Automobile differential mechanism

A technology for automotive differentials and differentials, which is applied to differential transmissions, transmission parts, belts/chains/gears, etc., can solve the problems of irreplaceable use and large inventory, and achieve material reduction and differential speed reduction The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

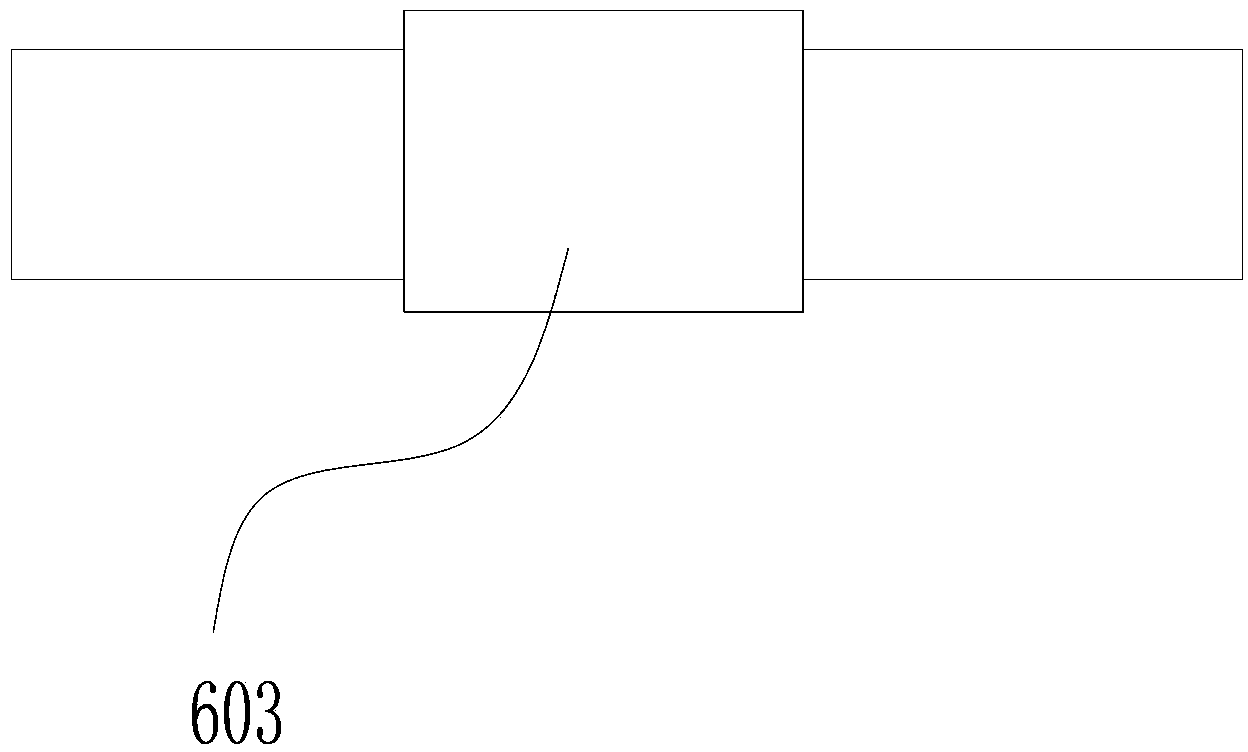

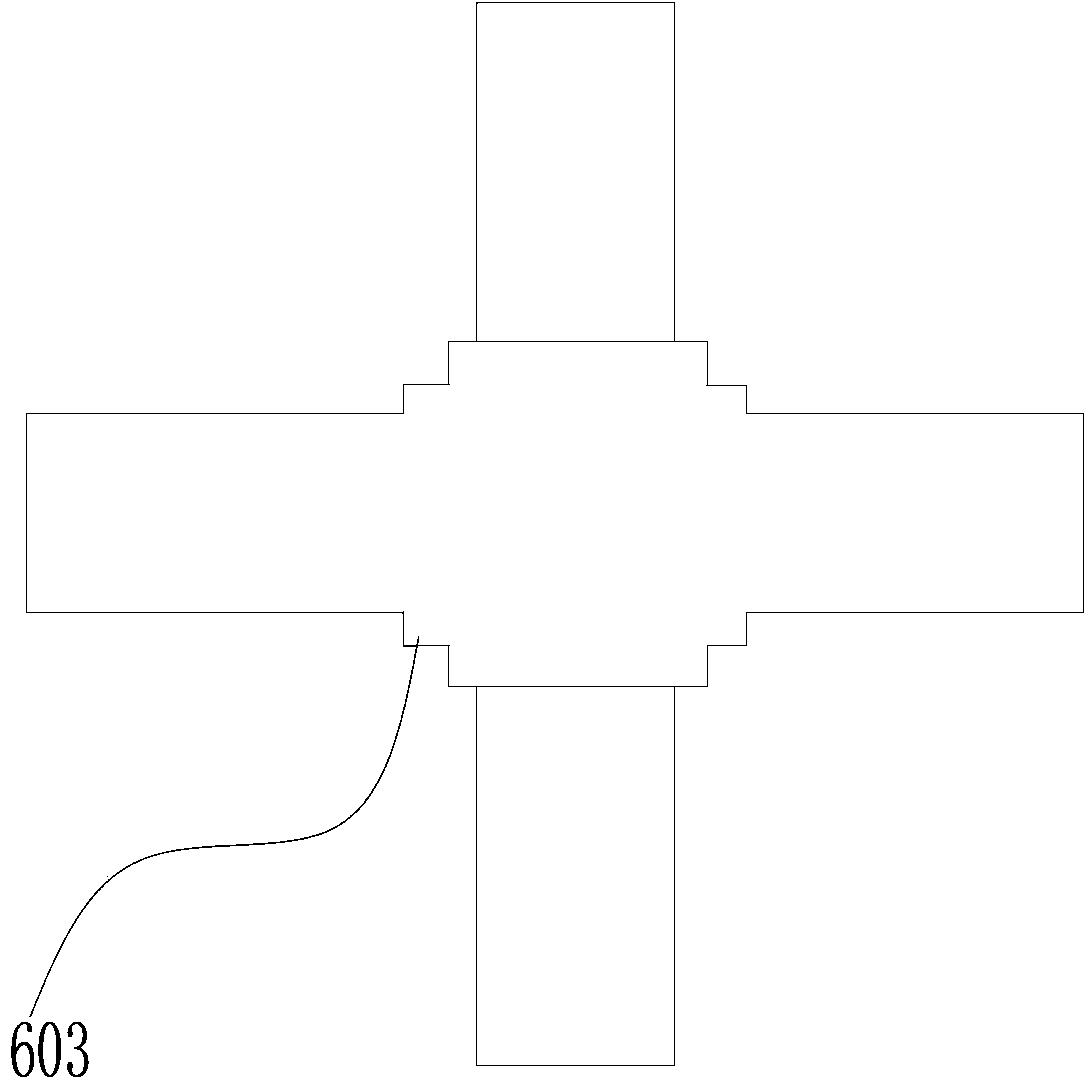

[0047] Such as Figure 3-Figure 8 As shown, the differential gear provided by the embodiment of the present invention includes:

[0048] housing 800;

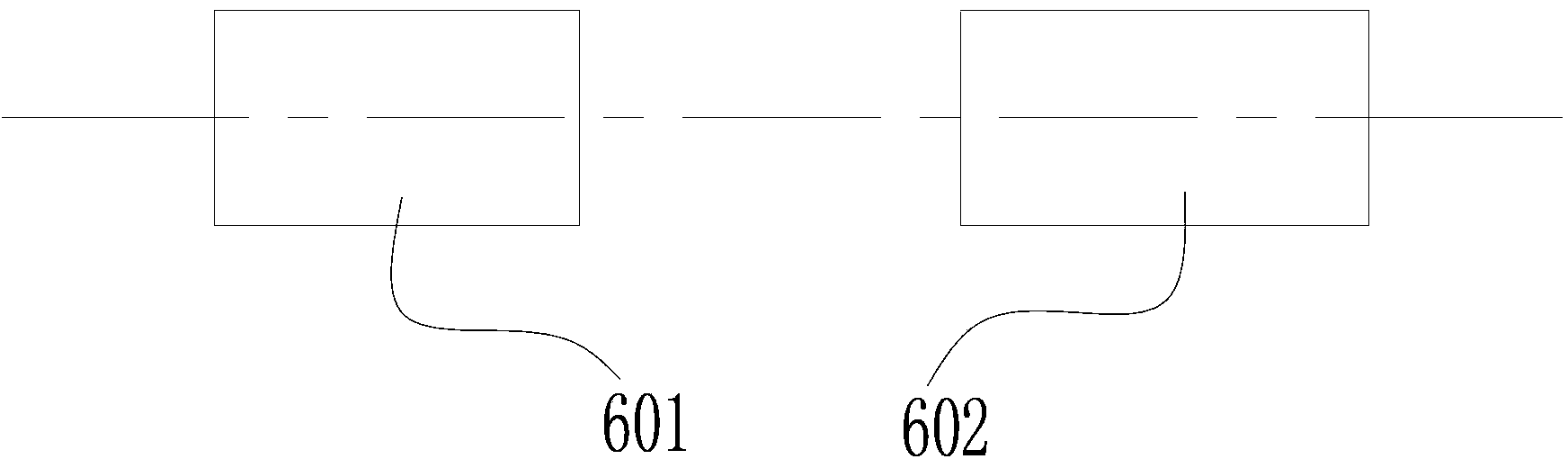

[0049] The side gear 200 is arranged inside the housing 800, and the side gear 200 is composed of a side gear 1 201 and a side gear 2 202;

[0050] The output shaft, the output shaft includes output shaft 1 and output shaft 2, the output shaft 1 and output shaft 2 are coaxially arranged and respectively penetrated in the housing 800, and one end of the output shaft is connected to the side gear 200 The other end is used to connect with the car wheel (not shown in the figure); the output shaft is connected with Figure 8 The output shaft slot 1000 in the match, the output shaft one cooperates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com