Space orientation computing method for numerical control bracket

A technology of spatial positioning and calculation method, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of long positioning time, inaccurate positioning, high labor intensity, and achieve the effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A spatial positioning calculation method for a numerically controlled bracket, which is performed in the following steps:

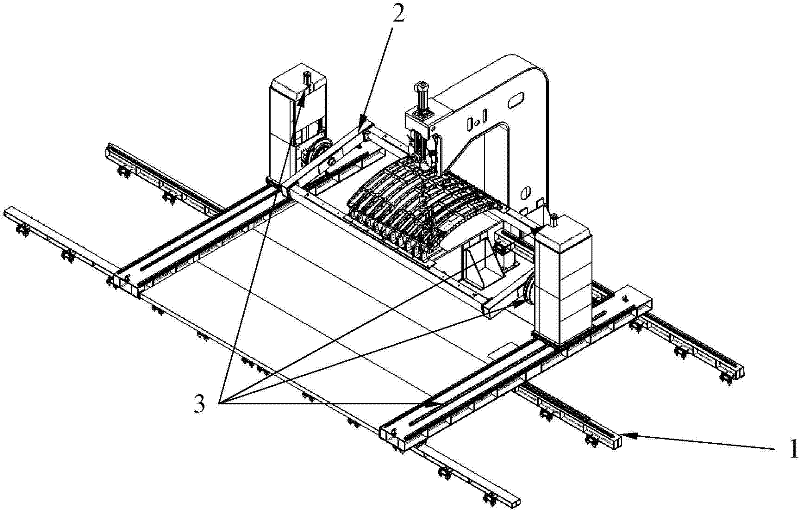

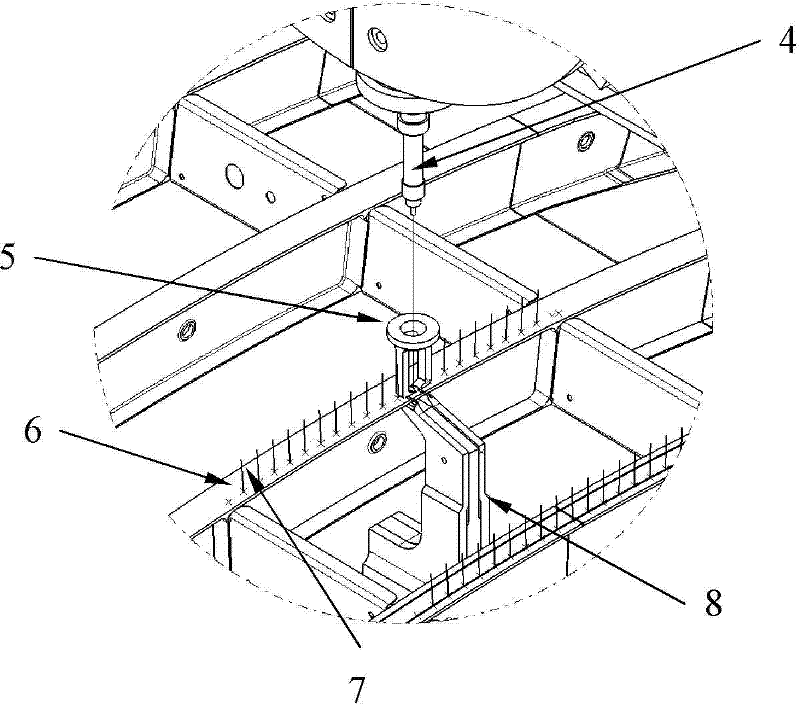

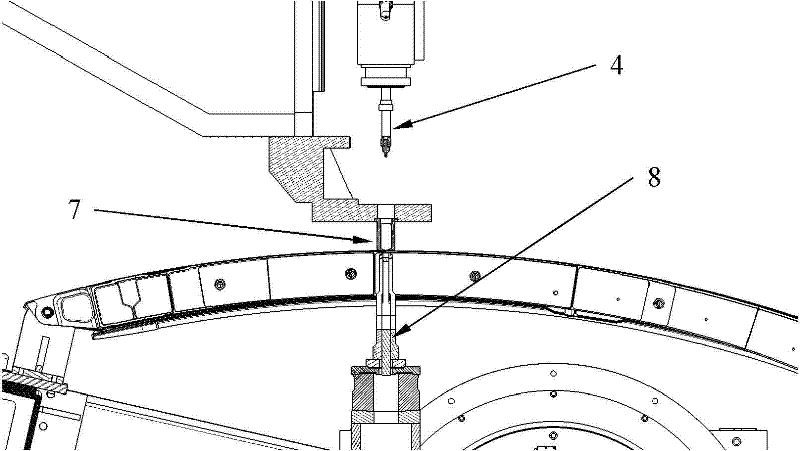

[0021] 1) if figure 1 As shown, use the CATIA or DELMIA 3D digital environment as a platform to process the 3D digital models of automatic drilling and riveting machines, CNC brackets and aircraft products. The mutual positional relationship of the space is constrained according to the actual position, and the riveting point 6 on the surface of the aircraft product is selected according to the actual needs, and the normal line with a fixed length value is established for each riveting point with the riveting point as the starting point by using the CATIA surface normal function 7;

[0022] 2) According to the actual processing form, analyze the movable parts of the CNC bracket and the automatic drilling and riveting machine, define the fixed mechanism and the moving mechanism in the digital model, and realize the X-axis guide rail of the automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com