Ceramic fiber raw material automatic matching, mixing and charging device and control method

An automatic proportioning and ceramic fiber technology, which is applied to chemical instruments and methods, packaging, mixers, etc., can solve the problems of high discharge dust, low work efficiency, and high labor intensity, so as to improve the wear resistance and improve the use The effect of short life and mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

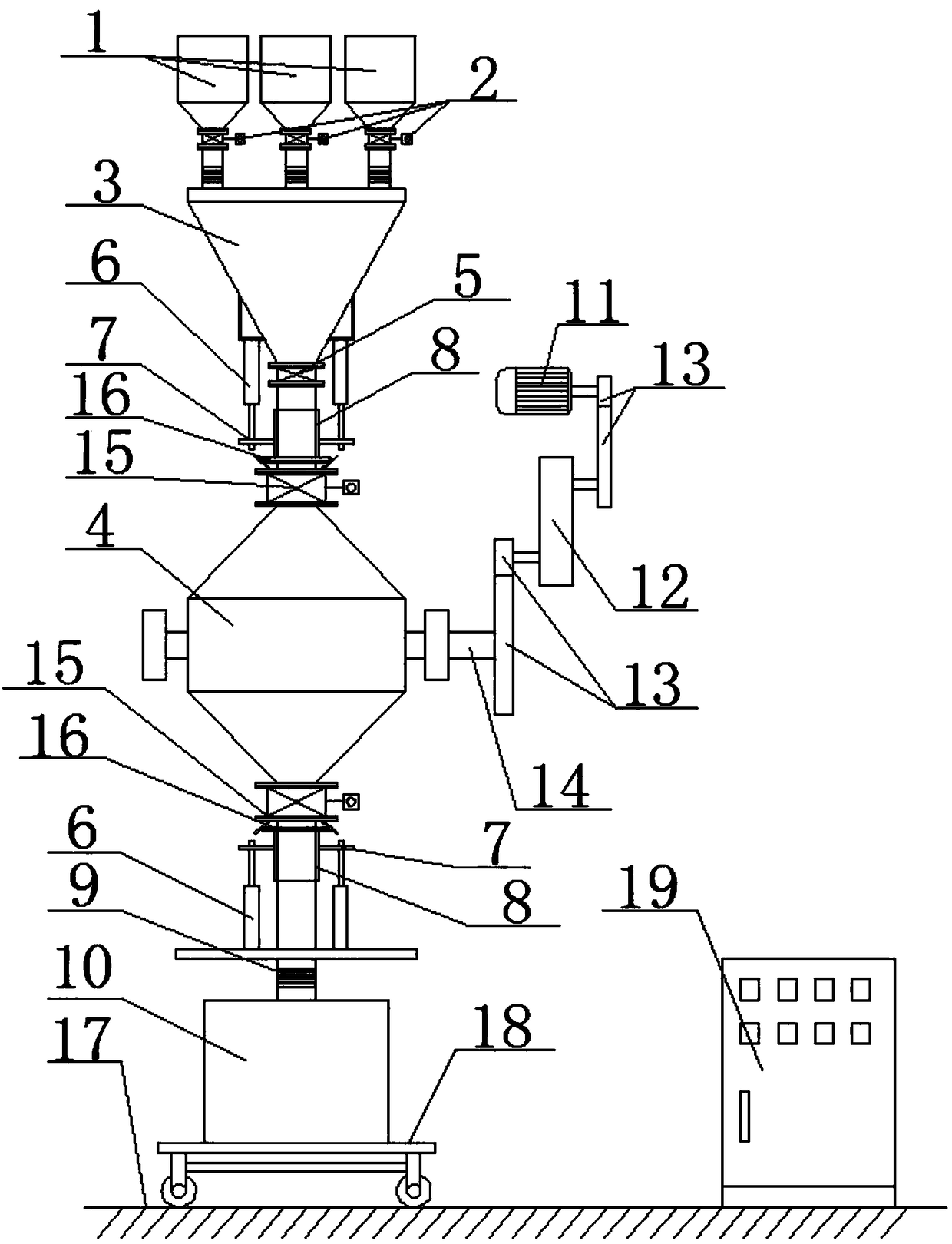

[0052] The ceramic fiber raw material automatic proportioning, automatic mixing and charging device of the present invention includes a storage device, a weighing device, a mixing device, a packaging device, a transportation device and an electrical control system 19 arranged sequentially from top to bottom;

[0053] The material storage device includes a plurality of storage tank warehouses 1, and the outlet of the material storage tank warehouse 1 is provided with an electric unloading valve 2 and connected to the inlet of the weighing device 3;

[0054] The mixing device includes a double-conical mixing tank 4 with sharp edges at both ends and a thick middle, and a mixing drive device. A wear-resistant corundum mosaic is arranged in the mixing tank 4. The mixing drive device includes a motor 11, a reducer 12, a transmission gear 13 and Rotating shaft 14, rotating shaft 14 is vertically arranged with two conical points of mixing tank 4 and is fixed on mixing tank 4, and motor...

Embodiment 2

[0068] The automatic proportioning, automatic mixing and charging control method of ceramic fiber raw materials of the present invention adopts a kind of automatic proportioning, automatic mixing and charging device for ceramic fiber raw materials in Embodiment 1 to automatically proportion and automatically mix ceramic fiber raw materials. The method for controlling mixing and charging includes the following workflow:

[0069] ①. First use the computer to write the program in the controller, and set the raw material ratio parameters. After the setting is completed, manually close the electric feeding valve under the weighing device;

[0070] ②. Write a program in the controller, set 90% of the raw materials in each storage tank bin 1 to be discharged quickly, and the remaining 10% of the raw materials to be discharged slowly, and then send a signal to the automatic proportioning control system and transmit it to the controller. The controller controls the frequency converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com