Mixing head device

A technology of mixing head and mixing body, which is applied to the device and coating of the surface coating liquid, can solve the problems such as the reduction of the production efficiency of the continuous production line of the sandwich panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

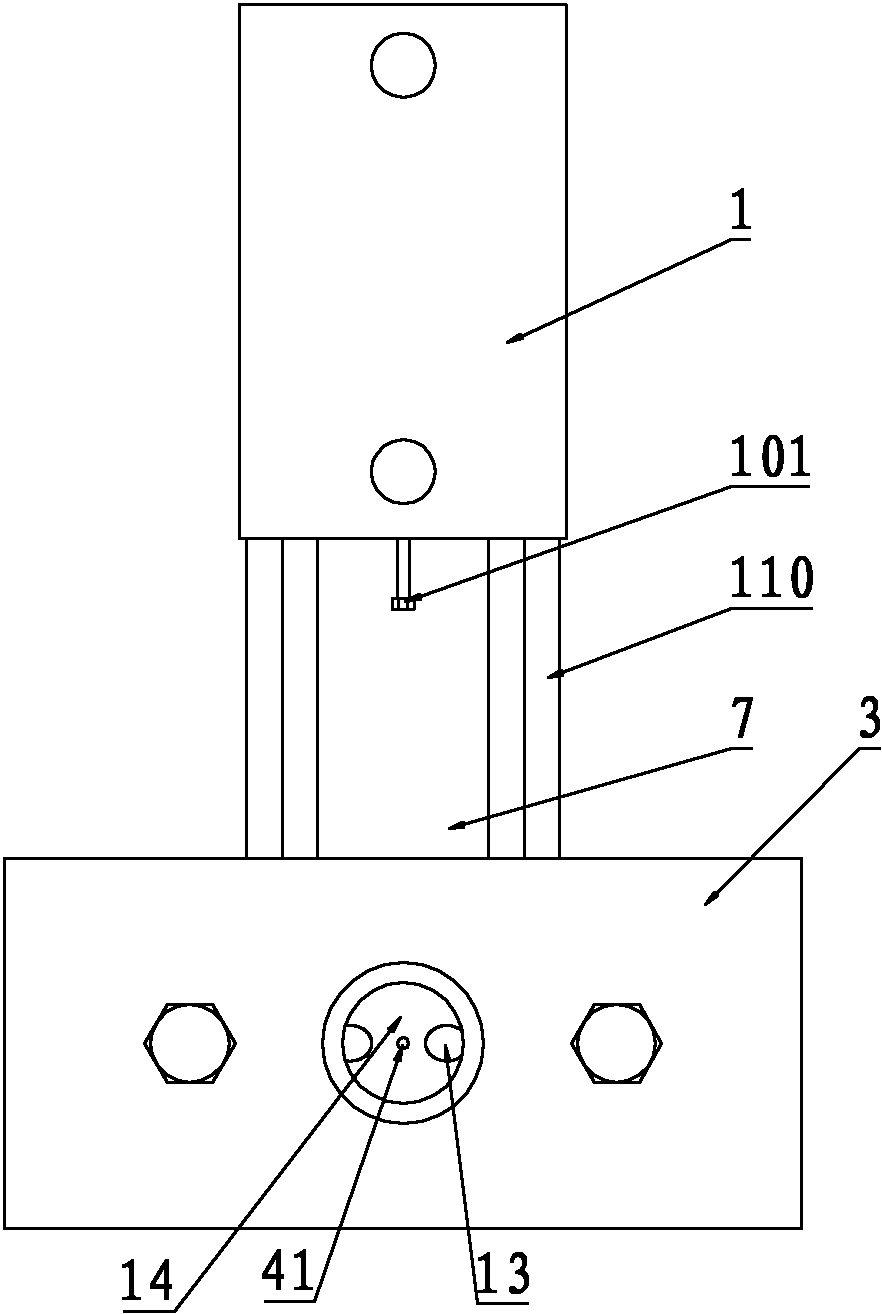

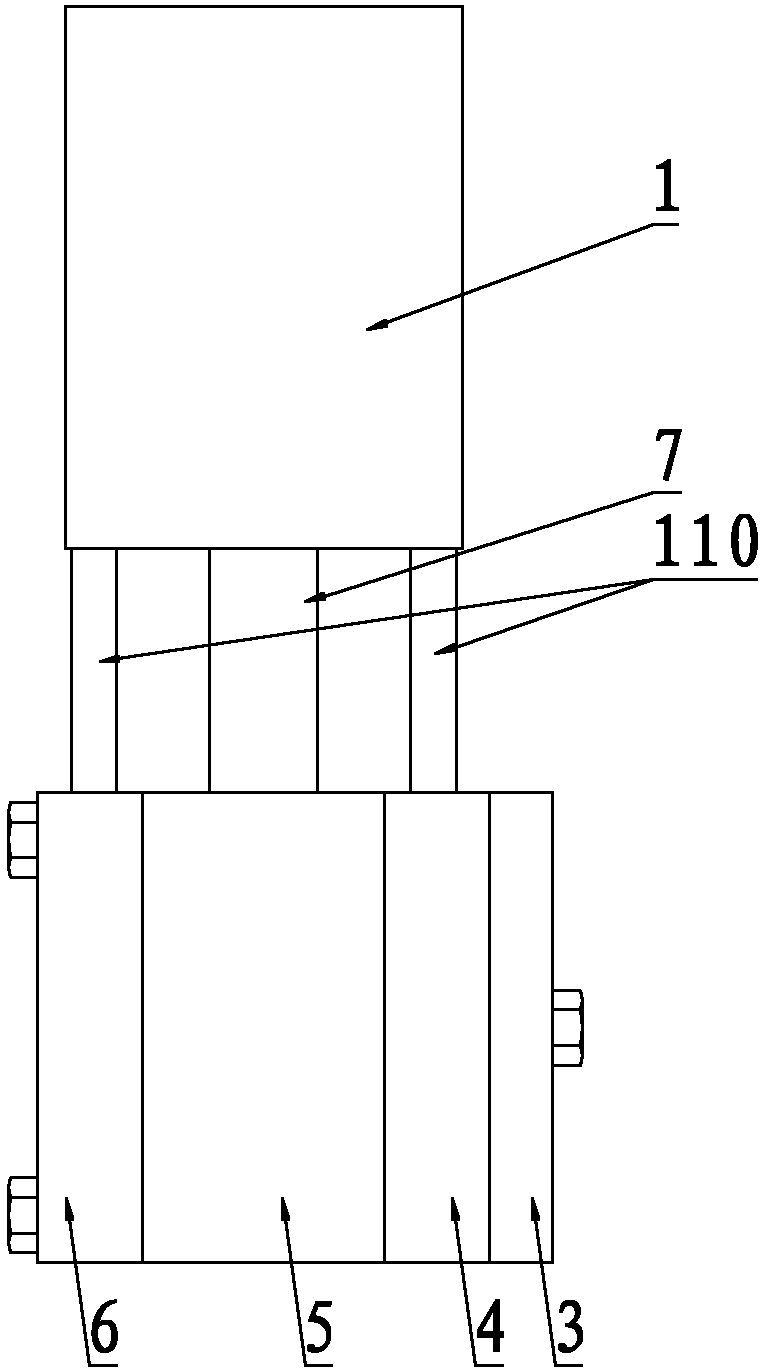

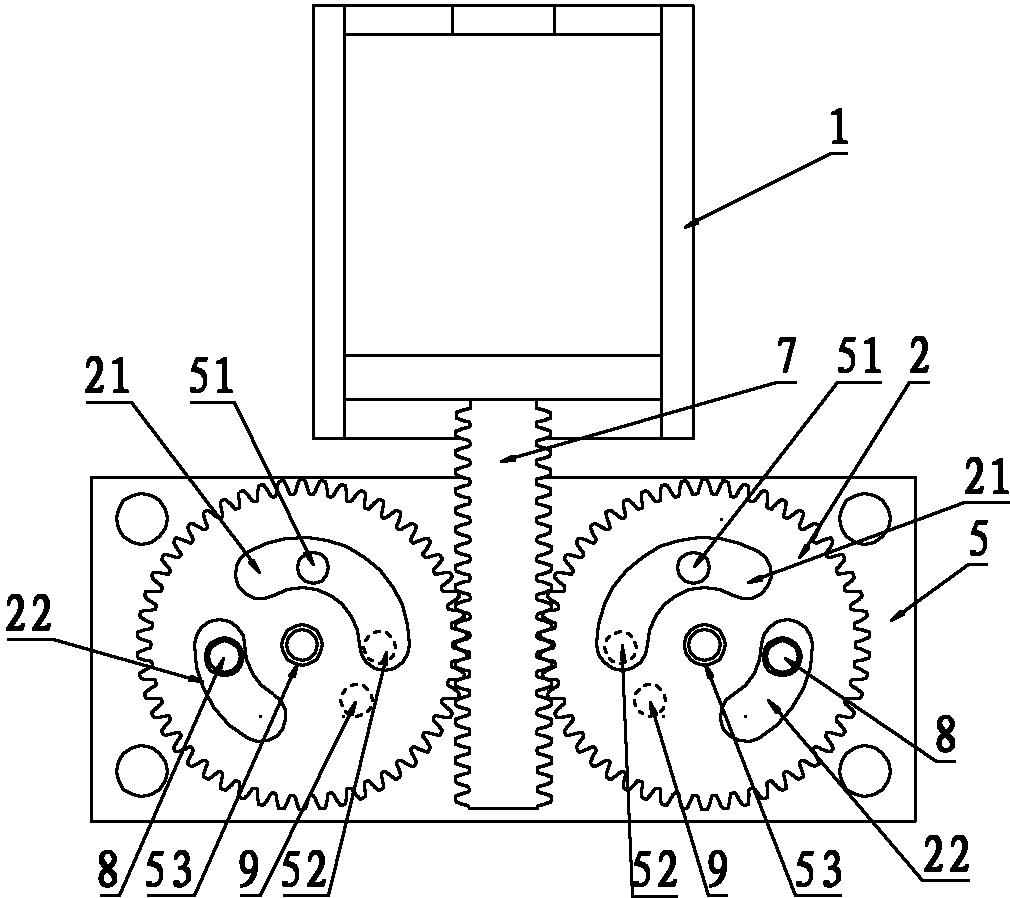

[0029] Embodiments of the mixing head device of the present invention: as Figure 1 to Figure 13 As shown, the mixing head device is located between the feed pipe and the discharge pipe, and the mixing head device is mainly composed of three parts: the main body of the device, the driving cylinder 1 and the regulating wheel 2. The main body of the device includes a mixing plate 3, a partition 4, a hollow cubic main valve body 5, and a pressure plate 6 fixedly connected in sequence from front to back, wherein the shape of the cavity of the main valve body 5 is a cube, and the front and rear side walls of the cavity are Symmetrically spaced planes. Adjusting wheel 2 is two gears, and is assembled in the left and right sides of cavity by the rotation of positioning sleeve 53, and the end face of adjusting wheel 2 is all parallel with the front and rear side walls of cavity. The driving cylinder 1 is fixed on the top of the main valve body 5 through the connecting stud 110, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com