Method for efficiently preparing cotton based mesoporous activated carbon fiber

An activated carbon fiber and cotton-based technology, which is applied to the chemical characteristics of fibers, textiles and papermaking, can solve the problems of low activation temperature, long preparation cycle, and short activation time, and achieve low bulk density, excellent adsorption performance, and lower activation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

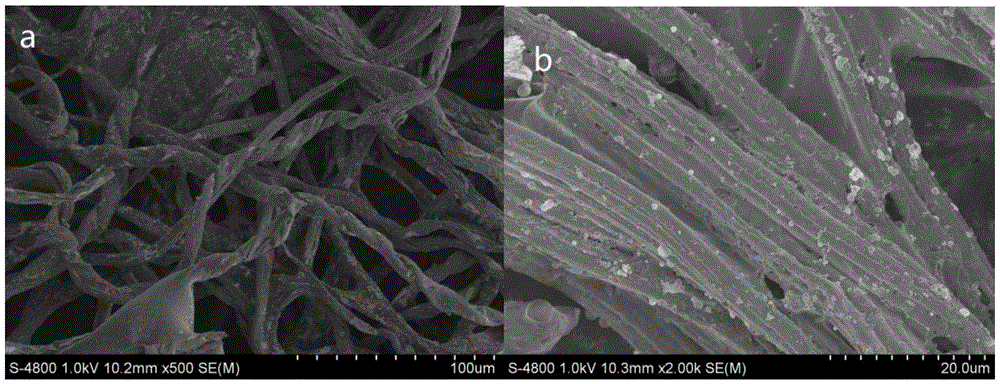

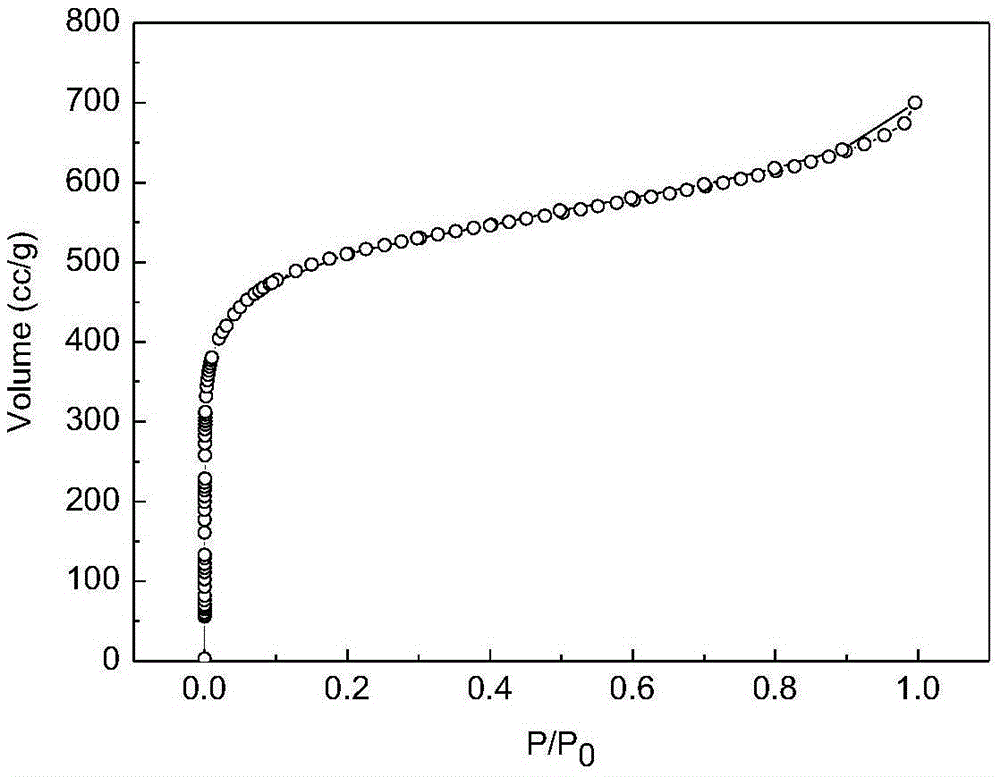

Image

Examples

Embodiment 1

[0029] After cleaning the cotton, it is placed in a hydrothermal kettle, heated to 180°C at a heating rate of 10°C / min and kept for 1 hour, and then cooled to room temperature for later use. 100g of the obtained carbonized material is placed in a microwave ultrasonic combined system (microwave ultrasonic Combination instrument), under the conditions of microwave power of 100w and ultrasonic power of 200w, immerse in 500mL phosphoric acid solution with a concentration of 30% (Wt%) for 30 minutes, then filter, and place the filter material in microwave heating equipment (microwave high temperature tube furnace) , 400w power activation for 15 minutes, the obtained material is cooled to room temperature in the furnace in a nitrogen atmosphere, and then repeatedly washed with distilled water until the pH of the washing liquid reaches 6.5-7, and then dried in an oven at 100°C to obtain 22g of activated carbon fiber product.

[0030] The iodine adsorption value of activated carbon fiber ...

Embodiment 2

[0033] The recovered waste cotton is cleaned and placed in a hydrothermal kettle, heated to 200°C at a heating rate of 15°C / min for 1.5 hours, and the carbonized material obtained is placed in a microwave-ultrasonic combined system. The microwave power is 200w, ultrasonic Under the condition of 300w power, it is immersed in a mixed solution of phosphoric acid with a concentration of 50% (Wt%) and potassium dihydrogen phosphate (added at 4% of the mass of the phosphoric acid solution) for 20 minutes and then filtered. The filter material is placed in a microwave heating device. Activated with 500w power for 9 minutes, the other steps are the same as in Example 1, the product activated carbon fiber has an iodine adsorption value of 910mg / g, a methylene blue adsorption capacity of 496mg / g, and a specific surface area of 1022m 2 / g, the yield is 51.2%, and the ratio of mesopores is 75.1%.

Embodiment 3

[0035] The cotton was cleaned and placed in a hydrothermal kettle, heated to 150°C for 2 hours at a heating rate of 20°C / min, and the resulting carbonized material was ultrasonically immersed in phosphoric acid and diammonium hydrogen phosphate with a concentration of 40% (Wt%) (Add 4% of the mass of the phosphoric acid solution) The solution is filtered after 3 hours, the filter material is placed in a microwave heating device, 400w power is activated for 12 minutes, the other steps are the same as in Example 1, the product activated carbon fiber has an iodine adsorption value of 1189mg / g , Methylene blue adsorption capacity 393mg / g, specific surface area 1307m 2 / g, the yield is 47.2%, and the ratio of mesopores is 64.7%.

[0036] The above examples show that by controlling the concentration of the activator impregnation solution and the microwave power during the activation process, activated carbon fibers with different mesopore contents can be obtained. Through sample detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com