A H-type 100-meter cable pylon line type control and rapid construction method

A cable tower line type and construction method technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of prolonging construction time, unfavorable climbing formwork efficiency and convenience, etc., so as to improve construction efficiency and construction quality , Improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

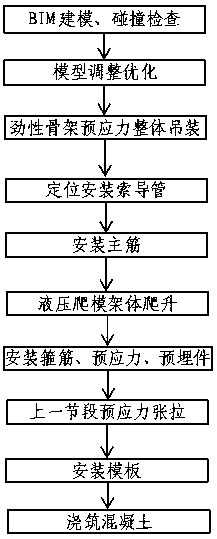

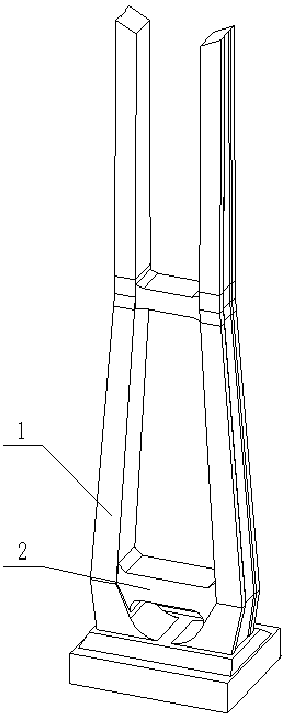

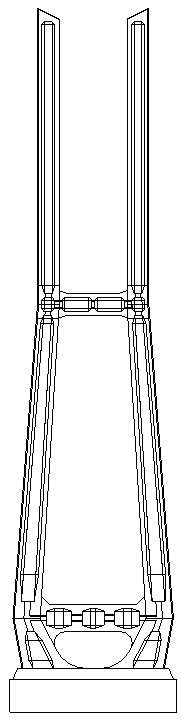

[0053] Such as Figure 1-Figure 4 As shown, a kind of H-type 100-meter cable tower linear control and rapid construction method of the present invention is used for H-type 100-meter cable tower. The crossbeam 2 is arranged at the lower part of the tower column 1, the cable conduit 3 is fixedly connected with the tower column 1, and the section of the tower column 1 is in the form of a variable section, including the following steps:

[0054] S1. Modeling calculation, BIM collision inspection: In the early stage of tower column construction, finite element software is used to analyze and calculate the force of the tower column model, BIM modeling is performed on tower column 1, and collision detection is performed on tower column modeling;

[0055]In this step, the simulation analysis and calculation not only need to consider the force of the structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com