Production line for producing foam microcrystal fire protection, heat insulation and decoration integrated board through smelting slag

A fire-proof, heat-preserving, integrated board technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult replacement of raw material varieties, easy aging of the decorative layer, and difficulty in escape, and increase product color and decoration. effect, reduce production pollutant emissions, energy saving and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

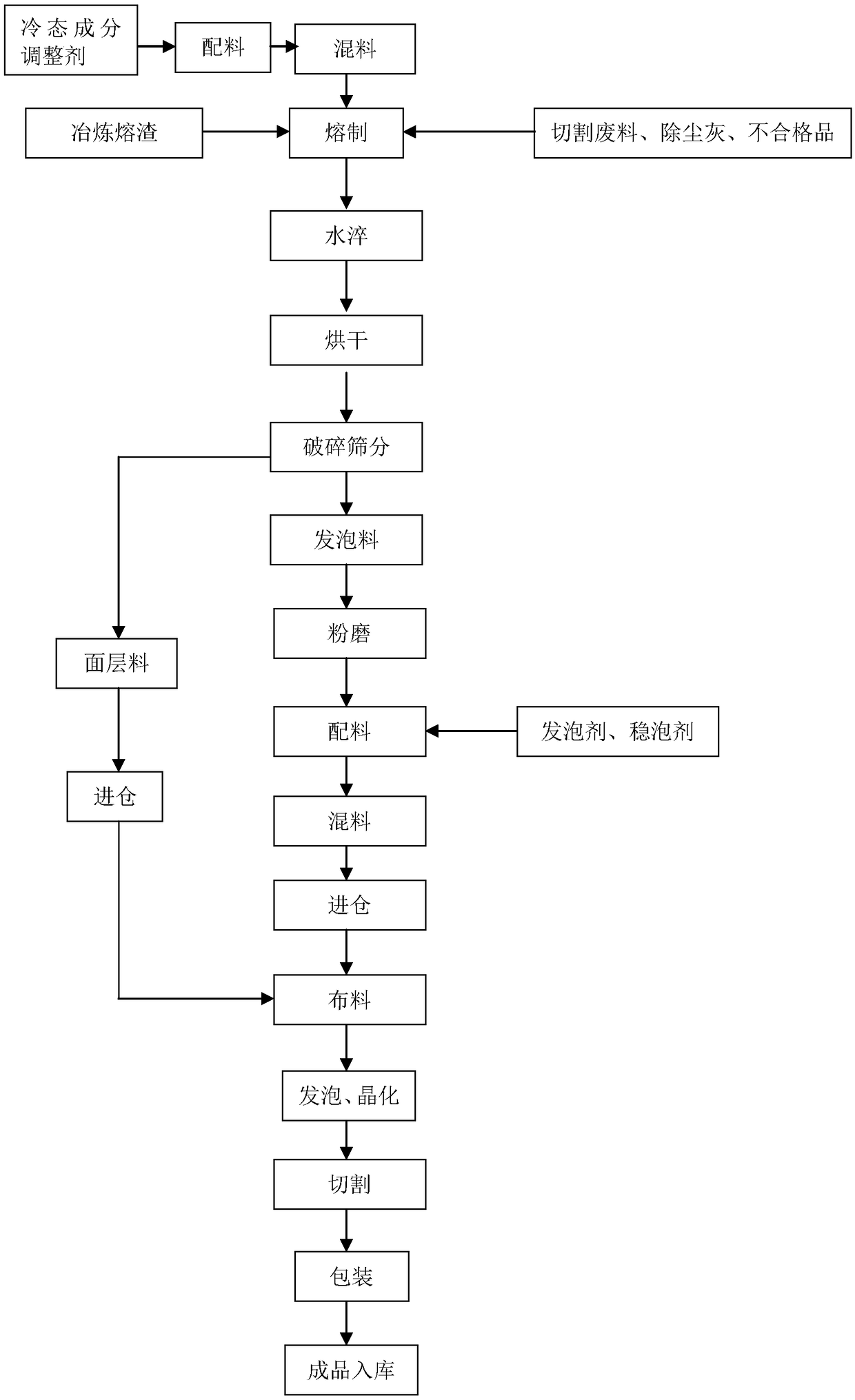

Method used

Image

Examples

Embodiment 1

[0051] Copper slag is the slag produced in the process of copper smelting, which is a kind of non-ferrous metal slag. The waste slag discharged from copper smelting by reverberatory furnace method is reverberatory furnace copper slag, and the waste slag discharged from blast furnace copper smelting is blast furnace copper slag. , The reverberatory furnace method produces 10-20t slag, and the blast furnace method produces 50-100t slag. The chemical composition of copper slag includes: 30-40% SiO in terms of mass percentage 2 , 5-10% CaO, 1-5% NaO, 2-4% Al 2 o 3 In addition, there are a large amount of iron 27-35% and a small amount of zinc 2-3%; the main mineral phase is fayalite (which is 90% FeSiO 4 ), followed by magnetite, glass and sulfide.

[0052] Use 50% reverberatory furnace to smelt copper slag, and 50% cold-state composition regulator to produce foamed microcrystalline fireproof and thermal insulation decorative integrated board. The melting temperature is 1480°C,...

Embodiment 2

[0055] Using 60% blast furnace smelting copper slag and 40% cold-state component regulator to produce foamed microcrystalline fireproof and thermal insulation decorative integrated board, the melting temperature is 1520°C, the melting time is 30h, the colorant is ferric oxide, and the amount added It is 0.12% of the melt; the particle size of the surface material is 100 mesh, and the particle size of the foam material is 250 mesh. The foaming agent is a mixture of sodium silicate and aluminum nitride, and the addition amount is 2.5% of the foam material. The additive is sodium phosphate, the addition amount is 3.6% of the foaming material, the flux is sodium fluorosilicate, and the addition amount is 3% of the foaming material; the foaming temperature is 1040°C, the foaming time is 100min, and the crystallization temperature is 1070°C, the crystallization time is 80min, the average cooling rate is 10°C / min, and the cooling time is 120min.

[0056] The facing layer of the obtai...

Embodiment 3

[0058] Ferromanganese slag is a kind of industrial waste discharged during the smelting of ferromanganese alloy. Generally, 2.0-2.5t of ferromanganese slag will be produced for every 1 ton of silicon-manganese alloy produced. The chemical composition of ferromanganese slag is CaO, SiO 2 , Al 2 o 3 , its CaO and SiO 2 The mass ratio is greater than 1.2, which belongs to alkaline slag, about 80% of which is vitreous, and contains anorthite, C 2 A small amount of crystals such as S, magnesia and manganese calcium pyroxene.

[0059] Using 65% ferromanganese smelting slag and 35% cold-state component regulator to produce foamed microcrystalline fireproof and thermal insulation decorative integrated board, the melting temperature is 1470°C, the melting time is 20h, the colorant is vanadium pentoxide, and the addition amount is It is 0.8% of the melt; the particle size of the surface material is 120 mesh, and the particle size of the foam material is 400 mesh. The foaming agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com