Stirrer with stretch-in stirring vane arranged outside bottom of stirrer

A stirring blade and stirrer technology, which is applied in the field of liquid mixing and processing equipment, can solve the problems of low mixing uniformity, increased production cost, slow reaction speed, etc., and achieve enhanced mixing and stirring effect, faster flow rate, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

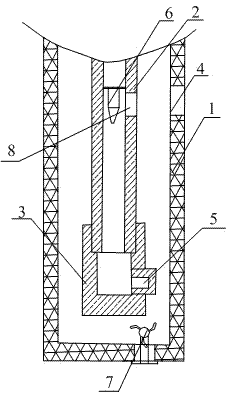

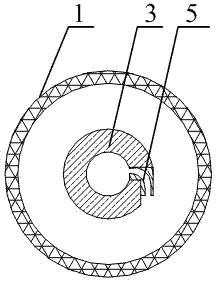

[0023] Such as figure 1 , 2 As shown, the chlorine dioxide generator mounting plate is equipped with a reactor, and the agitator with the bottom externally extending into the stirring blade is installed in the reactor, and it includes a cylindrical reaction vessel 1, which is located in the reaction vessel 1. The diversion column 2, the circular joint 3 arranged at the lower end of the diversion column 2, and the outflow hole 4 arranged at the upper end of the surface wall of the reaction vessel 1; Cavity, and arc-shaped guide holes 5 are provided on the surface wall of the circular joint 3.

[0024] After the liquid flows into the circular joint 3 from the diversion column 2, it flows into the reaction vessel 1 through the arc-shaped diversion hole 5, thereby changing the liquid from a vertical axial flow to a circumferential tangential flow, and then pushing the liquid in the reaction vessel 1 It rises in a spiral manner to achieve the purpose of stirring. This method not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com