Pressing-cutting integrated type roam raw material cutting device capable of mixing materials through crankshaft and connection rod

A technology of crankshaft connecting rod and cutting device, which is applied in the direction of grain processing, etc., can solve the problems of high use cost and maintenance cost, slow work efficiency, complex structure, etc., and achieve low use cost and maintenance cost, short cutting time, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

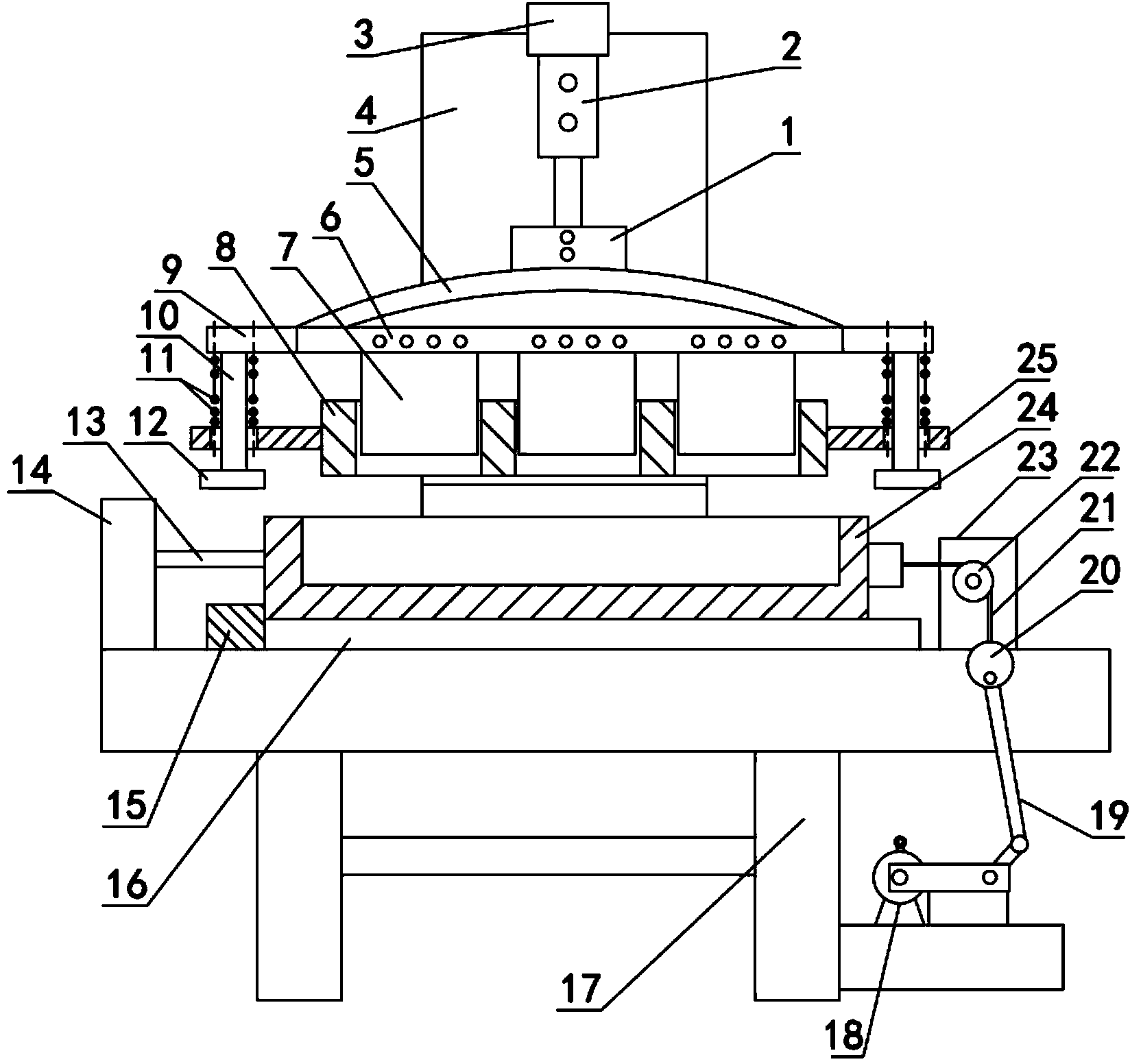

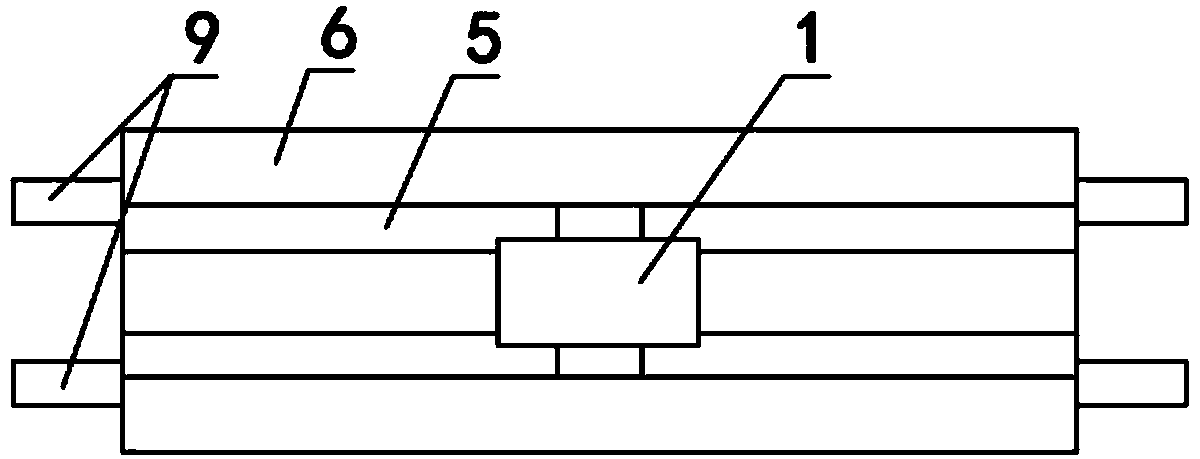

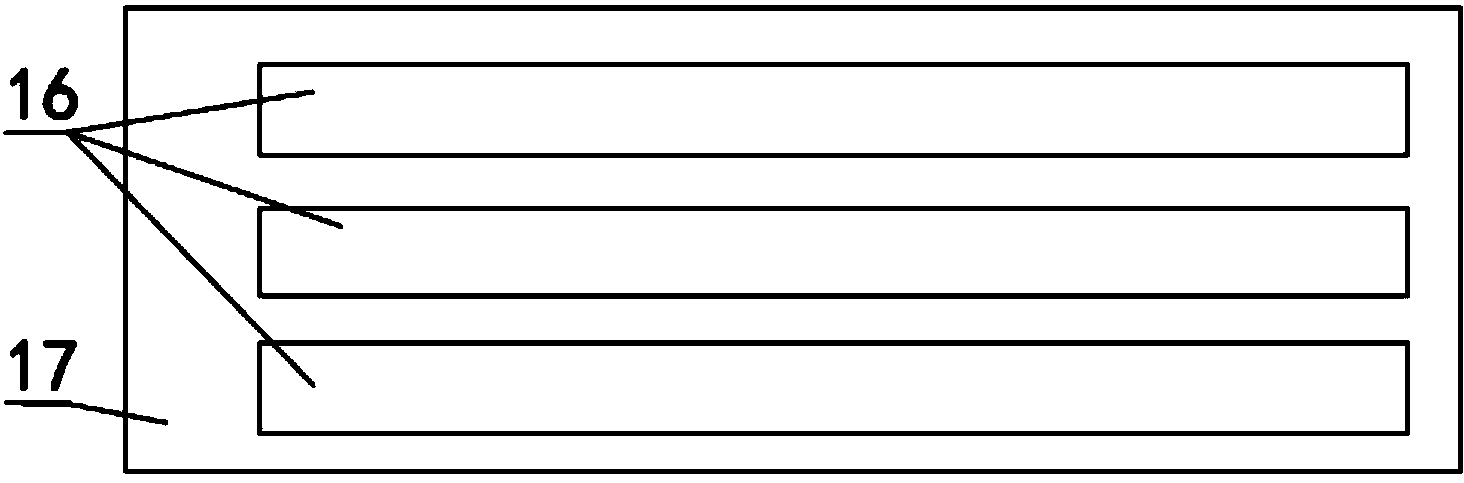

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the foam raw material cutting device for press-cutting integrated crankshaft and connecting rod mixing includes a workbench 17, on which a support leg 4 is vertically fixed, and a mounting bracket 3 is installed on the top of the support leg 4, and on the workbench 17 Three guide rails 16 are horizontally arranged in parallel, and a cutting groove 24 that can slide is installed on the guide rail 16. The right side of the cutting groove 24 is provided with a driving mechanism for pulling the cutting groove 24 to the right. The driving mechanism includes a base 29, a motor 18, and a crankshaft. 27. Connecting rod 19, mounting plate 23, steel rope 21 and fixed pulley 22, mounting plate 23 is vertically fixed on the workbench 17, fixed pulley 22 is installed on the mounting plate 23, one end of steel rope 21 is connected to the right side of cutting groove 24 The other end is connected to the uppe...

Embodiment 2

[0026] This embodiment is changed on the basis of the first embodiment, and the number of guide rails 16 is changed to two. Others are the same as embodiment one.

Embodiment 3

[0028] This embodiment is changed on the basis of the first embodiment, and the number of guide rails 16 is changed to four. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com