Distributed online integrated three-dimensional design method and system for power plant

A three-dimensional design and distributed technology, applied in the field of distributed online integrated three-dimensional design methods and systems, can solve the problems of low efficiency of thermal power plants, inability to collaboratively design by multiple people, uncontrollable collisions, etc., and achieve low efficiency and accurate improvement. The effect of buried iron load and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

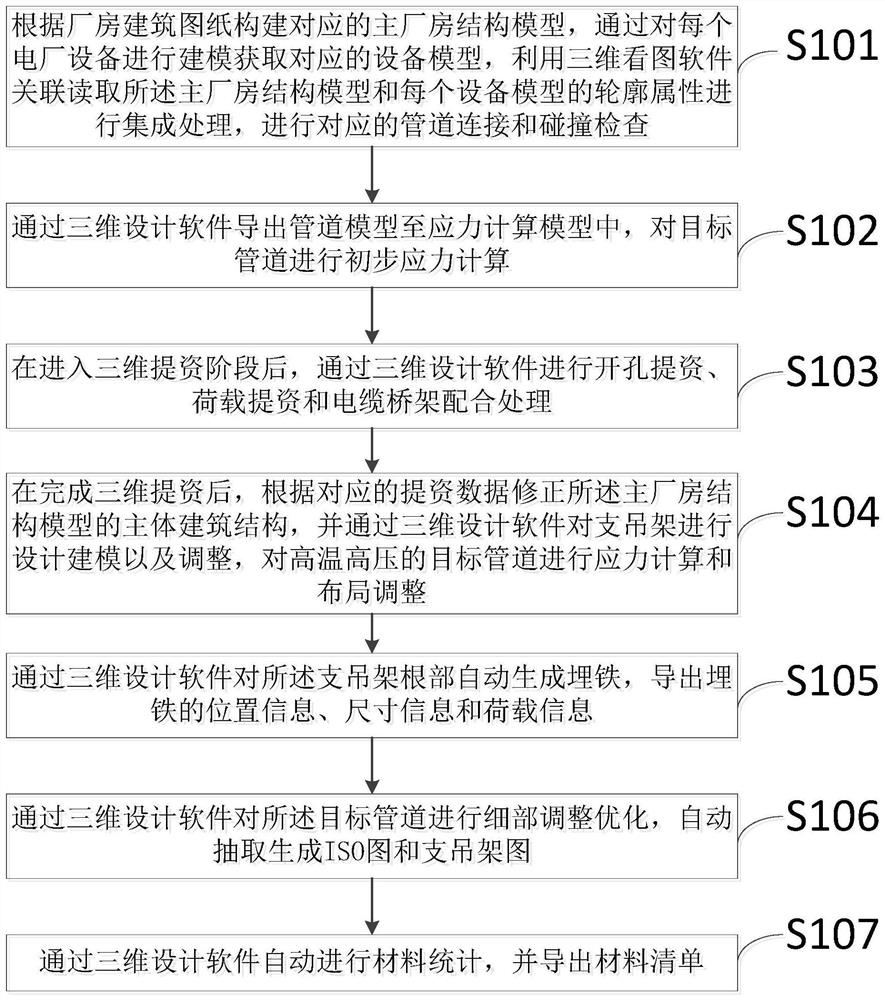

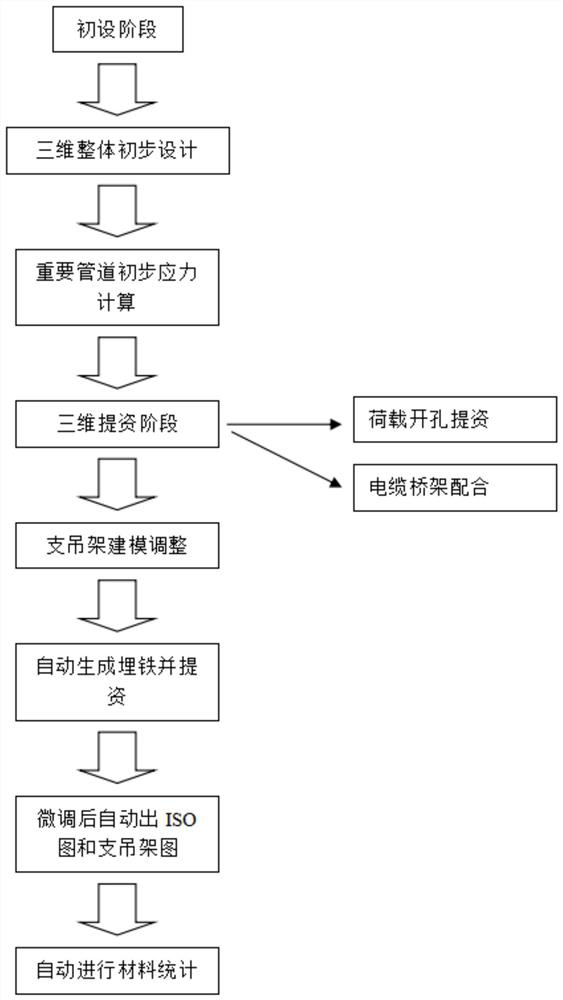

[0049] See Figure 1-3 .

[0050] Such as figure 1 As shown, this embodiment provides a distributed online integrated three-dimensional design method for power plants, which includes at least the following steps:

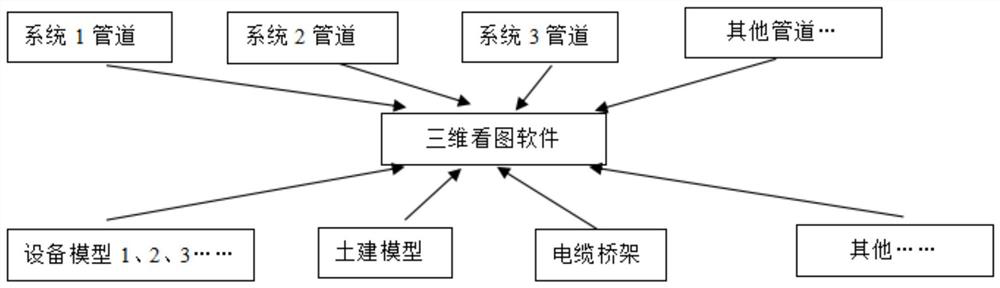

[0051] S101. Construct a corresponding main plant structure model according to the plant building drawings, obtain the corresponding equipment model by modeling each power plant equipment, and read the main plant structure model and the outline of each equipment model in association with a three-dimensional view software The attributes are integrated, and the corresponding pipeline connection and collision check are performed.

[0052] Specifically, for step S101, first construct a preliminary main plant structure model of the power plant according to the architectural drawings of the power plant, model the equipment of the power plant, or obtain equipment models from the manufacturer. The equipment models can be drawn and accurately drawn by a variety of three-dimensiona...

no. 2 example

[0095] See Figure 4 .

[0096] Such as Figure 4 As shown, this embodiment provides a distributed online integrated three-dimensional design system for power plants, including:

[0097] The three-dimensional integration module 100 is used to construct the corresponding main plant structure model according to the plant building drawings, obtain the corresponding equipment model by modeling each power plant equipment, and use the three-dimensional view software to read the main plant structure model and each plant. The contour attributes of each equipment model are integrated, and the corresponding pipeline connection and collision check are performed;

[0098] The pipeline stress calculation module 200 is used to export the pipeline model to the stress calculation model through 3D design software, and perform preliminary stress calculation on the target pipeline;

[0099] The three-dimensional fund raising module 300 is used to perform hole-opening fund raising, load raising fund and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com