Corn oligopeptide powder buccal tablet and preparation method thereof

A technology of corn oligopeptide powder and extract, applied in the field of health food, can solve the problems of difficult to guarantee efficacy, large toxic and side effects, poor palatability, etc., and achieve the effects of reducing incidence, reducing acute alcoholism, and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

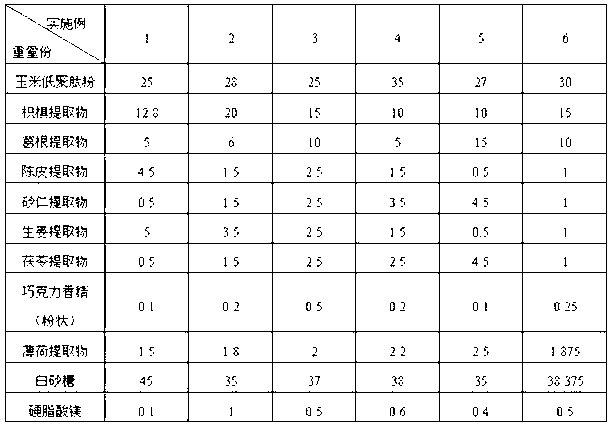

[0029] (1) Preparation of soft material: Weigh each component according to the weight components shown in Table 1, and use a grinder to grind corn oligopeptide powder, Hovenia dulcis Hovenia extract, Pueraria root extract, Chenpi extract, Amomum extract, ginger Extract, Poria cocos extract, peppermint extract and white granulated sugar are ground to a fineness of 80 meshes, add powdered chocolate essence and appropriate amount of water, put into a mixer and stir well to make a soft material, the amount of water added can be Granulation shall prevail.

[0030] (2) Granulation: Put the soft material prepared in step (1) into a wet granulator (product of Changzhou Bangyuan Drying Machinery Co., Ltd., model: GHL-50) for wet granulation to obtain wet granules.

[0031] (3) Drying of wet granules: put the wet granules prepared in step (3) into a hot air circulation oven (product of Changzhou Dongnan Drying Equipment Co., Ltd., model: CT-C-1), dry at 60°C, and measure with moisture ...

Embodiment 2

[0037] (1) Preparation of soft material: Weigh each component according to the weight components shown in Table 1, and use a grinder to grind corn oligopeptide powder, Hovenia dulcis Hovenia extract, Pueraria root extract, Chenpi extract, Amomum extract, ginger extract, Poria cocos extract, peppermint extract and white granulated sugar are ground to a fineness of 90 mesh, add powdered chocolate essence and appropriate amount of water, put into a mixer and stir well to make a soft material, the amount of water added can be Granulation shall prevail.

[0038] (2) Granulation: Put the soft material prepared in step (1) into a swing granulator (Jiangsu Taizhou Jintai Pharmaceutical Machinery Co., Ltd., model: YK90) for wet granulation to obtain wet granules.

[0039] (3) Drying of wet granules: Put the wet granules prepared in step (3) into a hot air circulation oven (product of Changzhou Dongnan Drying Equipment Co., Ltd., model: CT-C-1), dry at 65°C, and measure with moisture T...

Embodiment 3

[0045](1) Preparation of soft material: Weigh each component according to the weight components shown in Table 1, and use a grinder to grind corn oligopeptide powder, Hovenia dulcis Hovenia extract, Pueraria root extract, Chenpi extract, Amomum extract, ginger Extract, Poria cocos extract, peppermint extract and white granulated sugar are ground to a fineness of 100 mesh, add powdered chocolate essence and appropriate amount of water, put into a blender and stir well to make a soft material, the amount of water added can be Granulation shall prevail.

[0046] (2) Granulation: Put the soft material prepared in step (1) into a wet granulator (product of Changzhou Bangyuan Drying Machinery Co., Ltd., model: GHL-50) for wet granulation to obtain wet granules.

[0047] (3) Drying of wet granules: Put the wet granules prepared in step (3) into a hot air circulation oven (product of Changzhou Dongnan Drying Equipment Co., Ltd., model: CT-C-1), dry at 65°C, and measure with moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com