Bulk tobacco curing reverse-combustion hot-blast furnace and application method thereof

A technology of hot air stove and flue-cured tobacco, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of large heat radiation loss at the furnace door, poor coal charging operation comfort, poor safety and sanitation conditions, etc., and achieves significant energy saving and environmental protection benefits. Ease of combustion and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below in conjunction with the accompanying drawings.

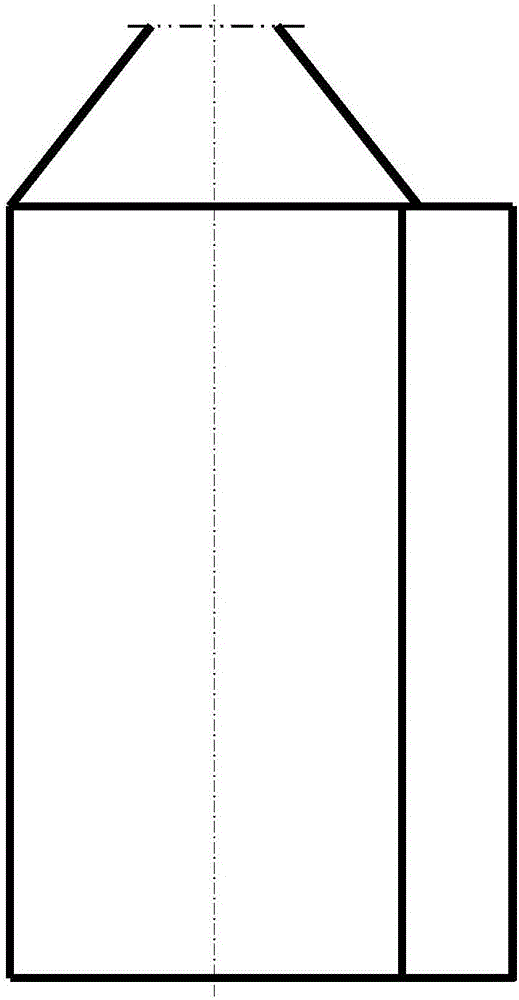

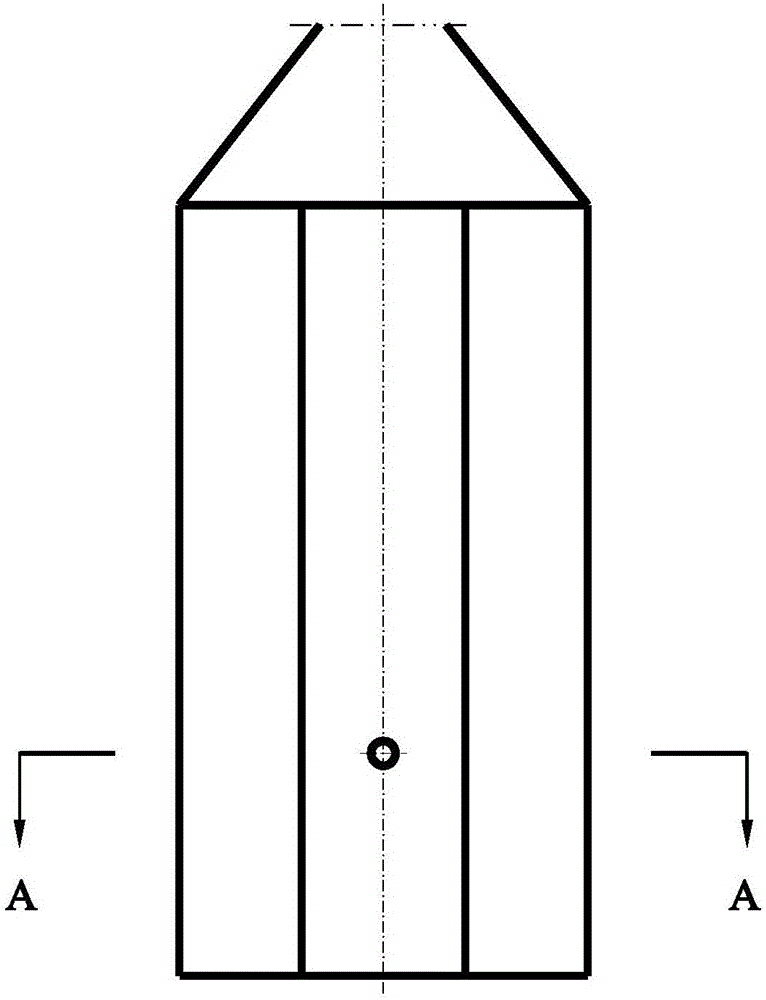

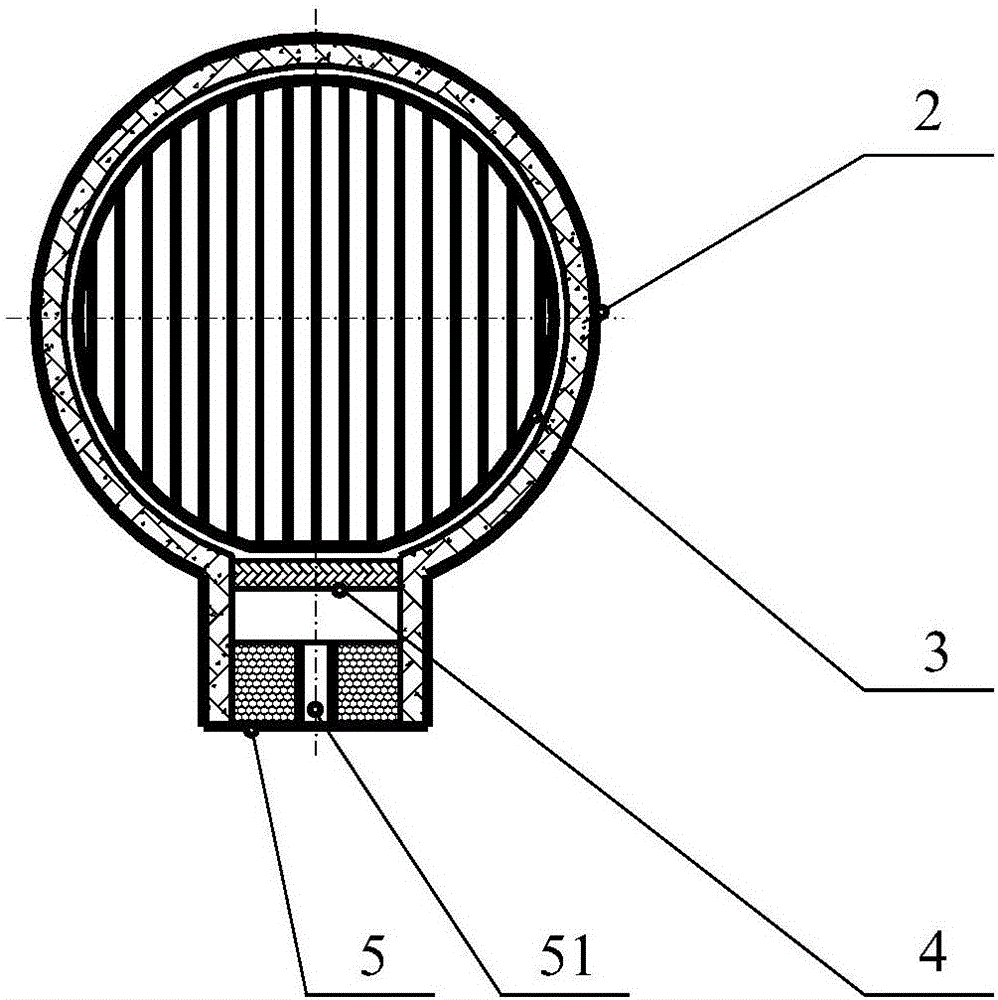

[0012] as attached figure 1 ~attached Figure 5 As shown, the dense flue-cured tobacco back-burning hot blast stove mainly includes a roof 1, a belly 2, a grate bar 3, an inner furnace door 4 and an outer furnace door 5.

[0013] The furnace top 1 is in the shape of an upright circular table with a height of 100mm-150mm. The circumference of the bottom end surface of the furnace top 1 and the circumference of the top surface of the furnace boll 2 are fully welded. The inner cavity of the furnace top 1 is the space required for the complete combustion of the ignition fuel, and the fuel consumption for ignition and ignition is small, and the height of the inner cavity of the furnace roof 1 is reduced to 100mm-150mm. The inner wall surface of the furnace top 1 is a heat reflection surface, which helps to maintain the combustion temperature of the top surface of the coal bed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com