Method for constructing multi-functional metro interchange station complex

A technology for subway transfer stations and complexes, applied in construction, earthwork drilling, underwater structures, etc., can solve problems such as poor operating conditions, long cycle times, and large investment, and achieve increased usable building area, small investment, and good engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

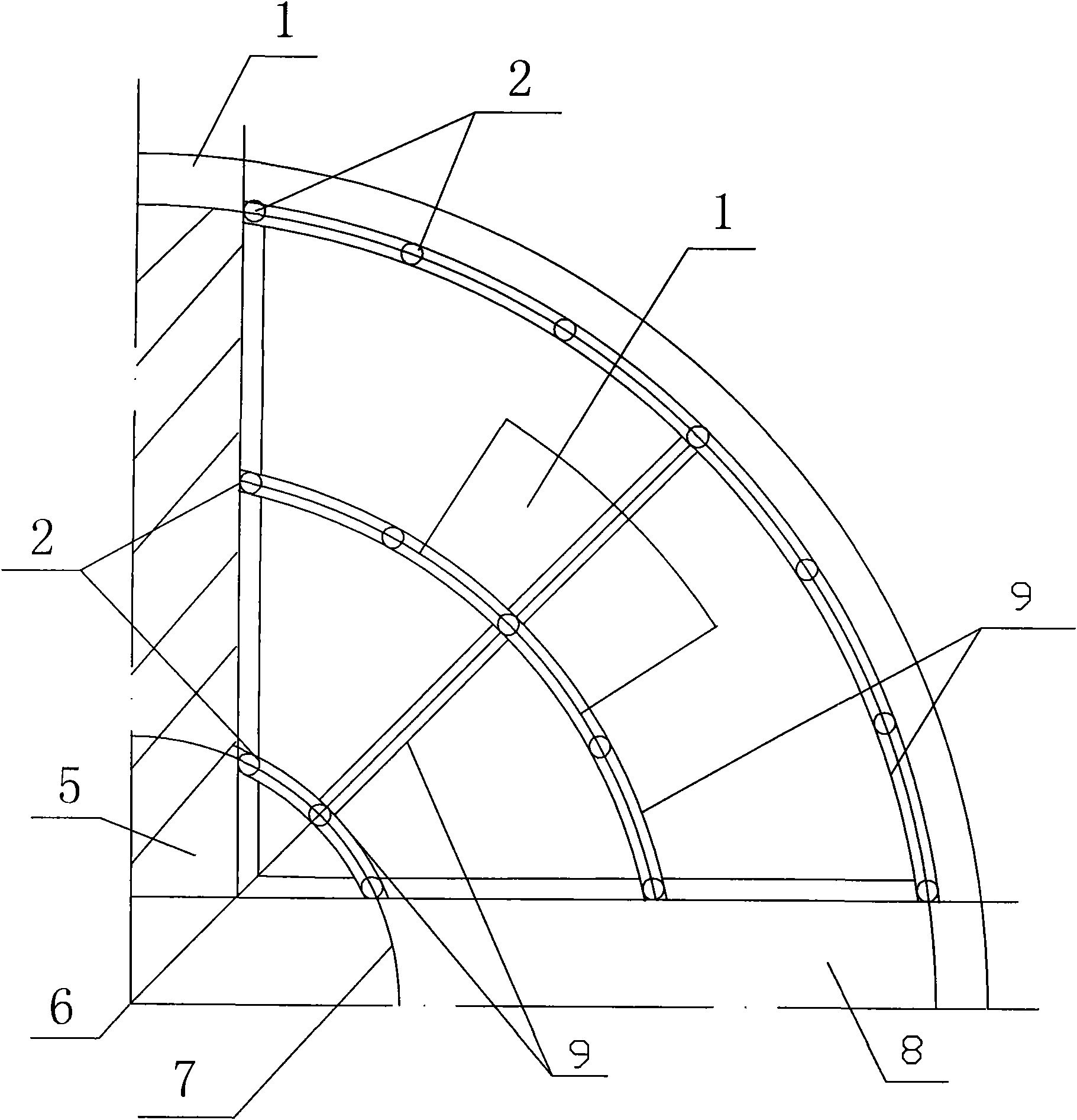

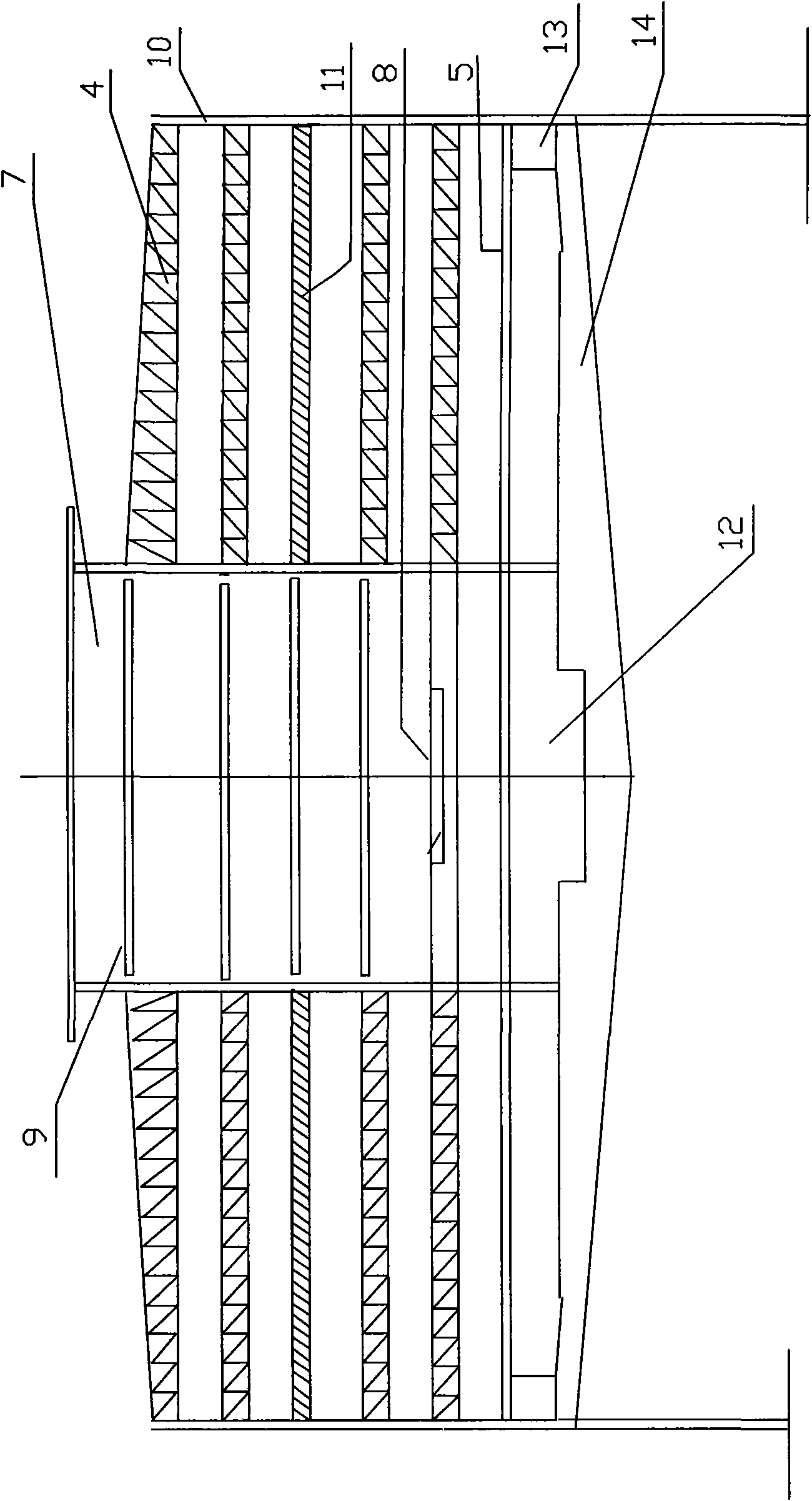

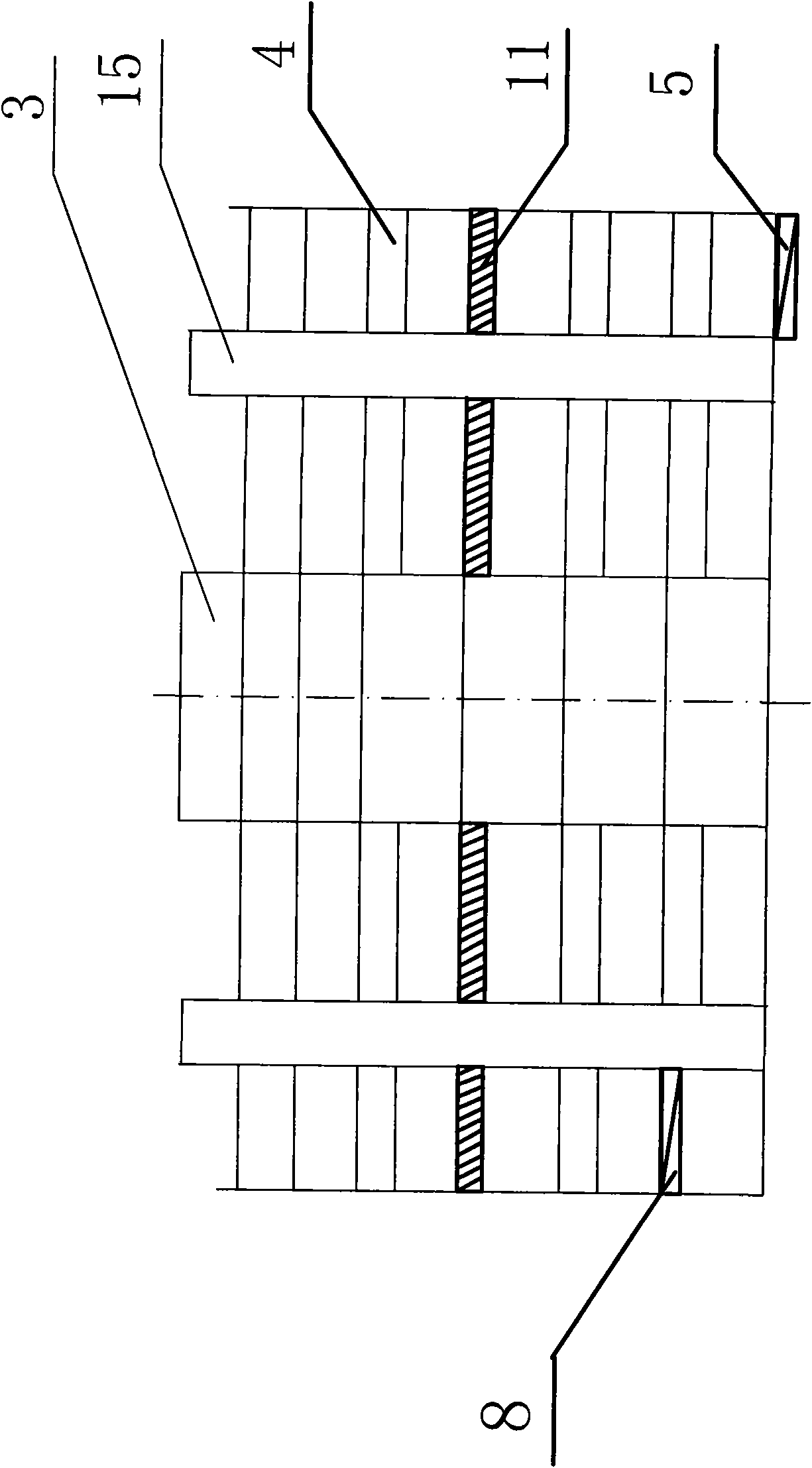

[0016] Example: such as Figure 1-4 As shown, the construction method of the multi-functional subway transfer station complex includes the following procedures in turn: (1) carry out high-pressure cement grouting for the foundation within the design scope of the subway transfer station complex, and place it under the position of the pre-built subway transfer station complex Form an anti-seepage body layer (water-proof layer); (2) Build an underground reinforced concrete diaphragm wall 1 (including the reinforced concrete support wall under the inverted arch floor) at the edge of the design range of the subway transfer station complex; Rigid pressure ring (concrete steel pipe structure) and reinforced concrete ring plate; according to geological conditions, reinforced concrete load-relief piles are installed in the soil outside the reinforced concrete continuous wall of the subway transfer station complex; (3) design of the subway transfer station complex Construction of steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com