Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

A nano-graphene, multi-component composite technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of fuel consumption, piston carbon deposition, large friction coefficient, etc., to improve thermal efficiency, improve working conditions, Outstanding wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

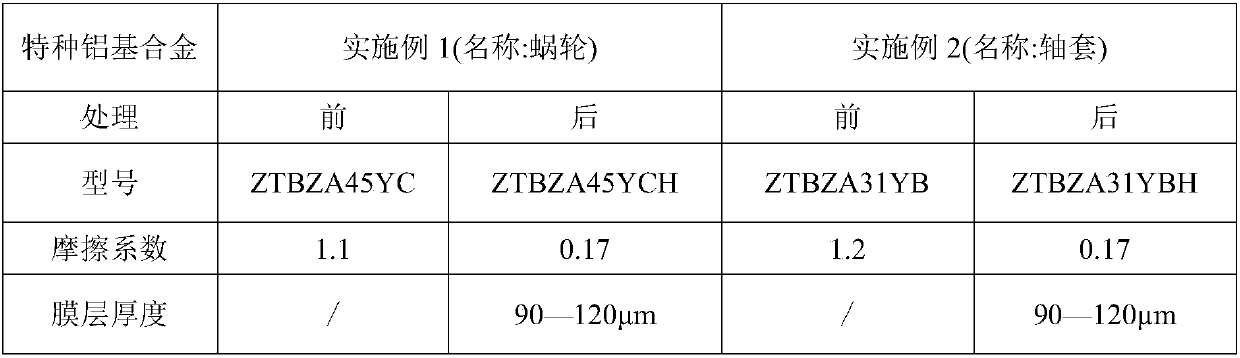

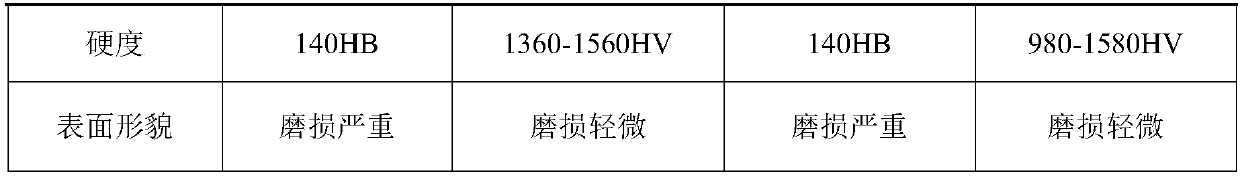

Embodiment 1

[0097] Install the ZTBZA45YC aluminum-based wear-resistant alloy precision worm gear on the frame, and use the non-polluting "super automatic emulsifier" to clean the surface that needs "locally enhanced surface characteristics". Unconditionally, you can use other cleaning agents to clean the alloy surface and clean it That is, it does not affect the realization of subsequent invention solutions.

[0098] Put it into the multi-component composite oxidation solution, the oxidation solution only needs to submerge the tooth surface. The multi-element composite oxidation solution contains:

[0099] Nano graphene 0.8g / L, zirconium dioxide 0.6g / L, lanthanum trioxide 0.7g / L, sodium silicate 11.5g / L, potassium hydroxide 1.4g / L.

[0100] , adjust pH=12~13 with NOH. But not limited to these types. Various combinations can also be made according to needs.

[0101] The power of the equipment is 150KW, and the surface area treated by the power limit is 35dm 2 / time, adjust the positi...

Embodiment 2

[0107] Clean the ZTBZA45Yc aluminum-based wear-resistant alloy bearing bush. Dry at 100°C for 20 minutes,

[0108] Put the frame into the multi-component composite nano-oxidizing solution, and the oxidizing solution submerges the "locally enhanced surface characteristics" part of the aluminum-based alloy bearing bush. The multi-component composite nano-oxidizing solution contains:

[0109] Nano graphene 0.8g / L, zirconium dioxide 0.6g / L, sodium silicate 11.5 / L, potassium hydroxide 1.2g / L. EDTA disodium salt 1.3g / L, adjust pH=12~13 with NOH. But not limited to these types. Various combinations can also be made according to requirements.

[0110] The power of the equipment is 150Kw, and the power limit surface area is 35dm 2 / time, adjust the positive pulse width and negative pulse width to 0.5~2 interval compound changes, adjust the pulse frequency to 37.5~75 interval compound changes, adjust the positive voltage to 180~380V interval compound changes, adjust the negative vo...

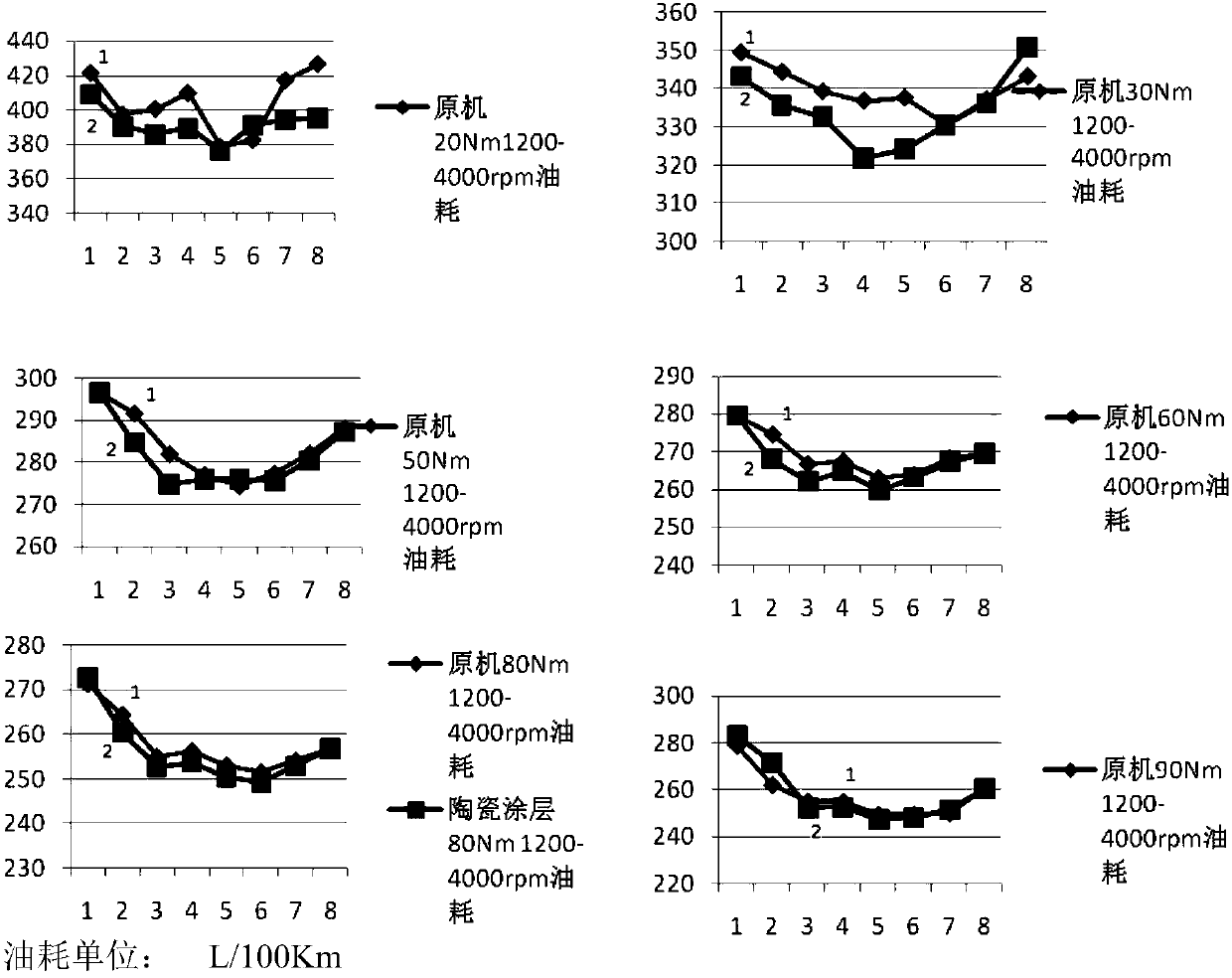

Embodiment 3

[0114] Use an emulsifier to wipe off the surface oil stains on the top of the aluminum alloy piston, the first ring groove and the ring bank of the diesel engine, and put them into the multi-component composite oxidation solution. The oxidation solution submerges the piston and oxidizes the surface. The multi-component composite oxidation solution contains: nano-graphene 0.8g / L, zirconium dioxide 0.6g / L, lanthanum trioxide 0.6g / L, sodium silicate 10.5g / L, potassium hydroxide 1.2g / L, EDTA disodium salt 1.0g / L, adjust pH with NOH =11~13.

[0115] The equipment power is 100KW, and the power limit surface treatment area is 25dm 2 / time, adjust the positive pulse width and negative pulse width to 0.5~2 interval compound changes, adjust the pulse frequency to 37.5~75Hz interval compound changes, adjust the positive voltage to 180~380V interval compound changes, adjust the negative voltage to 10~30V interval , the current density is controlled at 4~6A / dm 2 interval, oxidize for 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com