implementation risk is integrallycontrolled.

Owner:四川鸥鹏建筑工程公司

BIM-cloud-platform-based application of mobile terminal in engineering quality checking

InactiveCN107506907AEfficient managementReduced program management timeGeometric CADResourcesHand heldComputer science

The invention discloses a BIM-cloud-platform-based application of mobile terminal in engineering quality checking. According to the application, quality management of a construction site is realized by using a hand-held mobile terminal based on a BIM+cloud platform; and to be specific, virtual environment roaming, collision checking and reverse construction verification are carried out successively to realize high-efficiency management of the engineering quality.

Owner:CHINA MCC17 GRP

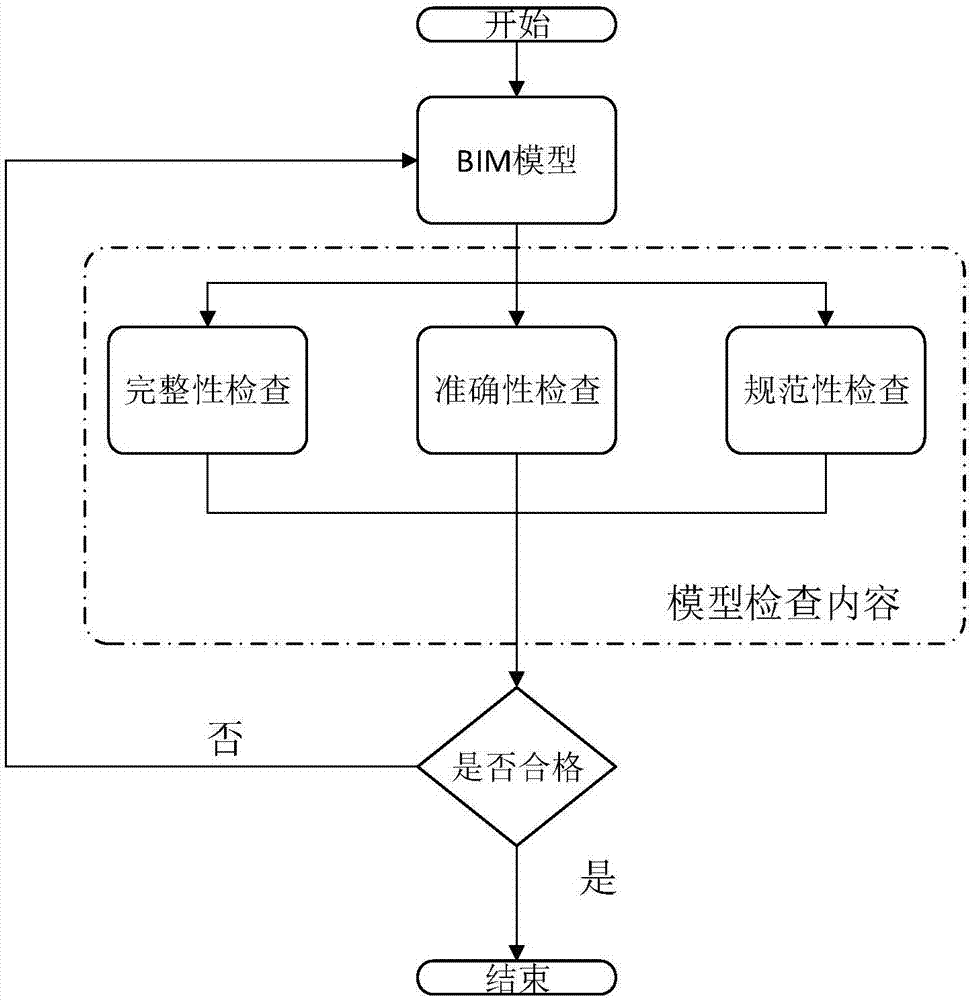

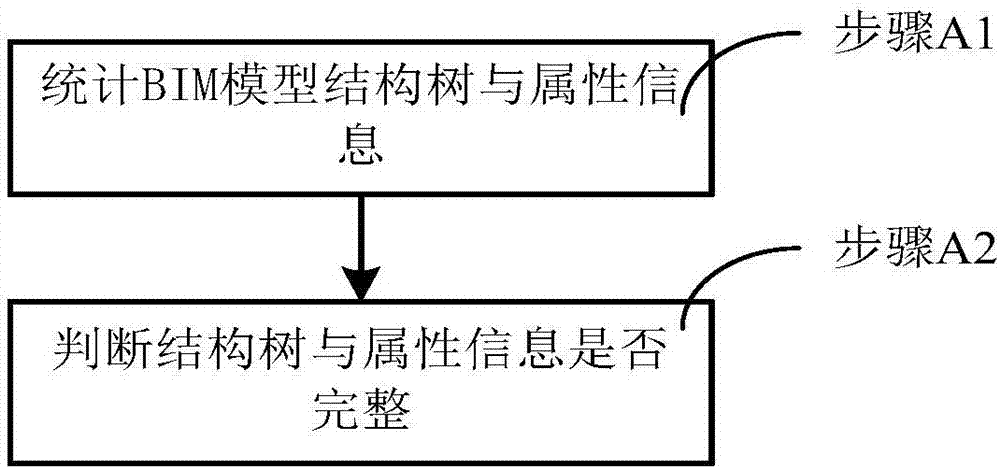

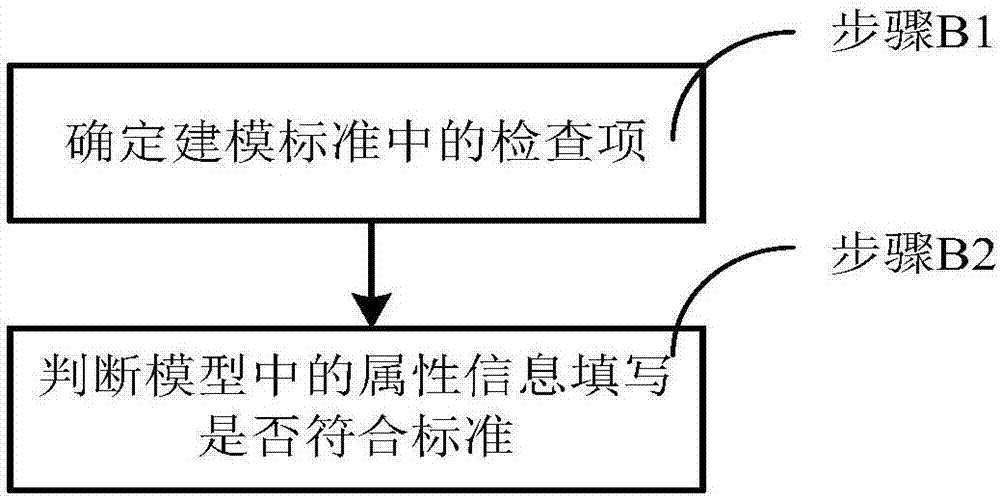

Check method for BIM design model of railroad bridge

InactiveCN107491603AIntegrity guaranteedIntegrity issues foundGeometric CADDesign optimisation/simulationDesign informationComputer science

The invention discloses a check method for a BIM design model of a railroad bridge. The method comprises the steps that completeness check, normativity check and accuracy check are performed on the BIM model, wherein according to the completeness check, a structure tree and property information in the BIM model are checked according to a bridge two-dimensional design drawing, and sampling is performed for material list check to ensure that parameter information in the making process of the BIM model is input completely; according to the normativity check, a spot check mode is adopted to select typical beam-type key segments for three-dimensional model visual check to ensure that the BIM model conforms to a modeling standard; according to the accuracy check, collision check of a full check mode and two-dimensional drawing output check of the spot check mode are adopted to perform collision check on the model to ensure the accuracy of spatial relation information of the BIM model; and whether the BIM model has completeness and / or accuracy and / or normativity problems is judged. The method has the advantages that the technical method and the standard process for check of the BIM design model of the railroad bridge are constructed, and the completeness of borne design information, the accuracy of a spatial relation and the normativity of a creation mode of the BIM model are ensured.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

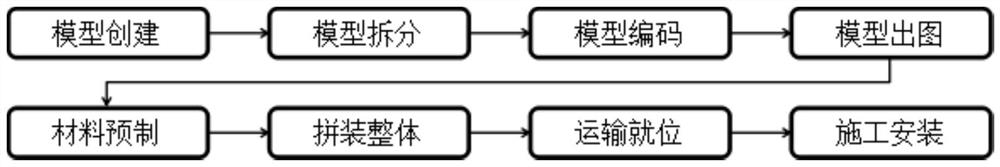

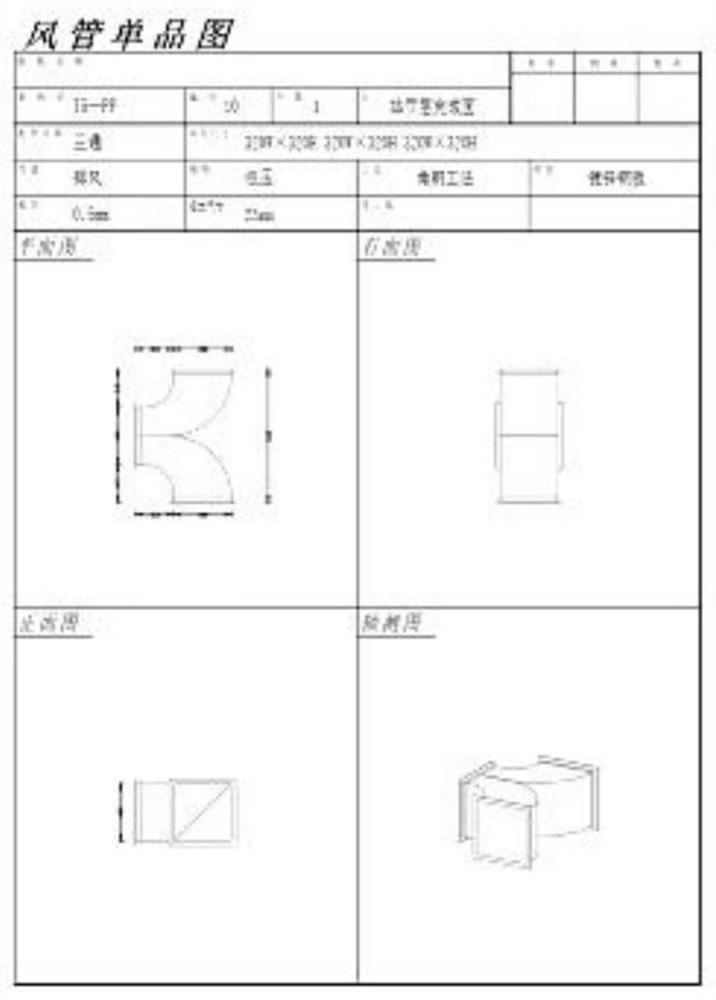

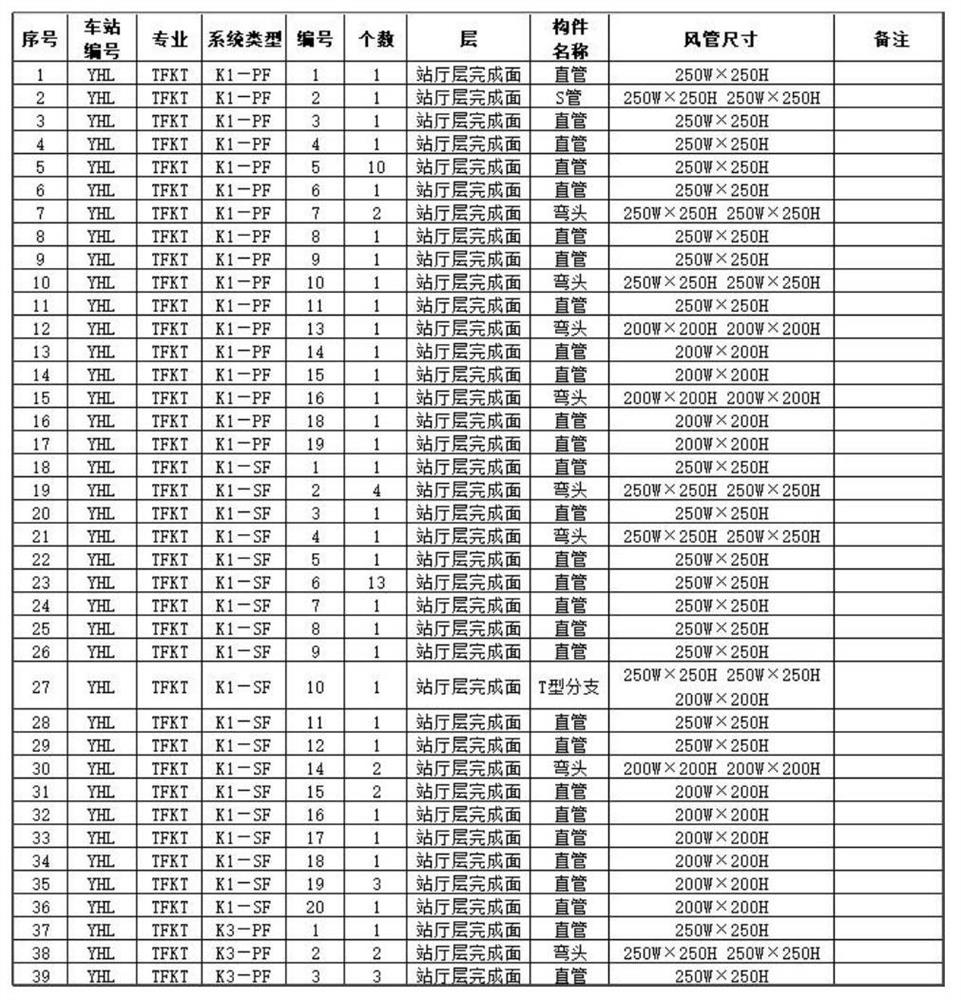

Integrated pipeline overall assembly method based on BIM technology

PendingCN112613100AReduce lossImprove efficiencyGeometric CADSpecial data processing applicationsProcess engineeringMaterial resources

The invention discloses a BIM technology-based integrated pipeline overall assembly method, which comprises the steps of creating a BIM model according to a drawing, then carrying out collision detection, and carrying out collision check by utilizing the BIM model, thereby being convenient, rapid, high in efficiency and low in error rate; carrying out three-dimensional visual disclosure on construction personnel by utilizing the BIM model, visually displaying the construction process, and ensuring that technical disclosure is in place; splitting the created model; after comprehensive pipeline segmentation is completed, carrying out pipeline and support coding, completing output of a material detail list and output of a machining drawing, carrying out accurate ordering according to the material detail list and the machining drawing, wherein material losses are low; enabling all pipelines to be subjected to factory prefabrication and assembly construction, so that the construction efficiency is improved; and transporting comprehensive pipelines in place at a time and installing the pipelines at a time, manpower, so that material resources and construction cost are saved, and the construction period is guaranteed.

Owner:中铁十一局集团电务工程有限公司 +1

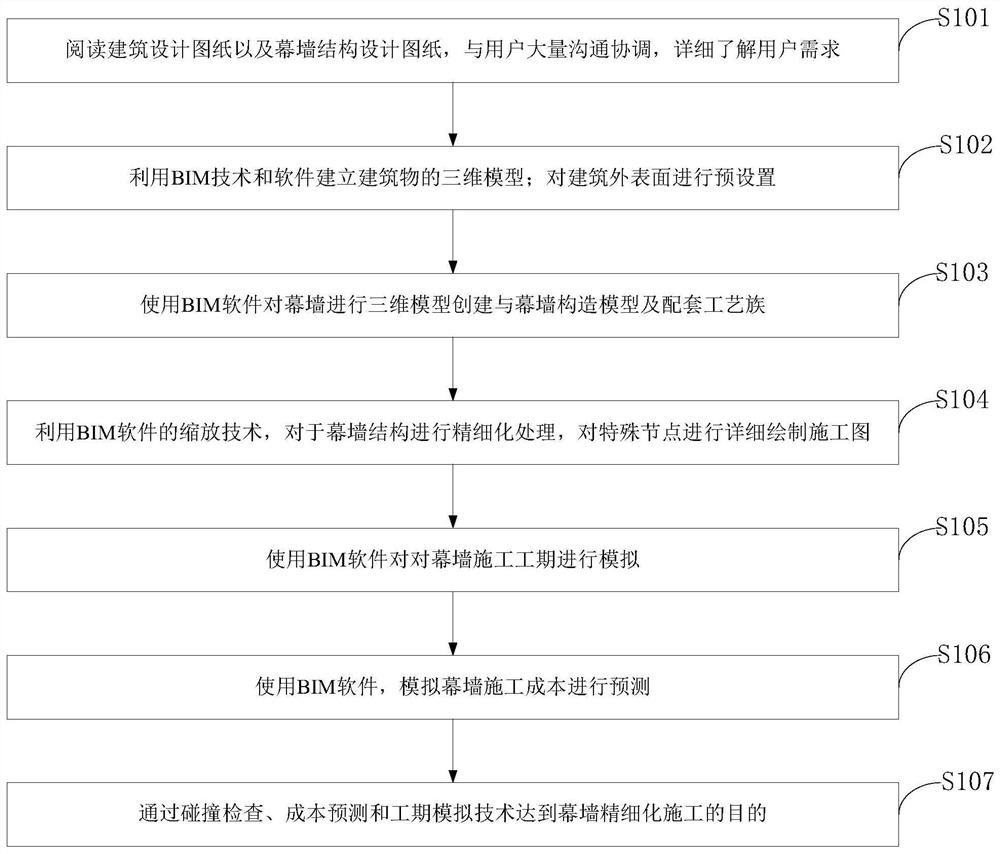

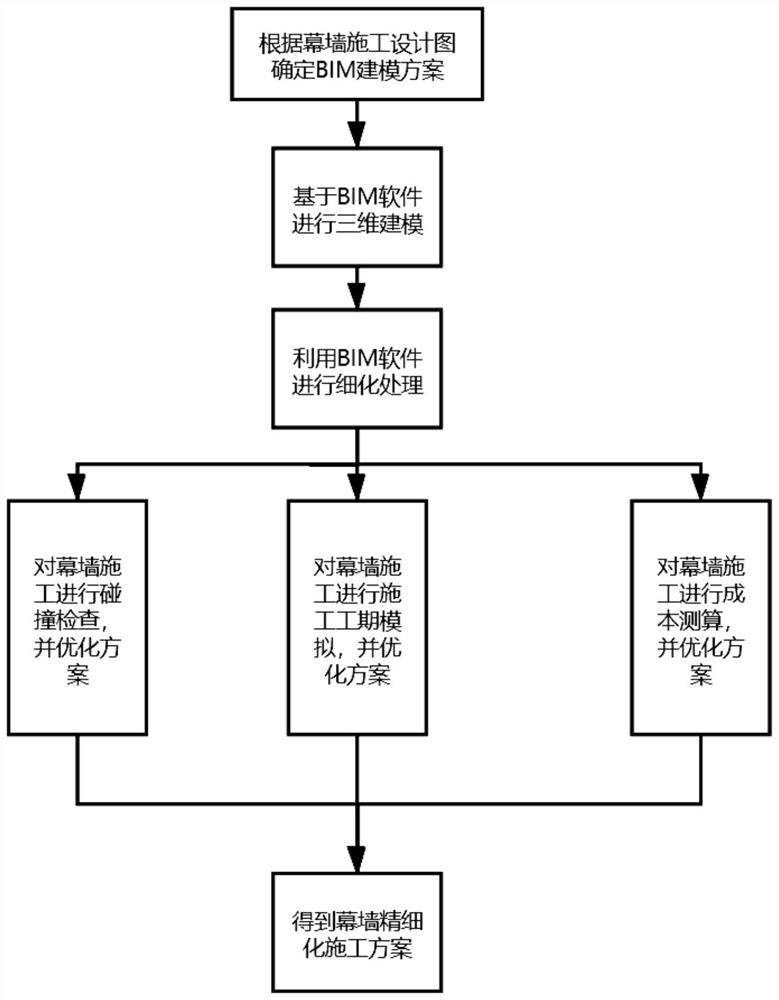

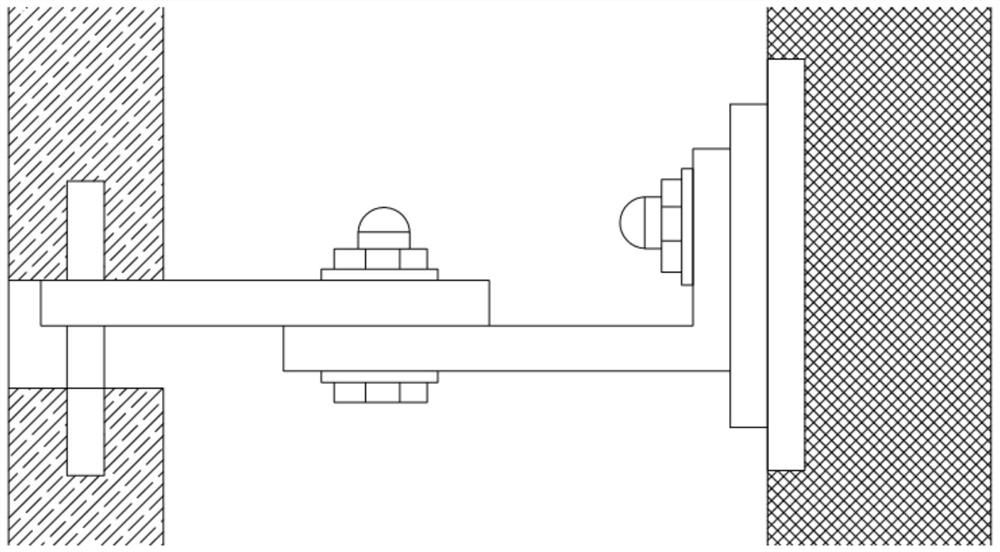

BIM-based curtain wall engineering refined construction method and system, terminal and medium

InactiveCN113656879AReduce lossesReduce the possibility of reworkGeometric CADArtificial lifeConstruction engineeringQuality control

The invention belongs to the field of curtain wall construction, and discloses a BIM-based curtain wall engineering refined construction method and system, a terminal and a medium. The method comprises the following steps: building a three-dimensional model of a building through the BIM technology and software; presetting the outer surface of the building; building a three-dimensional model of the curtain wall by using BIM software, and building a curtain wall construction model and a matched process family; by means of the scaling technology of BIM software, refining the curtain wall structure, and drawing a construction drawing in detail for special nodes; and establishing a BIM model, carrying out collision check, and optimizing and modifying a conflict part. The BIM software is used to schedule the curtain wall construction period. The construction cost of the curtain wall is simulated to predict. And a corresponding budget report is generated. According to the invention, the optimization of construction resources and scientific and reasonable site arrangement can be realized, the construction progress arrangement of the whole project can be optimized, and resource management and quality control can be optimized.

Owner:BINZHOU POLYTECHNIC

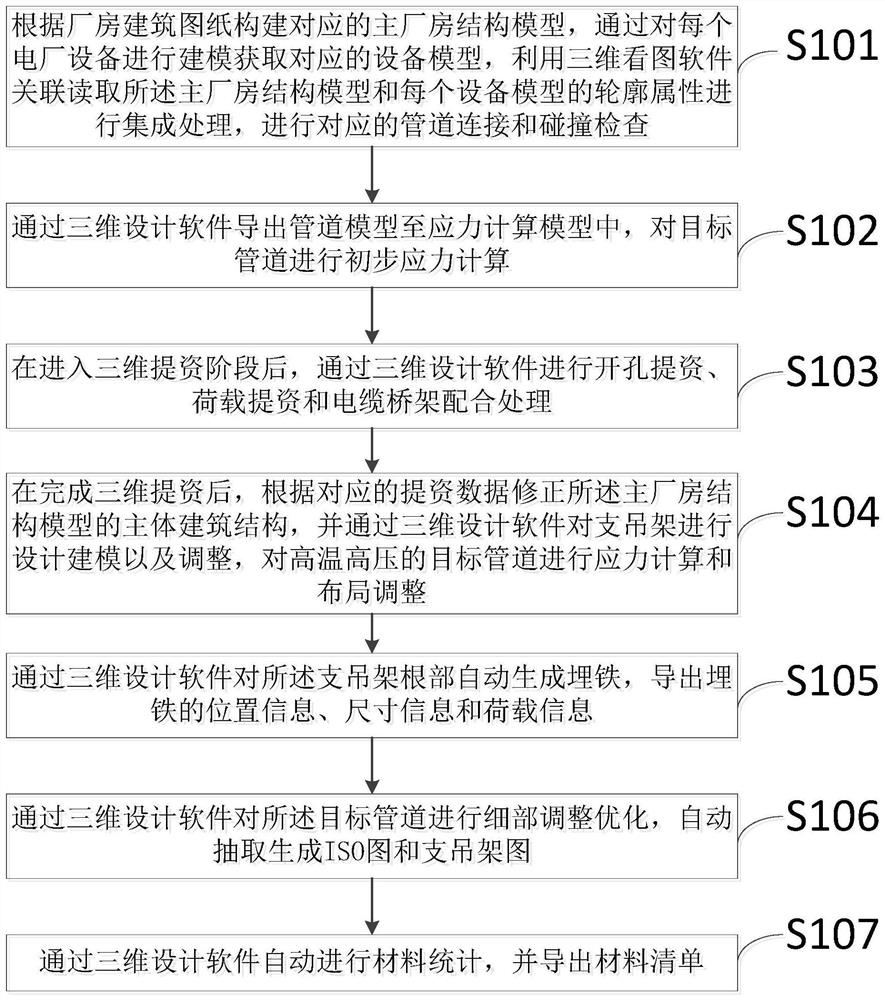

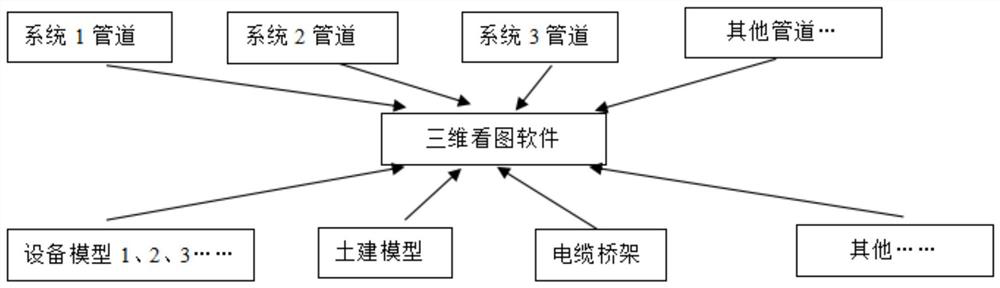

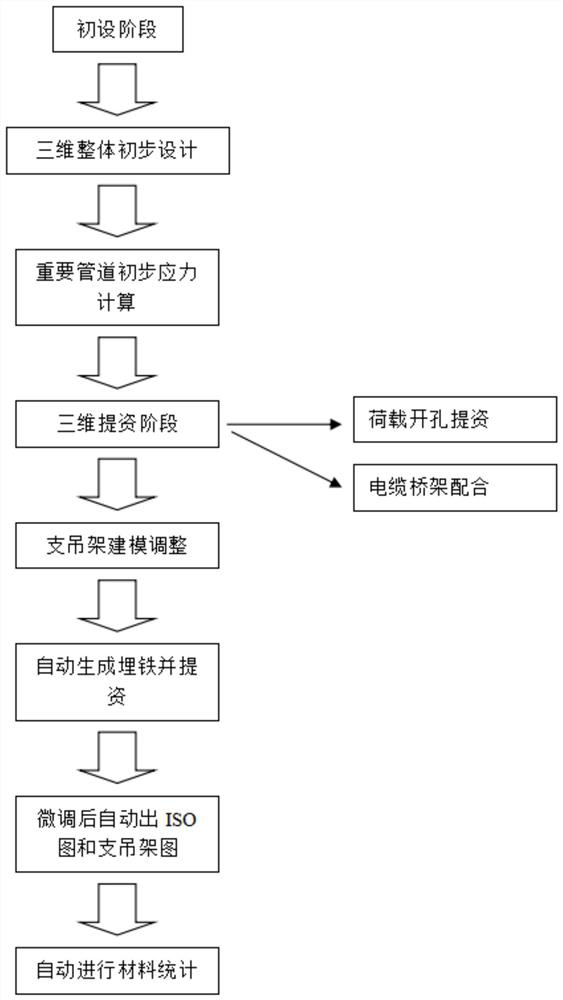

Distributed online integrated three-dimensional design method and system for power plant

ActiveCN111651815ASolve efficiency problemsSolve the repeatabilityGeometric CADDesign optimisation/simulationPower stationCable tray

The invention discloses a distributed online integrated three-dimensional design method and system for a power plant. The method comprises: reading a main power plant structure model and a power plantequipment model in an associated mode through three-dimensional view software for integrated processing and pipeline connection and collision checking; performing preliminary stress calculation on the pipeline model; in the three-dimensional capital raising stage, carrying out trepanning capital raising, load capital raising and cable bridge matching processing, carrying out main building structure adjustment on the main workshop structure model, and carrying out design modeling and adjustment on supports and hangers; automatically generating buried iron at the root of the support hanger, andexporting related information of the buried iron; adjusting and optimizing the target pipeline, and automatically extracting to generate an ISO graph and a support hanger graph; and automatically carrying out material statistics to export a material list. According to the invention, the pipeline and the equipment are divided into a plurality of files to be designed in the design software respectively, and are integrated through the drawing viewing software, so that the problems of low efficiency, uncontrollable collision and incapability of multi-person collaborative design in the design process of the thermal power plant are solved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

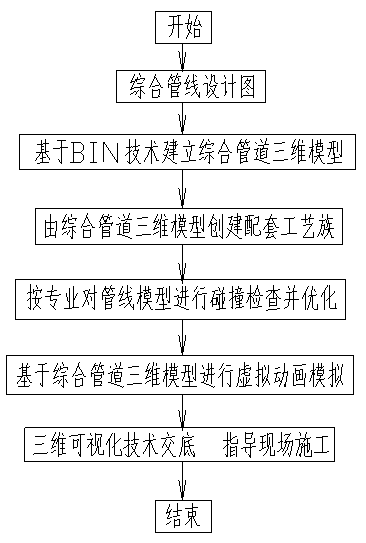

Comprehensive pipeline design and construction method based on BIM technology

PendingCN110991997AAvoid mistakesOvercome the arrangementGeometric CADOffice automationAnimationShop drawing

The invention discloses a comprehensive pipeline design construction method based on a BIM technology. The method comprises the steps that of creating a three-dimensional comprehensive pipeline modeland a matched process family for a building according to a comprehensive pipeline design drawing and based on the BIM technology; performing collision check on pipeline models related to the buildingmajor, the structure major and the electromechanical major, and optimizing pipeline design arrangement and a construction process; performing clearance design deepening and support-hanger design deepening on comprehensive pipeline arrangement according to a collision check result; providing a comprehensive pipeline arrangement construction drawing, a wall tapping position and size construction drawing and a support-hanger design construction drawing according to a pipeline model of the mechanical and electrical major; and making a technical disclosure of virtual animation simulation for guiding on-site construction, thereby assisting managers and operators in performing on-site comprehensive pipeline construction. According to the method, all professional pipelines are comprehensively designed on the basis of the building BIM model, design is optimized, actual construction is guided, construction cost is reduced, a construction period is shortened, and construction operation efficiencyis improved.

Owner:SHANGHAI BAOYE GRP CORP

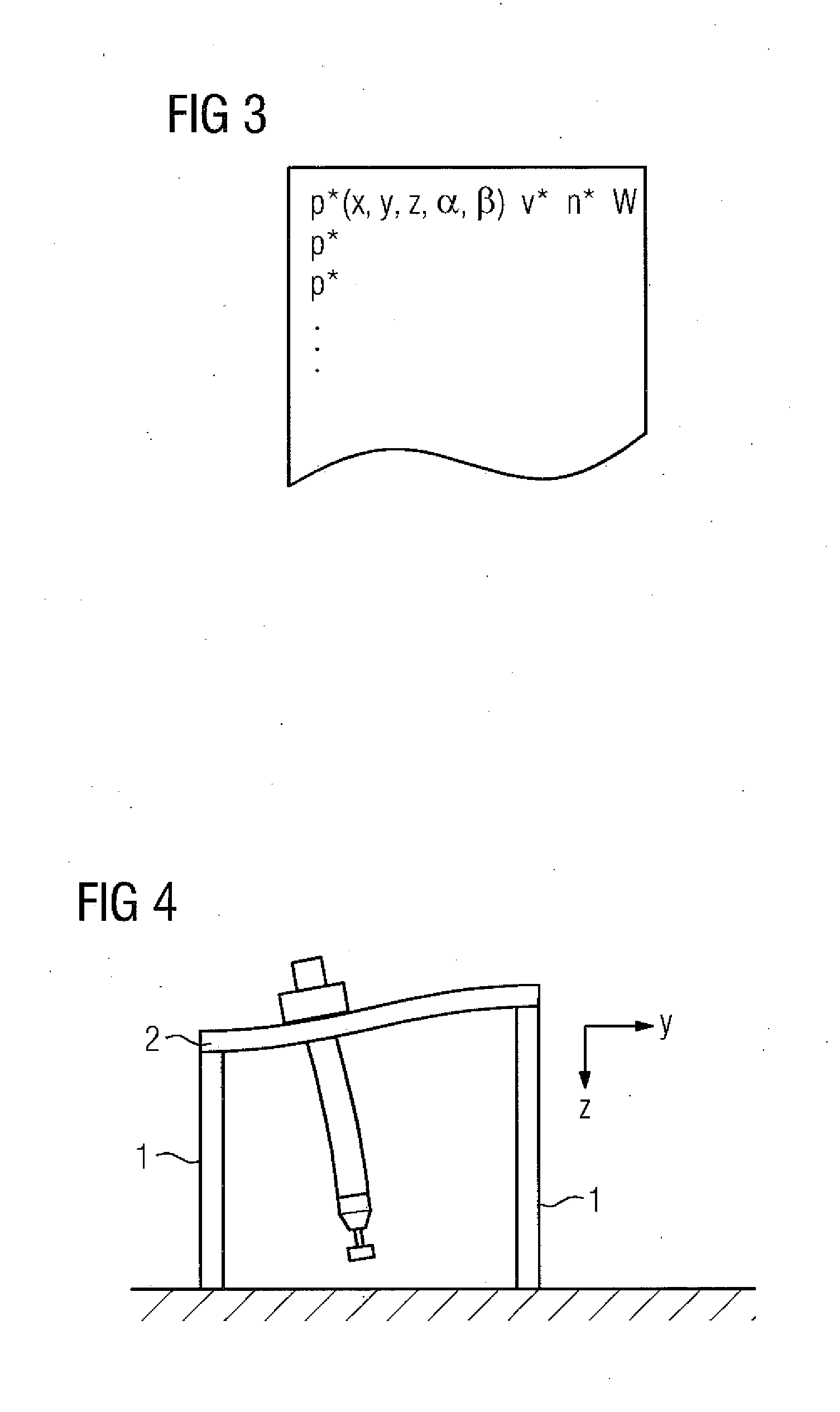

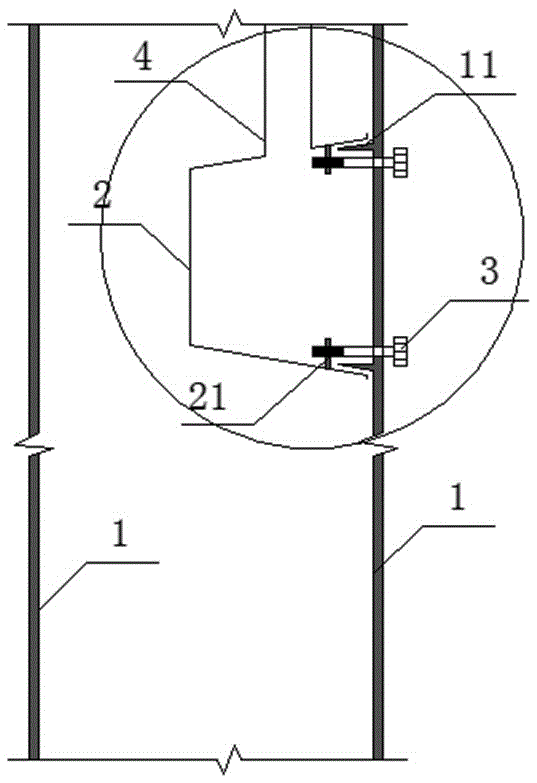

Processing machine which takes into account position errors during collision checking

ActiveUS20150261201A1Special data processing applicationsNumerical controlEngineeringBiological activation

A numerical controller of a processing machine determines corresponding setpoint axis values based on setpoint position values for position-regulated axes operating on machine elements. Before controlling the position-regulated axes, volumes to be occupied by protection bodies associated with the machine elements, a workpiece and a tool are defined and it is checked whether the protection bodies remain disjoint while controlling the position-regulated axes. Depending on the result of the checks, the controller either controls the position-regulated axes in accordance with the setpoint position values or merely executes an error response without control. The controller contains a position error field which specifies for any given setpoint axis value an actual position the tool relative to the workpiece. The position error field is taken into consideration, at least for a subset of the protection bodies, when defining the volumes to be occupied by the protection bodies upon activation of the position-regulated axes.

Owner:SIEMENS AG

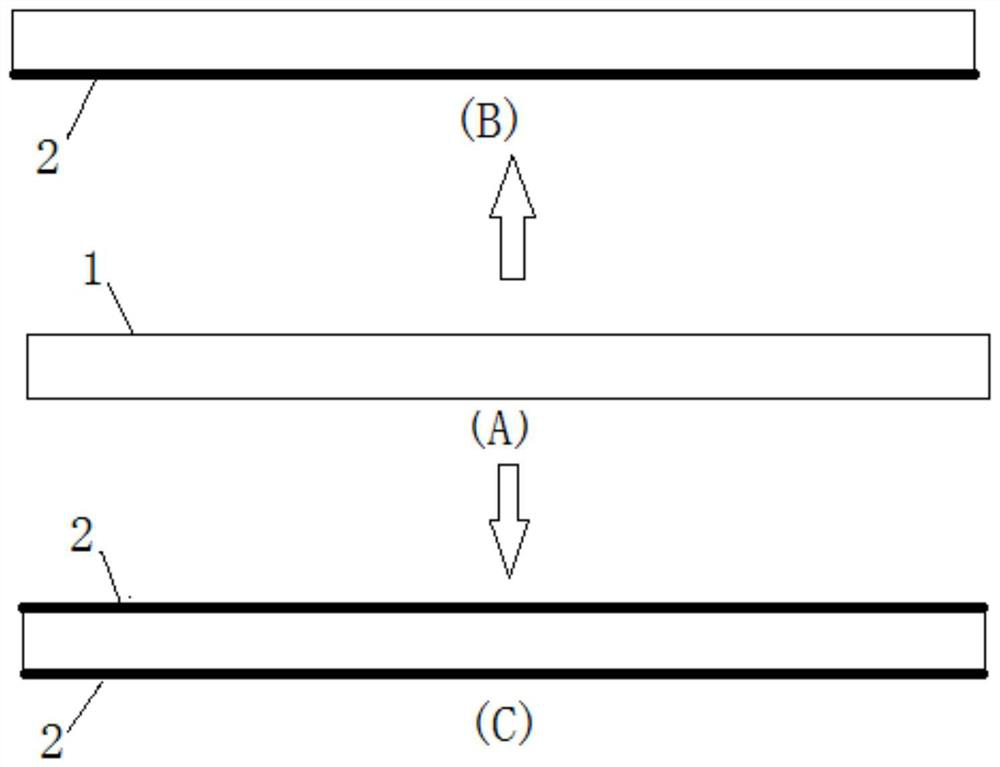

Accurately pre-buried junction box based on BIM and aluminum alloy formwork and construction method

ActiveCN106639261AGuaranteed one-time installation successAvoid secondary damageGeometric CADElectrical apparatusBlueprintSizing

The invention relates to a construction method for an accurately pre-buried junction box based on BIM and an aluminum alloy formwork. The construction method comprises the following operating steps that (1) the BIM technology is utilized, civil engineering and mechanical and electrical installation models are established, position, functionality and collision checking is conducted, and a mechanical and electrical installation construction drawing is deeply optimized; (2) according to a deeply-optimized construction blueprint, a BIM model is established, the splicing dimension, position and sequence of the aluminum alloy formwork are determined, and the aluminum alloy formwork with the determined splicing dimension is subjected to factory sizing manufacturing; (3) through junction box position information recorded by the BIM model, positioning clamp plates are manufactured on the aluminum alloy formwork while sizing manufacturing is conducted; and (4) during the construction stage of aluminum alloy formwork installation in concrete wall body construction, the junction box is installed according to the positions of the positioning clamp plates, and when concrete wall body construction is completed and the aluminum alloy formwork is dismantled, the junction box is accurately reserved in a concrete wall body. The invention further relates to the aluminum alloy formwork with the accurately pre-buried junction box, and the pair of positioning clamp plates are arranged on the inner side face of the aluminum alloy formwork.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

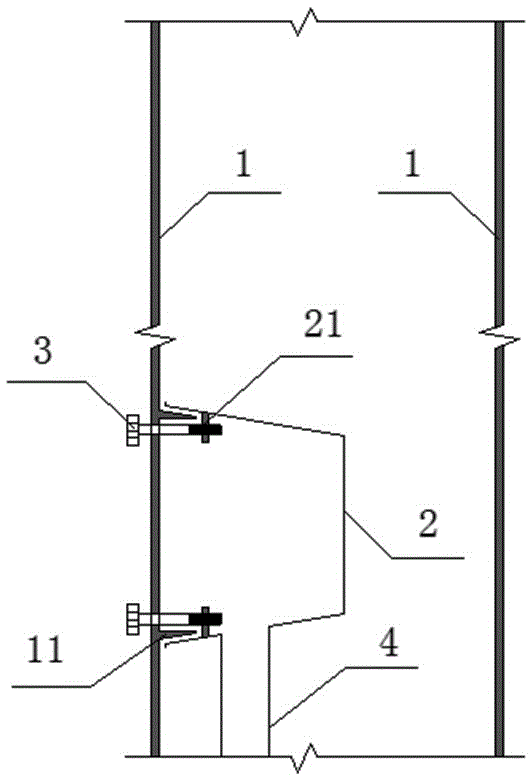

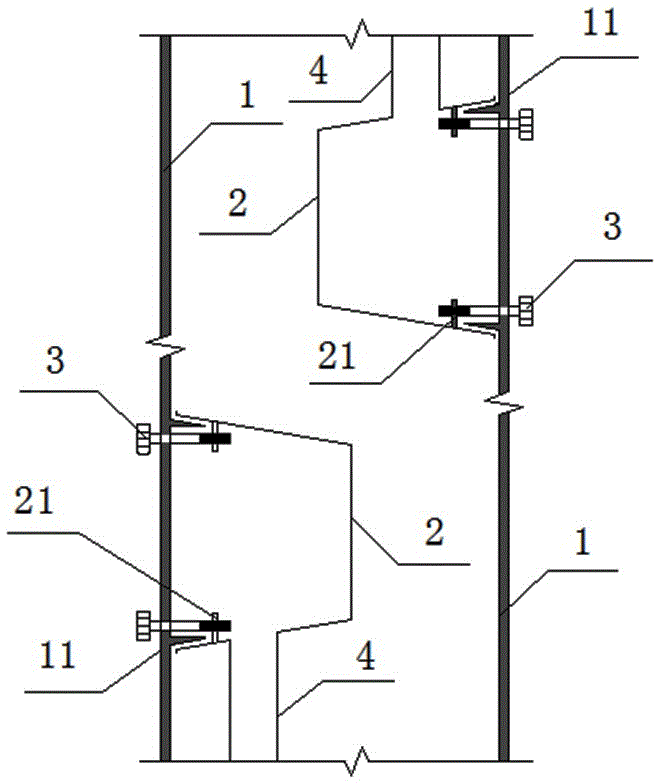

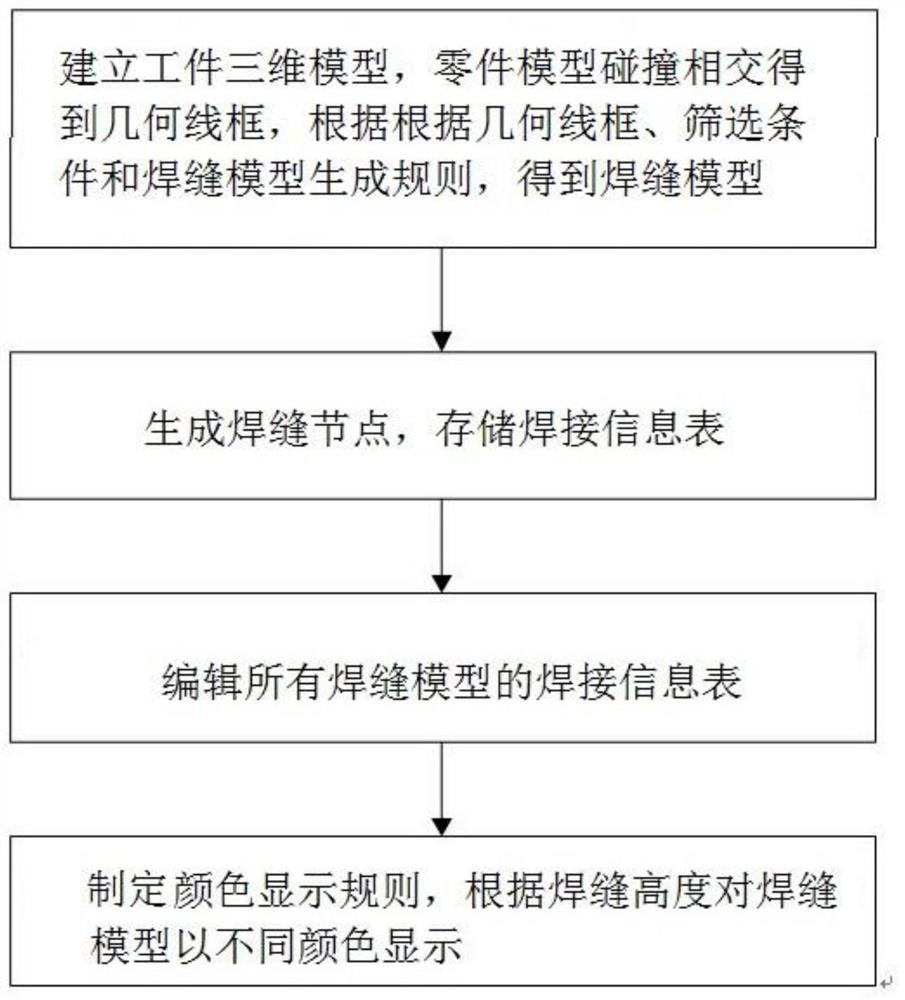

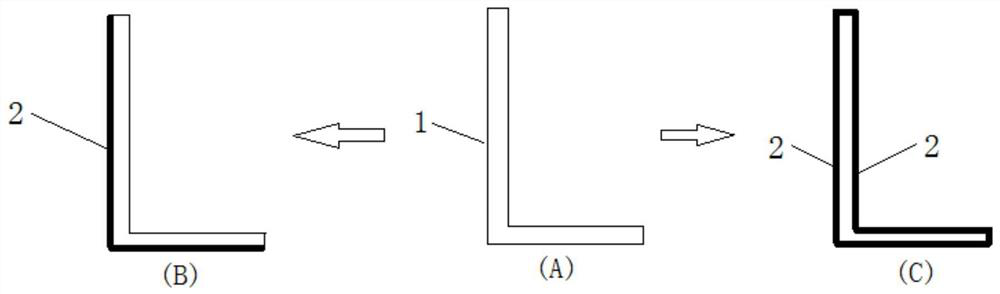

Welding joint expression method based on three-dimensional model

ActiveCN112464405AEasy accessOmit one-to-one comparisonGeometric CADSpecial data processing applicationsDesign softwareEngineering

The invention relates to a weld joint expression method based o. The method is used for expressing information of weld joints among parts in a workpiece, and comprises the following steps of: S1, establishing a three-dimensional model of a workpiece in three-dimensional design software, and carrying out collision check on part models in the three-dimensional model to obtain a closed geometric wireframe; formulating a screening condition, and screening out a geometric wireframe needing to be calculated; formulating a weld joint model generation rule, and obtaining a weld joint model on a geometric wireframe needing to be calculated; S2, generating a weld joint node on each weld joint model, and storing a welding information table in each weld joint node, wherein the welding information tables at least comprise parameter items such as weld joint types, weld joint stages and weld joint lengths; S3, editing welding information tables of all the weld joint models, and determining numericalvalues or information of parameter items in the welding information tables; and S4, formulating a weld joint color display rule, classifying the weld joint models according to the weld leg heights ofthe weld joint models, and displaying the weld joint models by adopting different colors for different classifications.

Owner:JIANGNAN SHIPYARD GRP CO LTD

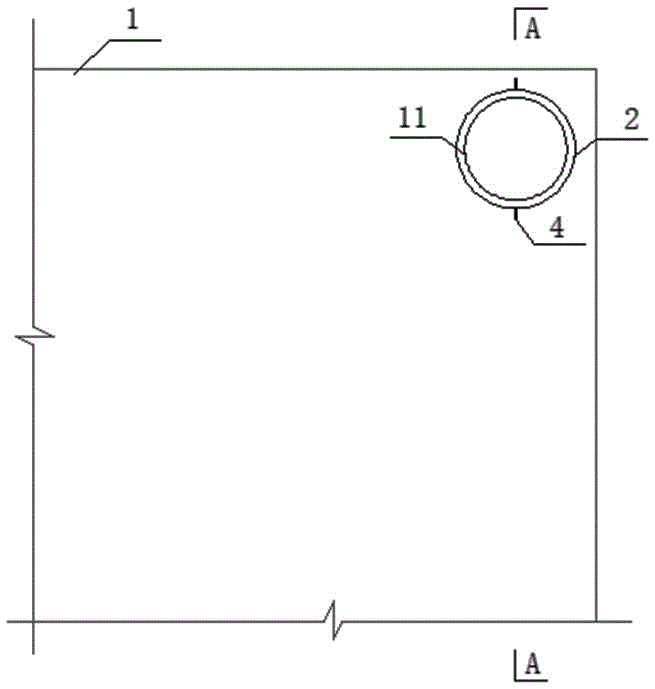

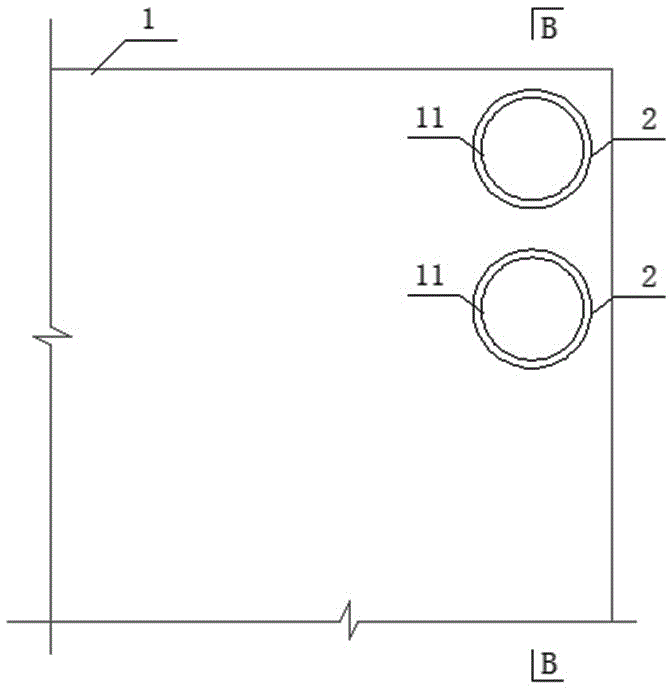

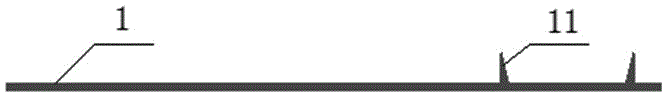

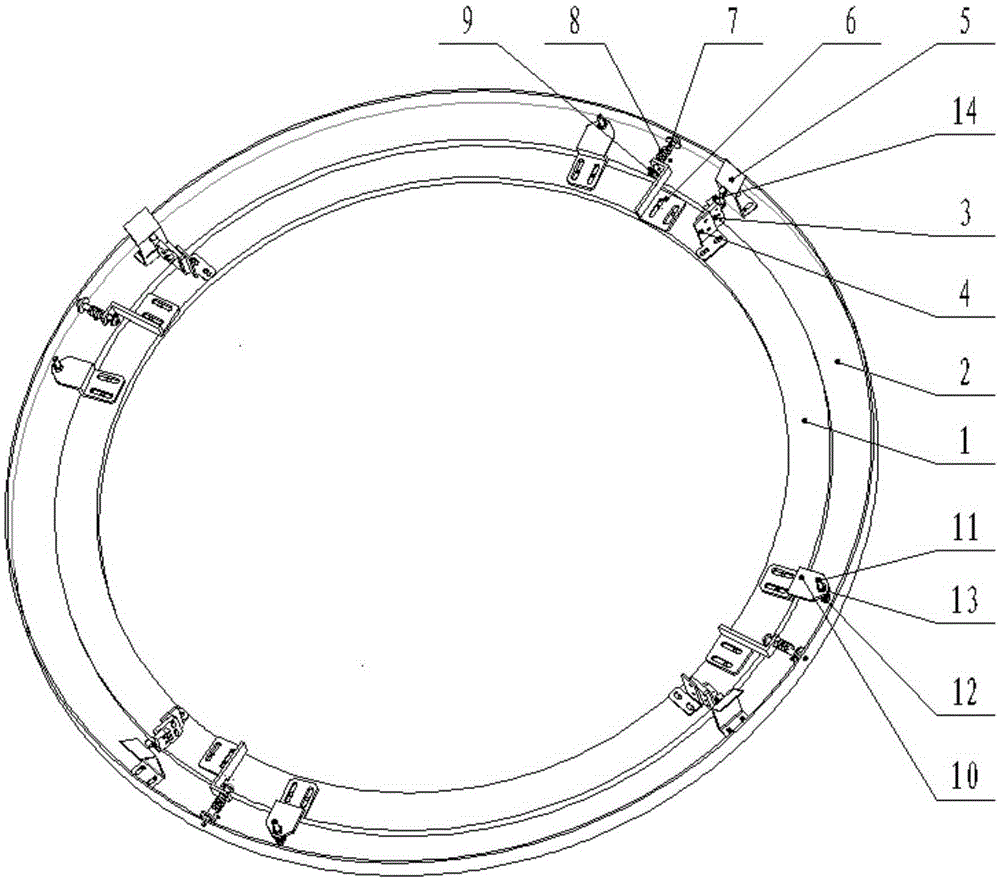

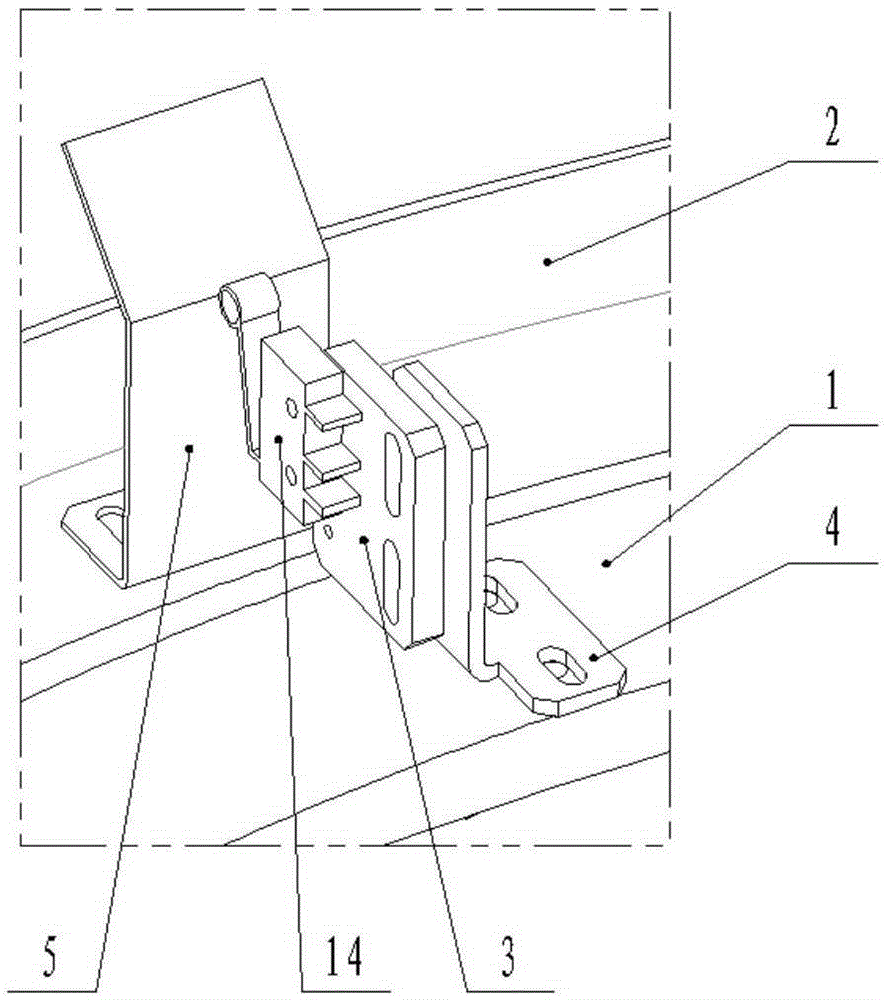

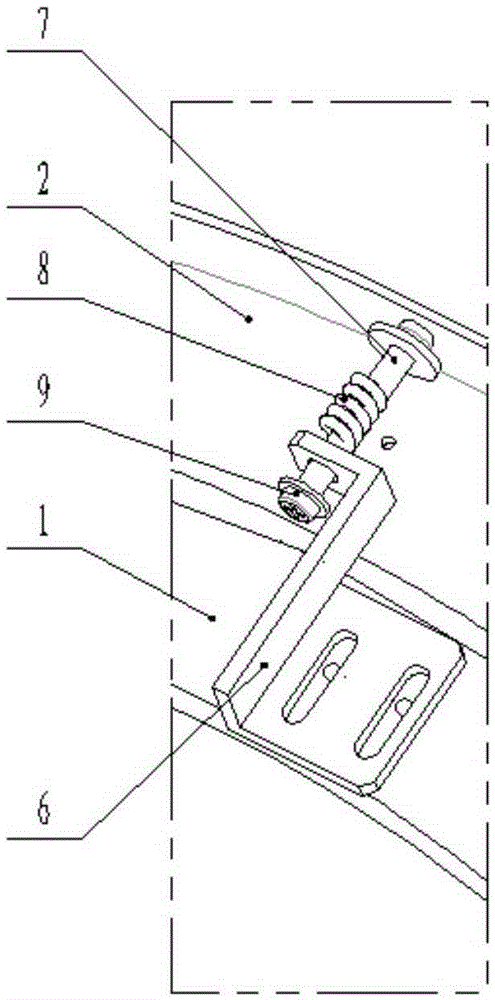

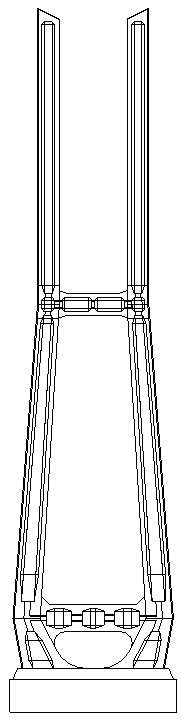

Therapeutic head efficient anti-collision mechanism

The invention discloses a therapeutic head efficient anti-collision mechanism. The therapeutic head efficient anti-collision mechanism comprises a mounting substrate, anti-collision checking ring, a switch assembly, a horizontal pushing assembly and a vertical pushing assembly; the mounting substrate is an annular flat plate; the anti-collision checking ring is of a circular cover-shaped structure; a concentric circular hole is machined in the bottom surface of the anti-collision checking ring; the diameter of the circular hole is greater than the inner diameter of the mounting substrate; the mounting substrate is movably connected with the anti-collision checking ring through the horizontal pushing assembly and the vertical pushing assembly; the switch assembly is fixedly connected onto the mounting substrate; and the horizontal and longitudinal displacement of the anti-collision checking ring can both trigger the switch assembly. The therapeutic head efficient anti-collision mechanism can transmit signals to a device control system when a therapeutic head is squeezed.

Owner:江苏海明医疗器械有限公司

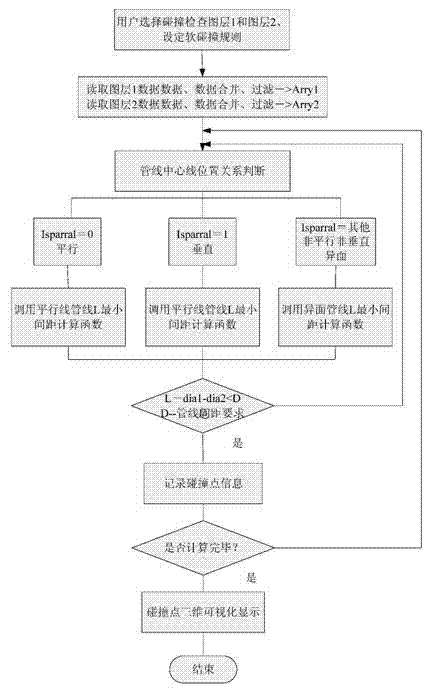

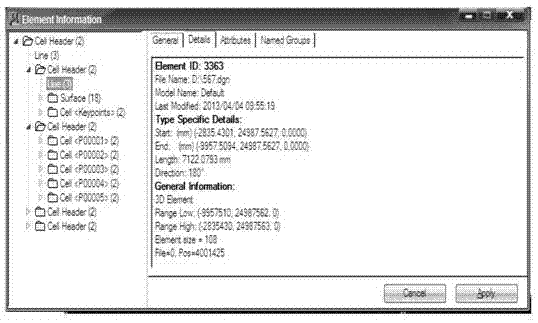

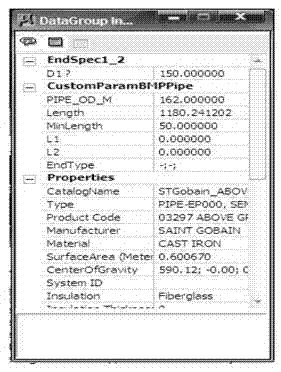

Outdoor three-dimensional integrated pipeline threshold detection method for urban rail transit depot

ActiveCN103617314AImplement soft collision checkingPut an end to abandoned projectsSpecial data processing applicationsReference modelLine tubing

The invention relates to an outdoor three-dimensional integrated pipeline threshold detection method for an urban rail transit depot. The method includes: (1) extracting pipeline information, and extracting a current model and pipeline starting point, terminal point and pipe diameter information in an additional reference model in the current model in outdoor three-dimensional integrated pipeline design data of the urban rail transit depot; (2) calculating information of the outdoor three-dimensional integrated pipeline design data of the urban rail transit depot by adopting a soft collision detection algorithm; (3) outputting a soft collision result of detected information; (4) visually displaying the soft collision result. By the technical scheme, soft collision detection can be performed on outdoor three-dimensional integrated pipelines of the urban rail transit depot in three-dimensional software effectively, efficiency in work design is improved greatly, accuracy is high, and abandoned pipeline construction work is completely eradicated.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

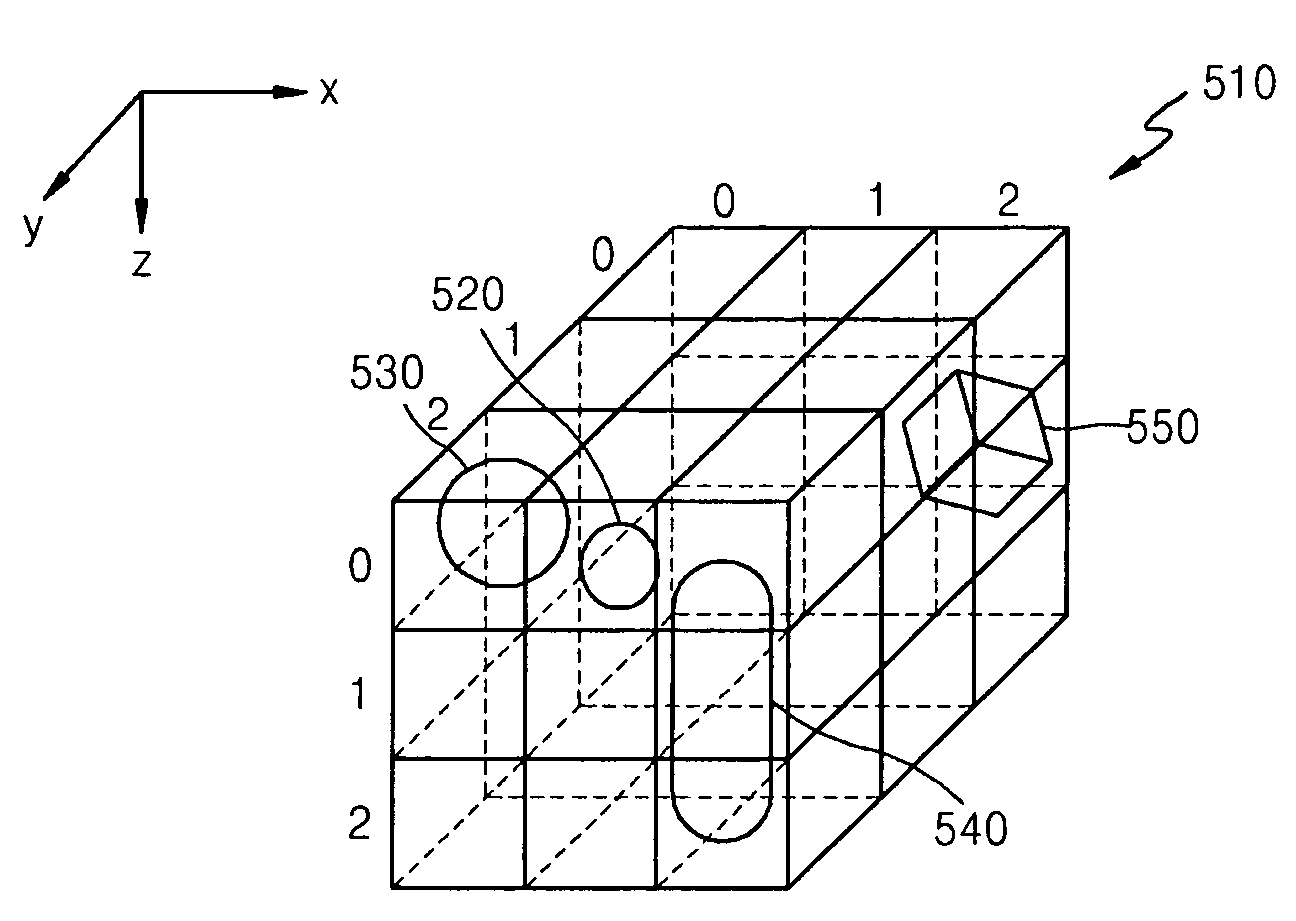

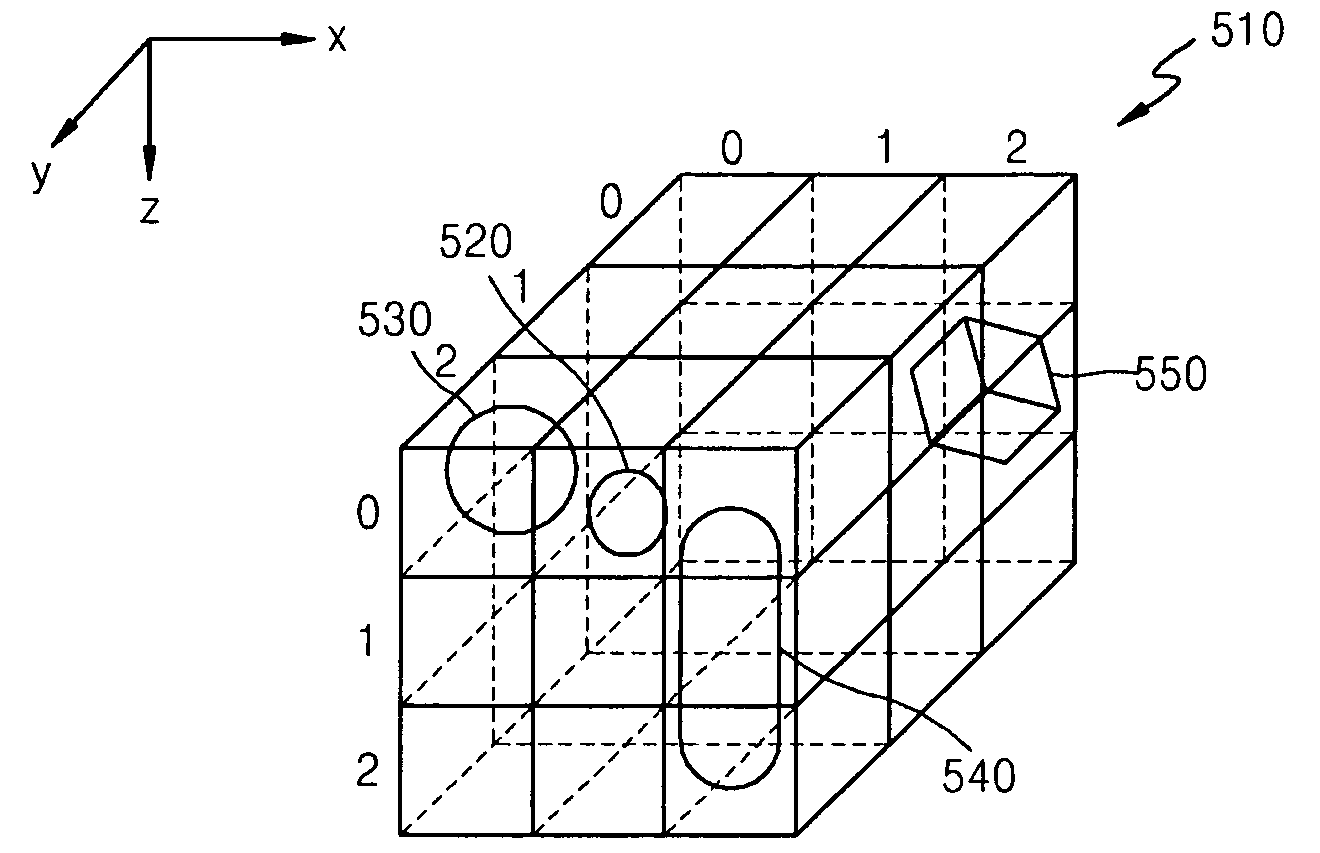

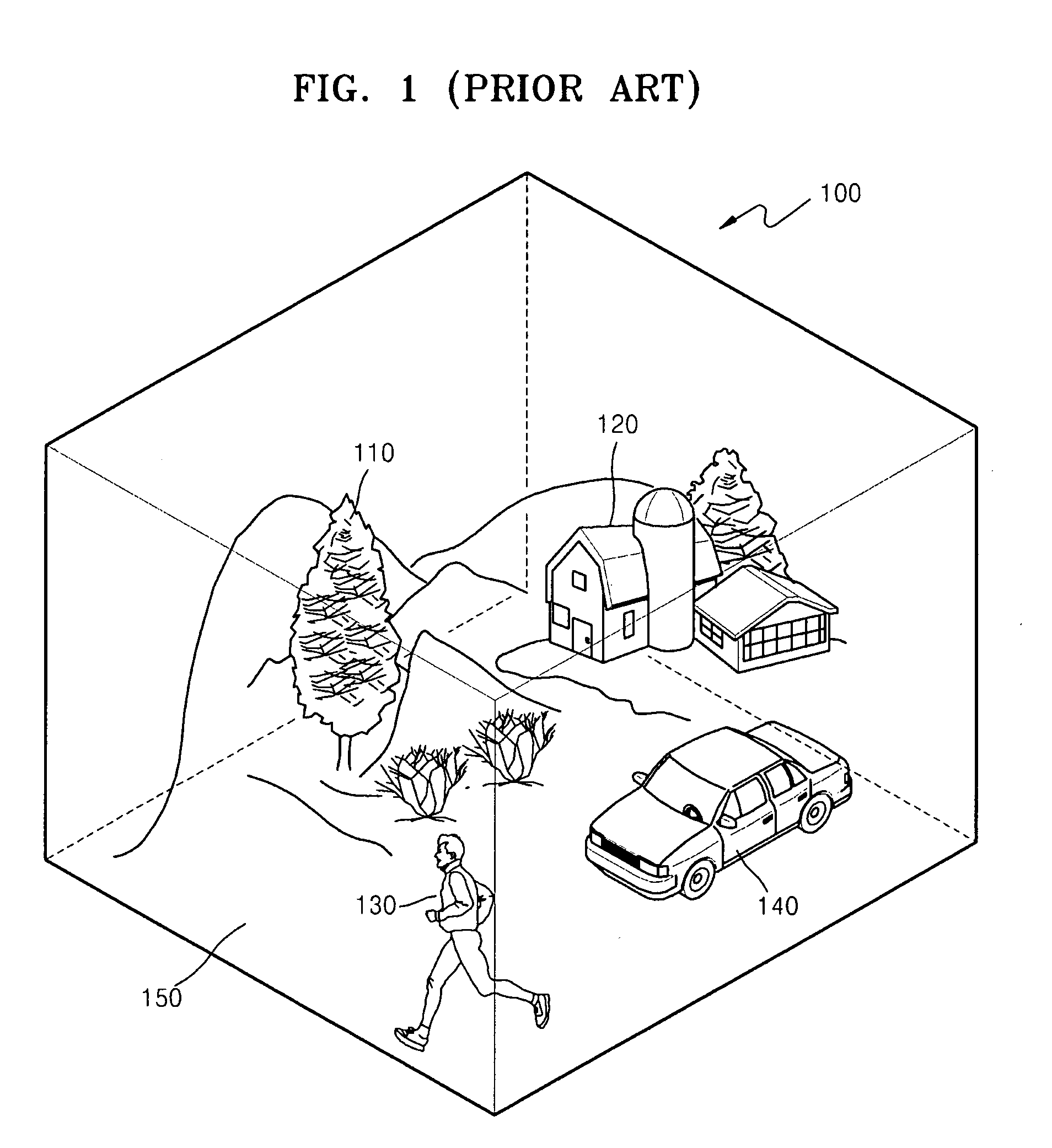

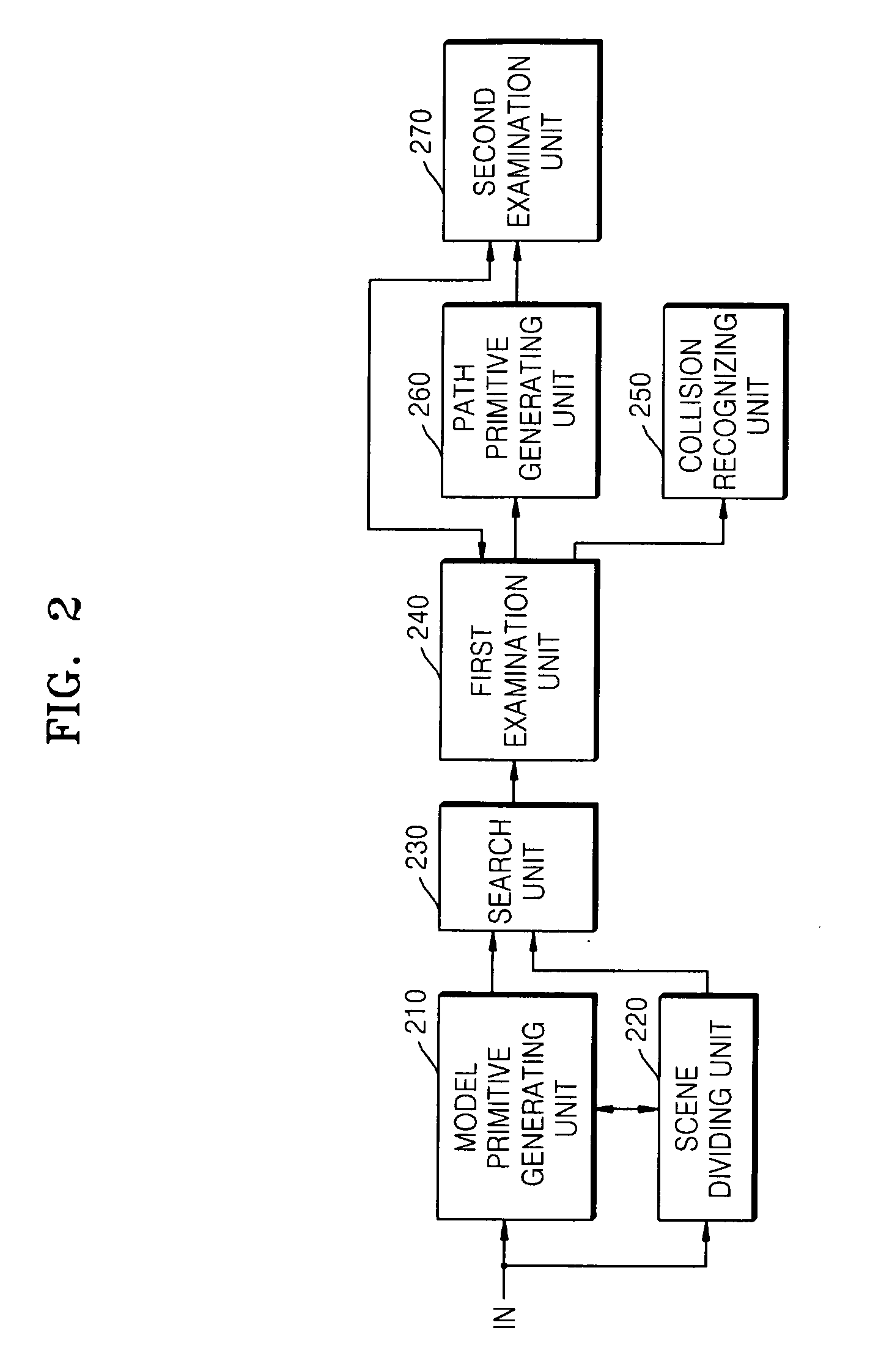

Method, medium and apparatus detecting model collisions

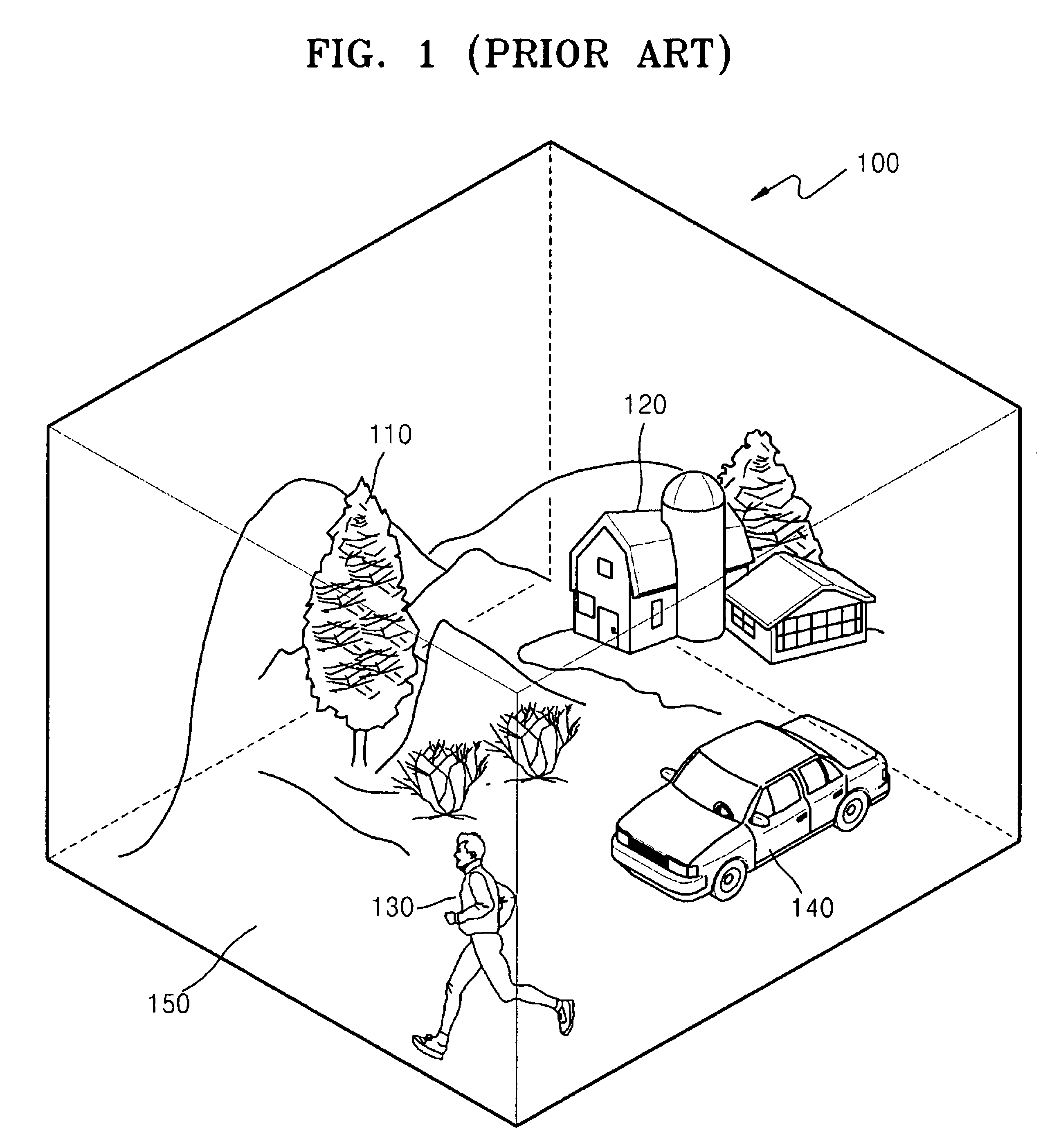

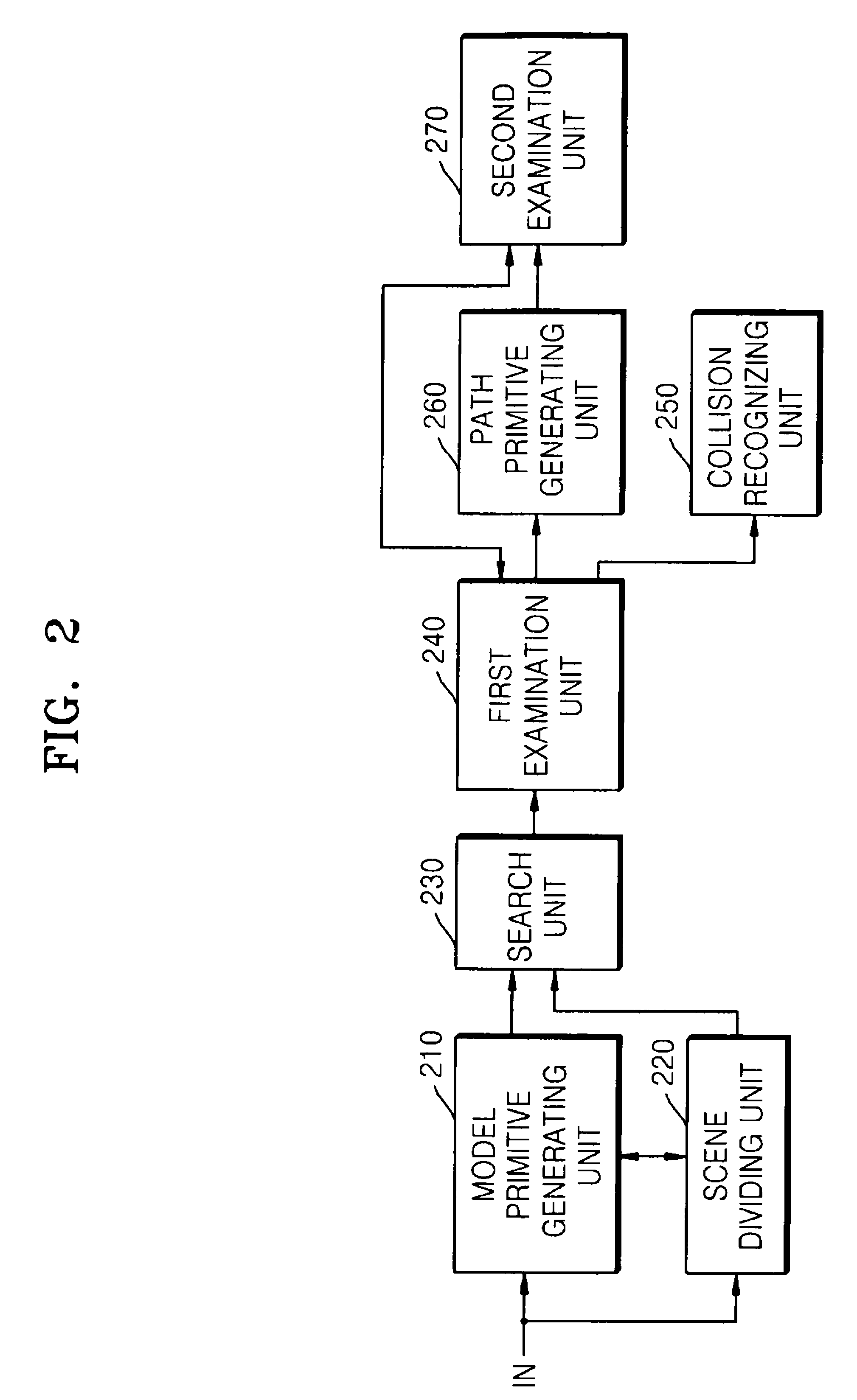

ActiveUS8130220B2Quick checkSpecial data processing applicationsImage generationCollision checkingReal-time computing

A method, medium and apparatus determining whether models collide with each other. In the model collision detecting method, medium and apparatus, it is possible to quickly examine whether models collide, and to recognize the collision generated at an arbitrary time, which is not a predetermined collision check time of the models, without missing the recognition of the collision generated at the arbitrary time, by determining whether paths reflecting movement of the model primitives between the current time and a previous time overlap when the model primitives do not collide at the current time, determining whether the model primitives collide with each other at an arbitrary time between the current time and the previous time when the path primitives overlap each other, and recognizing that the models collide with each other at the arbitrary time when the model primitives collide with each other at the arbitrary time.

Owner:SAMSUNG ELECTRONICS CO LTD

A H-type 100-meter cable pylon line type control and rapid construction method

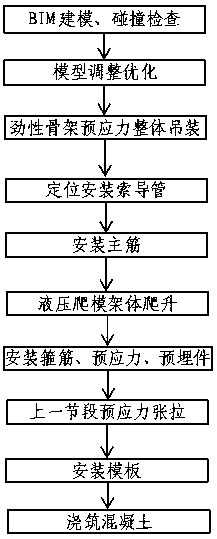

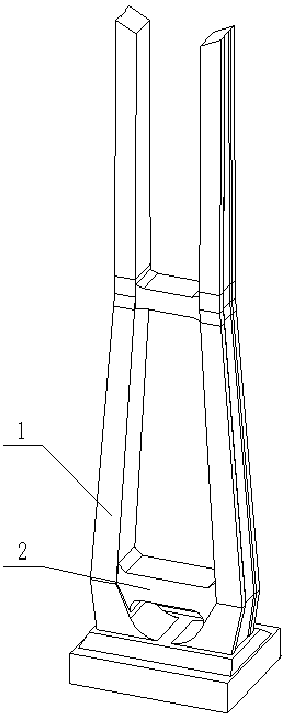

InactiveCN109098092AHigh control precisionImprove construction qualityBridge erection/assemblyLinear controlCable stayed

The invention discloses an H-type 100-meter cable pylon line type control and rapid construction method, belonging to the technical field of bridge construction. The technical problem to be solved isto provide an H-type cable pylon linear control and rapid construction method; The technical scheme adopted to solve the technical problem is as follows: including the following steps: modeling calculation, BIM collision checking; Model adjustment and optimization; Integral hoisting of prestressed members of rigid frame; Install positioning cable guide tube; Install main reinforcement; Hydraulic climbing formwork frame body climbing; Install stirrups and embedded parts; Tensioning of prestressed members in the previous section; Install template; Concrete pouring; The H-type 100-meter cable pylon line type control and rapid construction method improves the construction quality and the construction efficiency of the tower column of the cable-stayed bridge.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Method, medium and apparatus detecting model collisions

ActiveUS20080186312A1Quick checkSpecial data processing applicationsImage generationCollision checkingReal-time computing

A method, medium and apparatus determining whether models collide with each other. In the model collision detecting method, medium and apparatus, it is possible to quickly examine whether models collide, and to recognize the collision generated at an arbitrary time, which is not a predetermined collision check time of the models, without missing the recognition of the collision generated at the arbitrary time, by determining whether paths reflecting movement of the model primitives between the current time and a previous time overlap when the model primitives do not collide at the current time, determining whether the model primitives collide with each other at an arbitrary time between the current time and the previous time when the path primitives overlap each other, and recognizing that the models collide with each other at the arbitrary time when the model primitives collide with each other at the arbitrary time.

Owner:SAMSUNG ELECTRONICS CO LTD

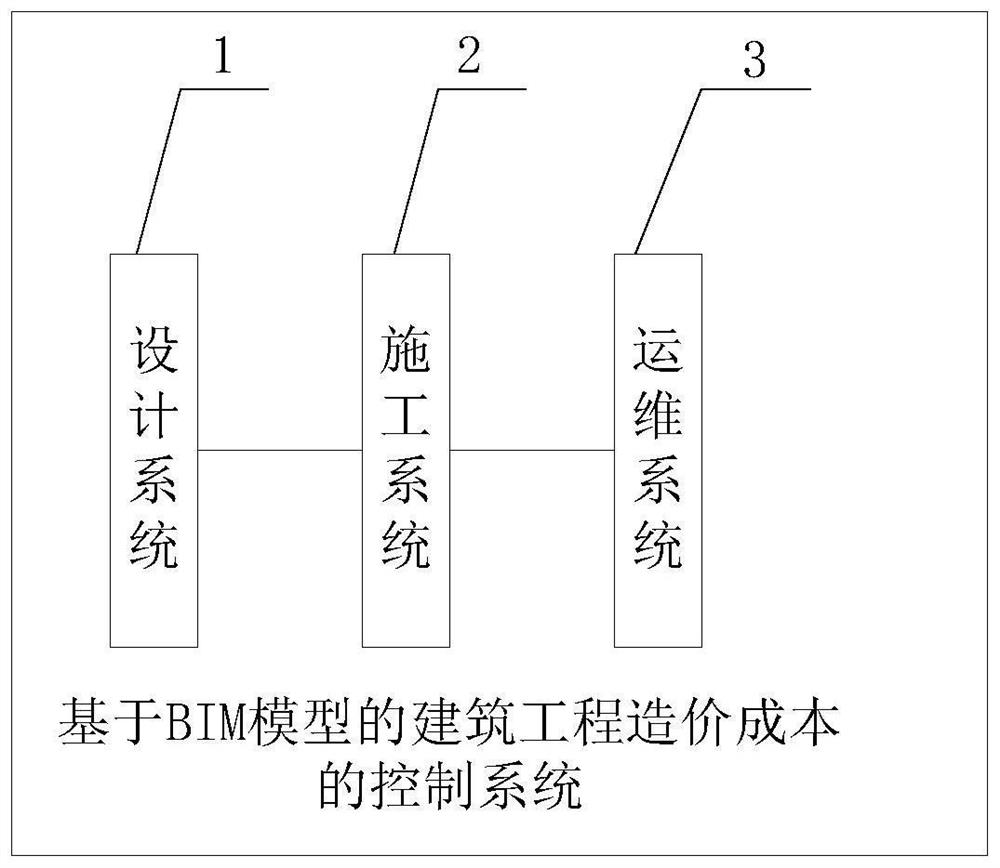

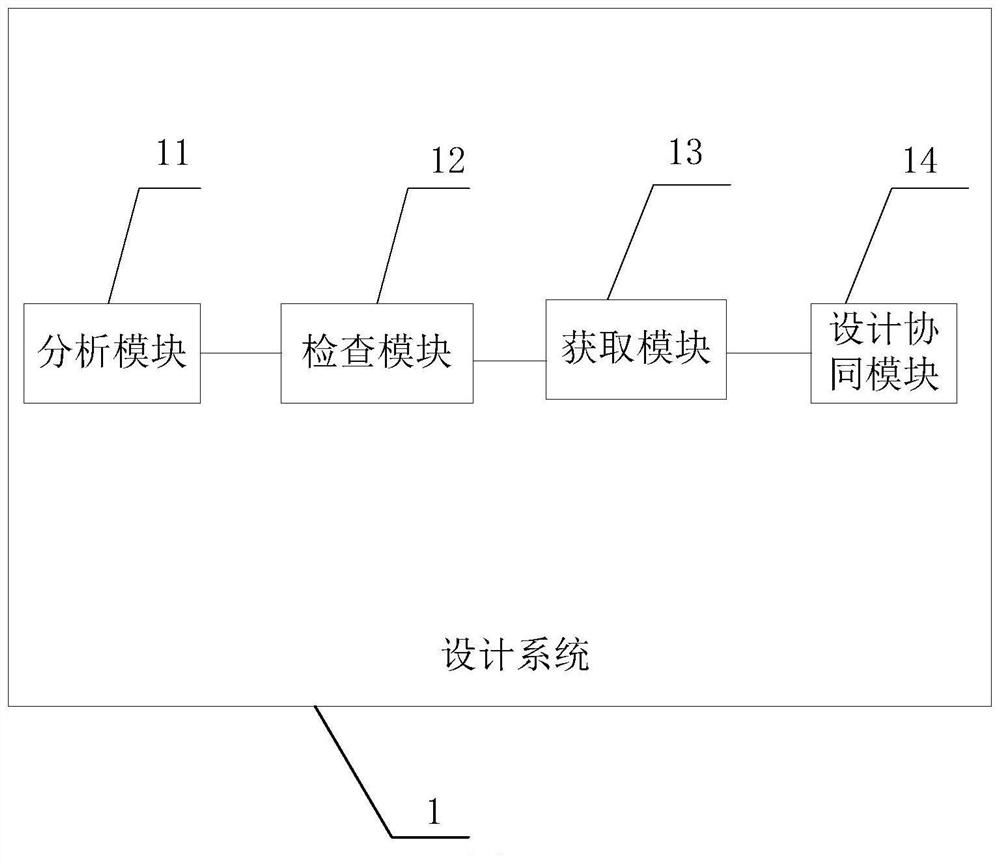

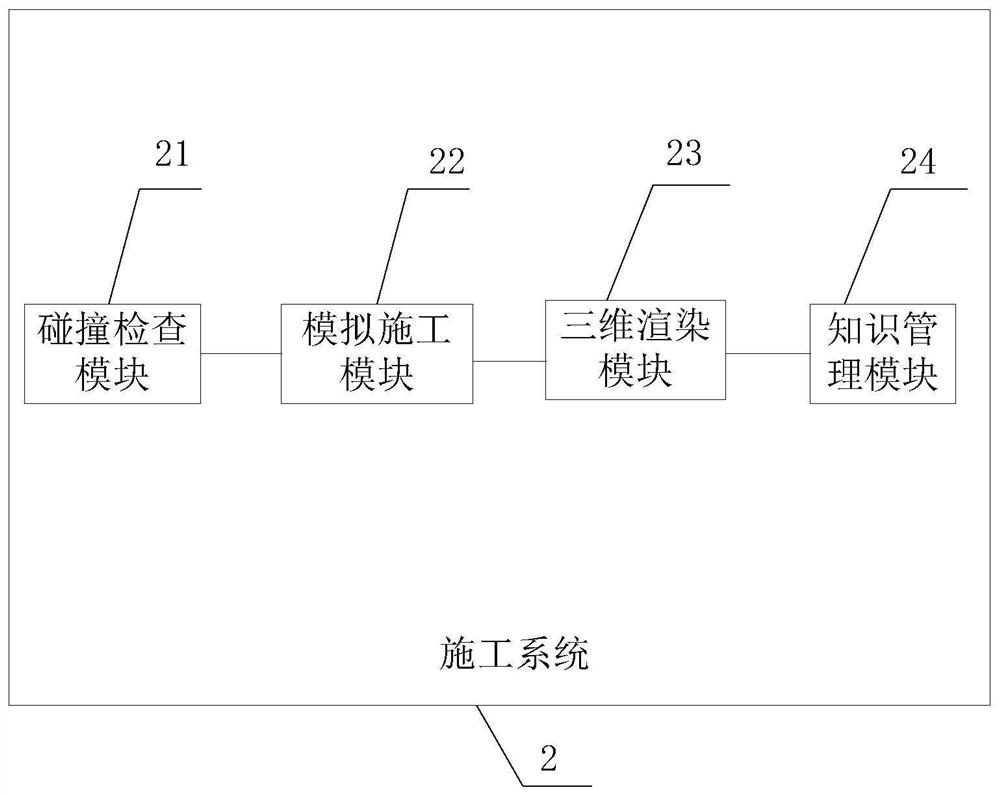

Building engineering cost control system based on BIM model

PendingCN113269529ALow costImprove management efficiencyGeometric CADMarket predictionsSystems designCost Controls

The invention provides a BIM model-based building engineering cost control system, which comprises a design system, a construction system and an operation and maintenance system. The design system comprises an analysis module, an inspection module, an acquisition module and a design collaboration module which are connected in sequence. The construction system comprises a collision checking module, a simulation construction module and a three-dimensional rendering module which are connected in sequence. The operation and maintenance system comprises a space management module, a facility management module and a hidden project management module which are connected in sequence, and the space management module is used for obtaining space position information of fire fighting equipment and converting the space position information into a three-dimensional graphic position; the facility management module is used for maintaining various facilities; and the hidden project management module is used for acquiring pipeline information based on a BIM model, and carrying out maintenance or equipment replacement on a damaged pipeline or line. According to the invention, the problem that the existing project cost management and control precision and efficiency are not high is solved.

Owner:重庆创新工程咨询有限公司

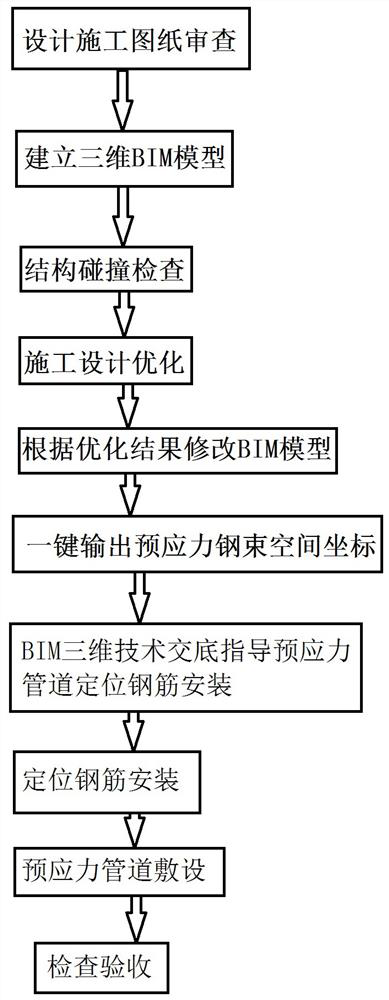

BIM technology-based railway continuous beam prestressed pipeline accurate positioning method

PendingCN112347549AIntuitive knowledgeAvoid reworkGeometric CADDesign optimisation/simulationBridge engineeringData bank

The invention discloses a BIM technology-based railway continuous beam prestressed pipeline accurate positioning method, which relates to a railway bridge prestressed pipeline positioning method. Themethod is invented mainly for solving the problem that at present, prestressed steel beam space positioning is based on a two-dimensional design drawing, and deviation is likely to occur in continuousbeam construction. Based on a drawing, a complete engineering model and a database are established according to construction procedures and system coding requirements, a BIM model adopts Tekla software for modeling, and an IFC general format is exported by utilizing the BIM model and transmitted to Navisworks. And through Navisworks display software, three-dimensional display of components is carried out on the bridge engineering, and meanwhile three-dimensional collision inspection is achieved. Programming is conducted through C# language to realize one-key output of the spatial coordinatesof the prestressed steel beam. Setting out and positioning rib welding are conducted according to the accurate positioning coordinates of the prestressed pipeline output by the BIM model and a BIM simulation positioning scheme. The method has the advantage of reducing building quality problems.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

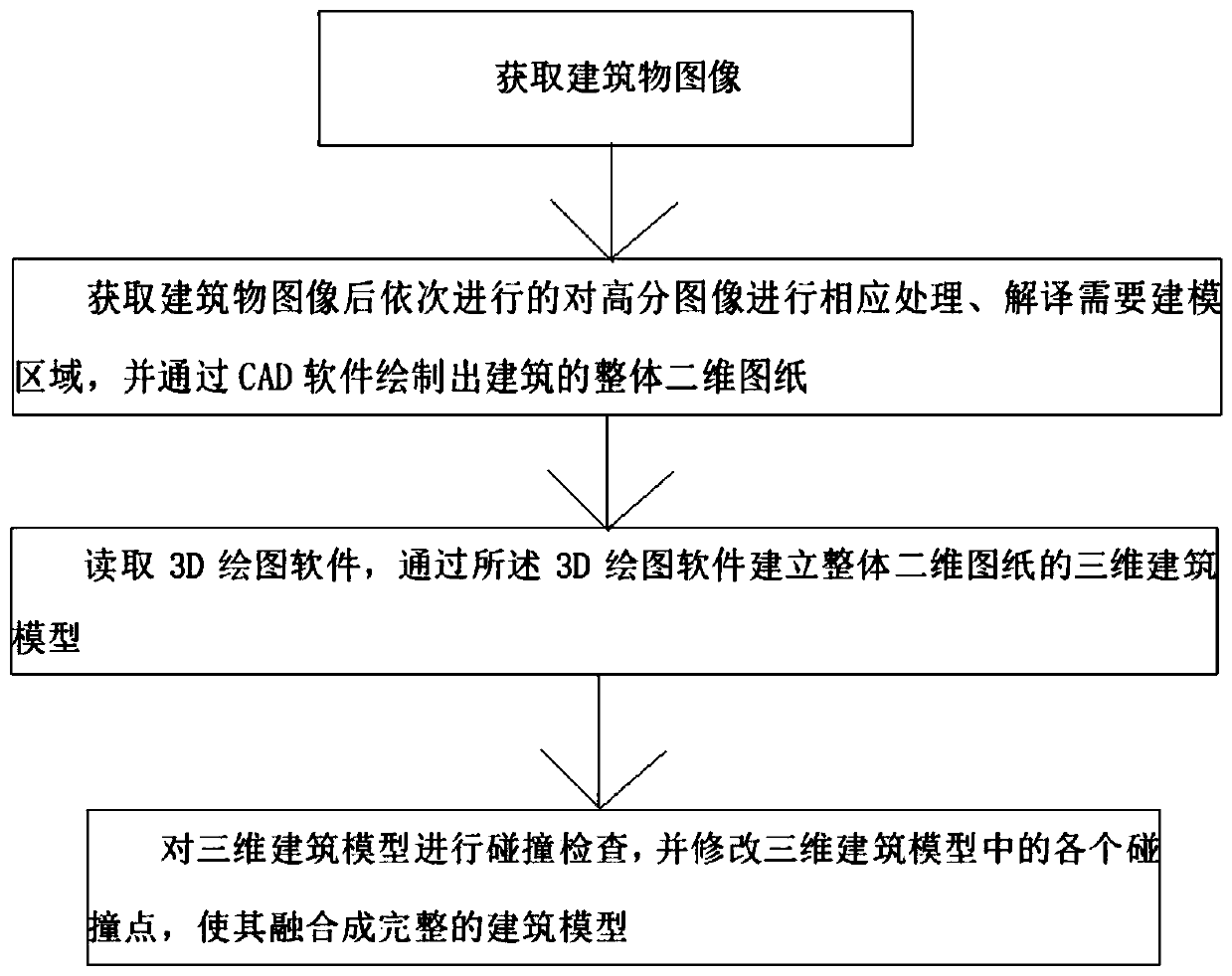

Building model image design method based on 3D software

PendingCN111046459AImprove design efficiencyGeometric CADDesign optimisation/simulationAlgorithmModelSim

The invention discloses a building model image design method based on 3D software, and the method comprises the following steps: 1, obtaining a building image which mainly comprises the obtaining of the orientation of a building, wherein the orientation of the building comprises the obtained building information around a main building and the building information of the main building; 2, after building images are obtained, correspondingly processing the high-resolution images in sequence, interpreting areas needing modeling, and drawing an overall two-dimensional drawing of a building throughCAD software; 3, reading 3D drawing software, and establishing a three-dimensional building model of an overall two-dimensional drawing through the 3D drawing software; and 4, performing collision check on each three-dimensional building model in the step 3, and modifying each collision point in the three-dimensional building model to fuse the collision points into a complete building model. According to the method, through 3D modeling, problems occurring in design are directly reflected, the building model design efficiency is improved, and meanwhile building model design with various requirements can be met.

Owner:广州凡拓动漫科技有限公司

Teach mode collision avoidance system and method for industrial robotic manipulators

ActiveUS10766140B2Shorten speedAvoid collisionProgramme controlProgramme-controlled manipulatorSimulationEngineering

A robot system includes a robot, a teach pendant having an operator interface, and a robot controller with a computer and associated hardware and software containing a virtual representation of the robot and the environment. The system employs a method for avoiding collisions including moving a manipulator arm along an actual path in an environment containing objects constituting collision geometry. Operator input is entered into the teach pendant, whereby the operator is able to directly control motion of the robot along the actual path. A recent history of the motion of the robot is recorded, and a predicted path of the robot is developed based on the input entered into the teach pendant and the recent history of the motion of the robot. Real-time collision checking between the predicted path and the collision geometry is performed while the operator manually controls the robot using the teach pendant.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com