Patents

Literature

55results about How to "Constant contact pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

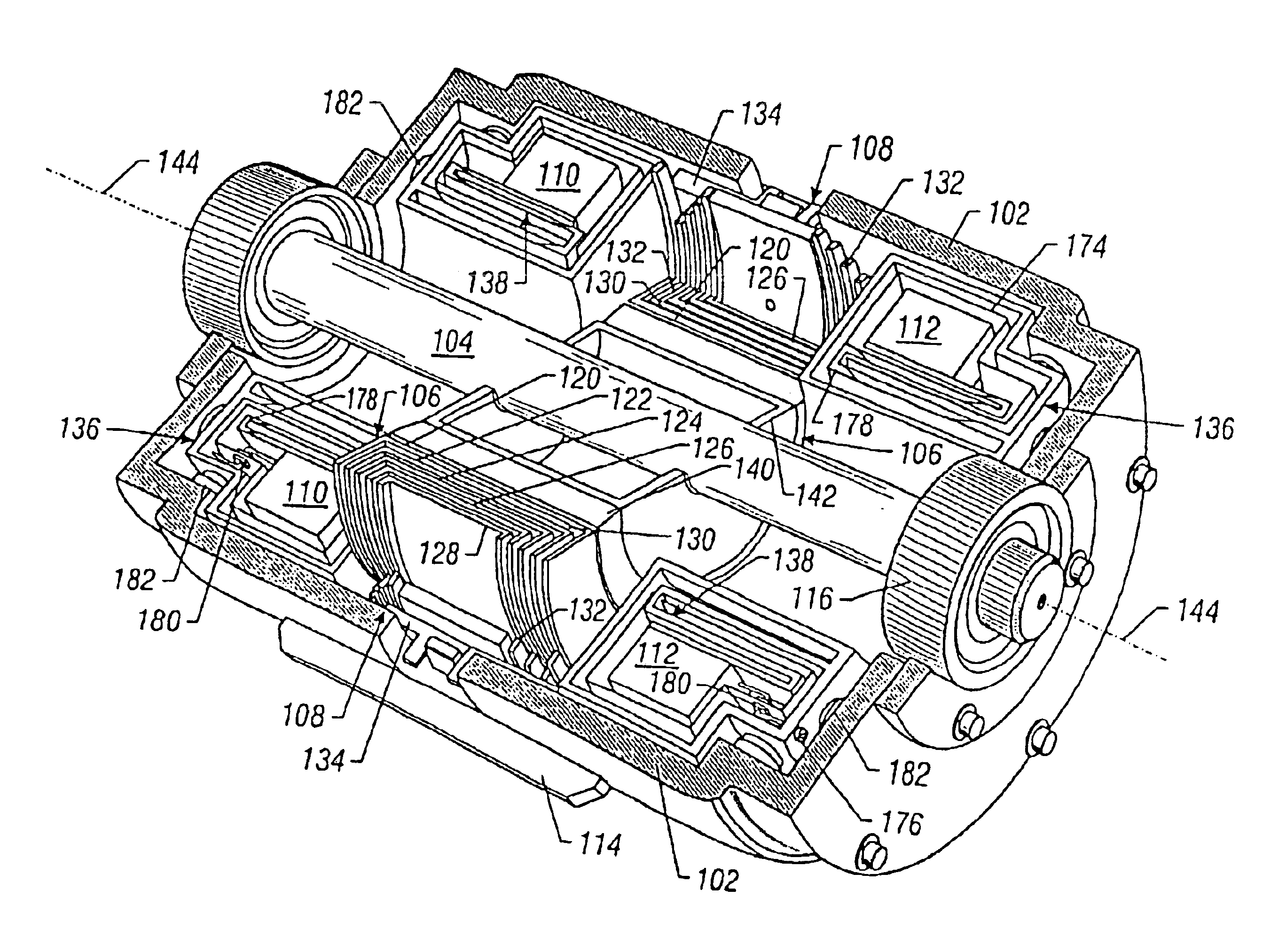

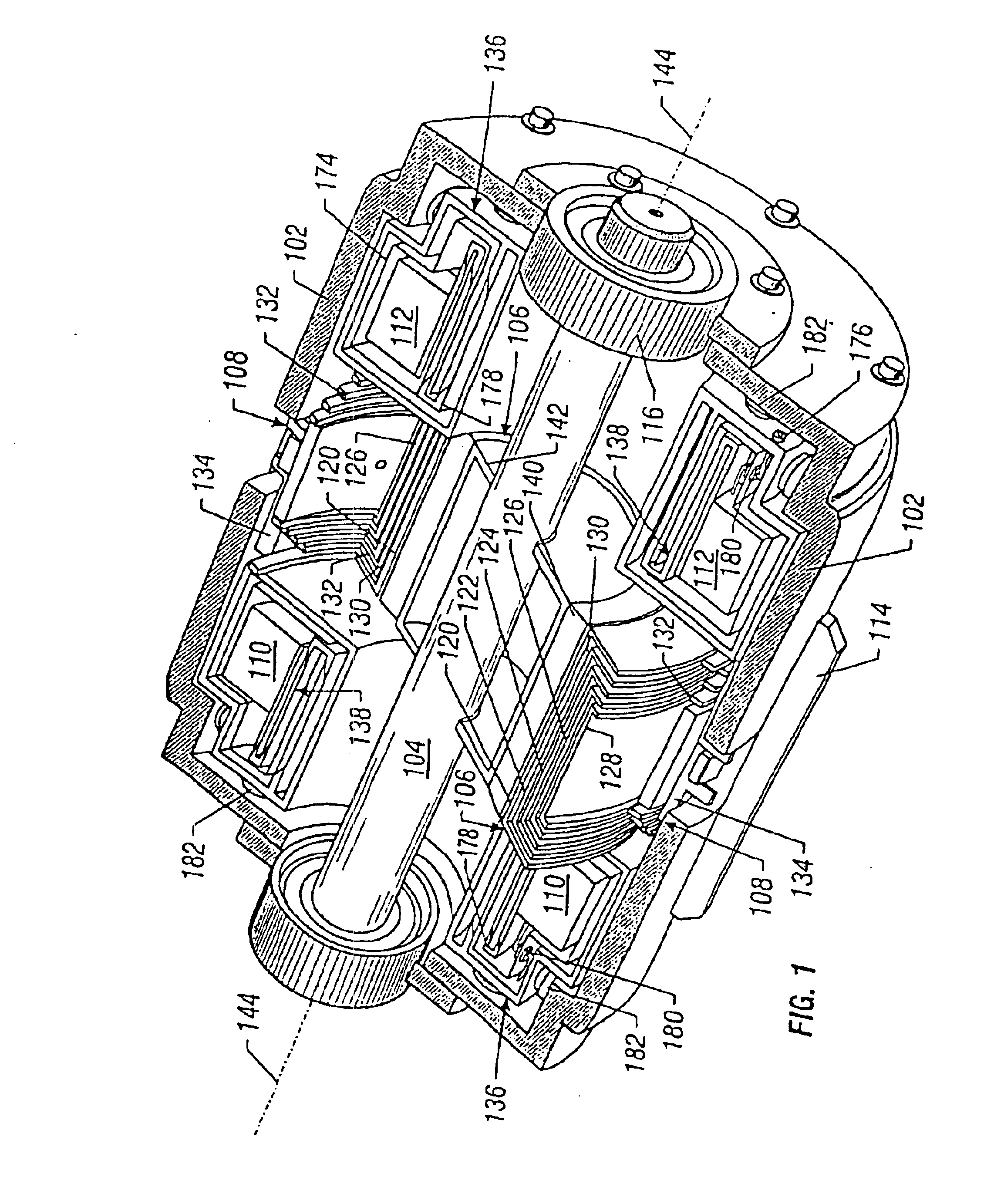

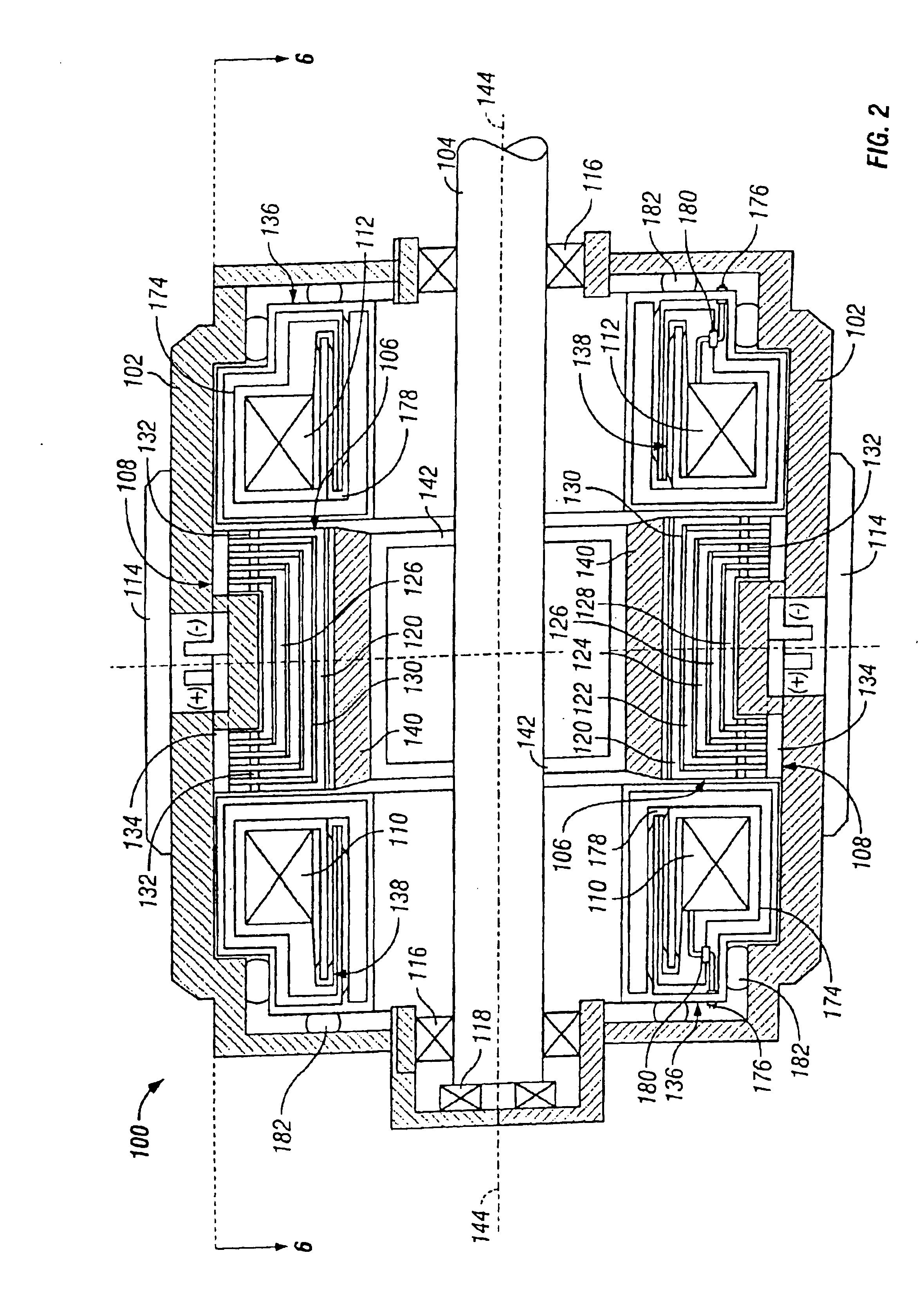

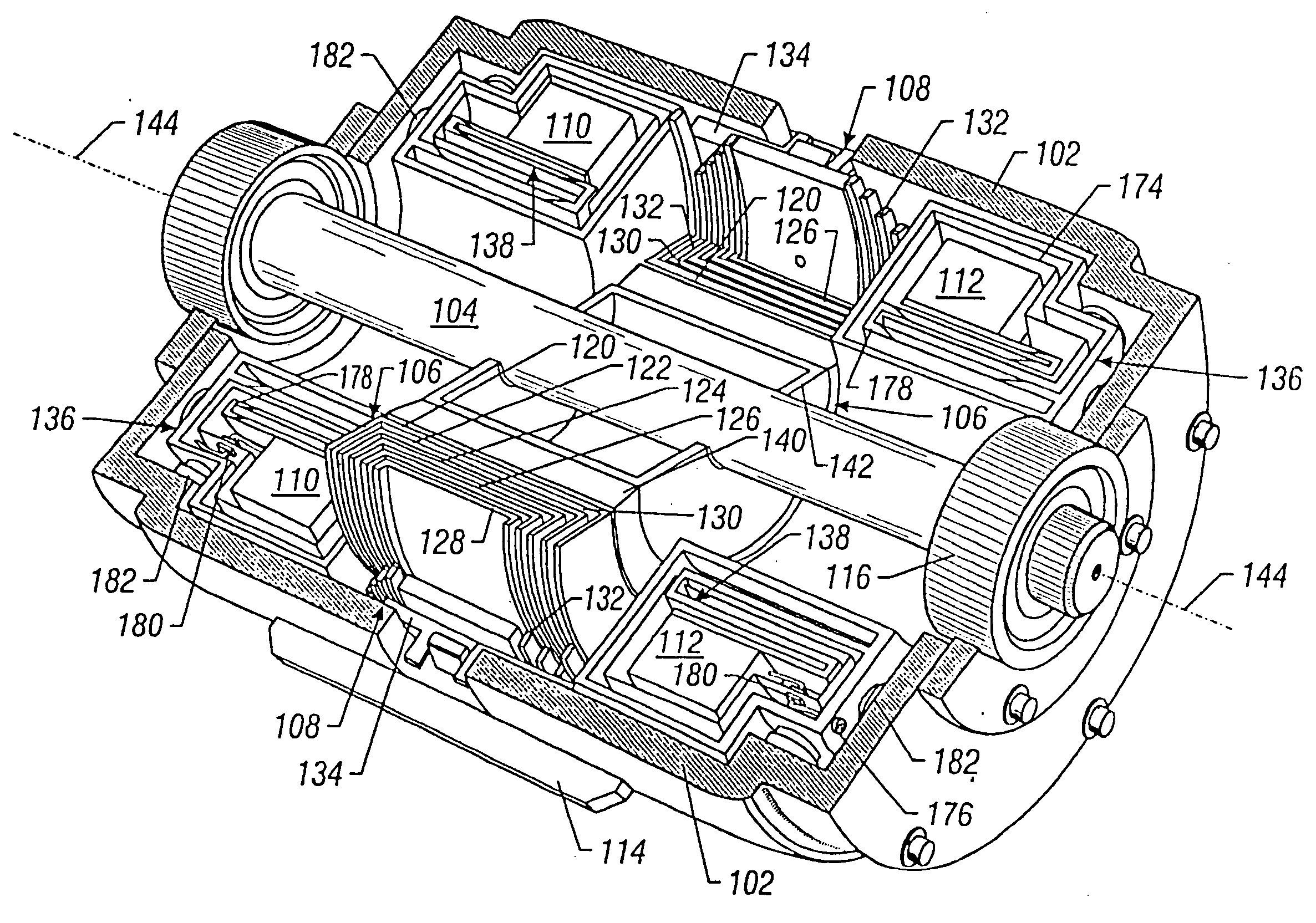

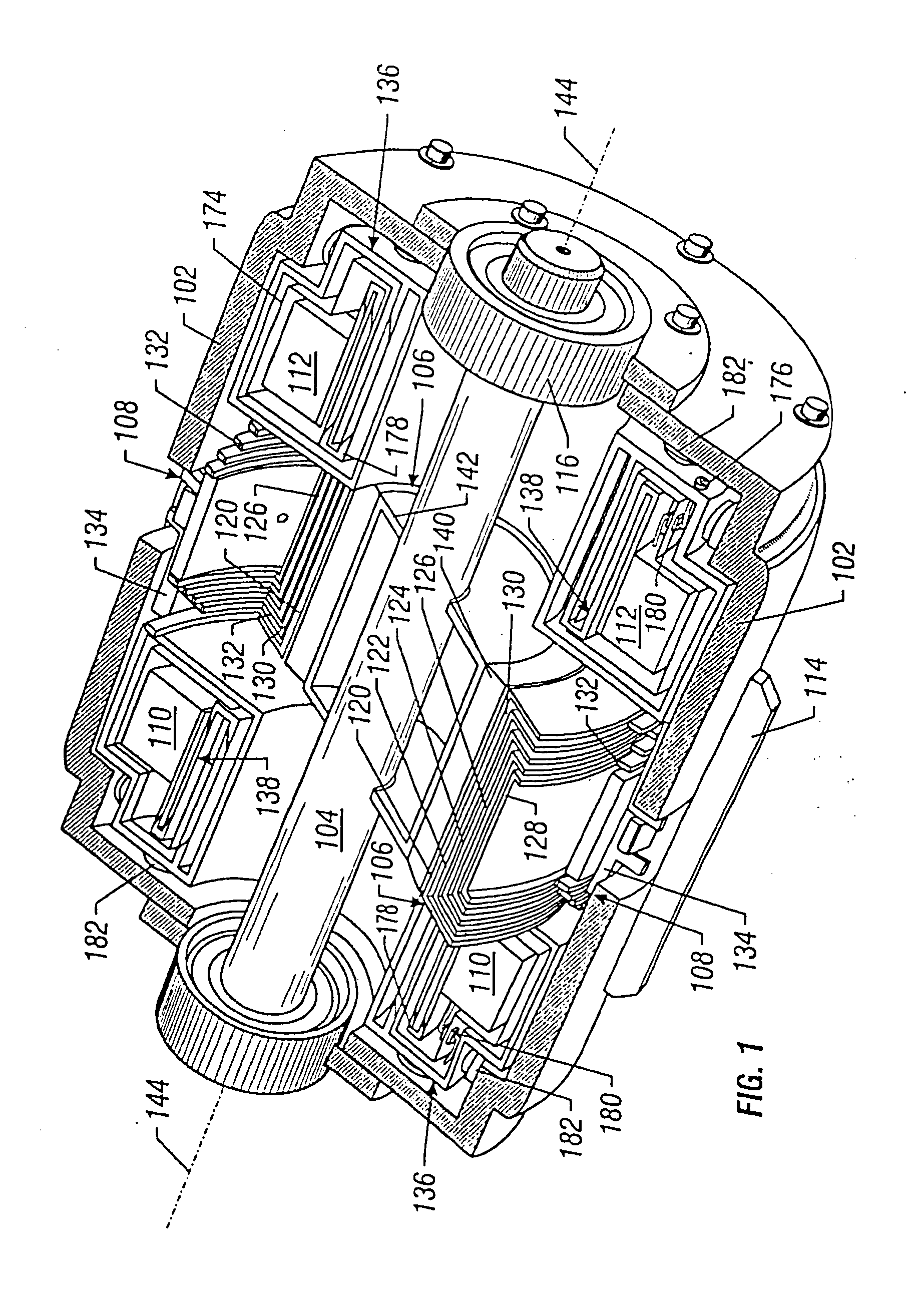

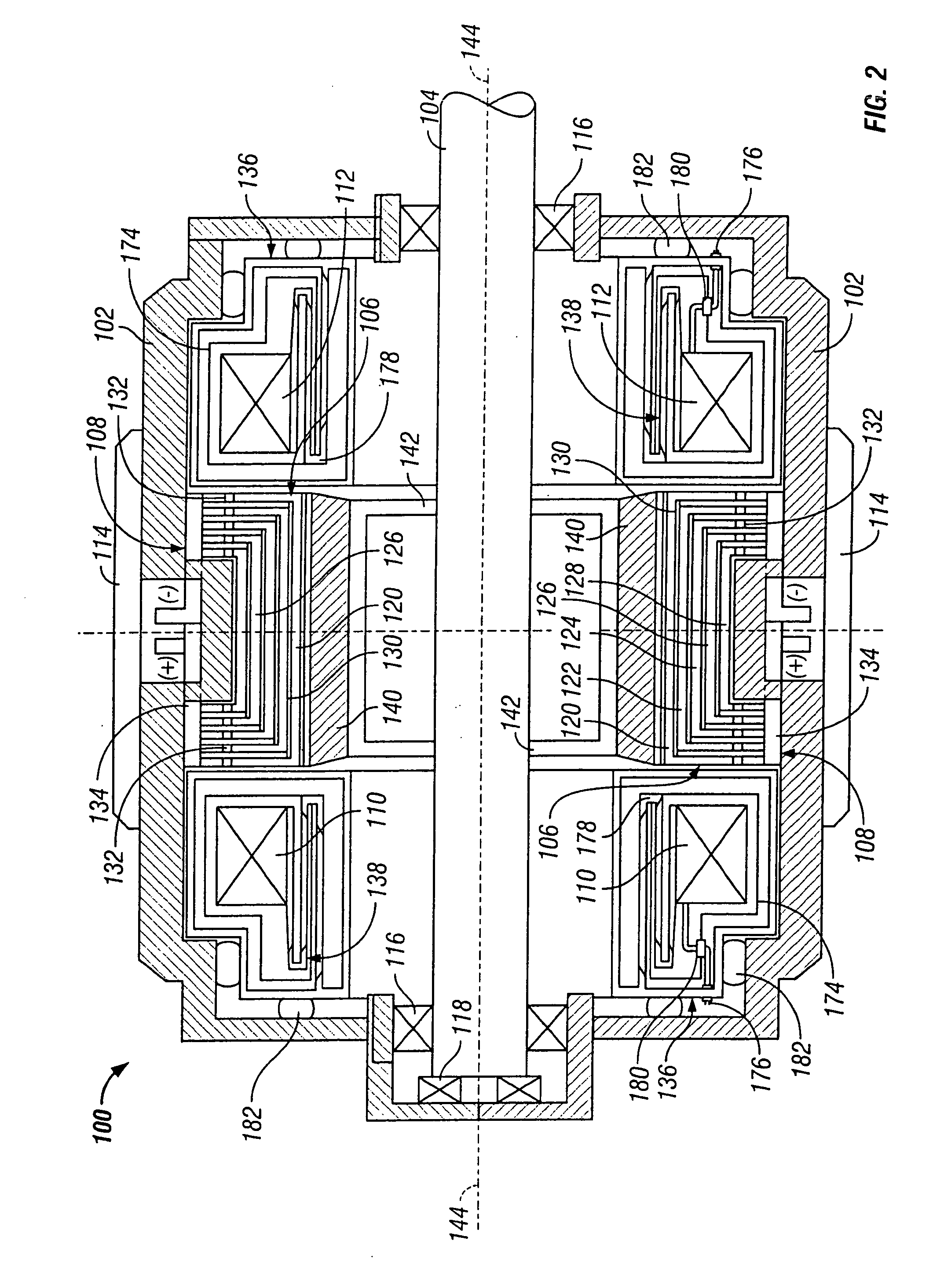

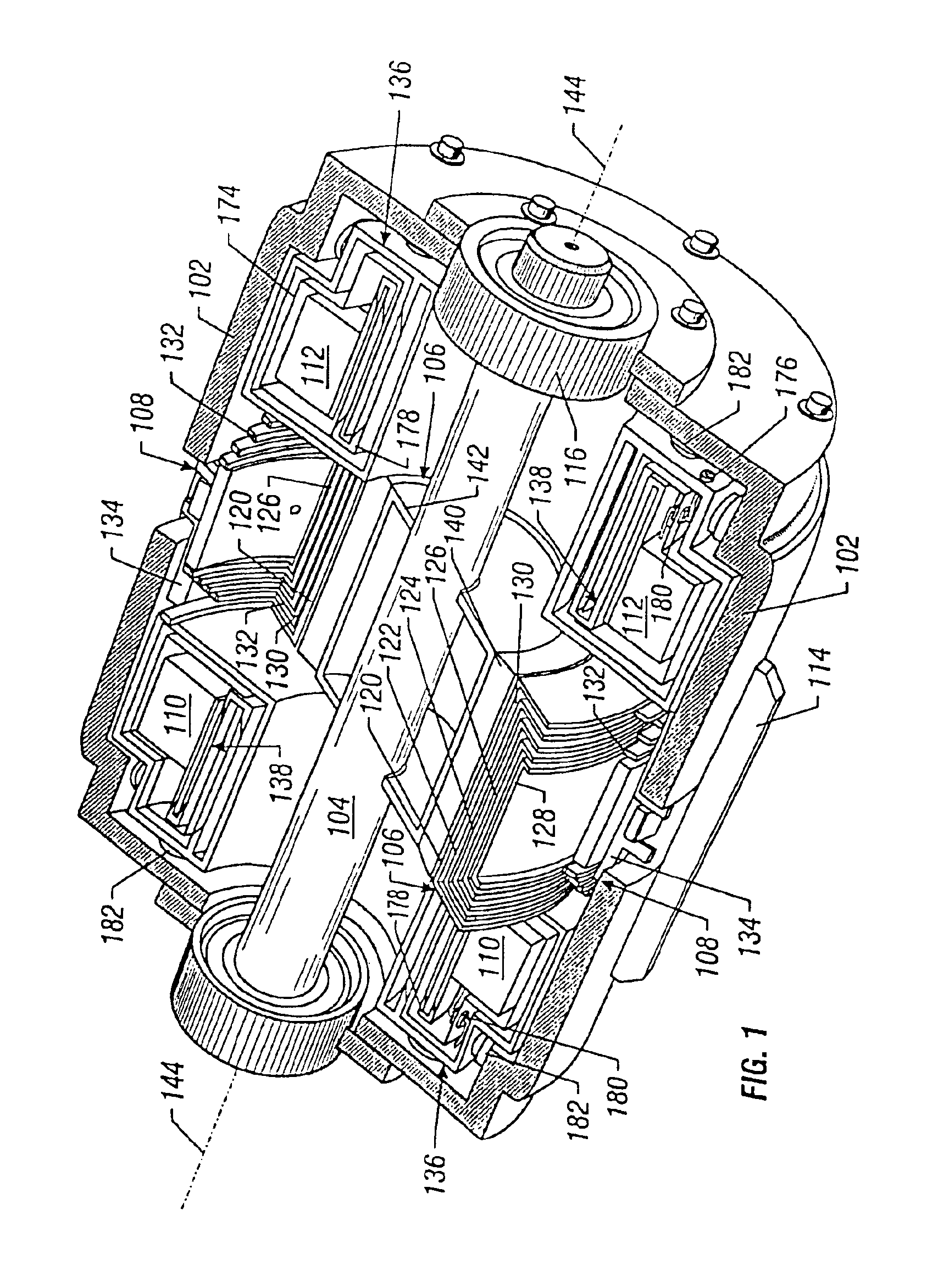

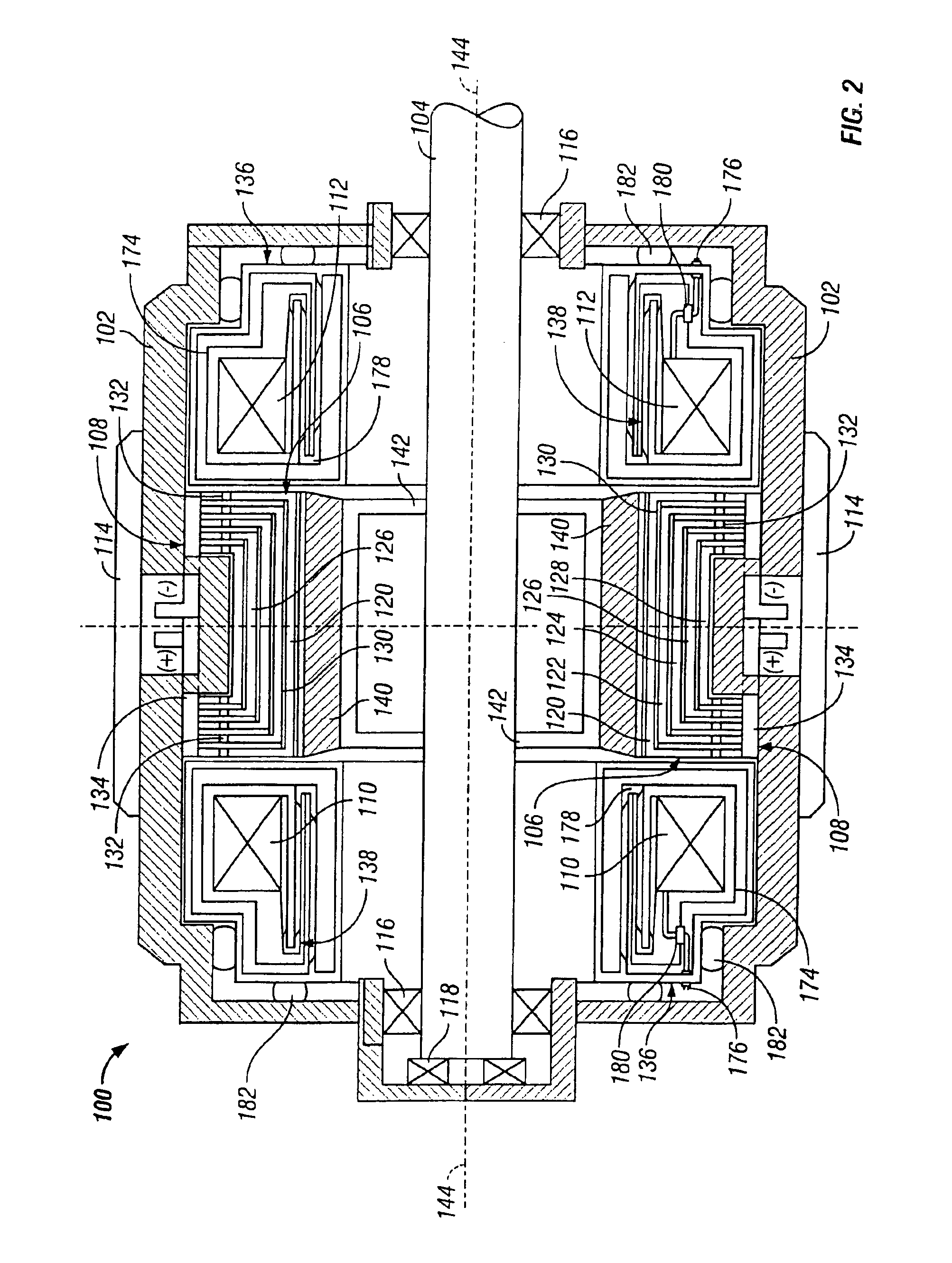

Homopolar machine with shaft axial thrust compensation for reduced thrust bearing wear and noise

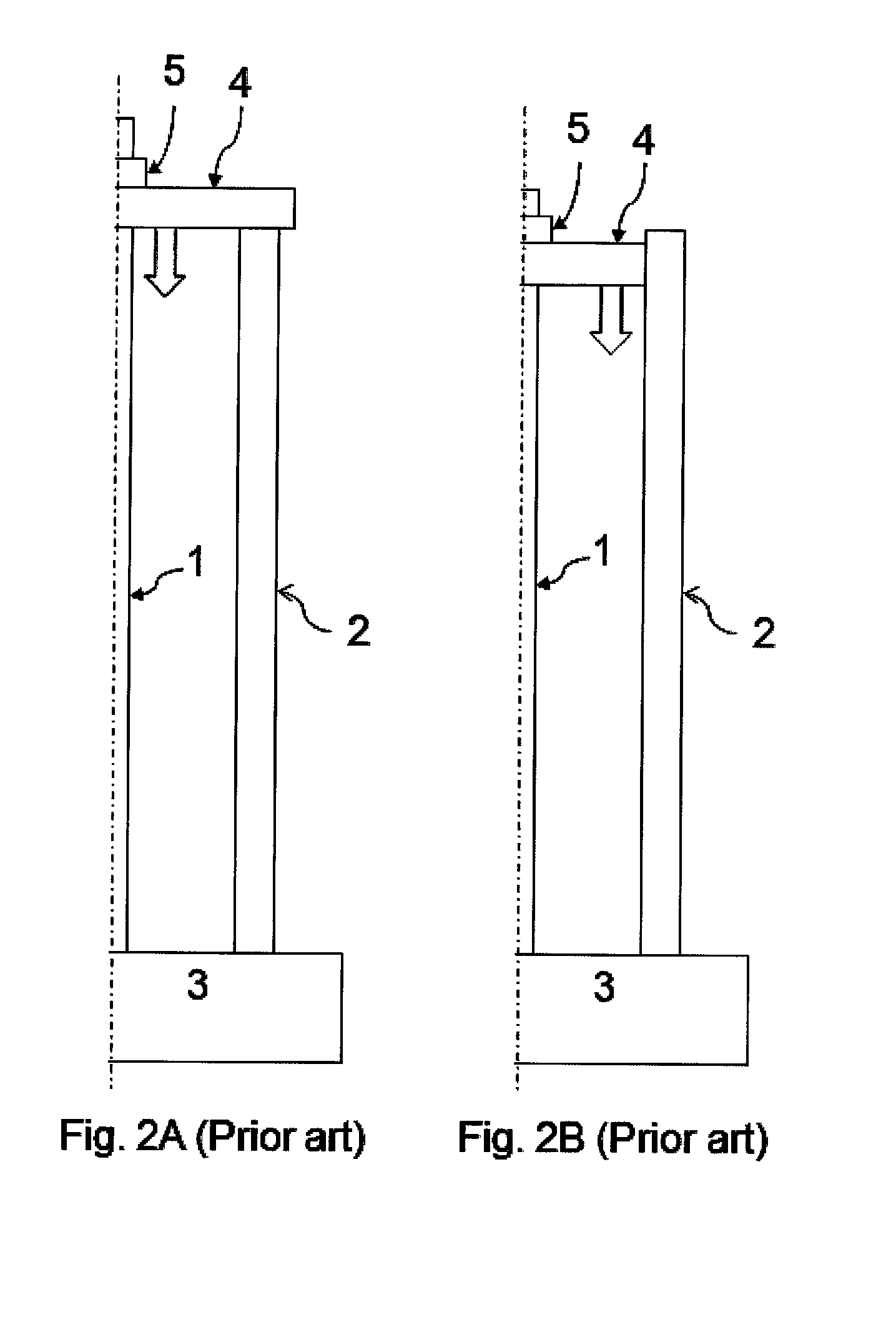

InactiveUS6856062B2Reduce induced magnetic forceConstant contact pressureRotary current collectorMagnetic bodiesFiberContact pressure

A homopolar machine produces an axial counter force on the rotating shaft to compensate for the load on the shaft's thrust bearing to reduce wear and noise and prolong bearing life. The counter force is produced through magnetic interaction between the shaft and the machine's field coils and is created by changing the current excitation of the field coils, which results in a magnetic flux asymmetry in an inner flux return coupled to the shaft. The homopolar machine may also have a configuration that uses current collectors that maintain substantially constant contact pressure in the presence of high magnetic fields to improve current collector performance. The current collectors are flexible and may be made from either electrically conductive fibers or stacked strips such that they bear up against the armature so that the pressure is maintained by the spring constant of the current collector material. The homopolar machine may also have a configuration where the brushes are oriented so that the current is aligned as much as is practical with the local magnetic field lines so as to reduce the lateral electromagnetic forces on the brushes.

Owner:GENERAL ATOMICS

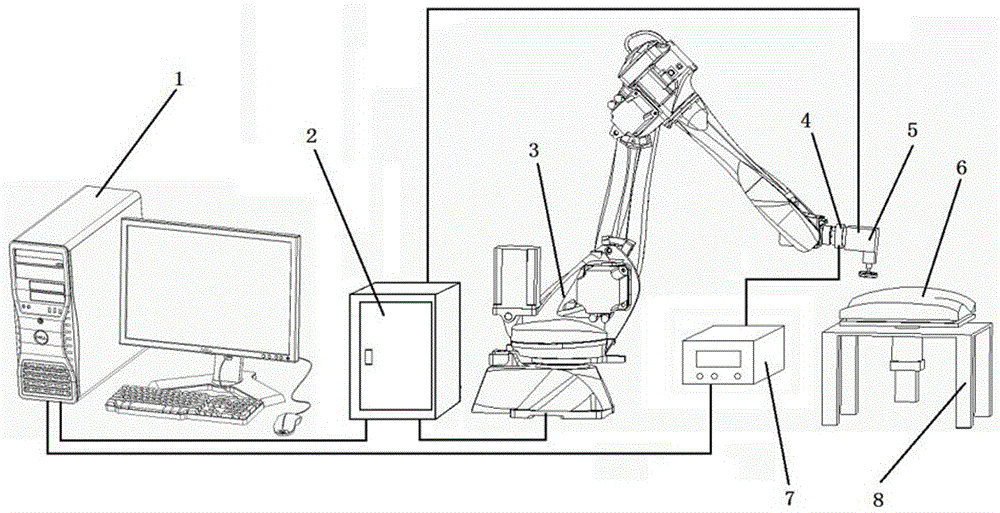

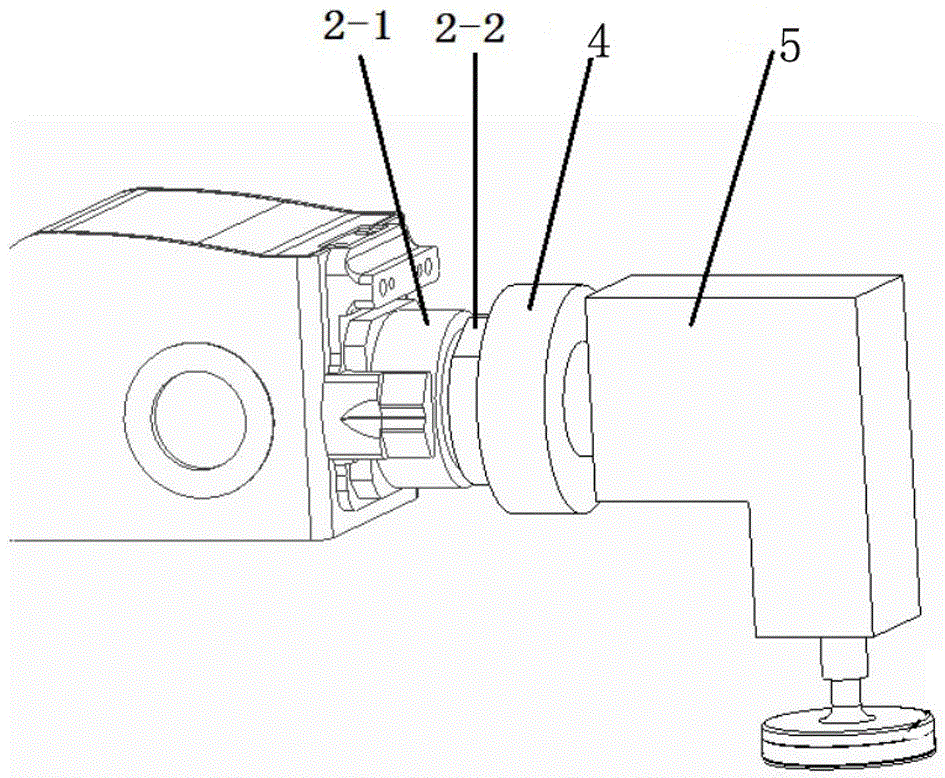

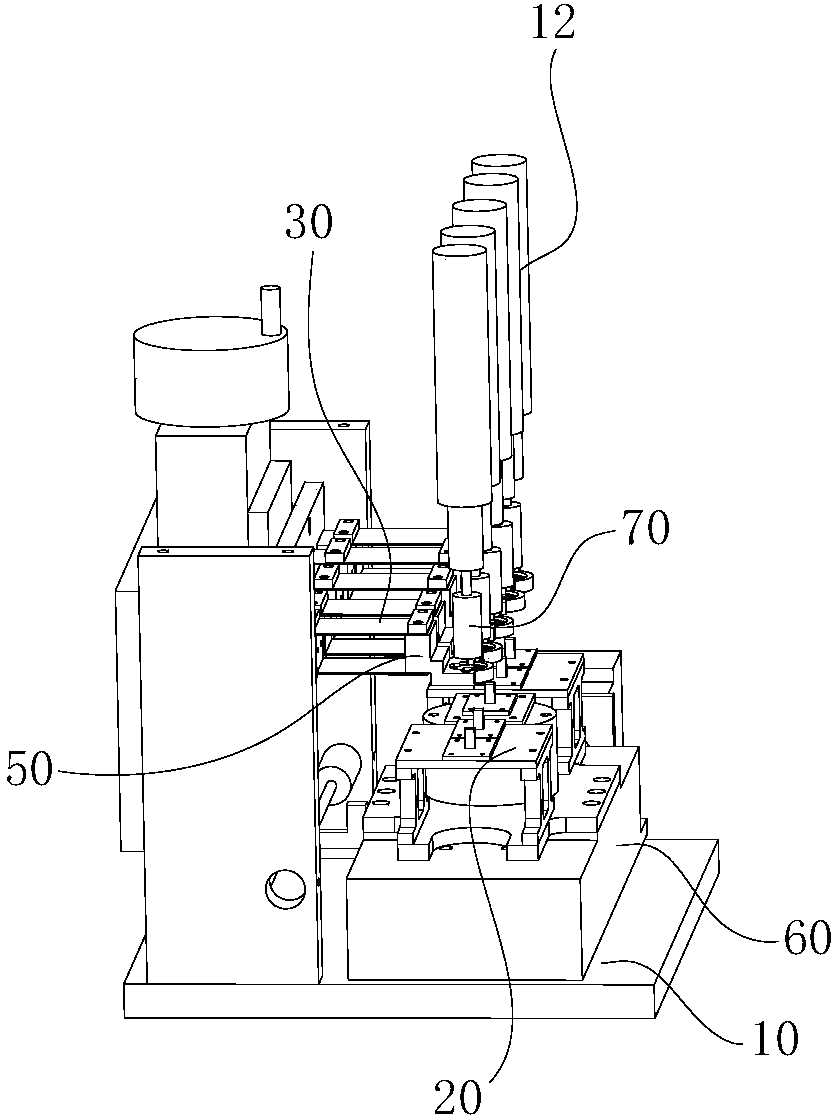

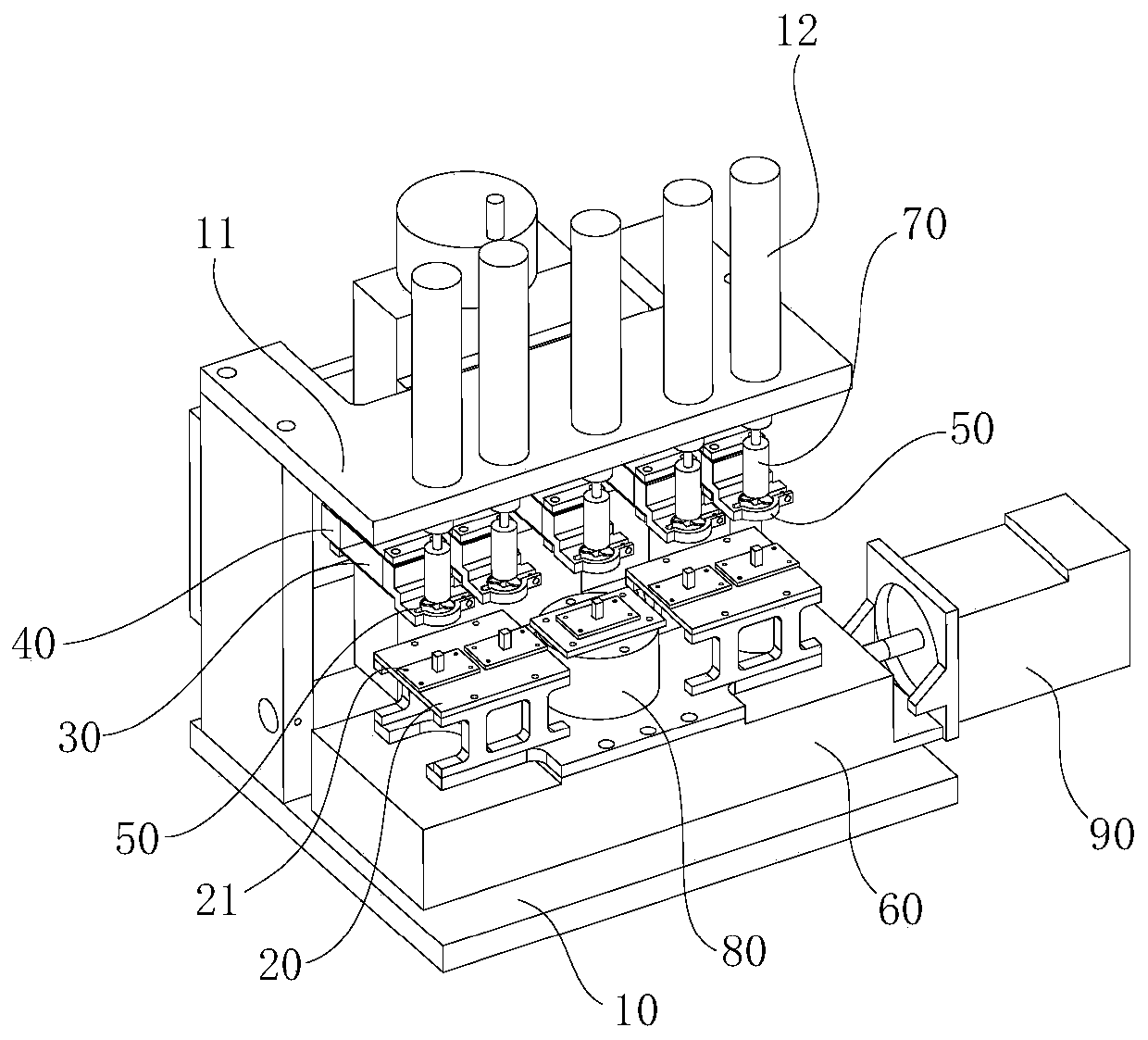

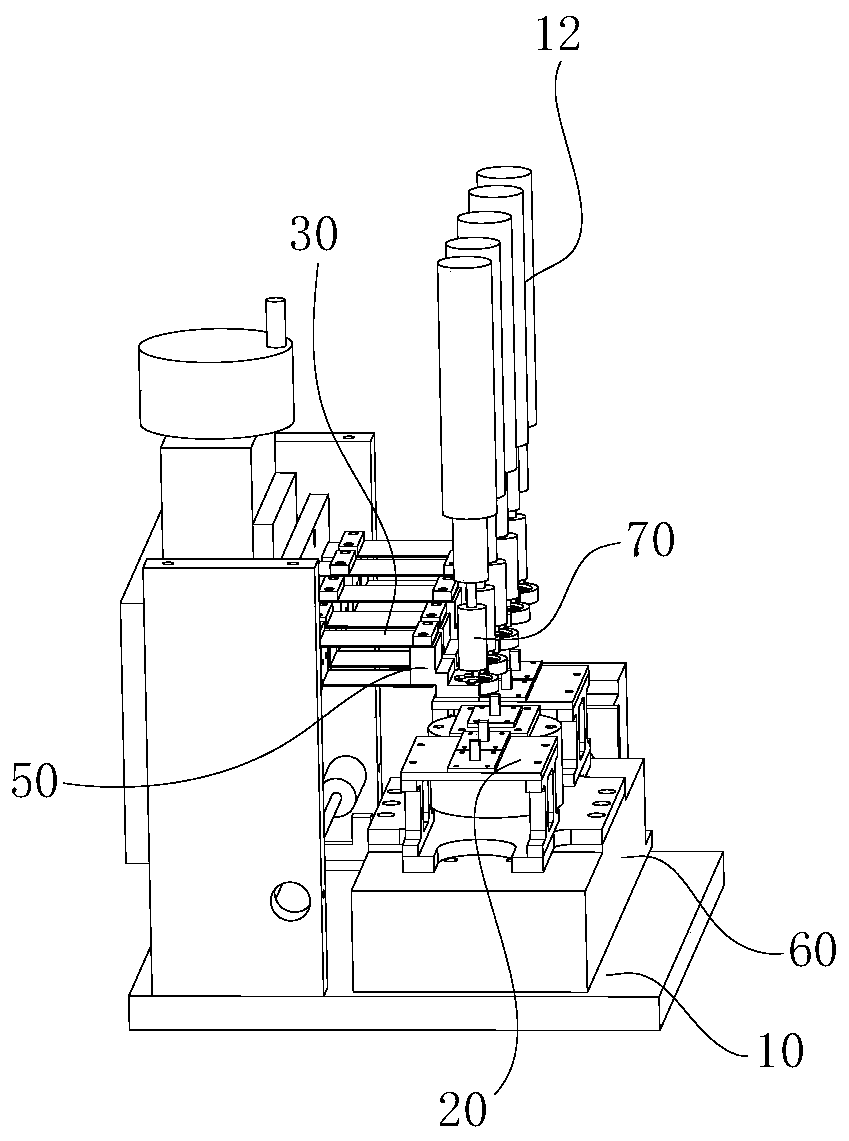

Automatic free-form surface polishing and grinding system with industrial robot and method

ActiveCN106799738AConstant contact pressureAdjustable contact pressureProgramme-controlled manipulatorGrinding drivesSurface grindingFree form

The invention relates to an automatic free-form surface grinding and polishing system with an industrial robot and a method. The system comprises an upper computer, the industrial robot, a robot controller, a force sensor, a signal collector, a grinding and polishing device and a work table. The upper computer is connected to the signal collector and the robot controller, the robot controller is connected to the industrial robot and the grinding and polishing device, and the signal collector is connected with the force sensor; the industrial robot is connected with the grinding and polishing device, the force sensor is arranged at the connection position of the grinding and polishing device and the industrial robot, and the work table is used for fixing workpieces. The system can directly polish and grind the free surfaces without off-line programming in advance, contact pressure can be constant and adjustable during free-form surface grinding and polishing, and control is simple while operation is easy to perform.

Owner:FUZHOU UNIVERSITY

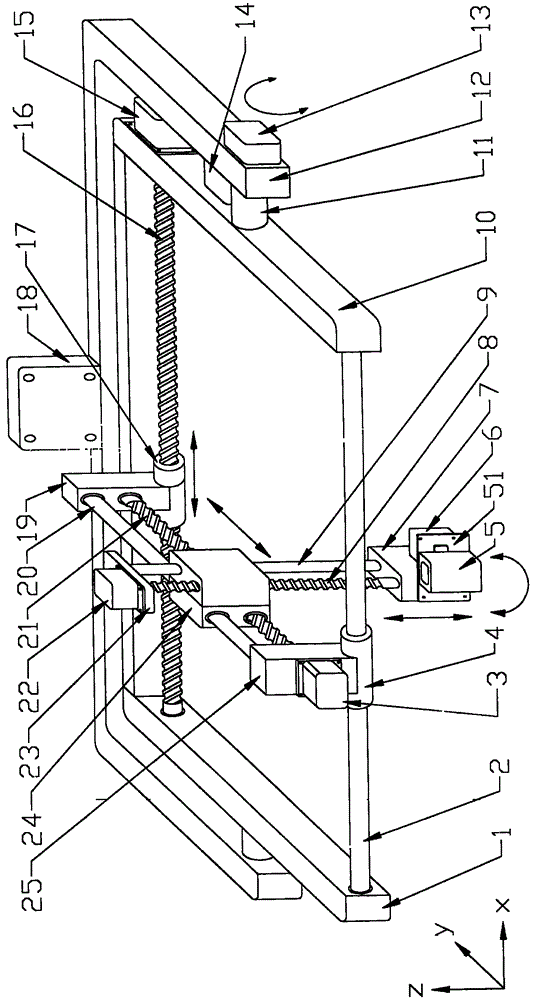

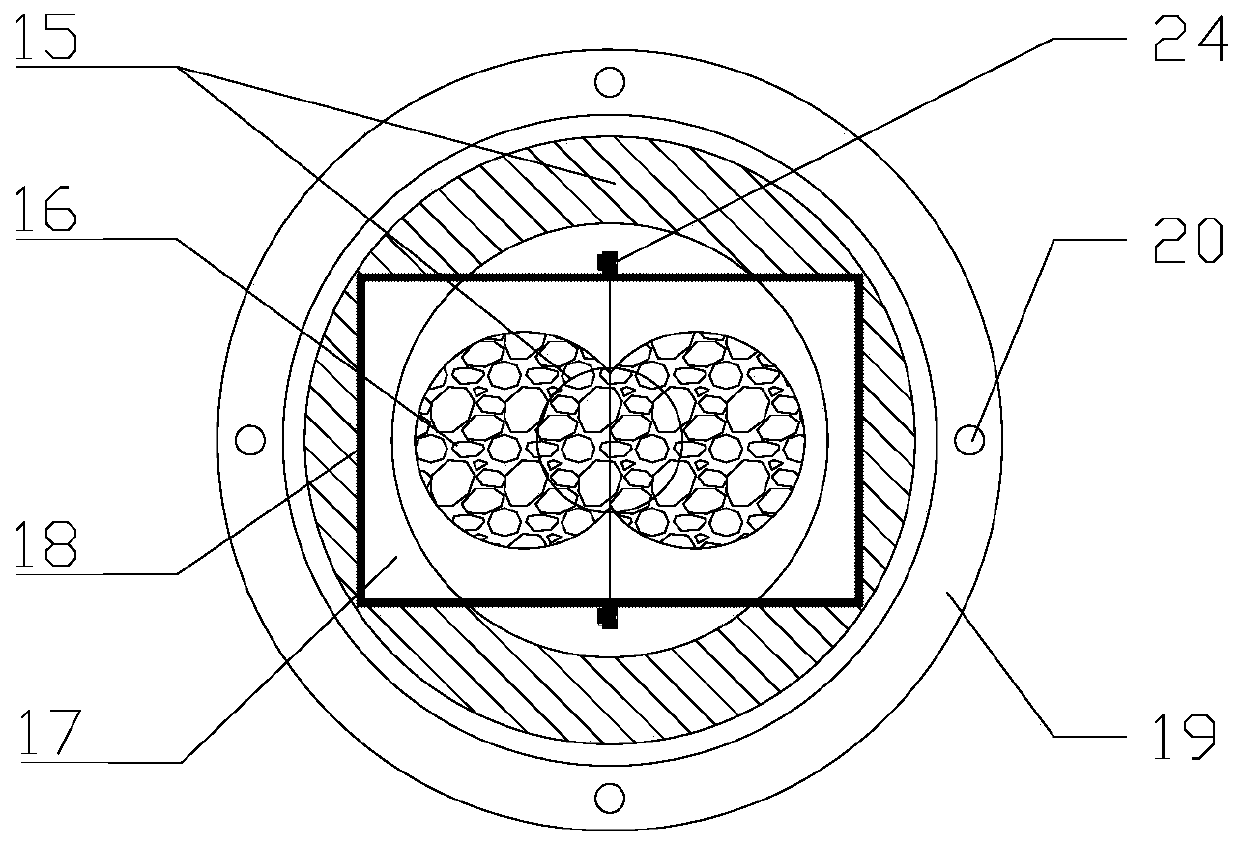

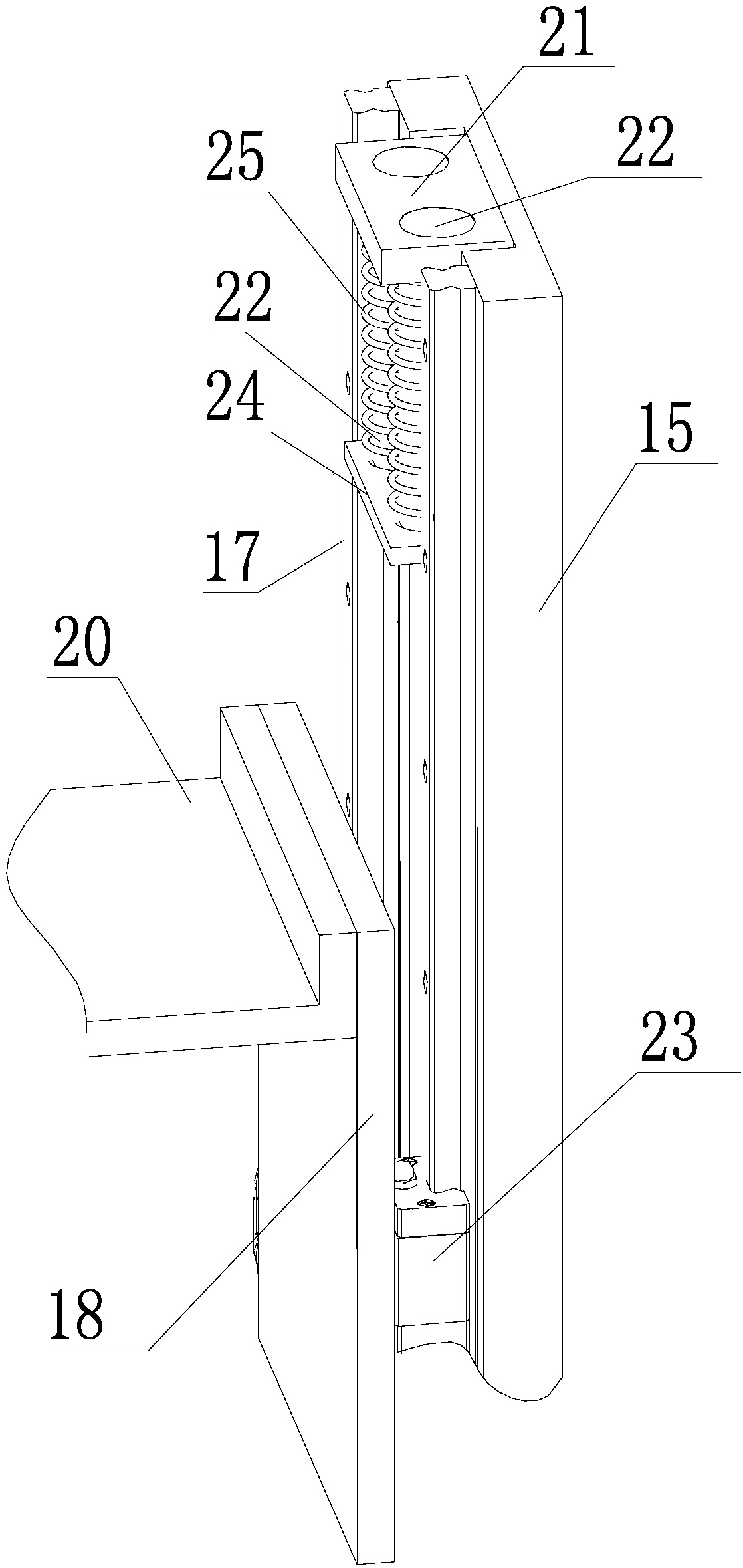

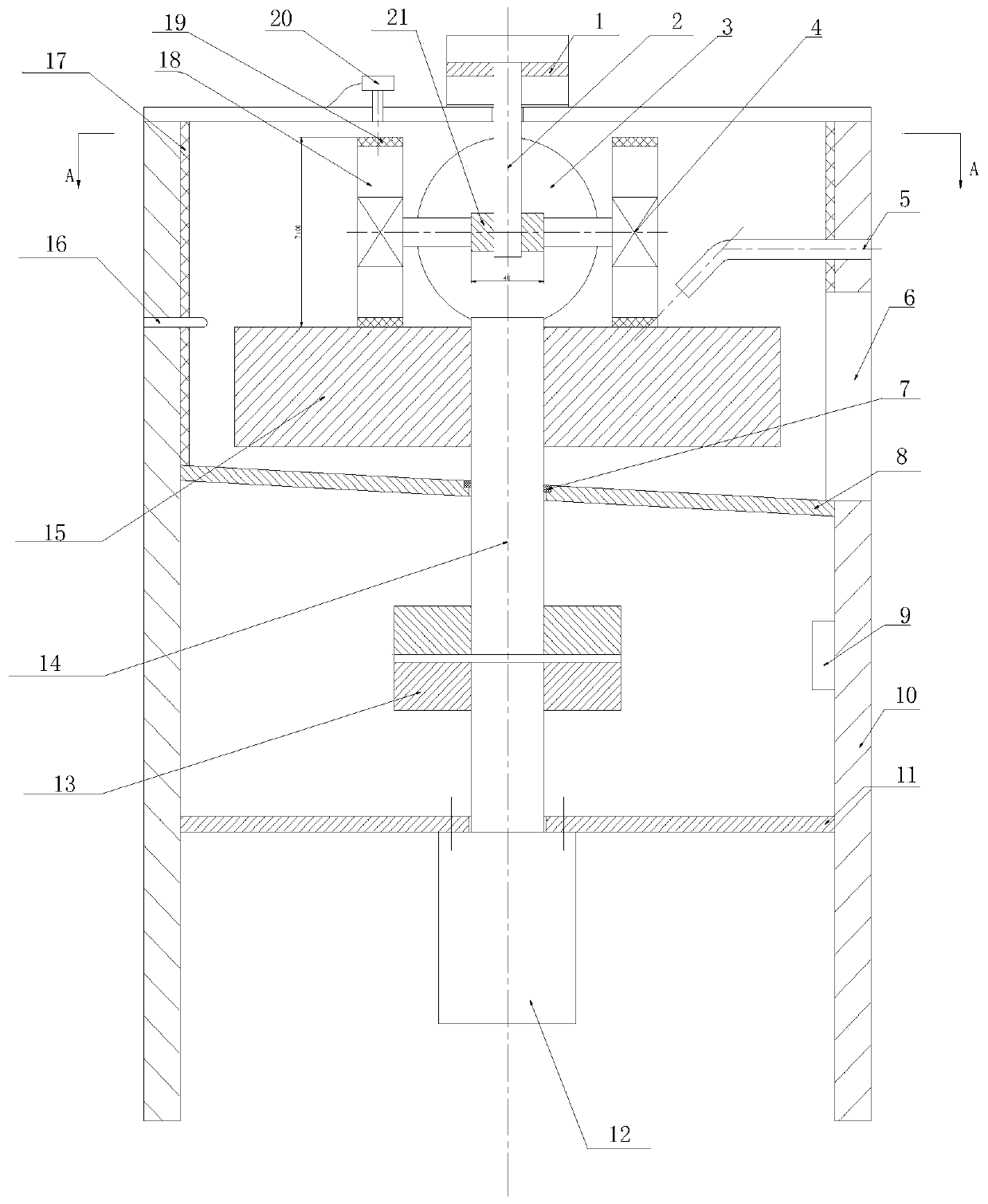

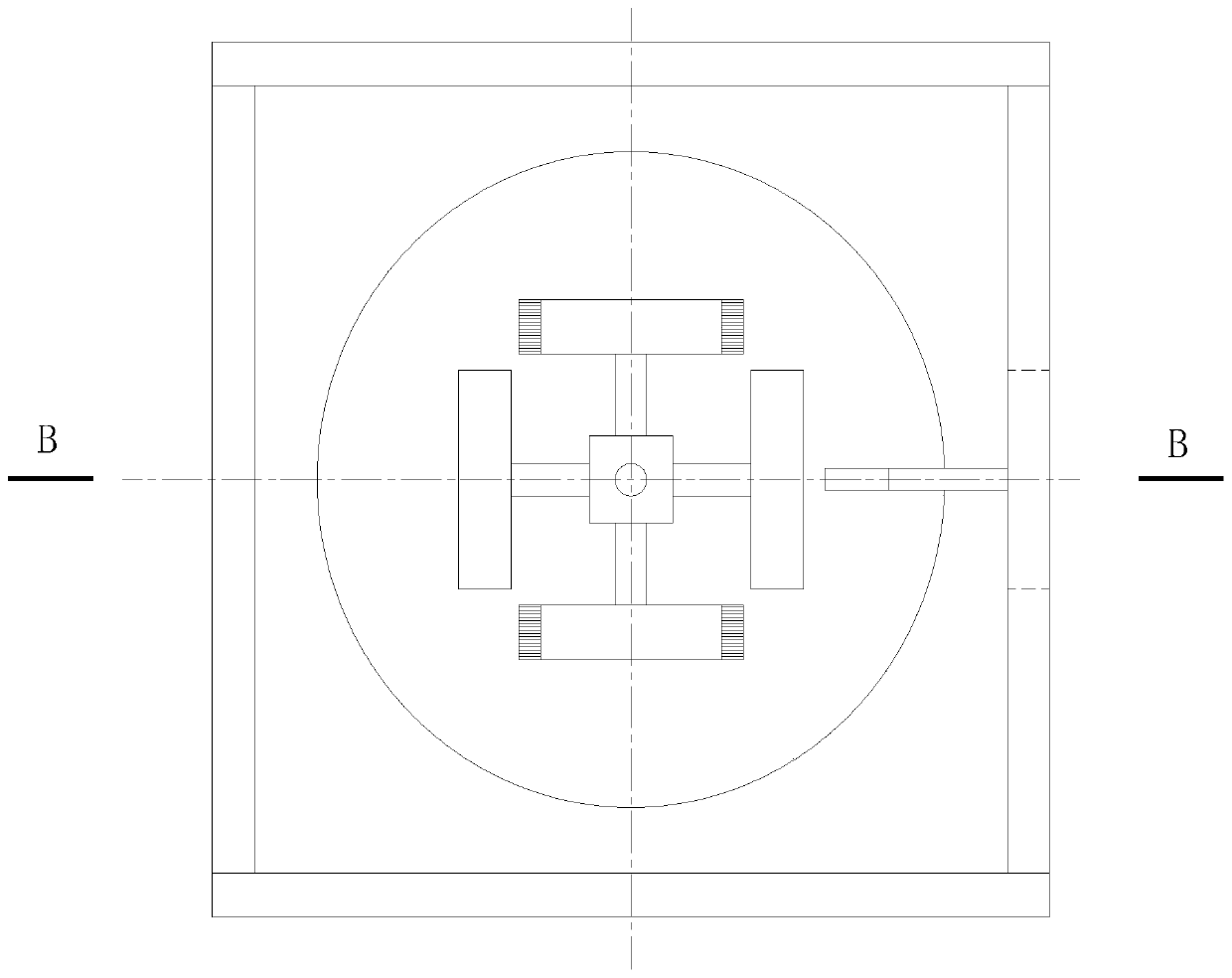

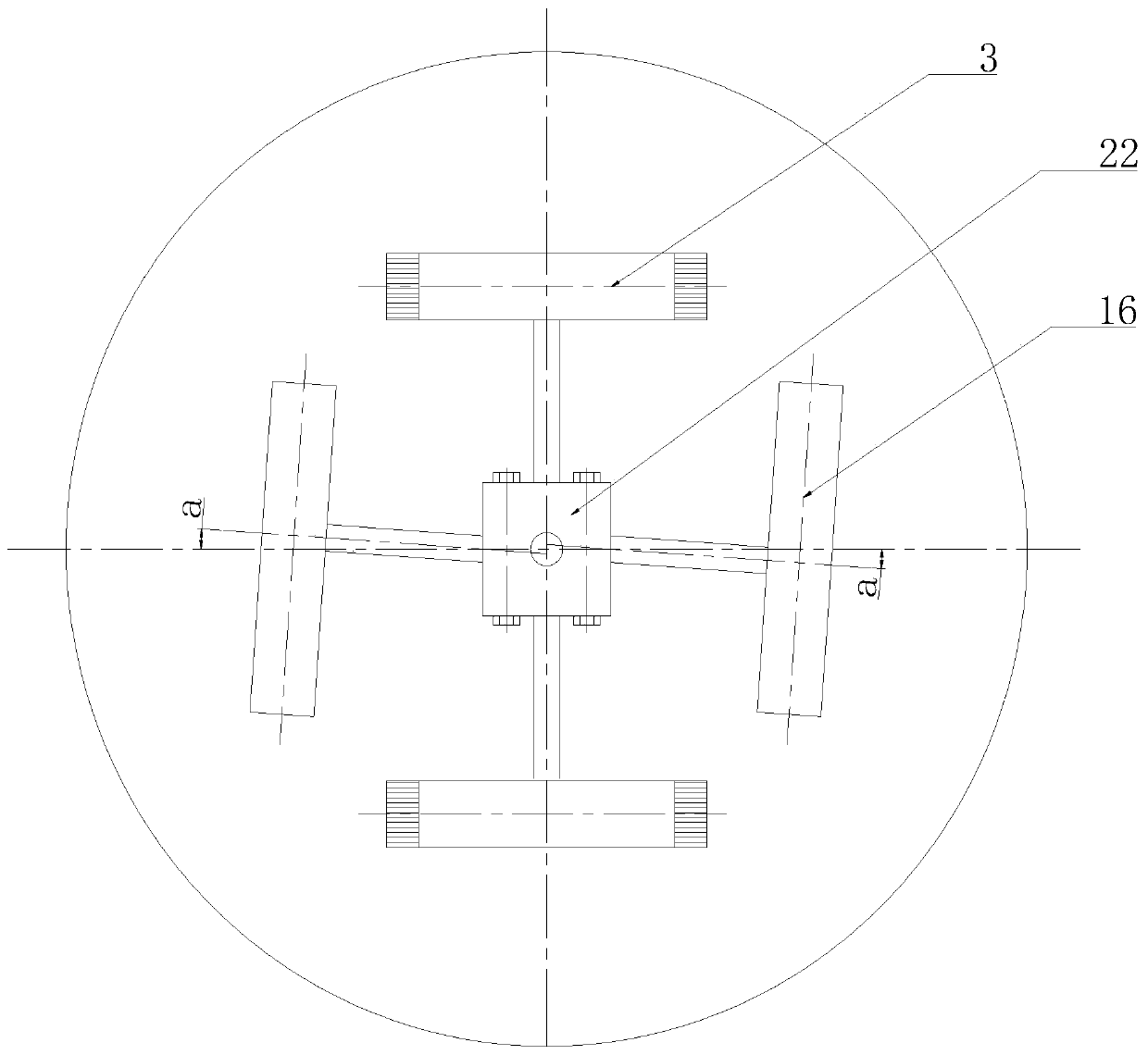

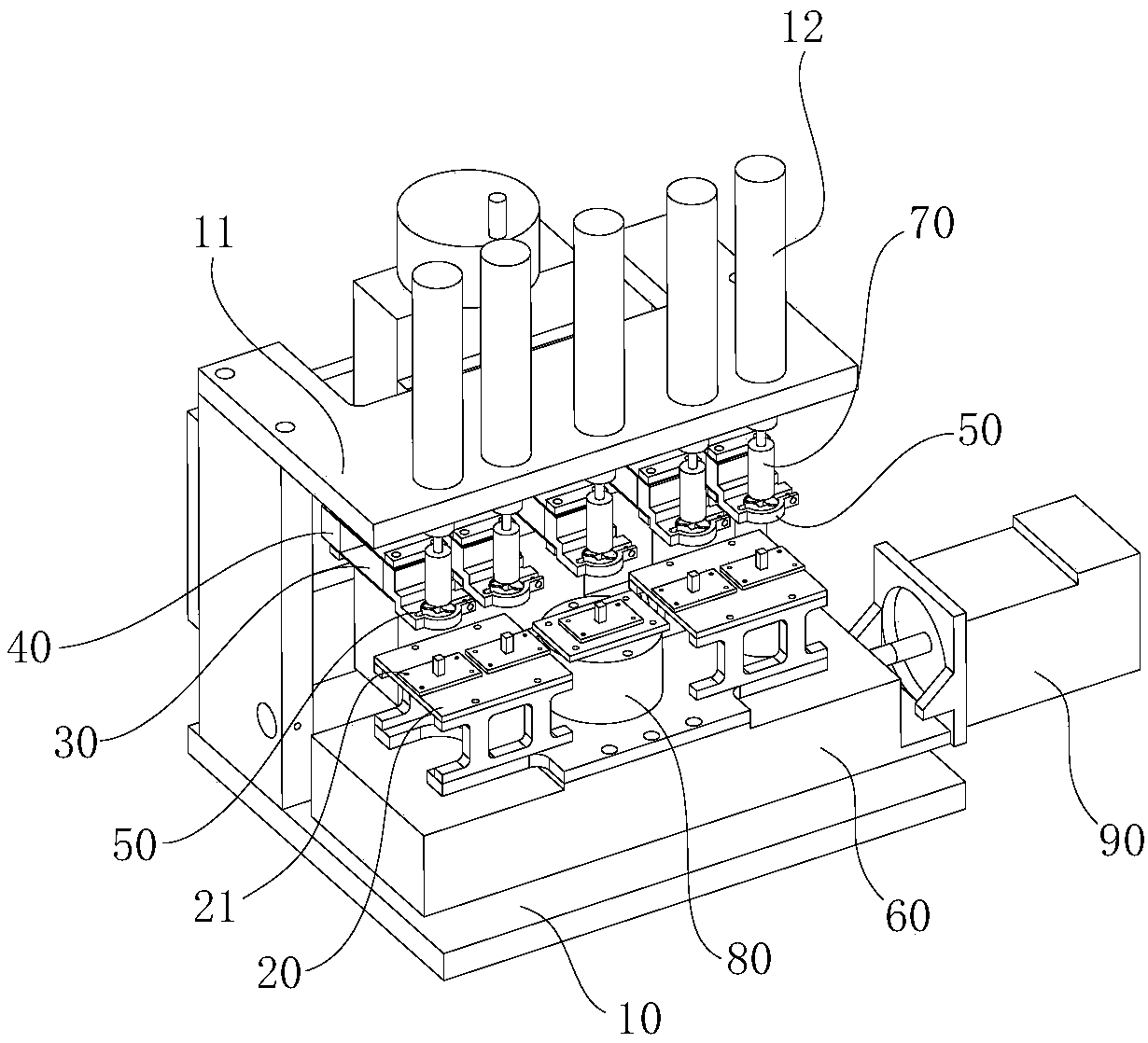

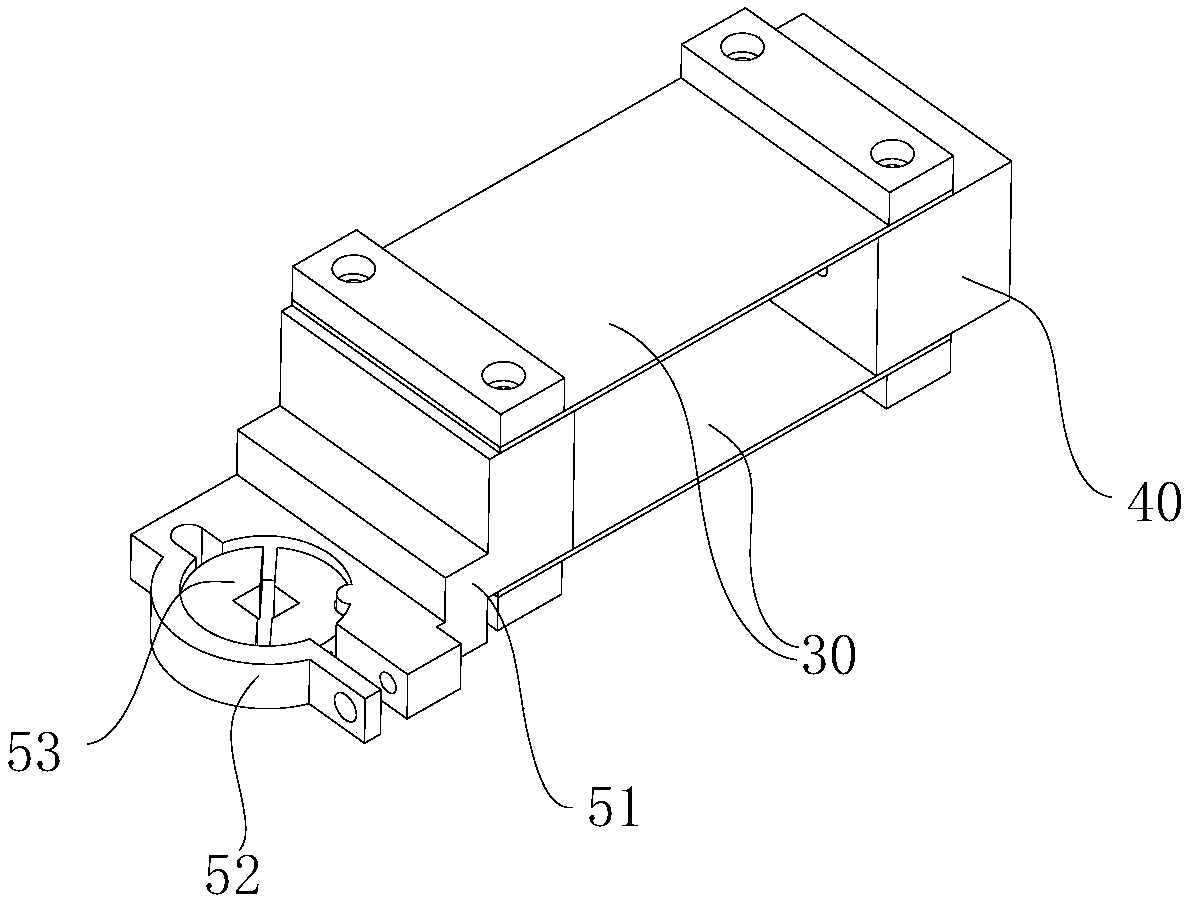

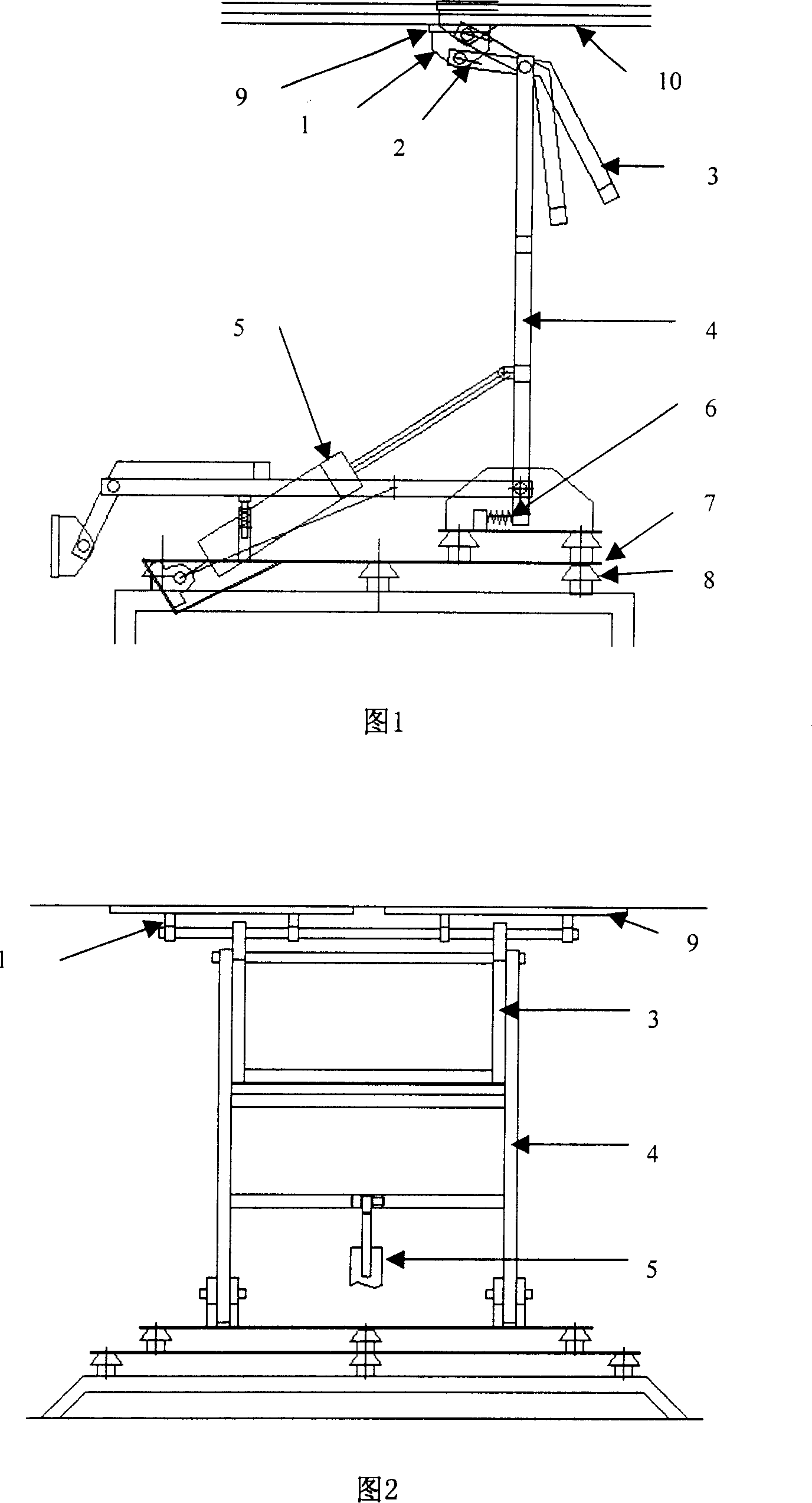

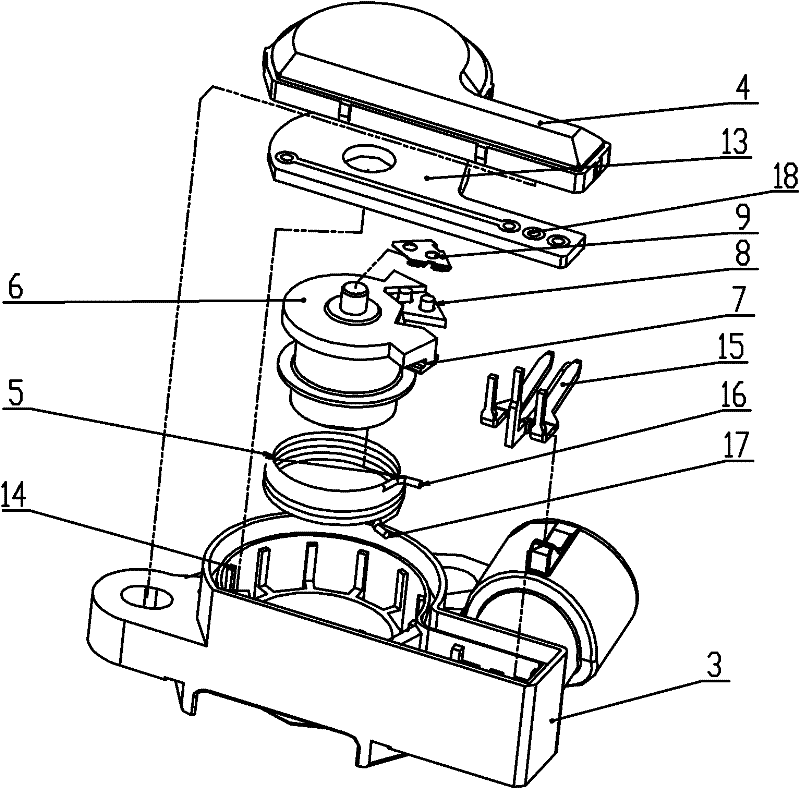

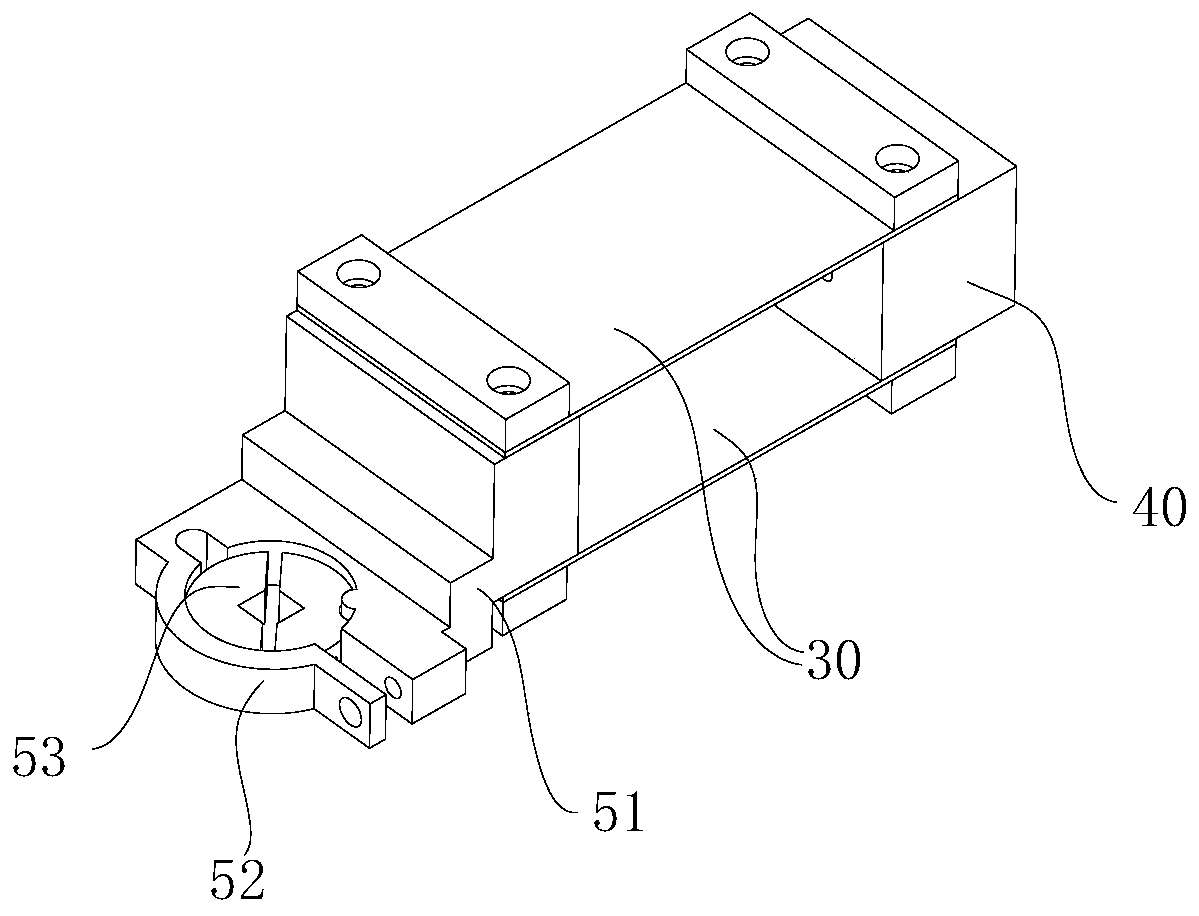

Constant-speed constant-pressure plain scanning guide rail of B ultrasound probe

InactiveCN104665931ASolve the technical defect that the B-ultrasound probe cannot be missed at a uniform speedAddressing Individual DifferencesUltrasonic/sonic/infrasonic diagnosticsGearingAcoustic waveEngineering

The invention provides a mechanical device and a method for achieving constant-speed, constant-pressure and non-missing plain canning of a B ultrasound probe. The device comprises a guide rail assembly and a guide rail assembly bracket; the guide rail assembly comprises an X axial guide rail, a Y axial guide rail, a Z axial guide rail, and a rotatable B ultrasound probe clamp which is mounted at the bottom end of the Z axial guide rail; a pressure sensor and an angle measuring sensor are arranged on a lower bracket of the Z axial guide rail; the guide rail assembly is connected with the guide rail bracket through a rotating shaft and can be rotated around the rotating shaft; the guide rail assembly rotates to drive a motor and a rotating speed reduction device; the transmission mode of the guide rail is performed through a precision lead screw or a gear belt; the B ultrasound probe is driven by a driving mechanism to axially move at constant speed in the X, Y and Z directions; meanwhile, the probe is swung under the effect of the probe clamp rotating mechanism; a track assembly is driven by the rotating mechanism to rotate to adjust the vertical relationship between the ultrasound direction and the detection surface, so as to achieve constant-pressure, constant-speed, non-missing and overlapping-free scanning of the B ultrasound probe.

Owner:BEIJING NINGHE YIFENG TECH

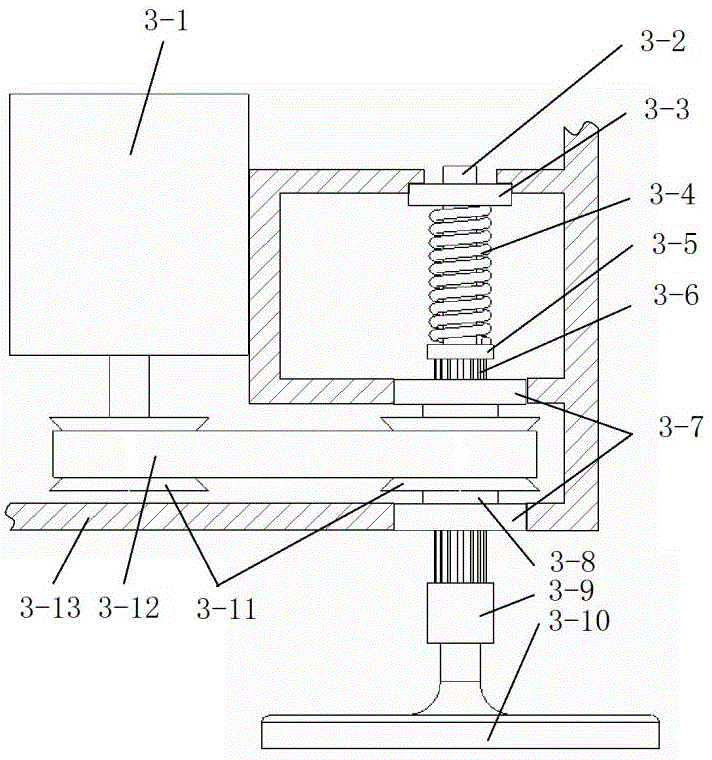

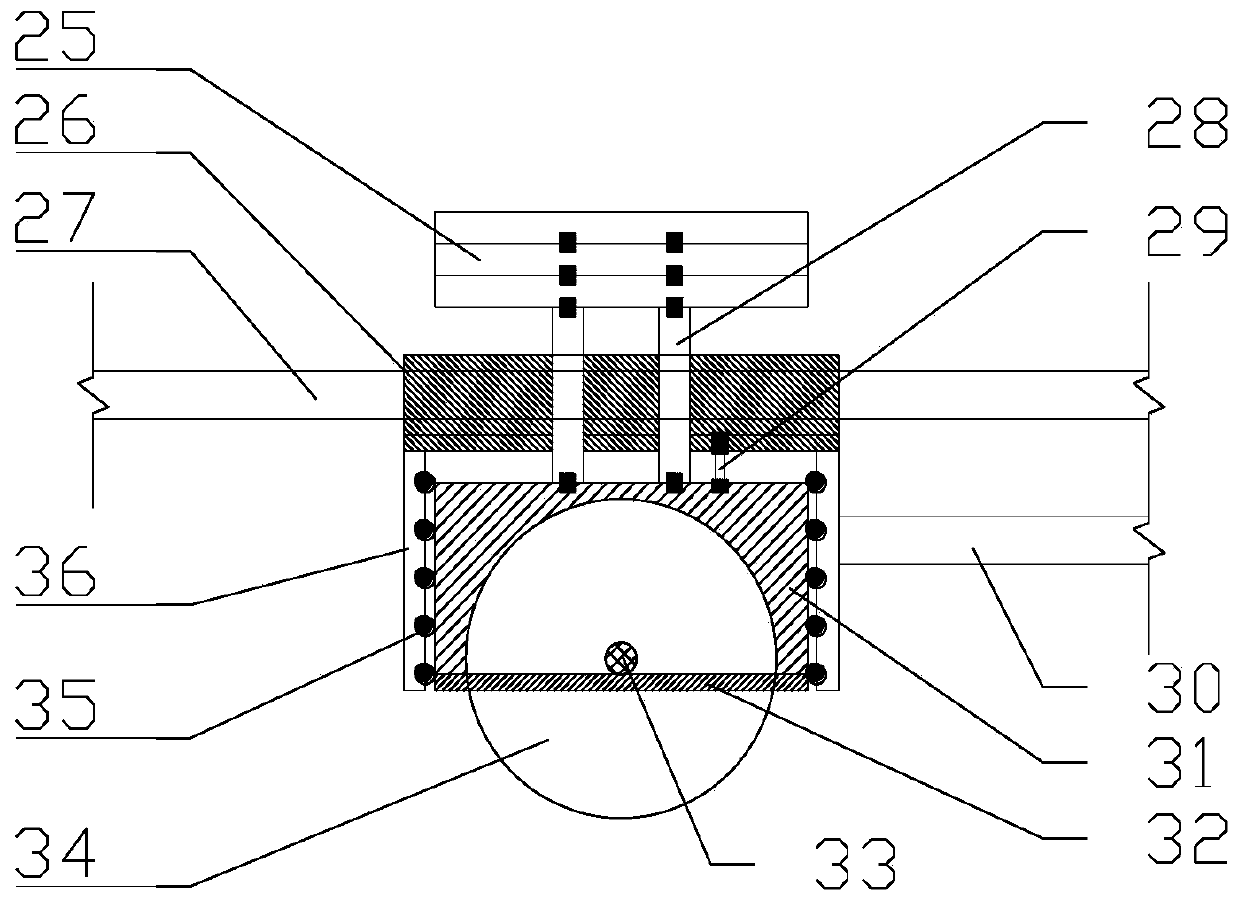

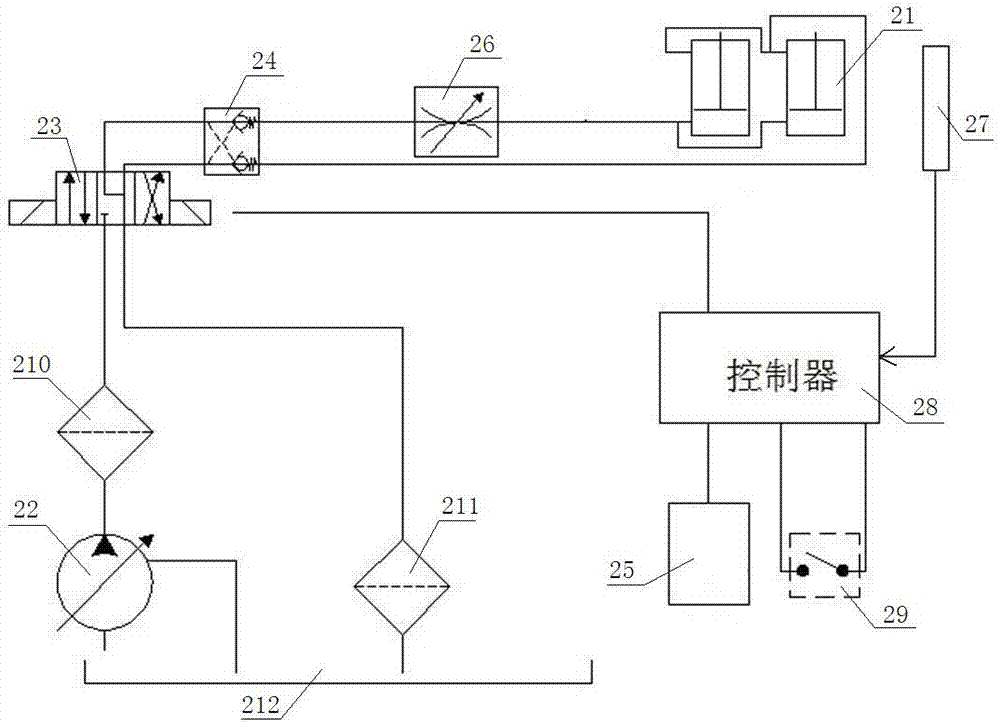

Rut test system for asphalt mixture in hydrodynamic pressure environment and test method

PendingCN109932260AEffective simulationThe test result is accurateMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesWater bathsTemperature control

The invention provides a rut test system for an asphalt mixture in a hydrodynamic pressure environment and a test method, which belong to the technical field of road engineering material performance test. The system comprises a hydrodynamic pressure generating device, a wheel system loading device, an asphalt mixture sample fixing device and a temperature control water bath device. An external servo hydraulic system drives a piston to perform reciprocating movement along a vertical direction according to a preset frequency and an amplitude, a hydrodynamic pressure environment is formed, and the process of generating instantaneous hydrodynamic pressure when a vehicle tire quickly drives on an actual asphalt pavement can be effectively simulated. Constant wheel contact pressure is realized through setting of a linear bearing sliding sleeve, the rut depth is monitored in real time by adopting a form of fixing two ends of a displacement sensor, and the rut test for the asphalt mixture in the hydrodynamic pressure environment can be realized to evaluate the water damage resistance performance. The process of applying the vehicle load to the asphalt mixture in the hydrodynamic pressure environment can be realized, and the specific influences of the hydrodynamic pressure caused by the vehicle tire on the asphalt pavement can be more realistically simulated and quantitatively evaluated.

Owner:UNIV OF SCI & TECH BEIJING

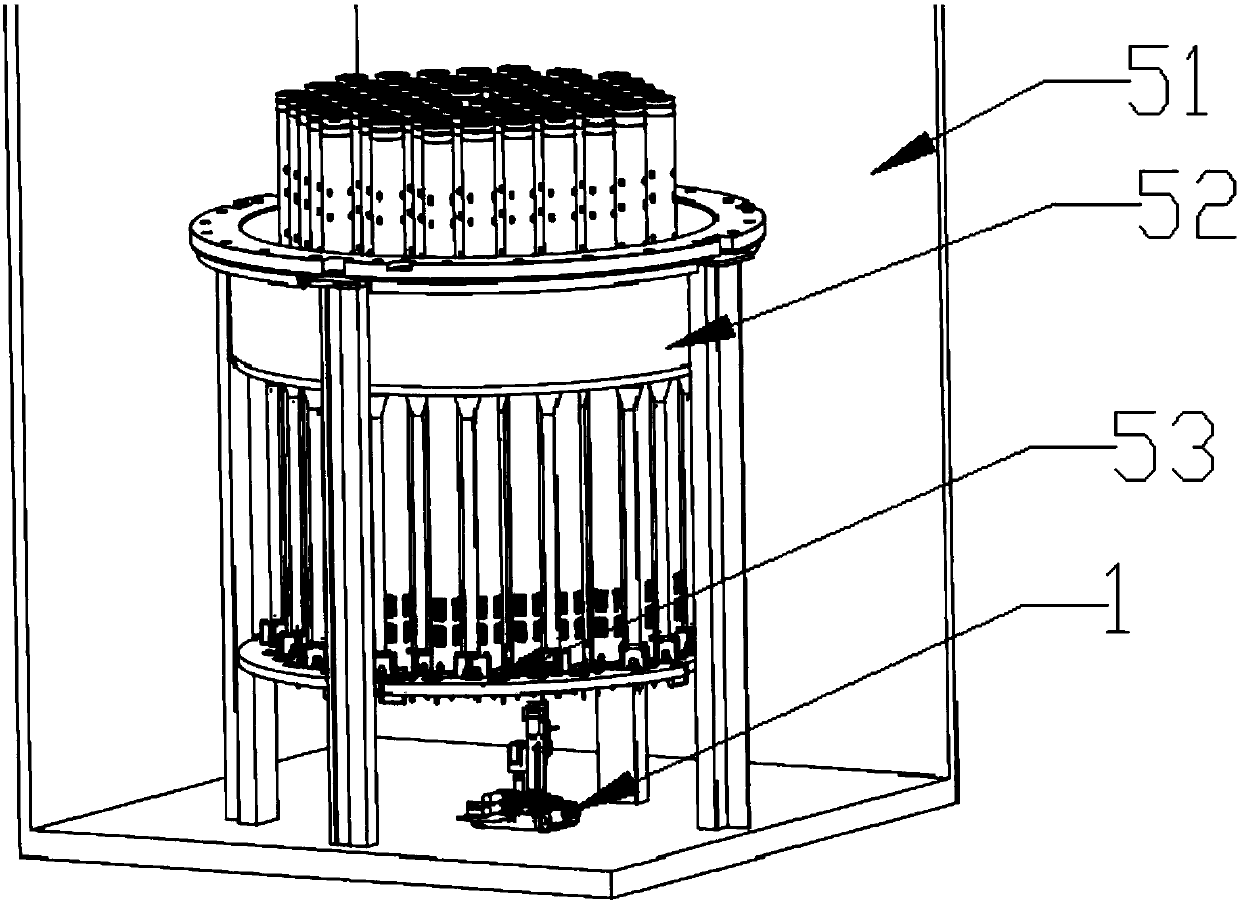

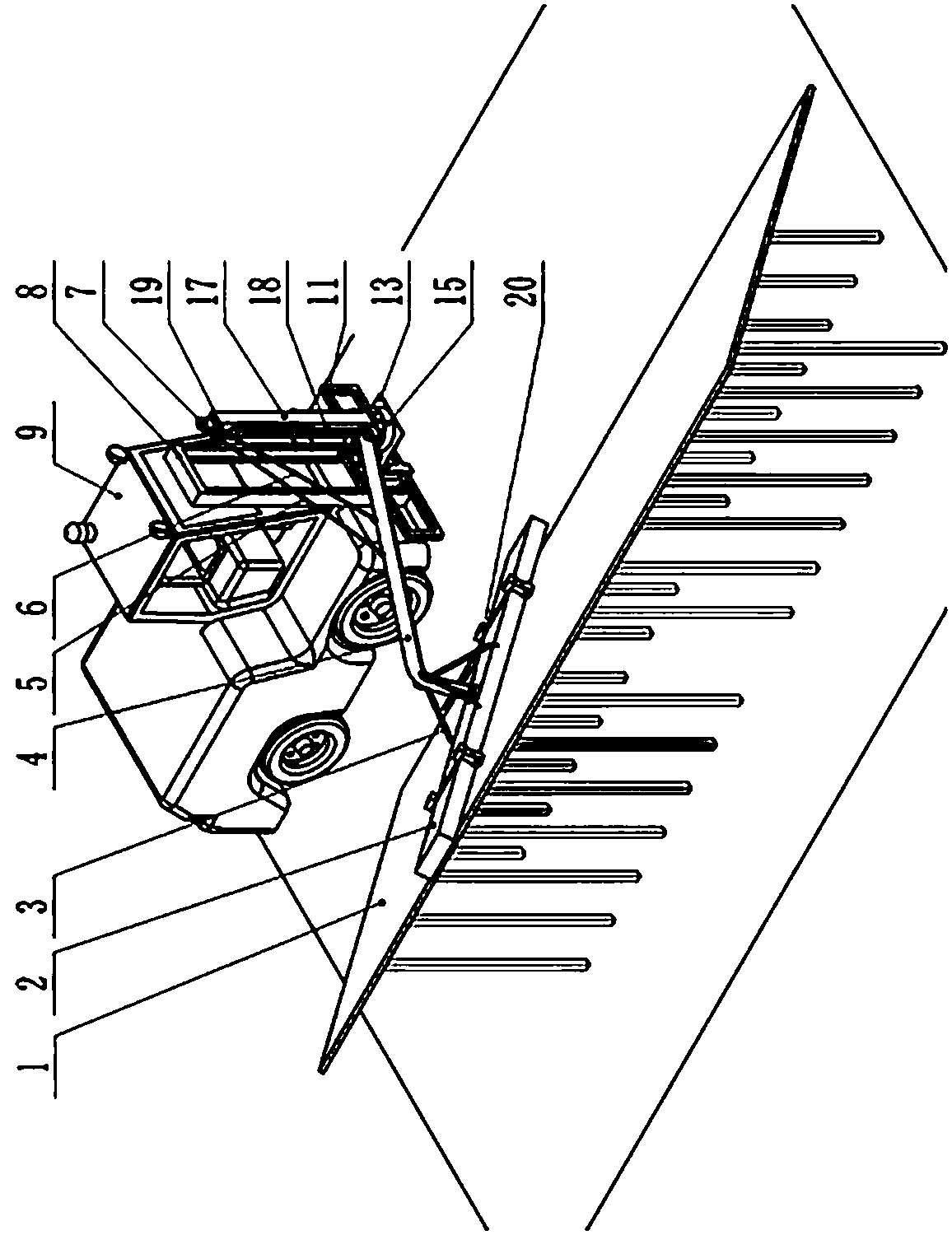

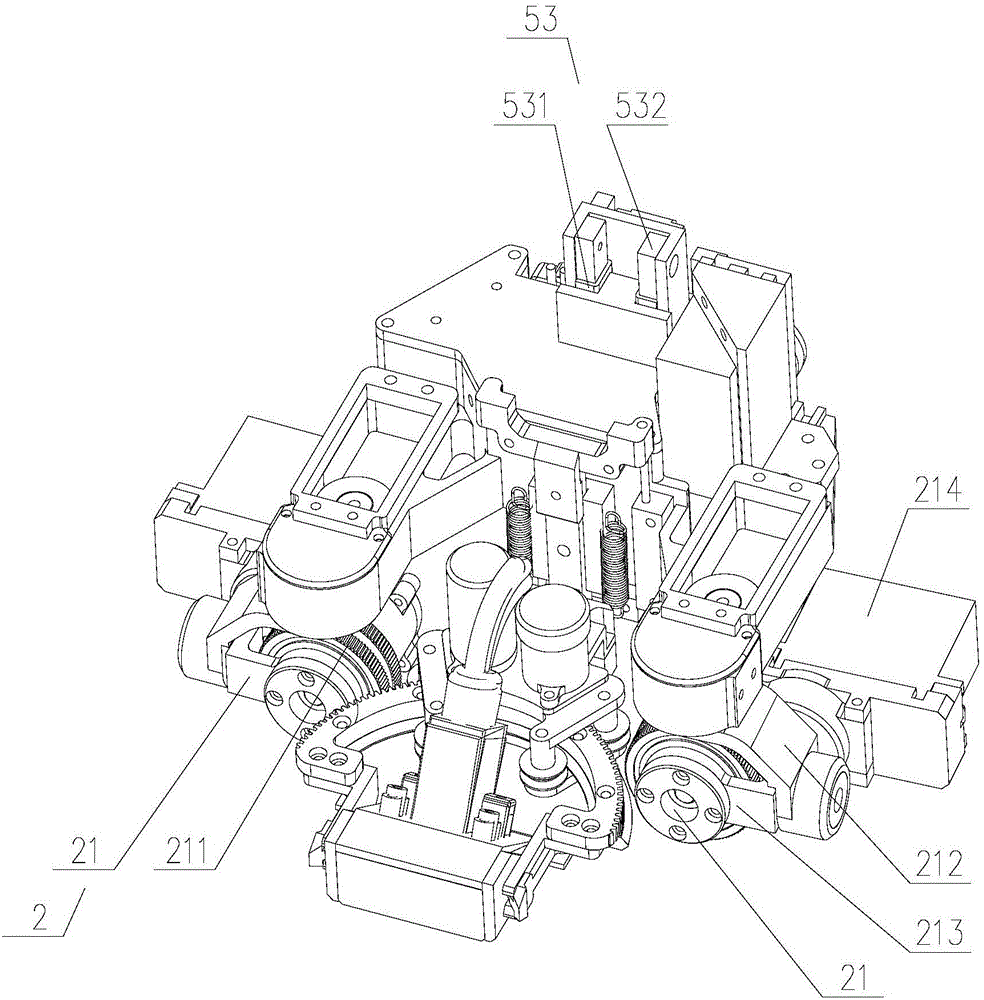

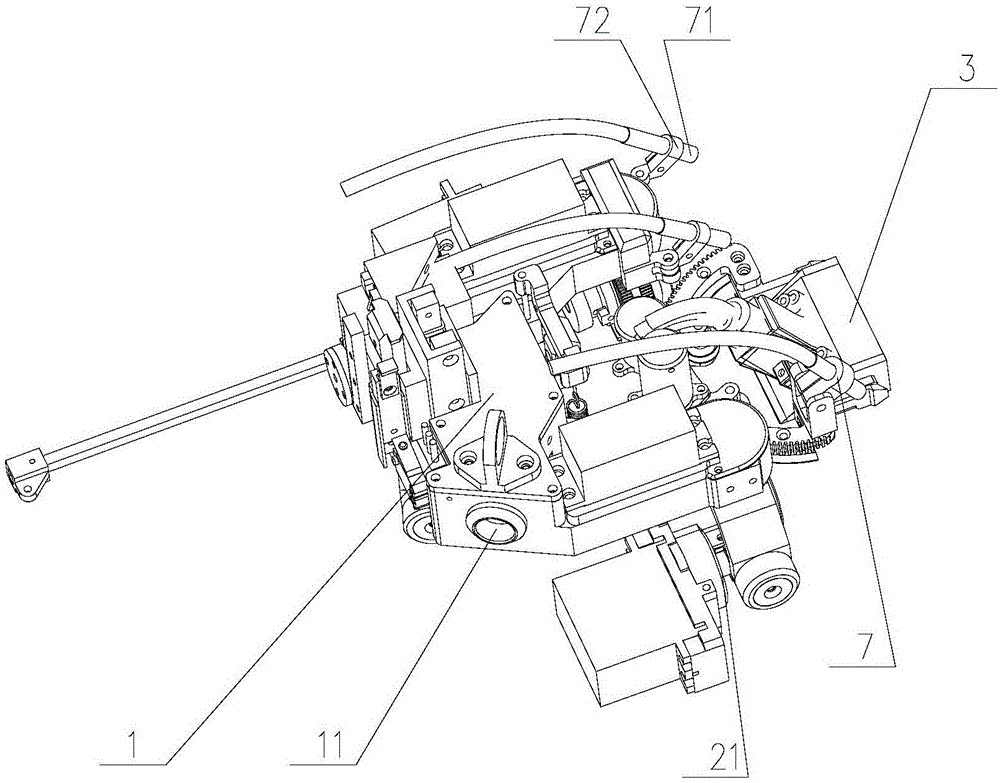

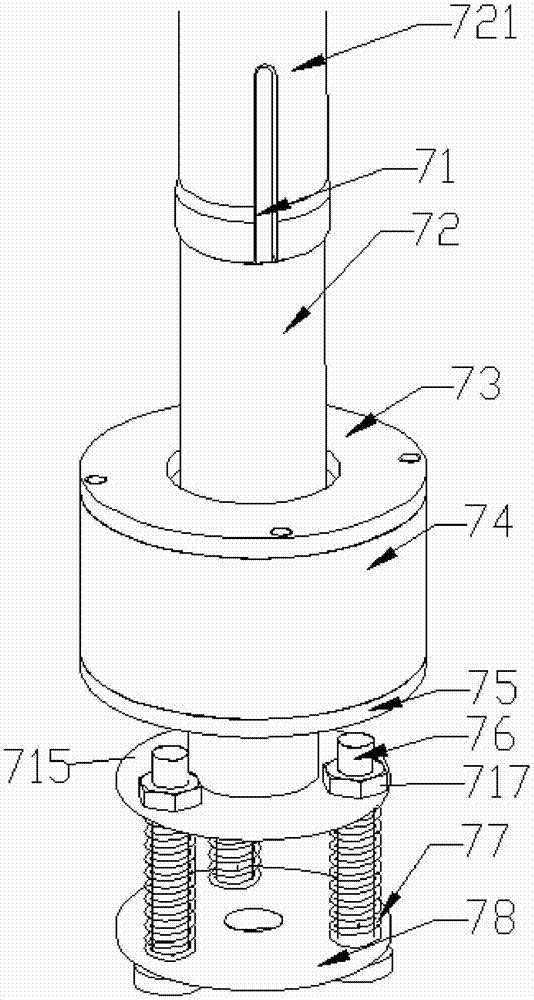

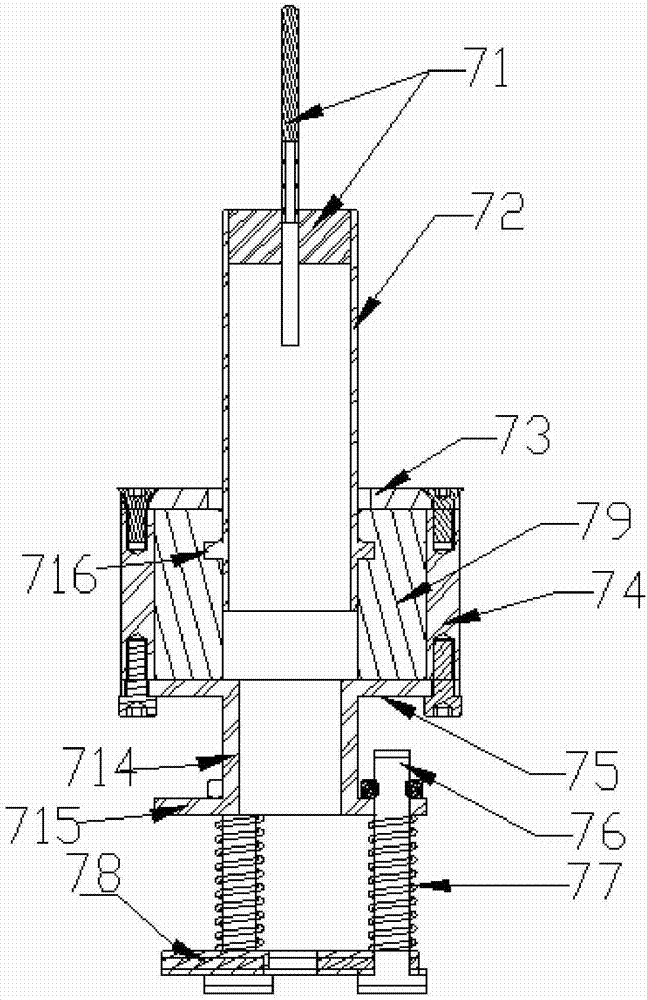

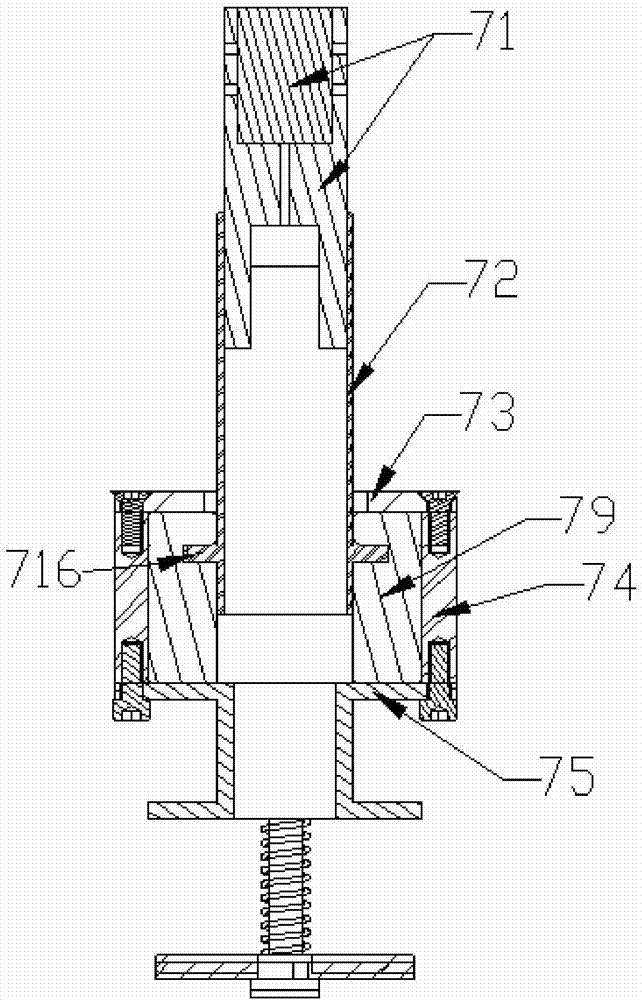

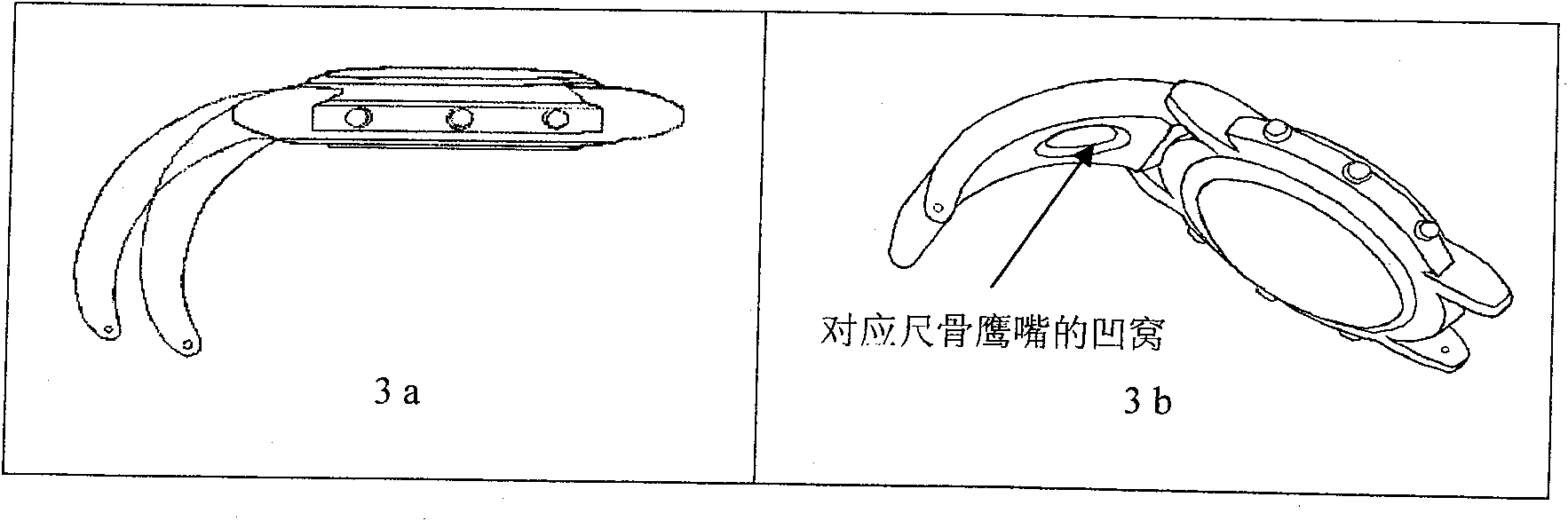

Robot for detecting cotter pin of control rod guide tube and locating method

ActiveCN107731329AOvercoming Visuospatial EffectsPrecise positioningNuclear energy generationNuclear monitoringUltrasound testAutomotive engineering

The invention discloses a robot for detecting a cotter pin of a control rod guide tube and a locating method. The robot comprises a vehicle body, a vertical lifting mechanism, a probe component, a video locating mechanism and a three-degree-of-freedom locating mechanism; the three-degree-of-freedom locating mechanism comprises a theta-axis drive mechanism, a Y-axis drive mechanism and an X-axis drive mechanism, the vertical lifting mechanism is installed on the X-axis drive mechanism, the theta-axis drive mechanism is installed on the vertical lifting mechanism, the probe component is installed on the theta-axis drive mechanism, the drive direction of the X-axis drive mechanism and the drive direction of the Y-axis drive mechanism are mutually vertical and are both parallel with the upperend face of the vehicle body, the theta-axis drive mechanism drives the probe component to rotate, and the vertical lifting mechanism is vertical to the upper end face of the vehicle body. The robot overcomes the influence of the limited visual space, realizes accurate locating, provides certain flexibility, and can self-adapt to the locating error and the installation error, and the constant contact pressure between the cotter pin and a probe chip is favorable for the repeatability of the ultrasonic examination.

Owner:CGNPC INSPECTION TECH +3

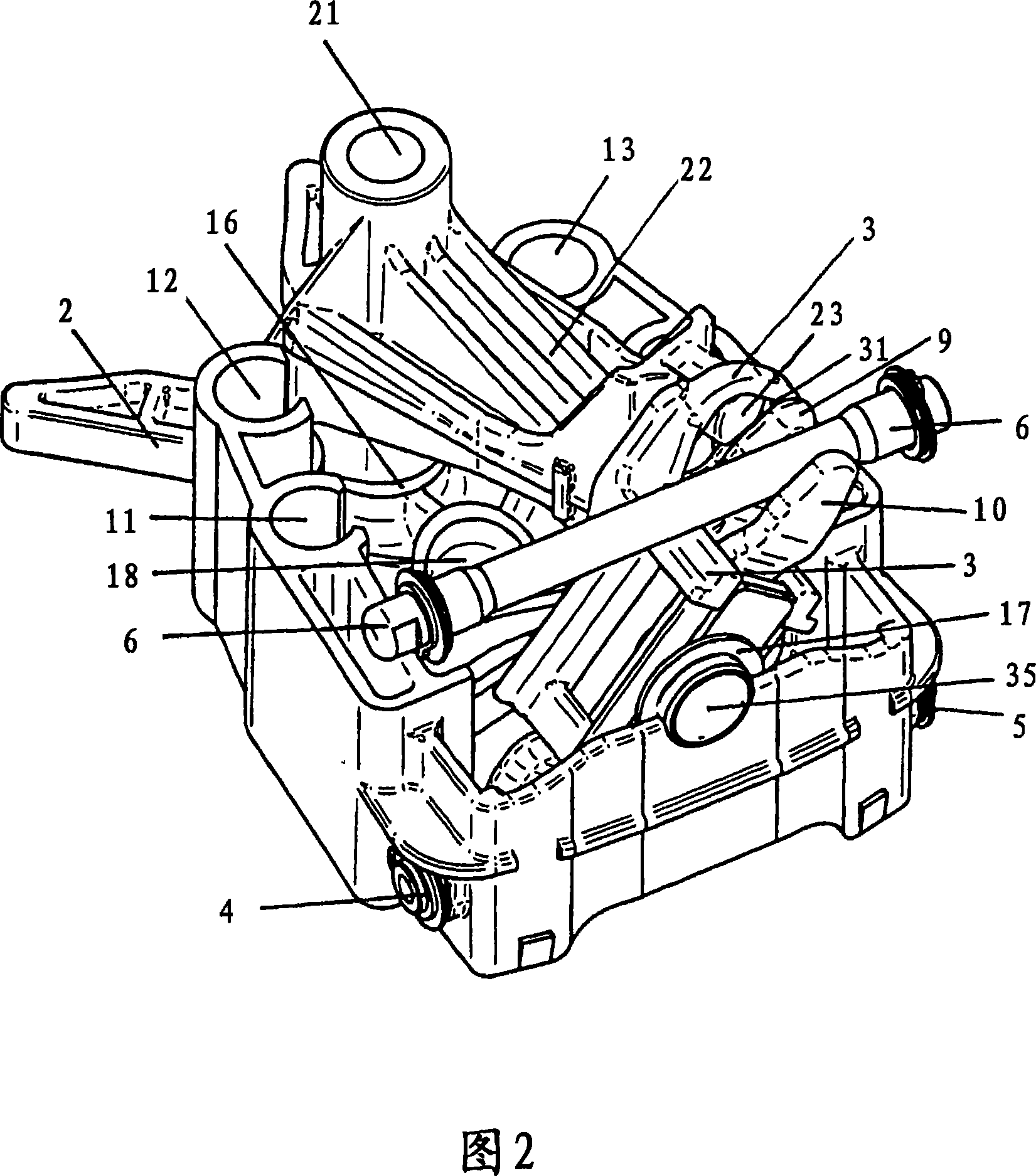

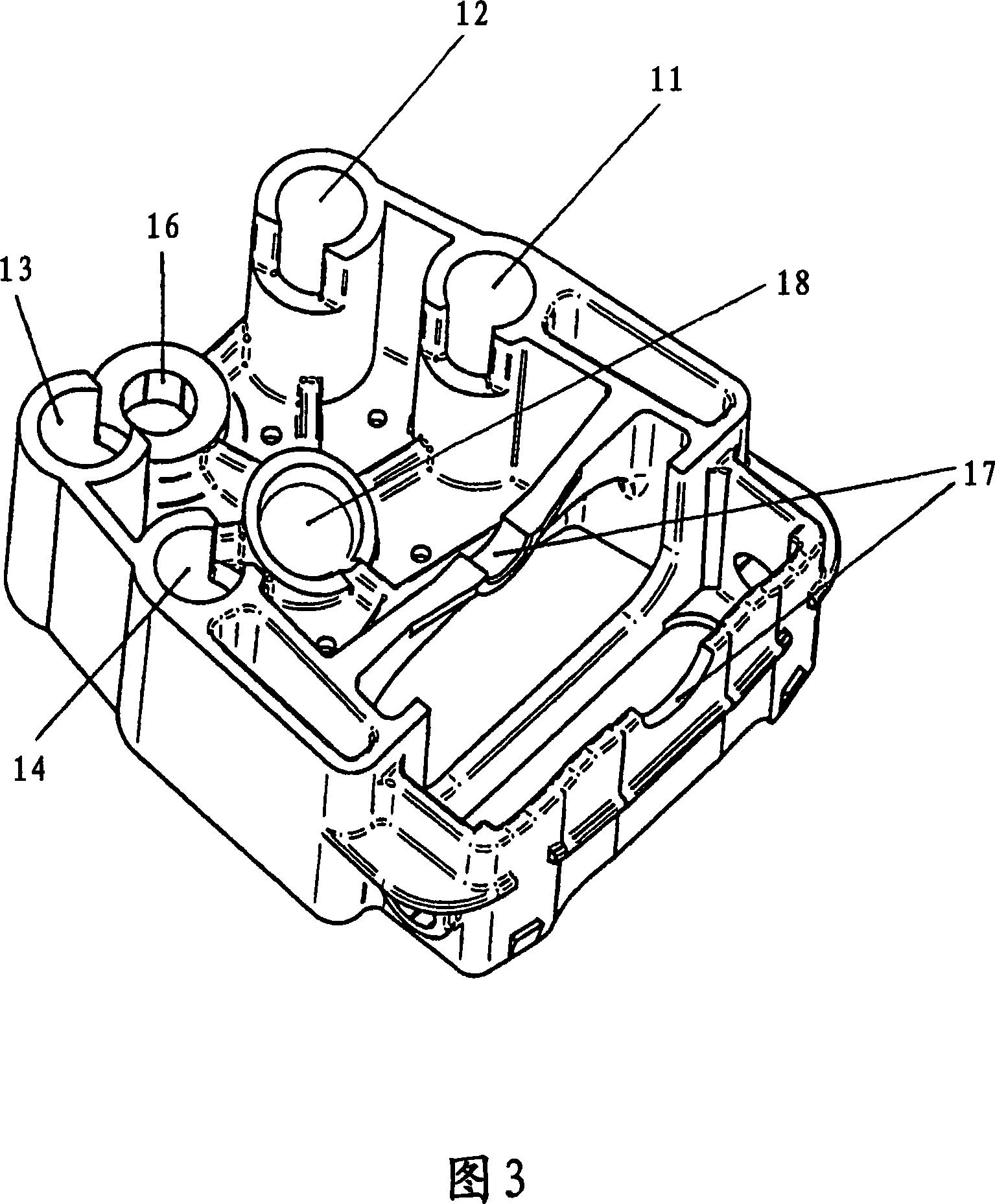

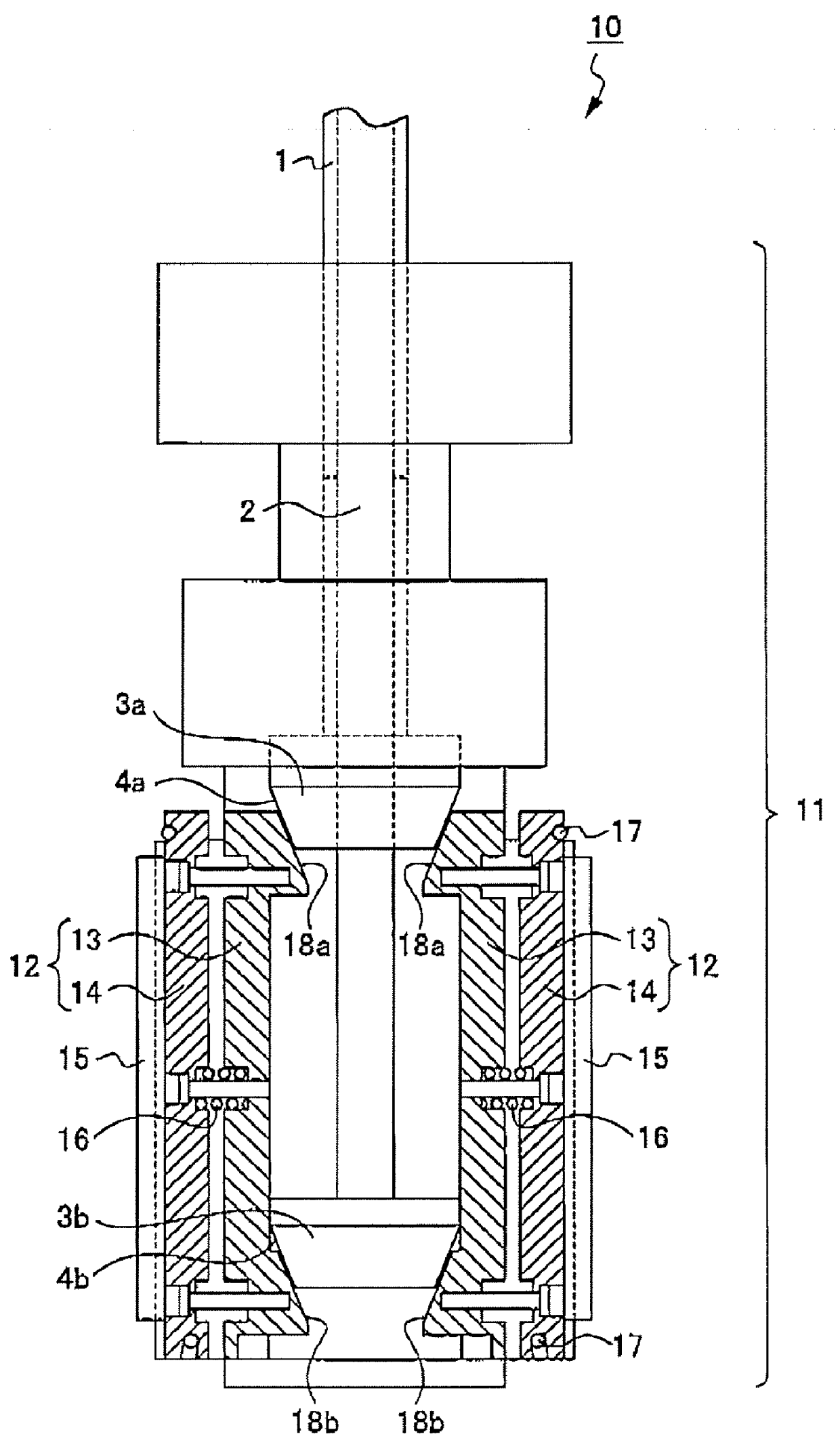

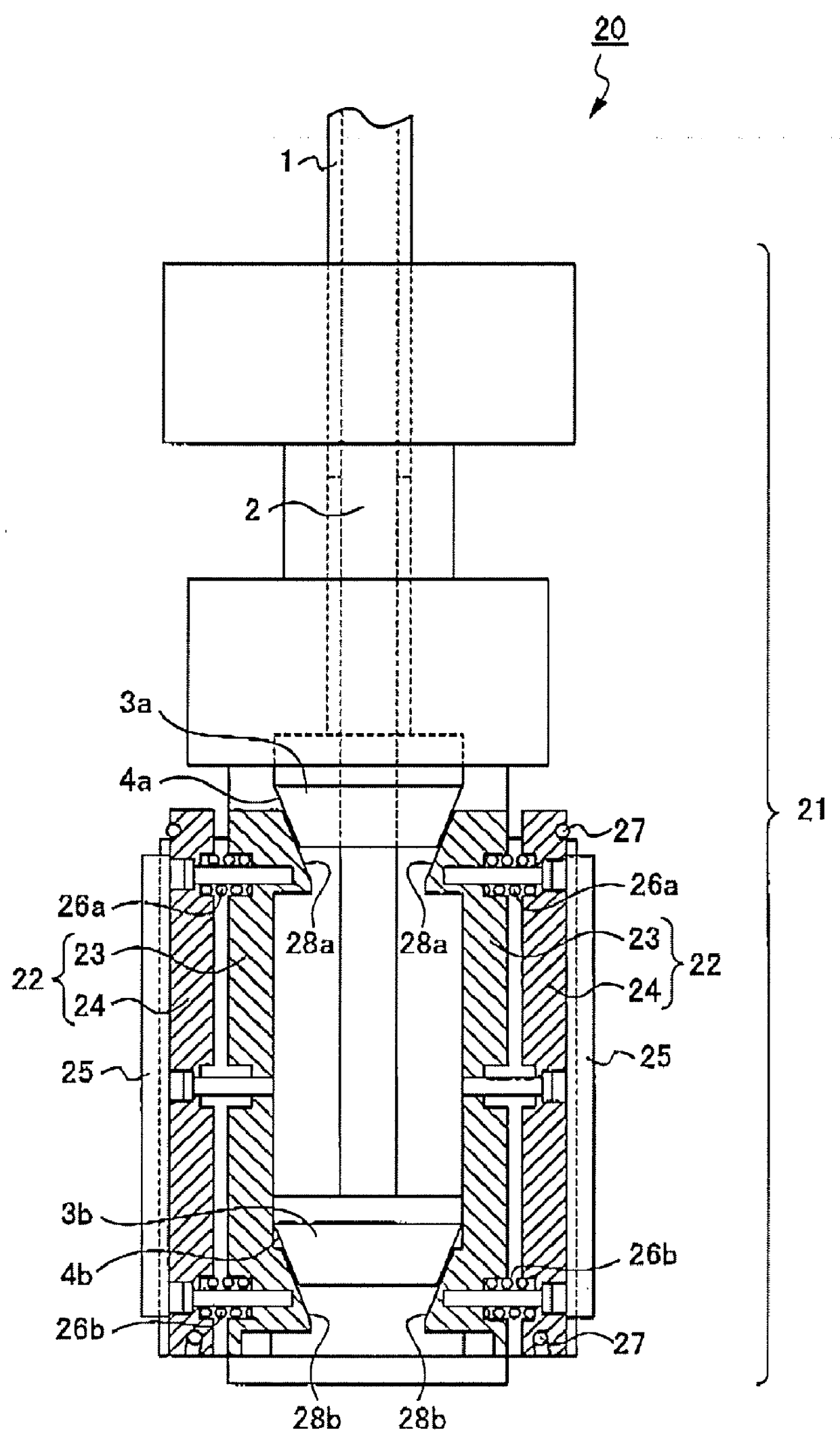

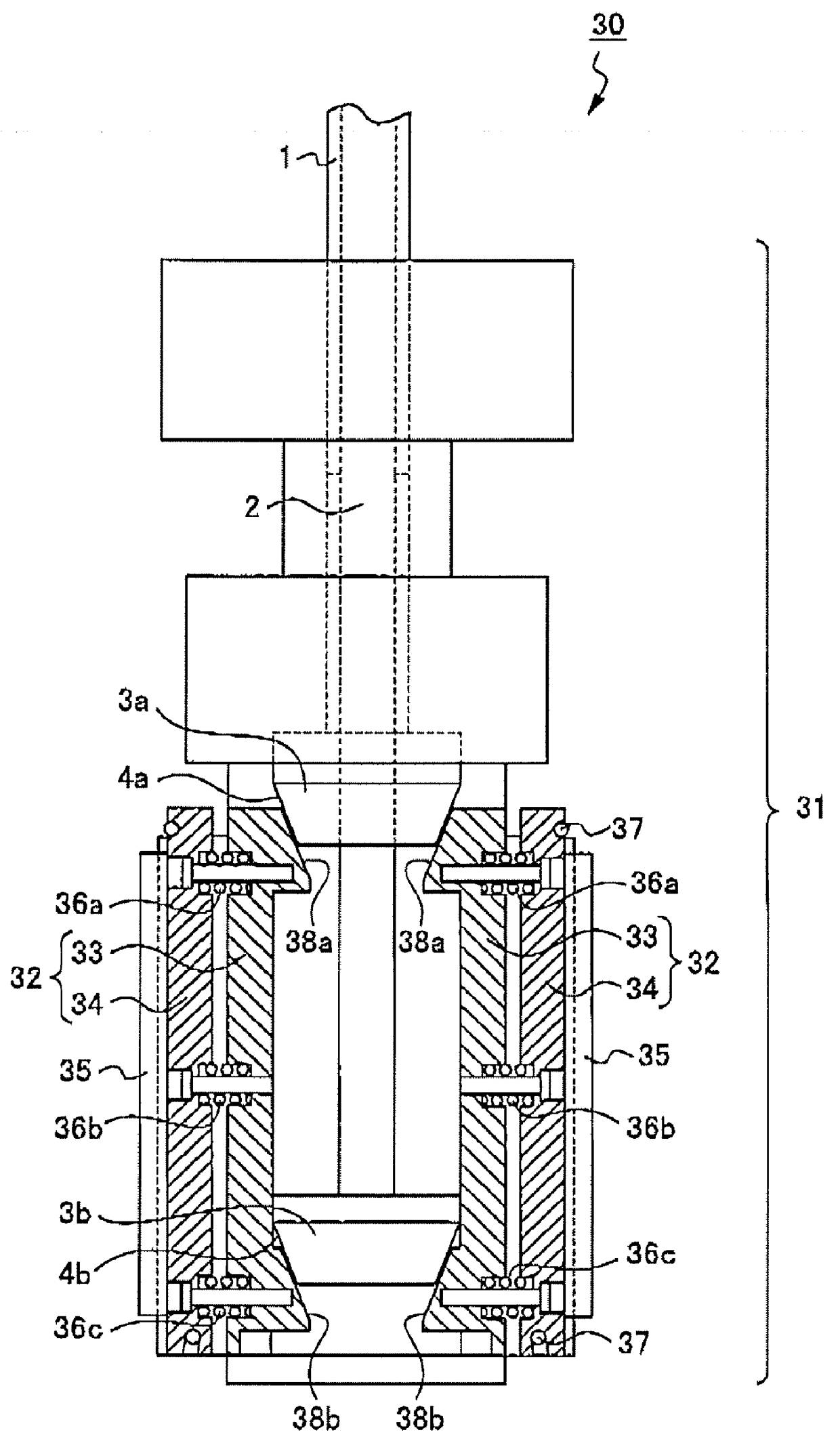

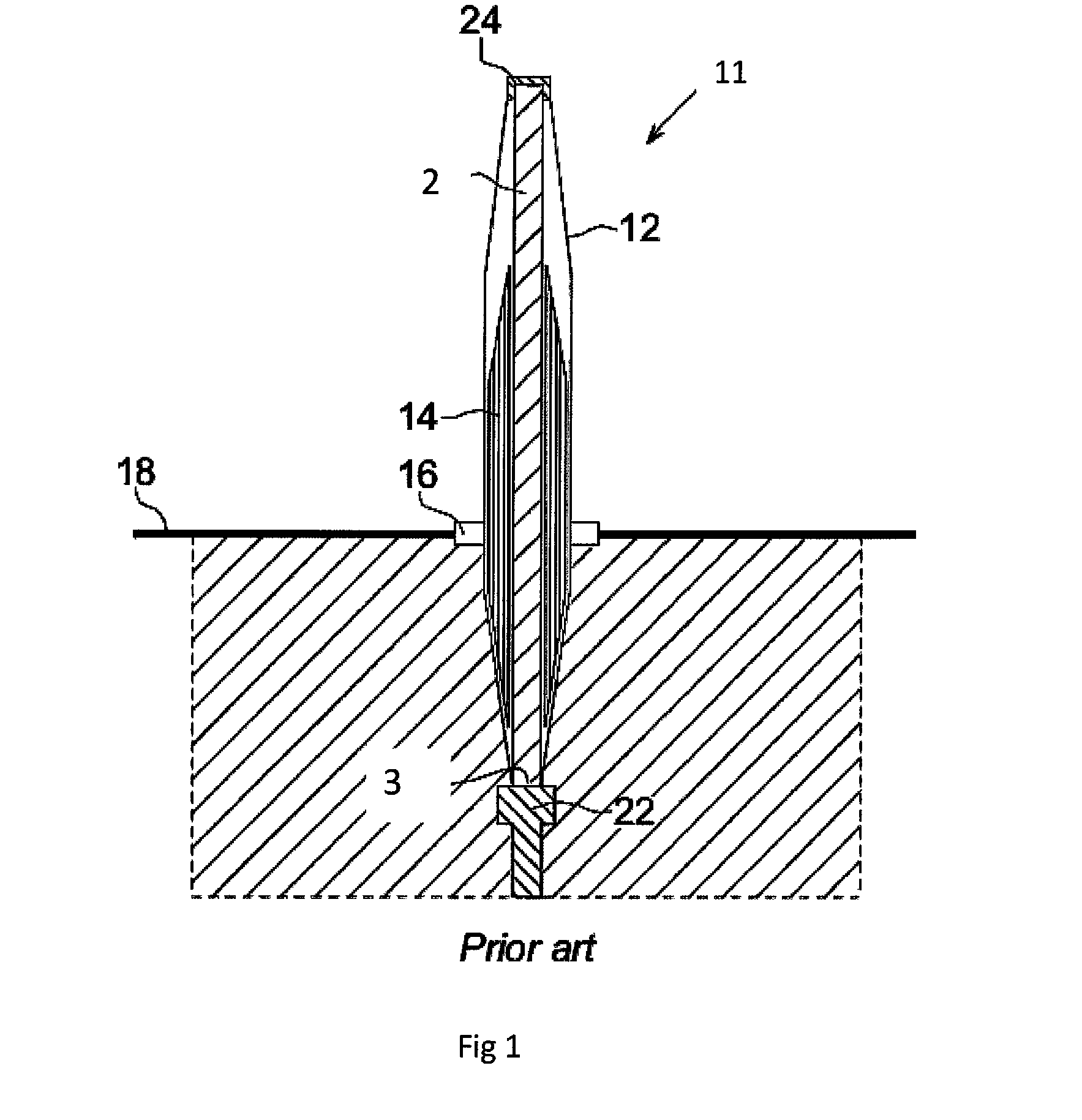

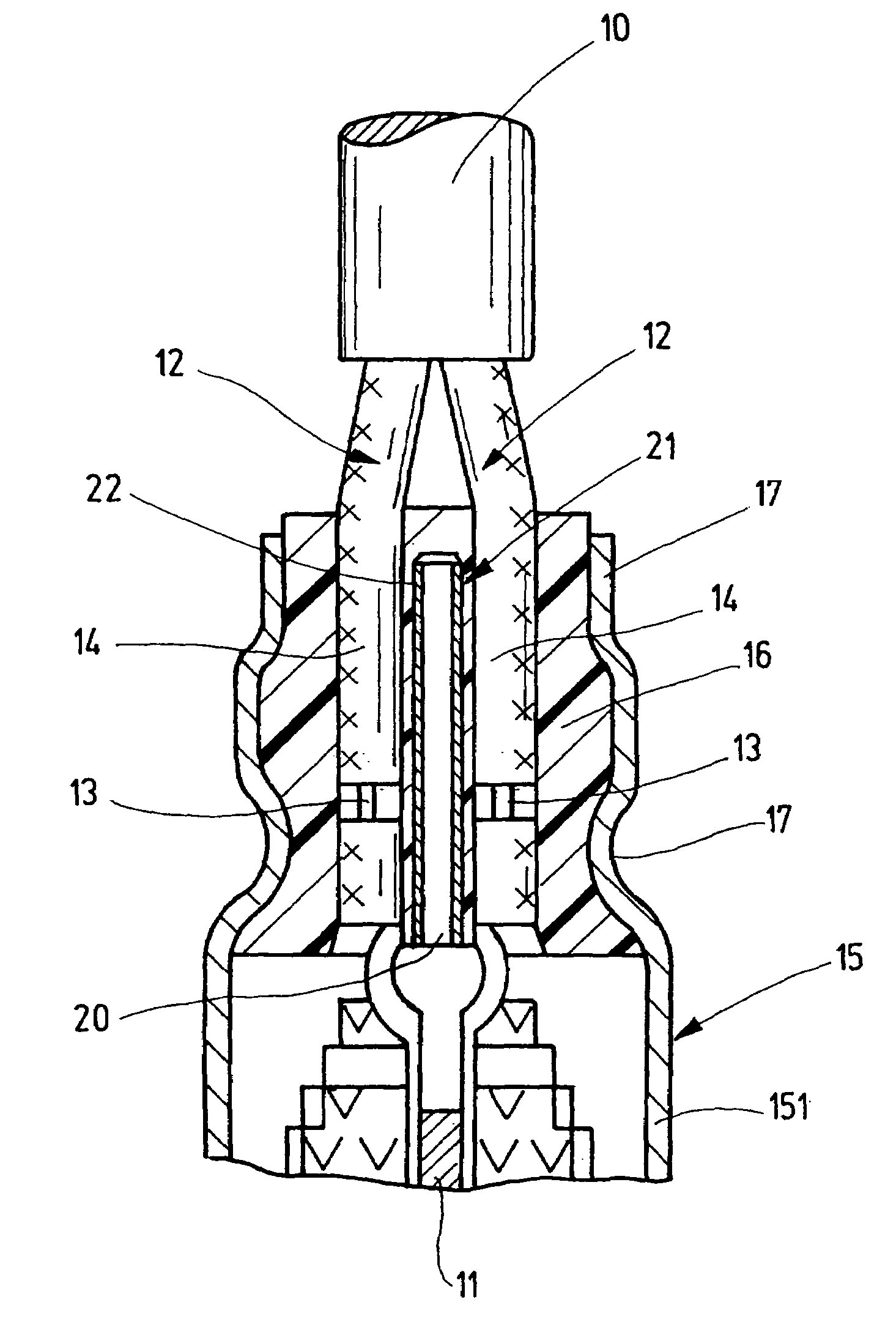

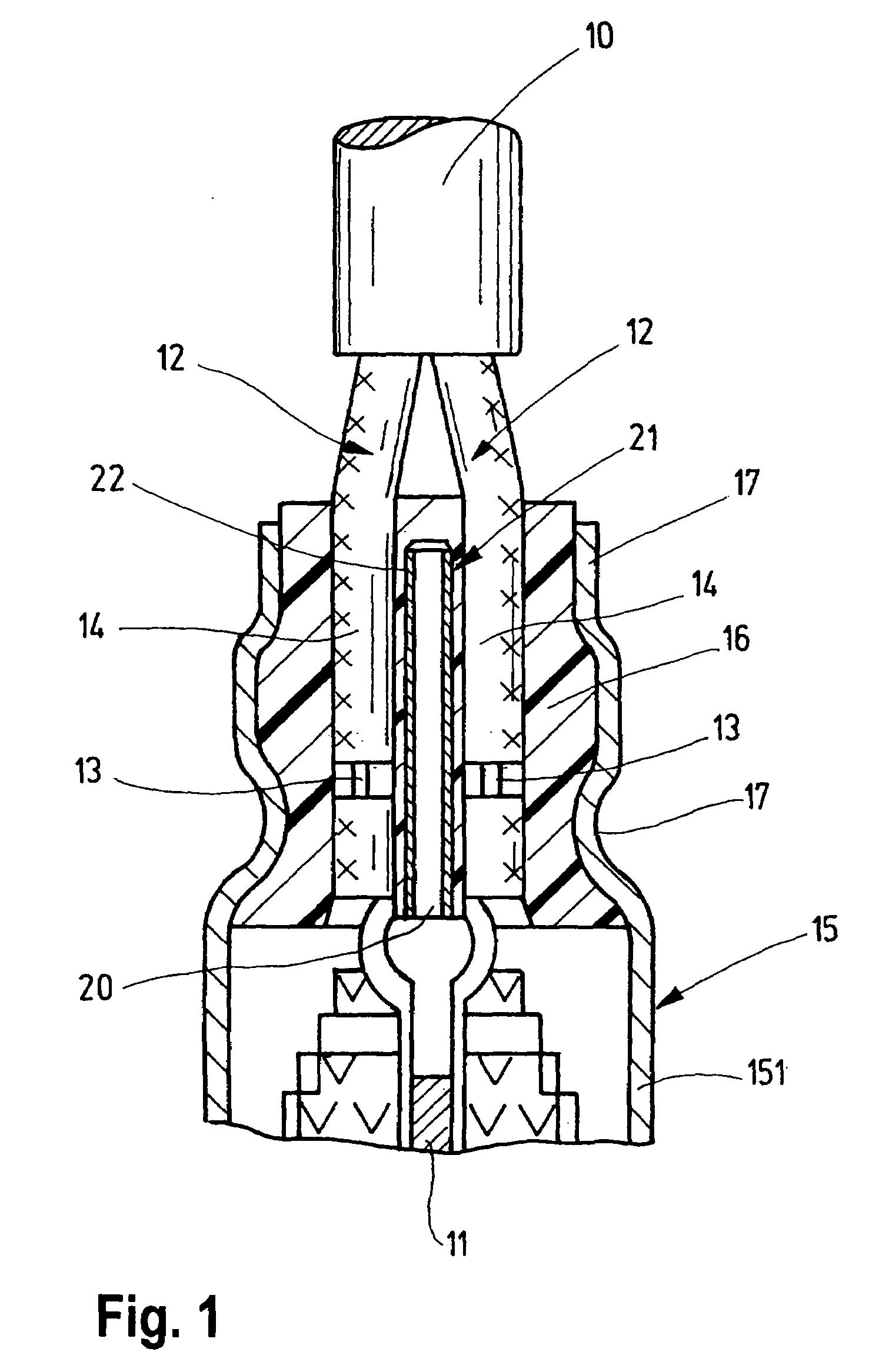

Homopolar machine with improved brush lifetime

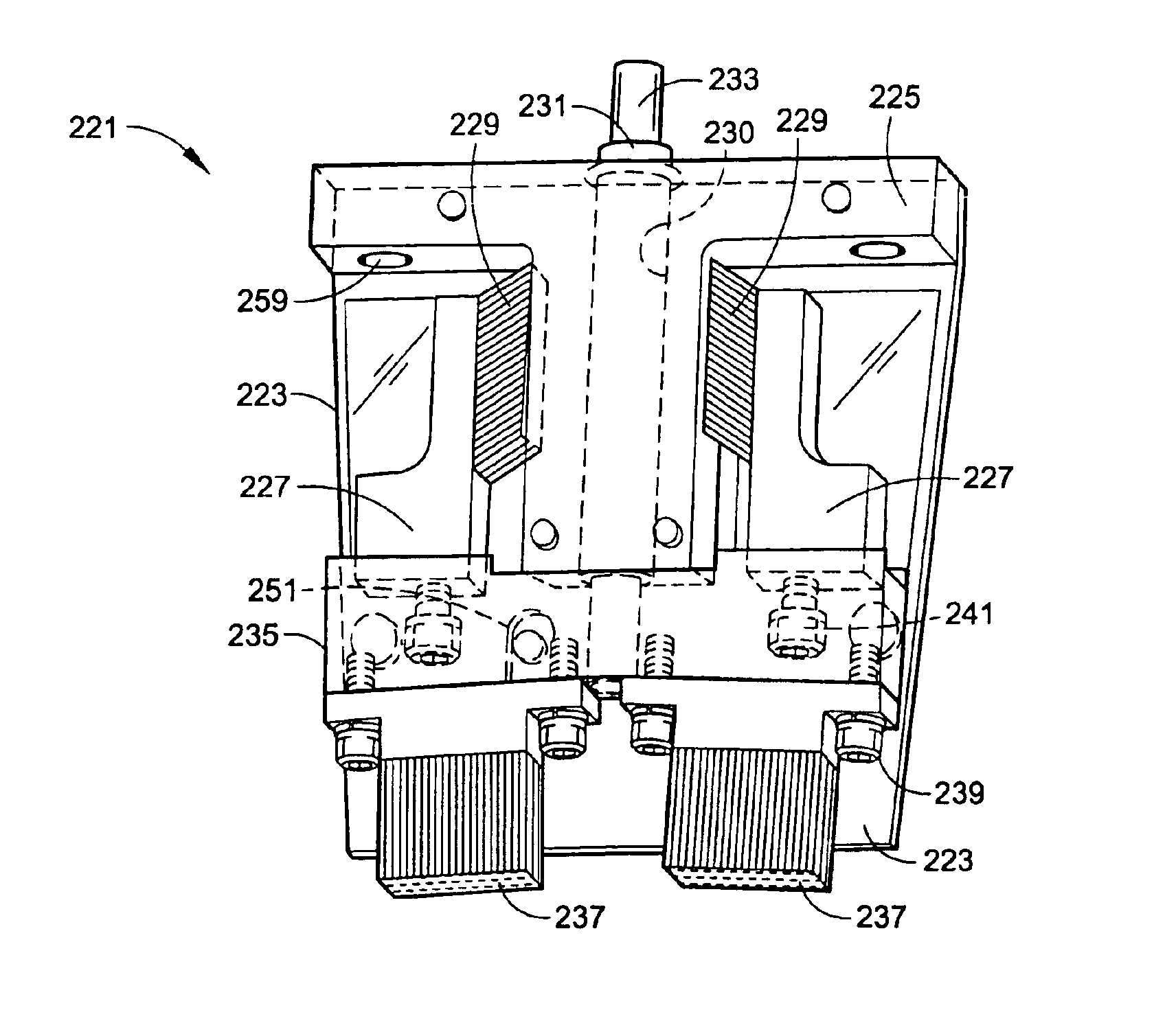

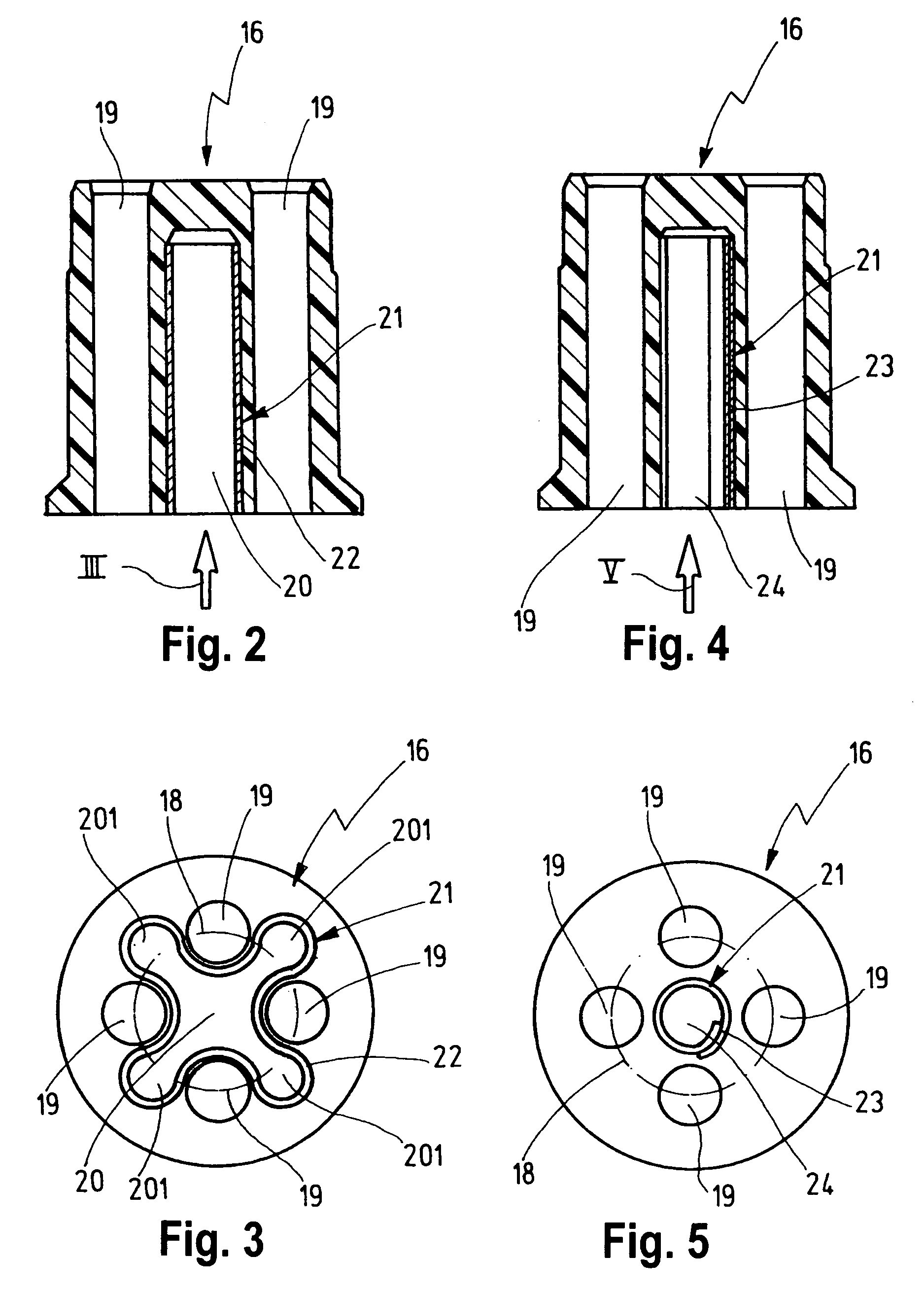

InactiveUS20050077795A1Reduce stepsImprove reliabilityRotary current collectorAcyclic motorsMagnetic tension forceContact pressure

A homopolar machine which exhibits reduced wear and prolonged brush life. Current collectors or brushes are mounted so as to maintain substantially constant contact pressure and so that all of them are polarized negative. Brush holders are provided which facilitate the application of precise and constant contact pressure in a region of very high magnetic forces.

Owner:GENERAL ATOMICS

Homopolar machine with improved brush lifetime

InactiveUS6873078B1Reduce stepsImprove reliabilityRotary current collectorAcyclic motorsMagnetic tension forceContact pressure

A homopolar machine which exhibits reduced wear and prolonged brush life. Current collectors or brushes are mounted so as to maintain substantially constant contact pressure and so that all of them are polarized negative. Brush holders are provided which facilitate the application of precise and constant contact pressure in a region of very high magnetic forces.

Owner:GENERAL ATOMICS

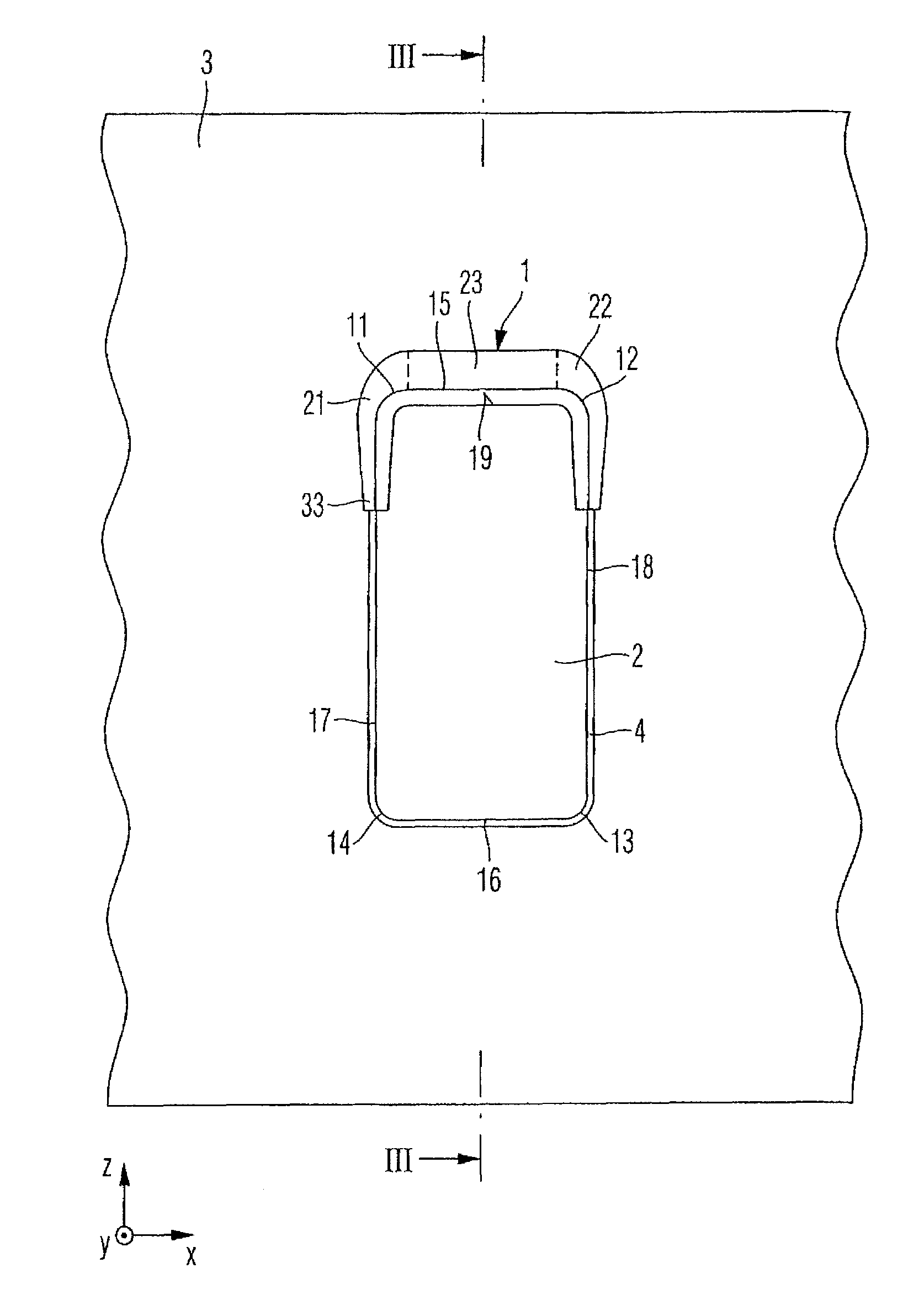

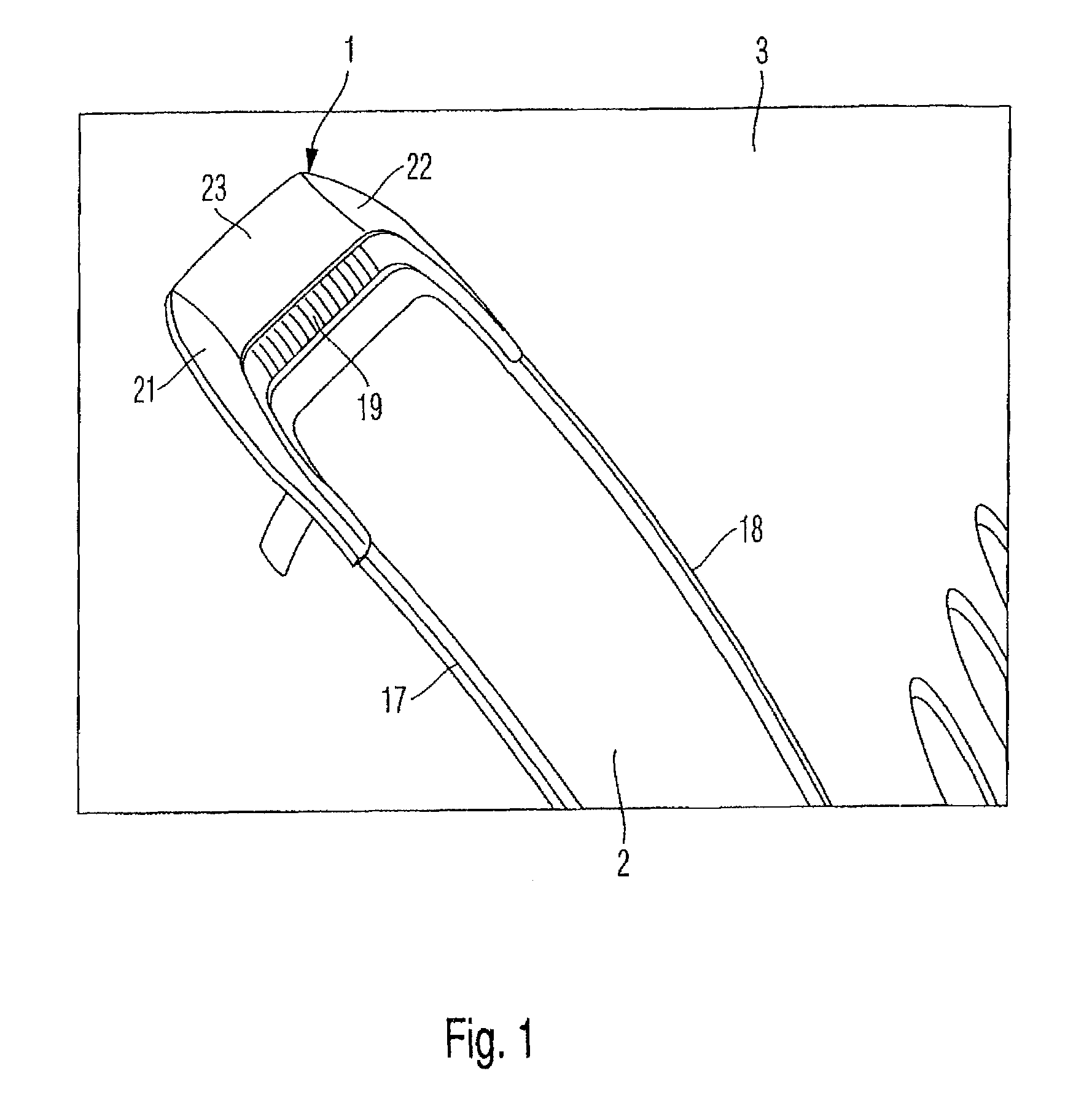

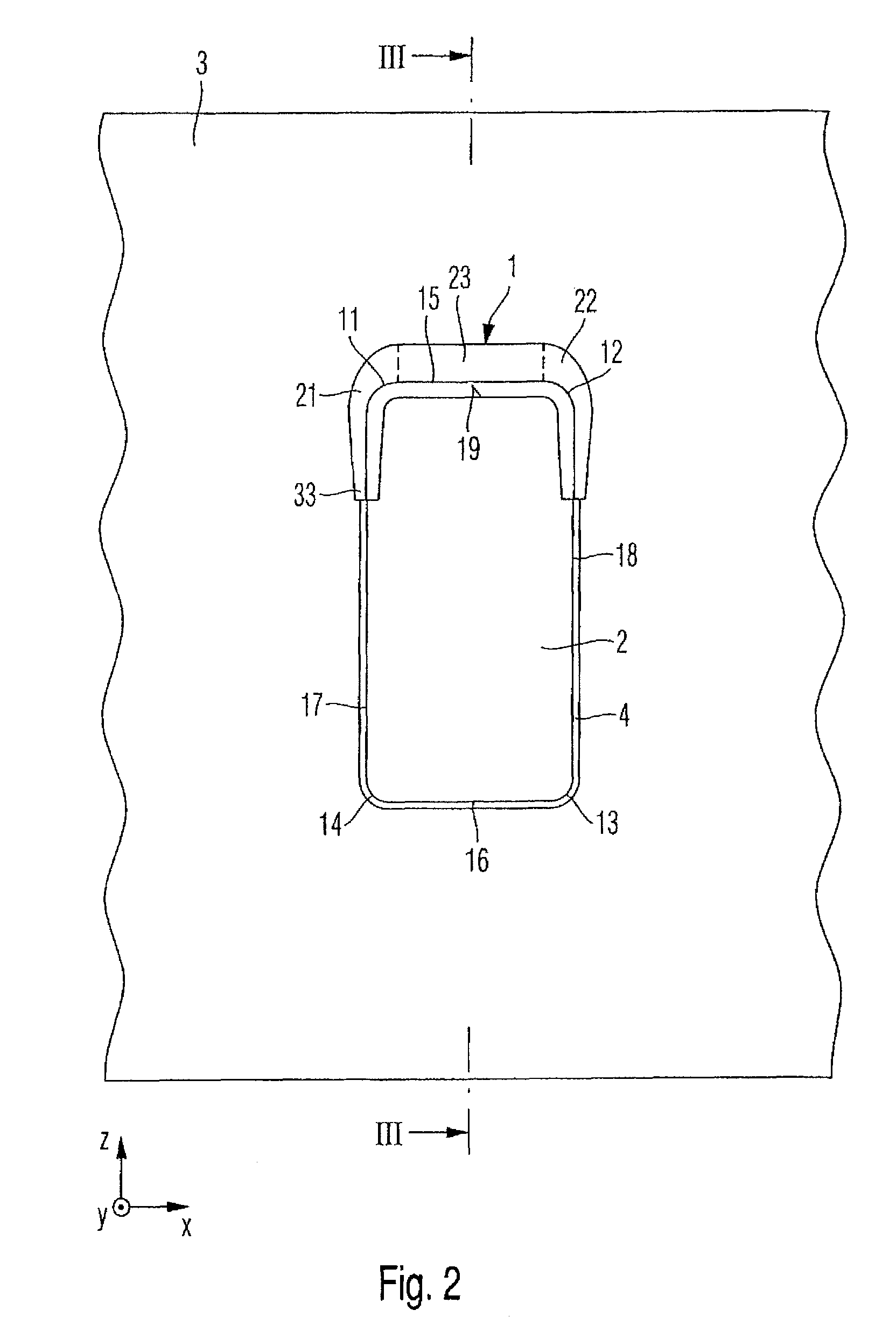

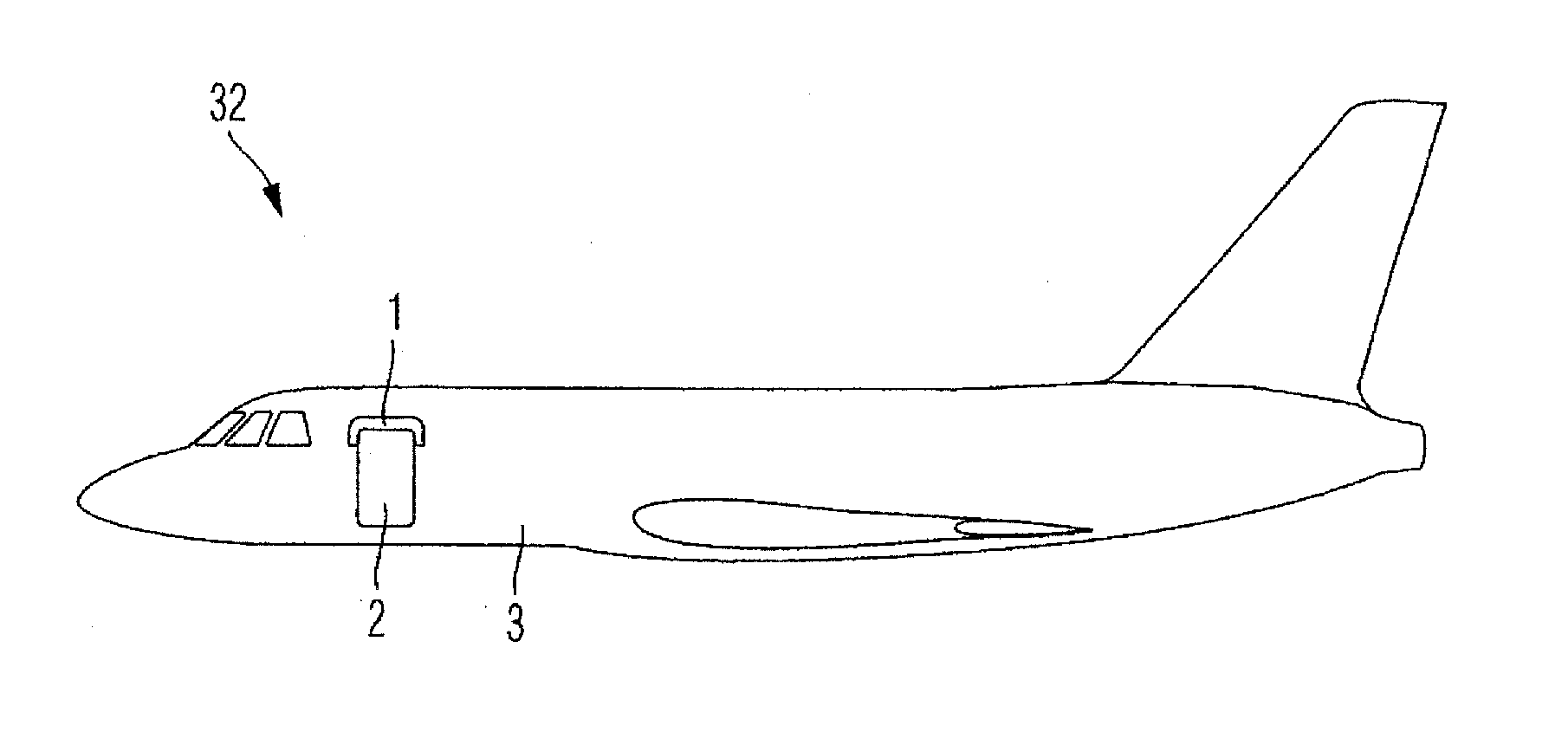

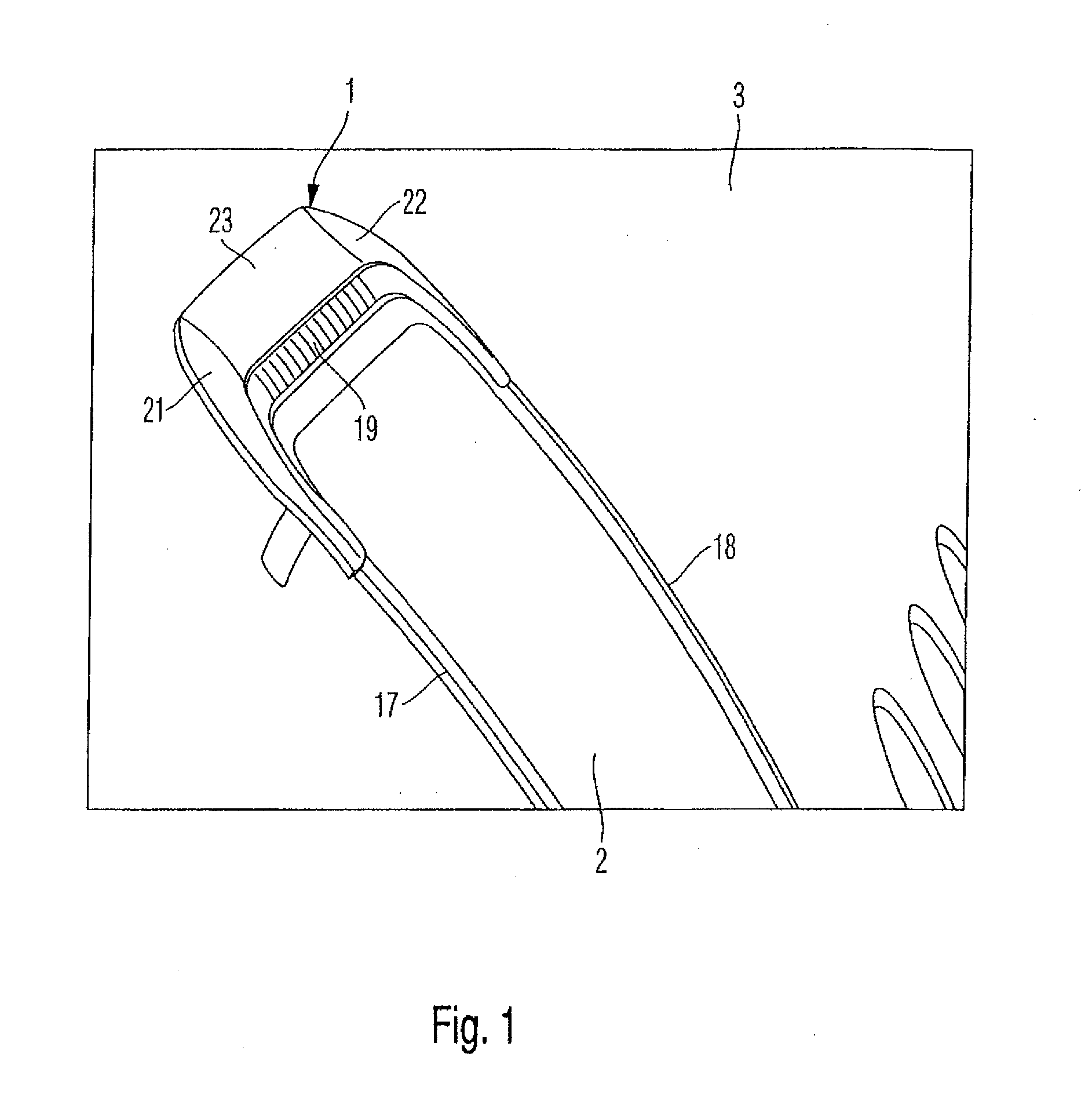

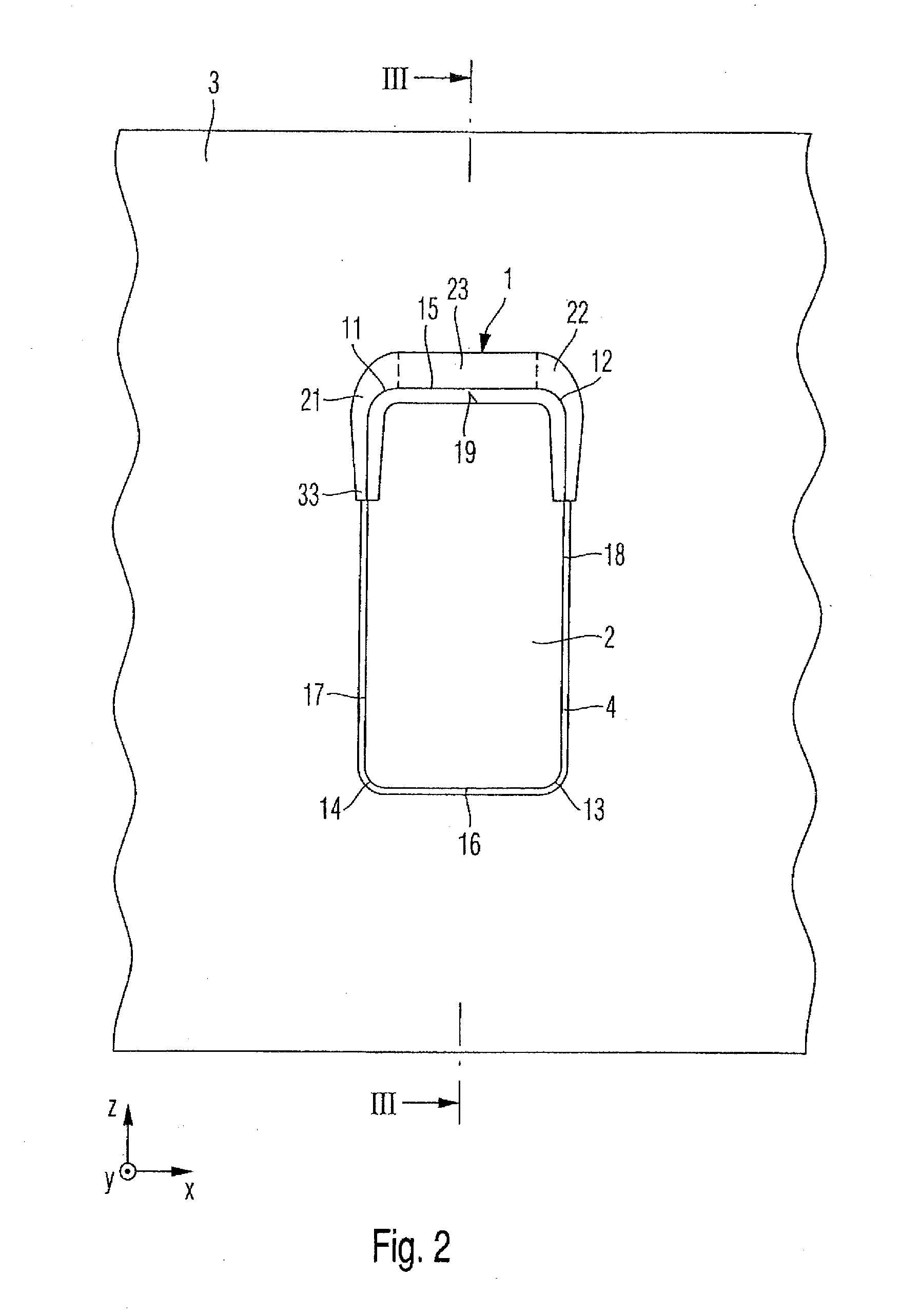

Cover plate, door covering and aircraft or spacecraft

InactiveUS8833700B2Avoid developmentConstant contact pressureAircraft doorsFuselagesContact pressureFuselage

The present invention provides a cover plate for covering at least portions of a door gap formed between a door covering and a fuselage cell of an aircraft or spacecraft, comprising: a fastening portion by which the cover plate can be mounted on an outer surface of the door covering; a contact portion which rests in a contacting manner against an outer skin of the fuselage cell when the door covering is closed; at least one corner portion associated with a corner of the door covering; and a side portion associated with a side of the door covering, the at least one corner portion and the side portion being configured to press the contact portion with a constant contact pressure against the outer skin of the fuselage cell when the door covering is closed. The present invention further provides a door covering for an access opening in a fuselage cell of an aircraft or spacecraft having a cover plate of this type as well as an aircraft or spacecraft having a cover plate of this type and / or having a door covering of this type.

Owner:AIRBUS OPERATIONS GMBH

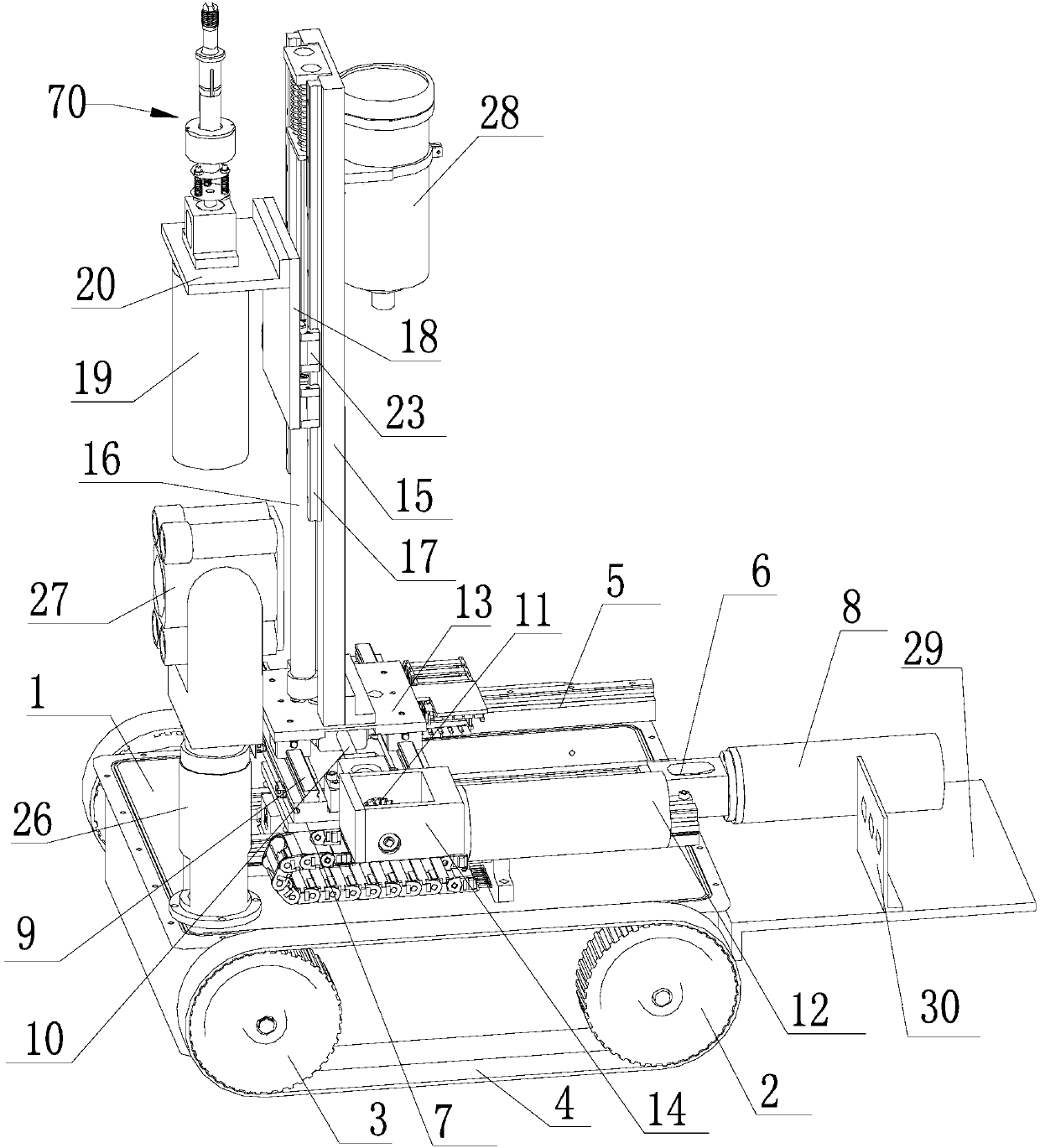

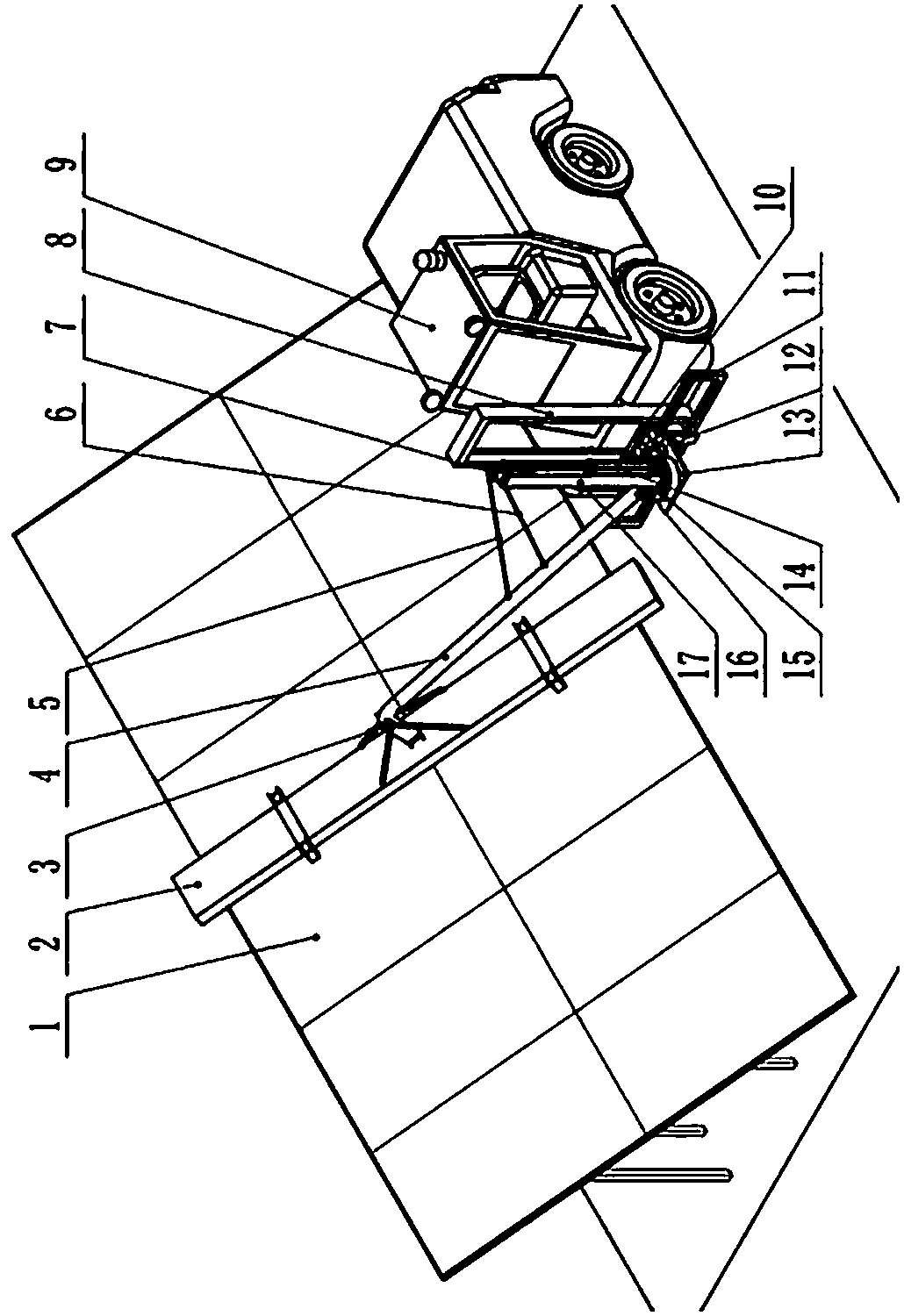

Efficient dust removal device for solar photovoltaic panel

ActiveCN111014105AClean thoroughlyClean and applicablePhotovoltaicsCleaning using toolsDust controlGas spring

The invention provides an efficient dust removal device for a solar photovoltaic panel. The front end of a vehicle body 9 is fixedly provided with a vertical moving guide rail 8, and a vertical sliding table 10 is installed in the vertical moving guide rail 8; a horizontal moving guide rail 11 is fixed to the vertical sliding table 10, and a horizontal sliding table 13 is installed in the horizontal moving guide rail 11; a rotary table 15 is installed on the horizontal sliding table 13, and a rotary oil cylinder 12, a gas spring 14, a hinged support 16, an upright column 17 and a lift cylinder18 are installed on the rotary table 15. A pulley 7 is installed on the top of the upright column 17, and a pulley 19 is installed on the portion, close to the top, of the side face of the upright column 17. The root of a transverse beam 4 is fixed to the hinged support 16, one end of a steel wire rope 5 is fixed to the transverse beam 4, and the other one penetrates through the pulley 7 to be fixed to the gas spring 14; one end of a steel wire rope 6 is fixed to the transverse beam 4, and the other end penetrates through the pulley 19 to be fixed to the lift cylinder 18; a cleaning brush 2 is fixed to the transverse beam 4 through a universal hinge 20, one end of a balance spring 3 is fixed to the transverse beam 4, and the other end of the balance spring 3 is fixe to the cleaning brush.

Owner:兰州瑞科新能源装备有限公司

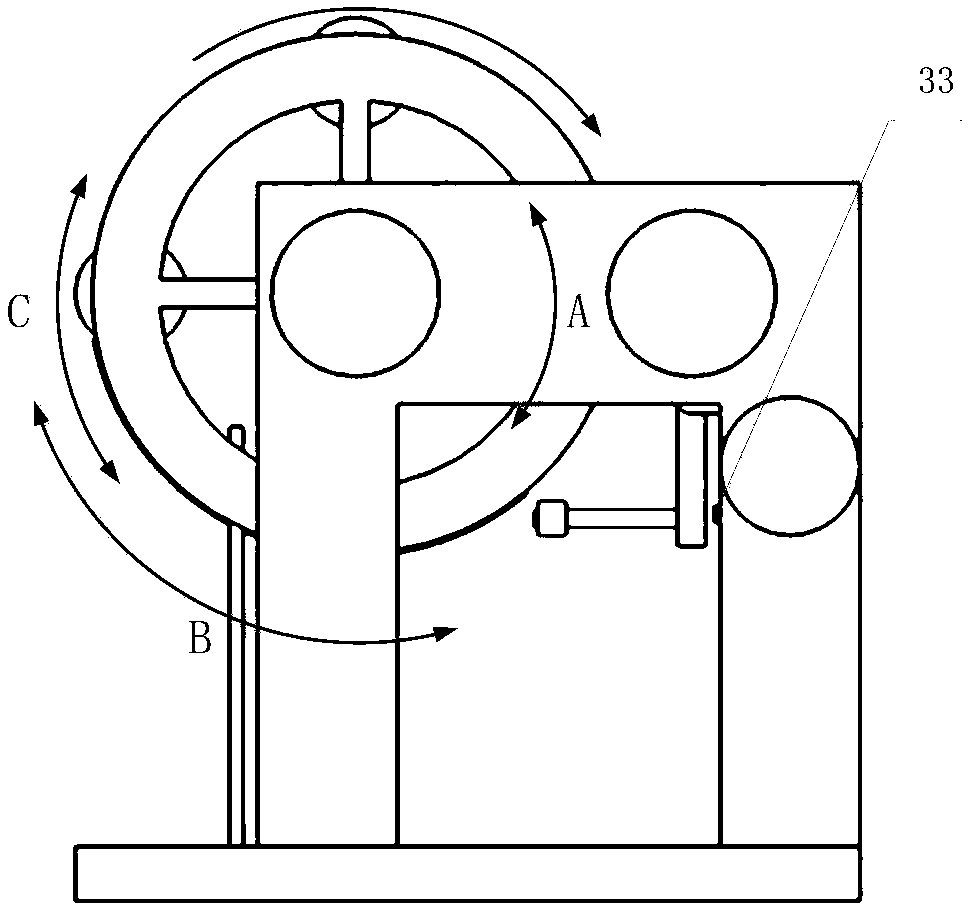

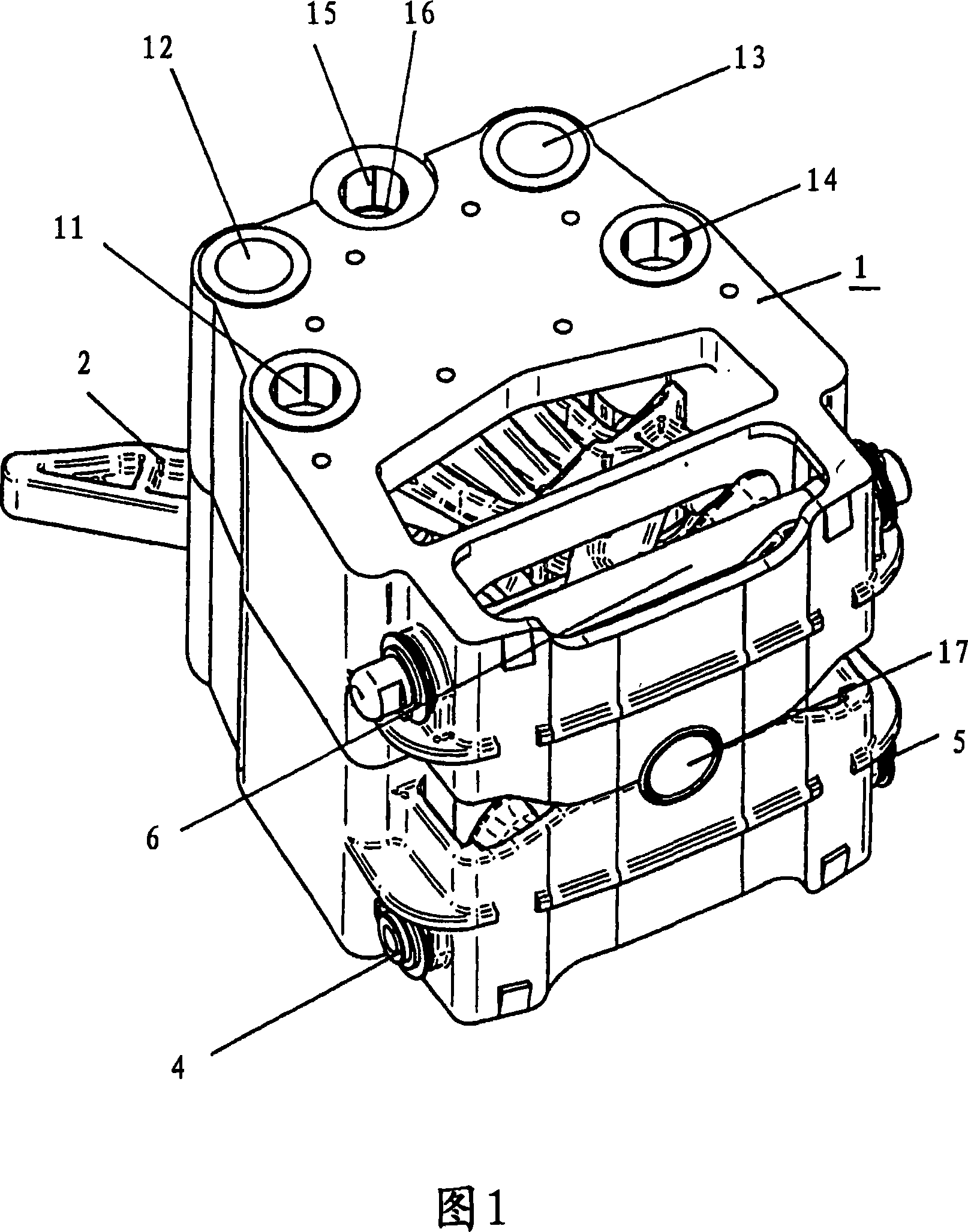

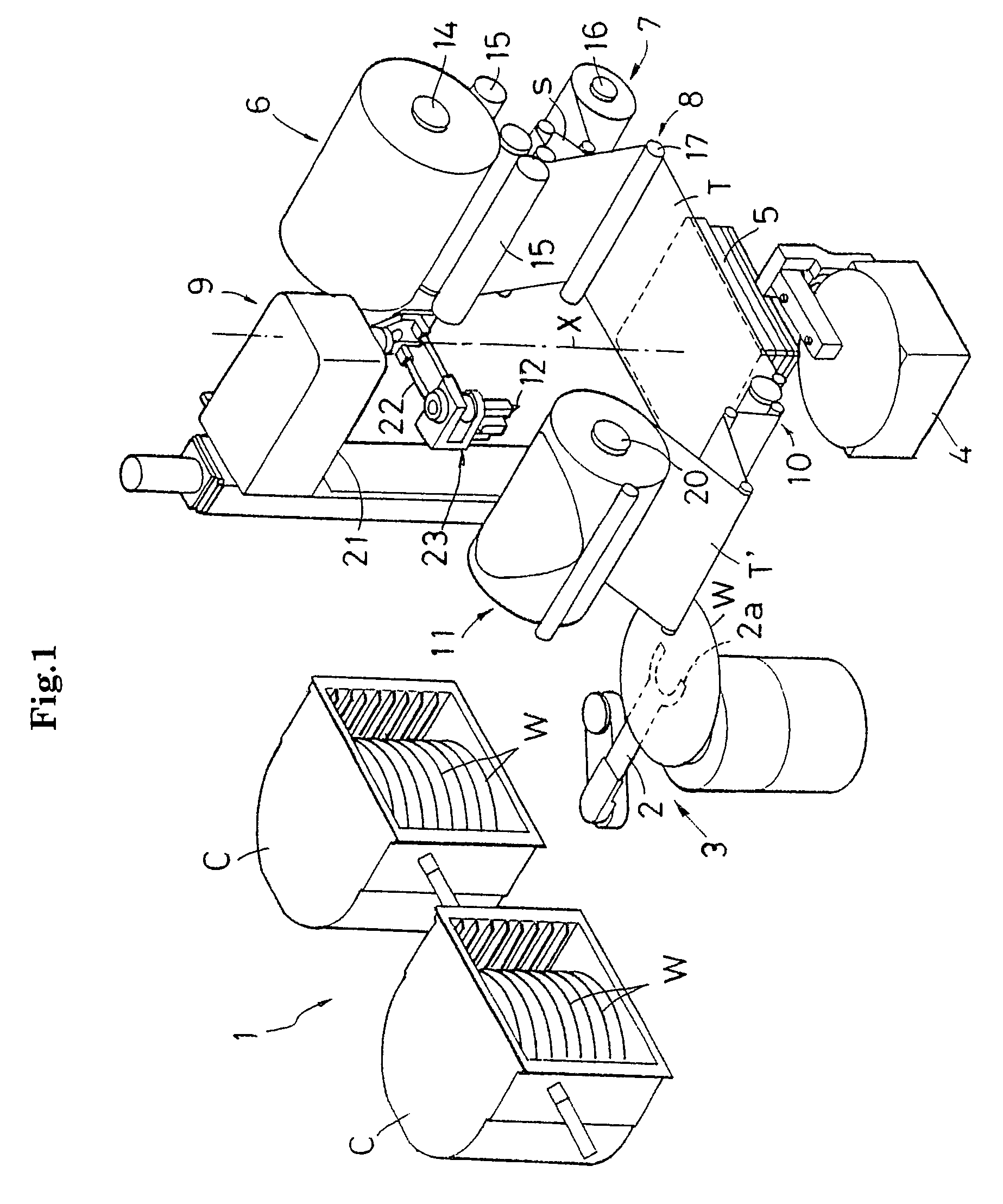

Use method of automatic peeling machine

ActiveCN108338374AConstant contact pressureStable peeling thicknessVegetable peelingQuincunxEngineering

The invention discloses a use method of an automatic peeling machine. The use method specifically comprises the following steps of: 1. performing feeding: in a feeding area C, placing materials between a core clamper and a quincunx core clamper, and tightly clamping the materials under the effect of axial elastic force generated when elastically expanding, contracting and rotating the quincunx core clamper in the axial direction; 2. performing transportation: using a feeding and discharging device to drive the materials to rotate to a peeling area A; 3. performing peeling; 4. performing outputof the materials; and 5. performing re-feeding and recycling the steps of 1-5. Through the adoption of the use method, labor intensity is reduced, work efficiency is improved, and automatic production of peeling materials such as roots, stems and fruits is achieved.

Owner:DALIAN UNIVERSITY

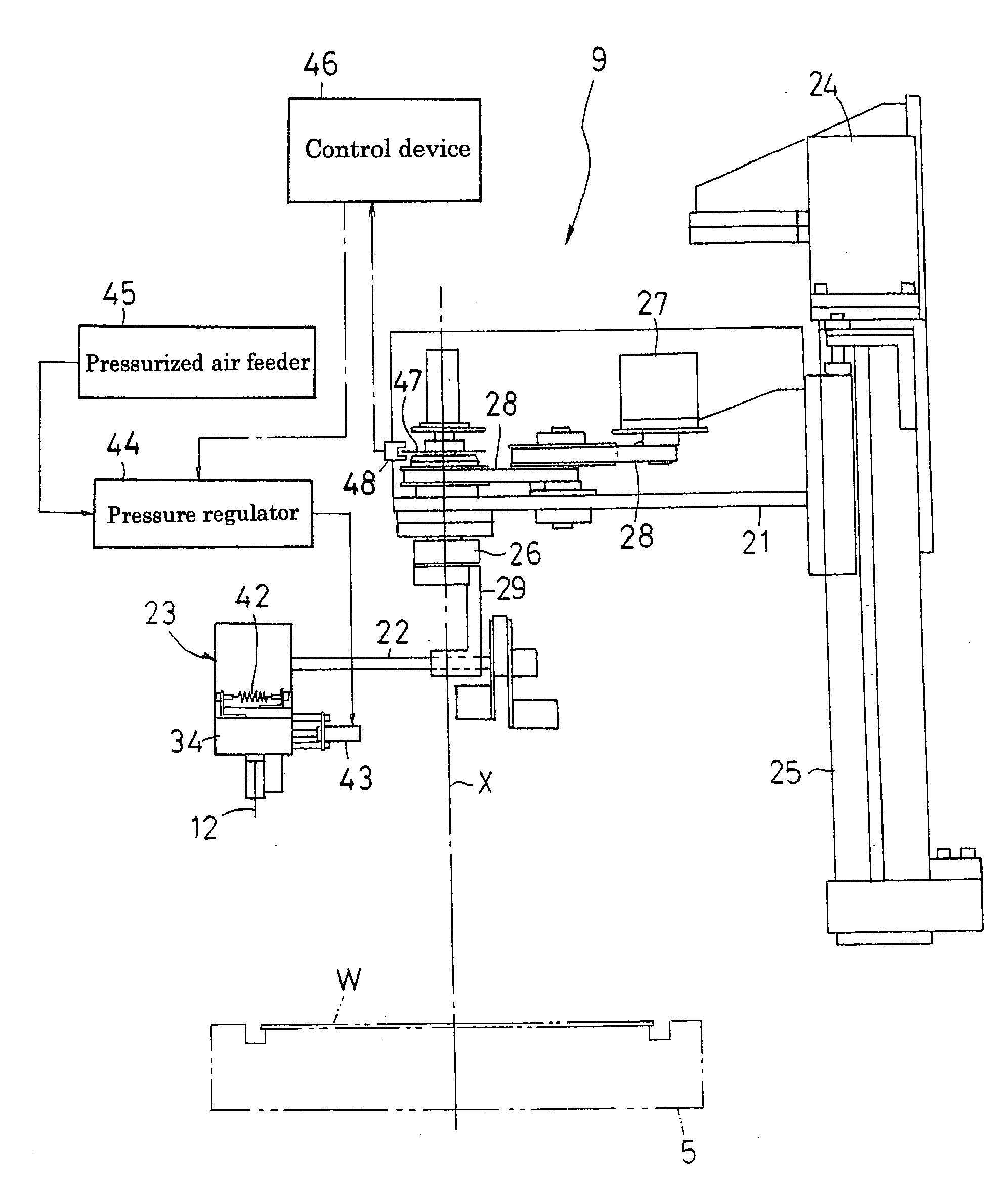

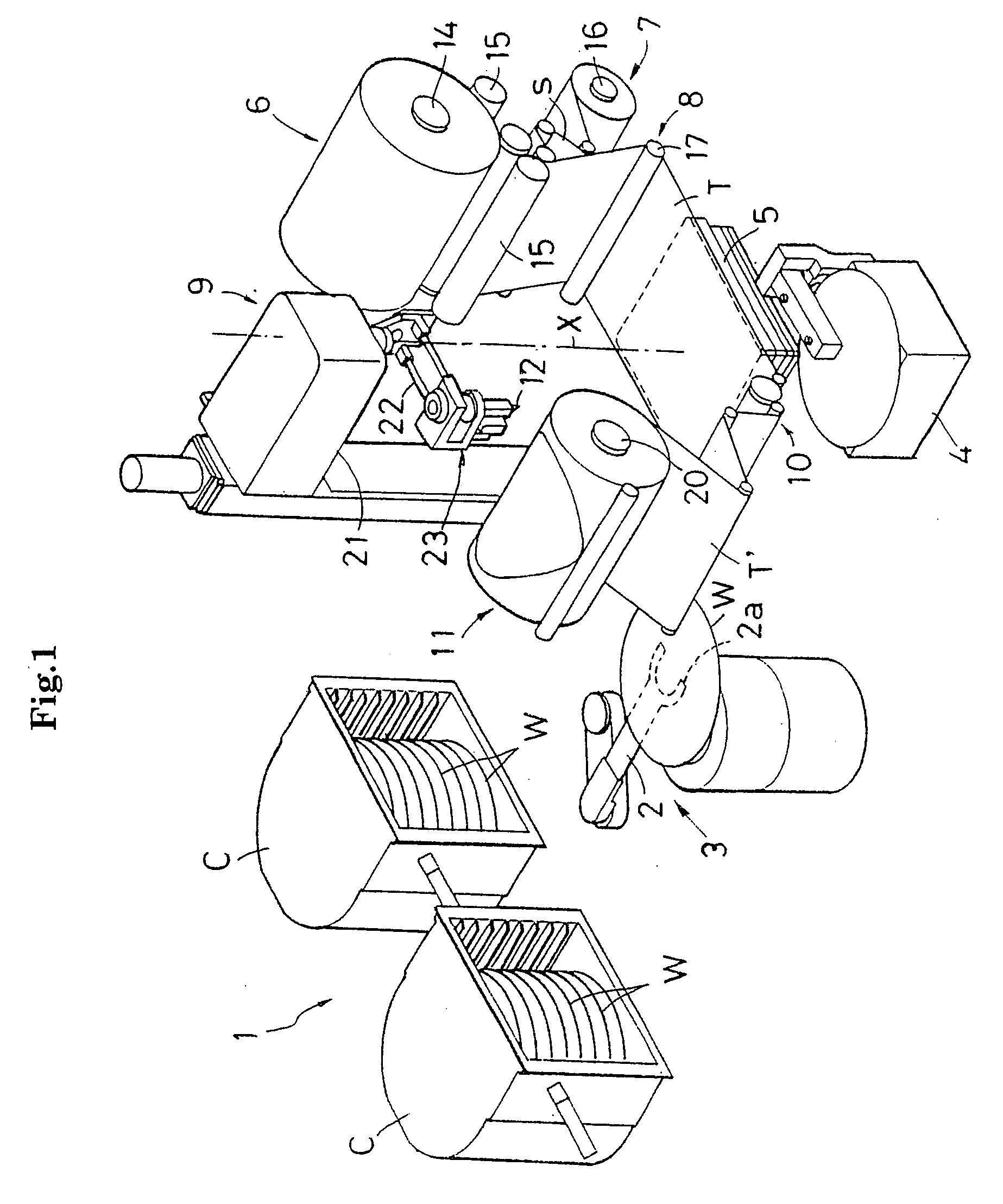

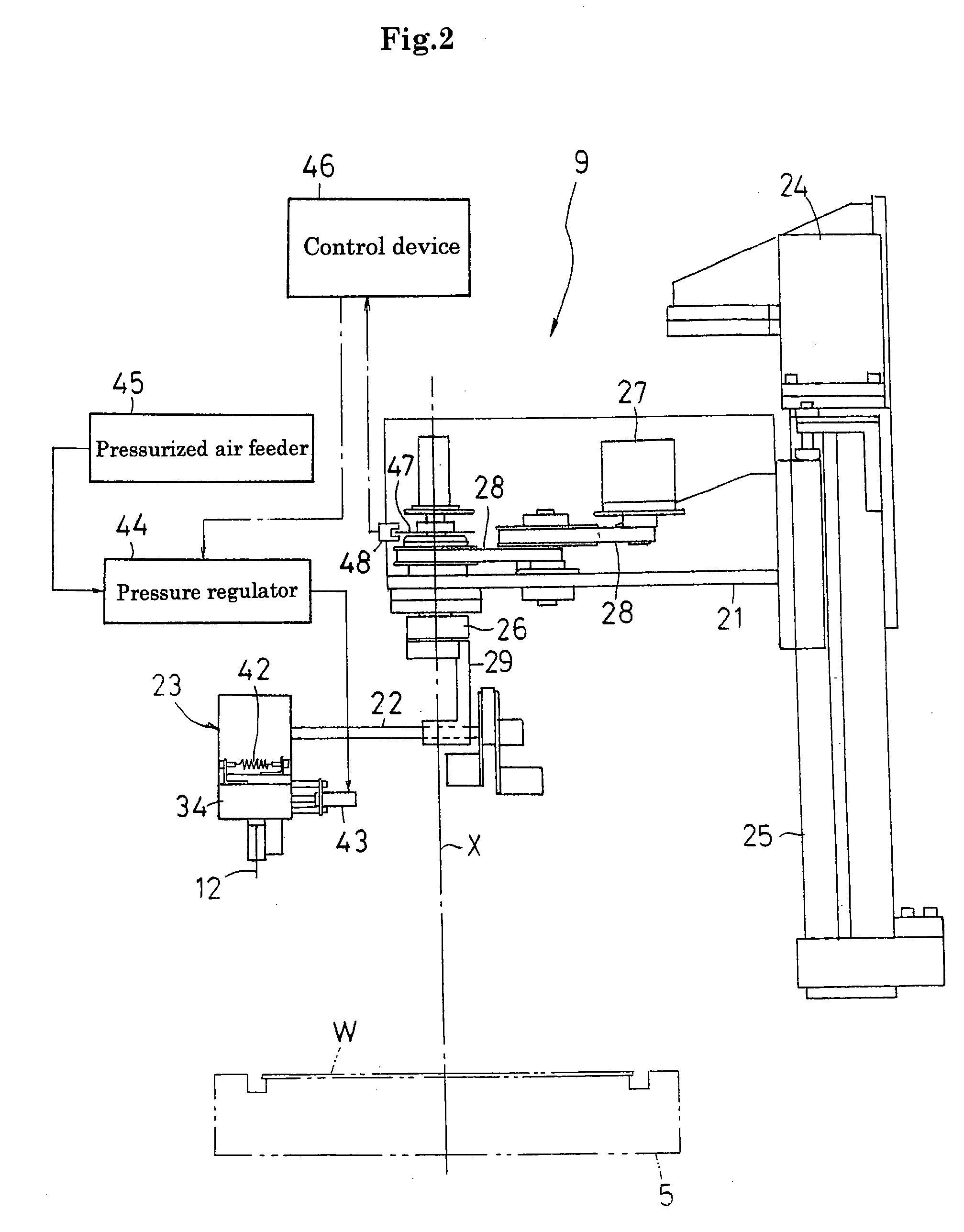

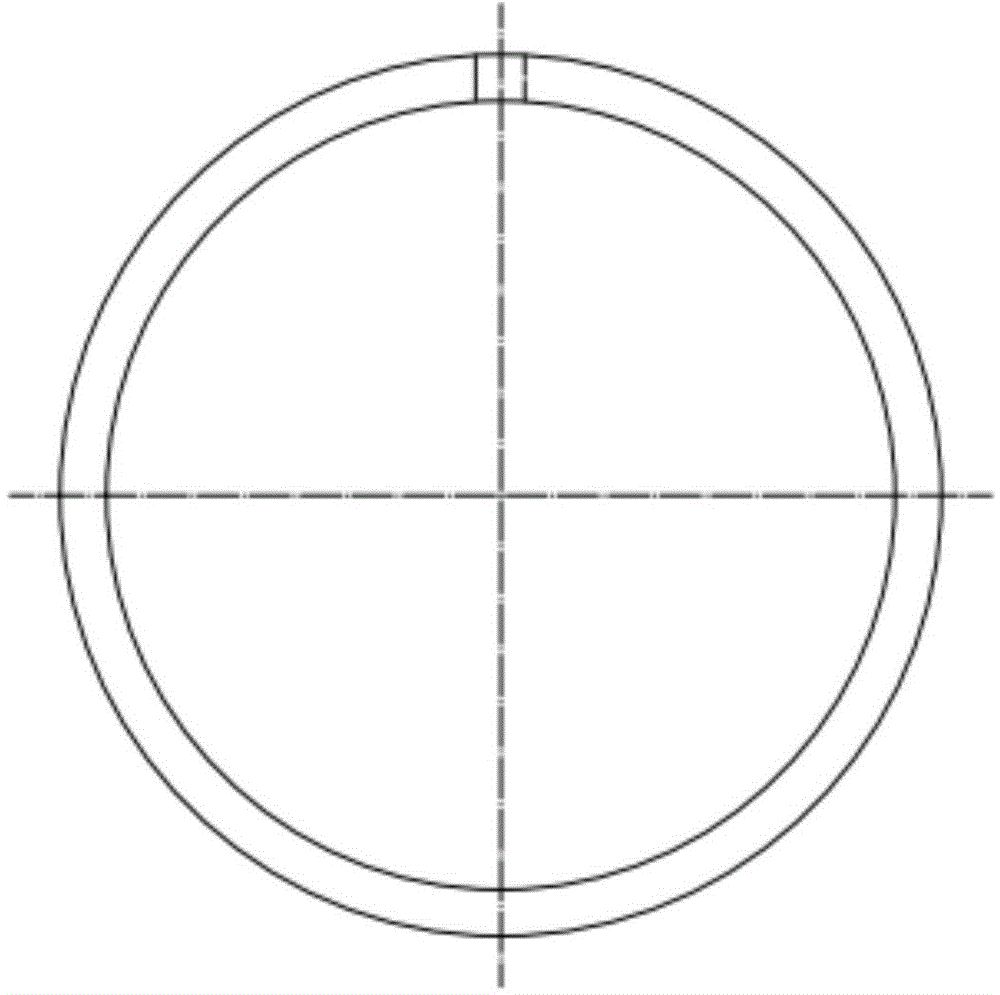

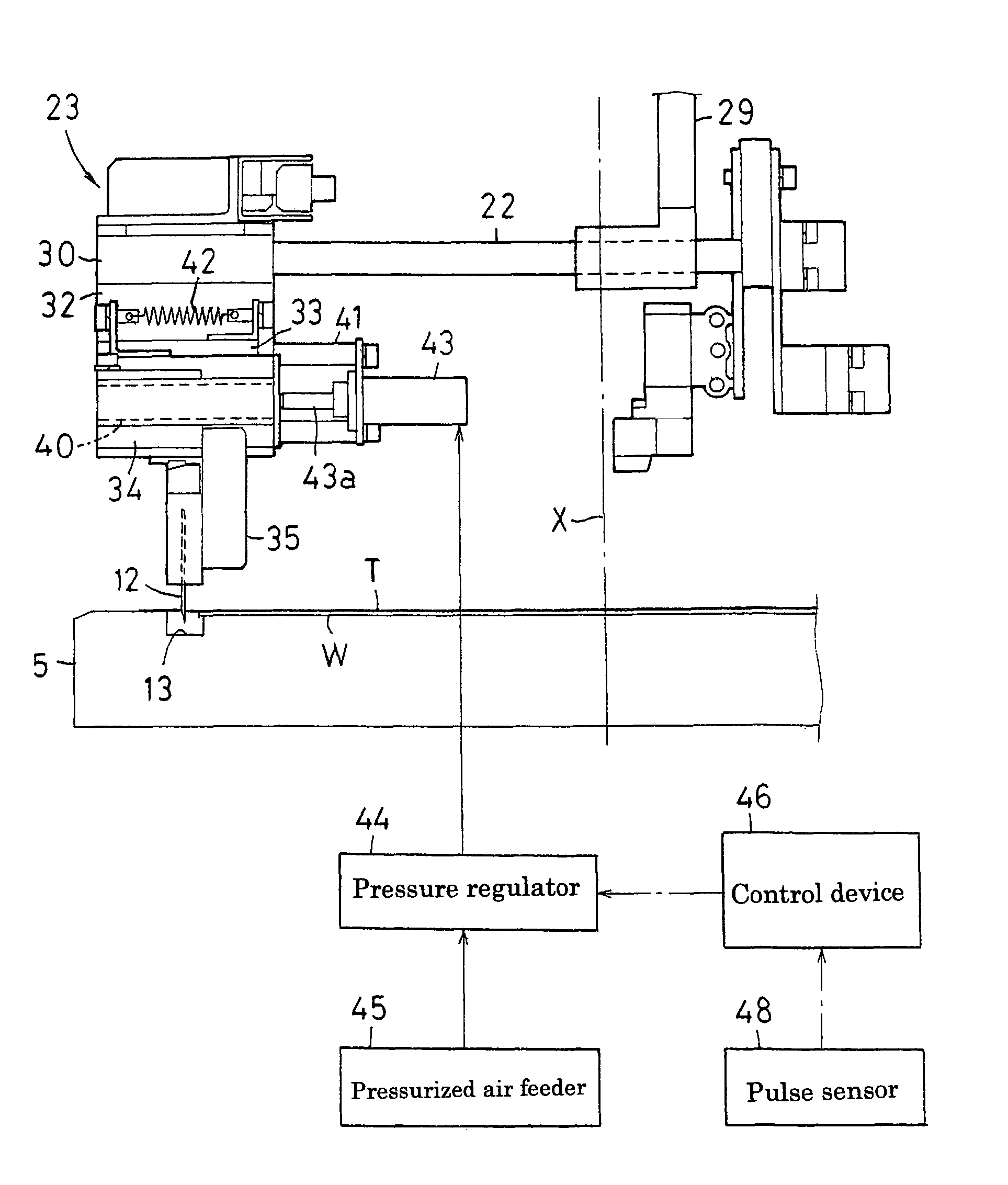

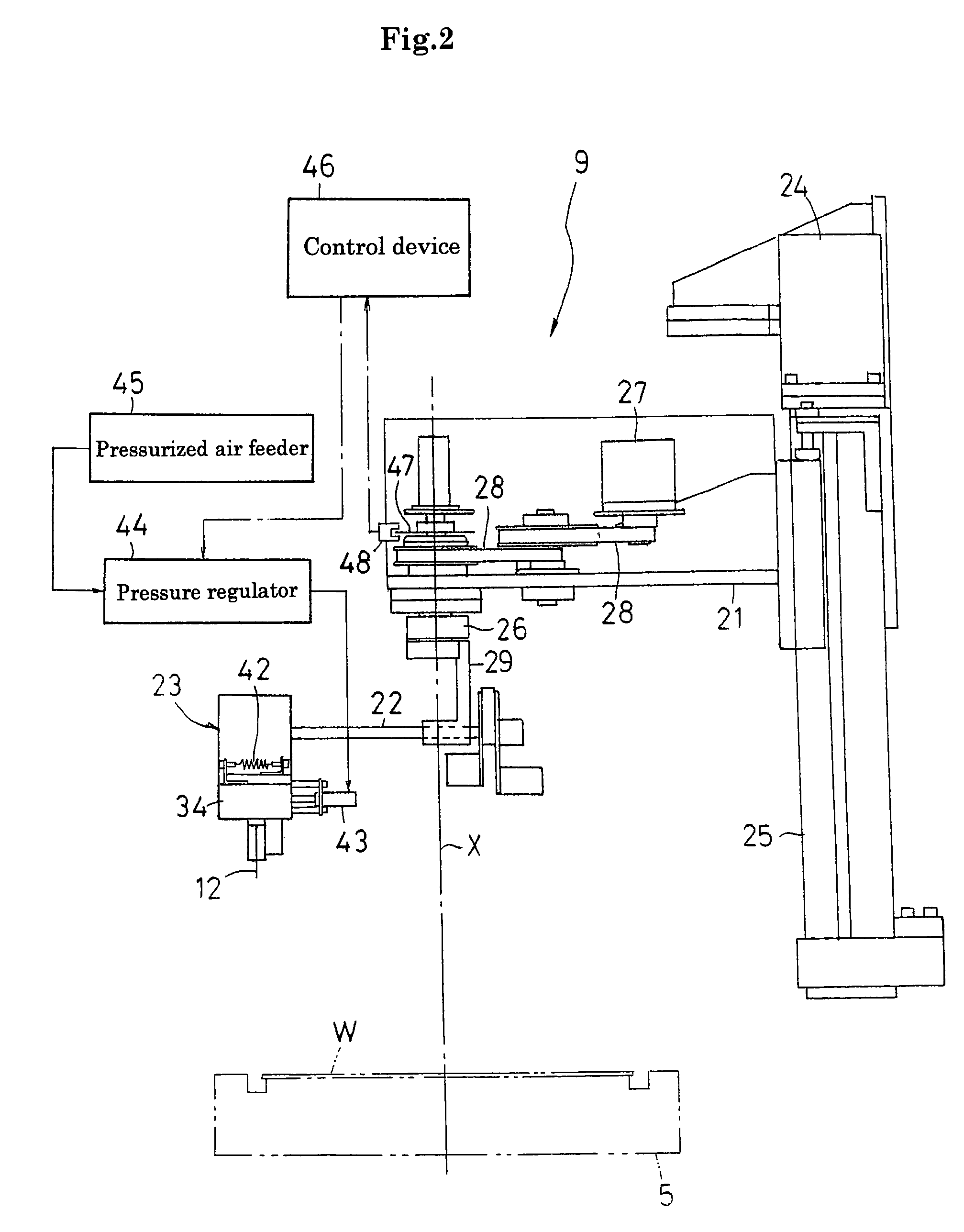

Method for cutting protective tape of semiconductor wafer and apparatus for cutting the protective tape

InactiveUS20080113492A1Improve accuracyGood precisionAutomatic control devicesSemiconductor/solid-state device manufacturingContact pressureEngineering

A cutter blade movably in a radial direction of a wafer is pressed for biasing to an outer circumferential edge of the semiconductor wafer. Simultaneously, the pushing biasing force of the cutter blade is controlled constant with automatic regulation corresponding to a traveling speed variation of the cutter blade, so that effect of a centrifugal force that works at the time of rotating travel of the cutter blade may not vary a pushing biasing force of the cutter blade. As a result, a contact pressure of the cutter blade to the outer circumferential edge of the semiconductor wafer is maintained stable.

Owner:NITTO DENKO CORP

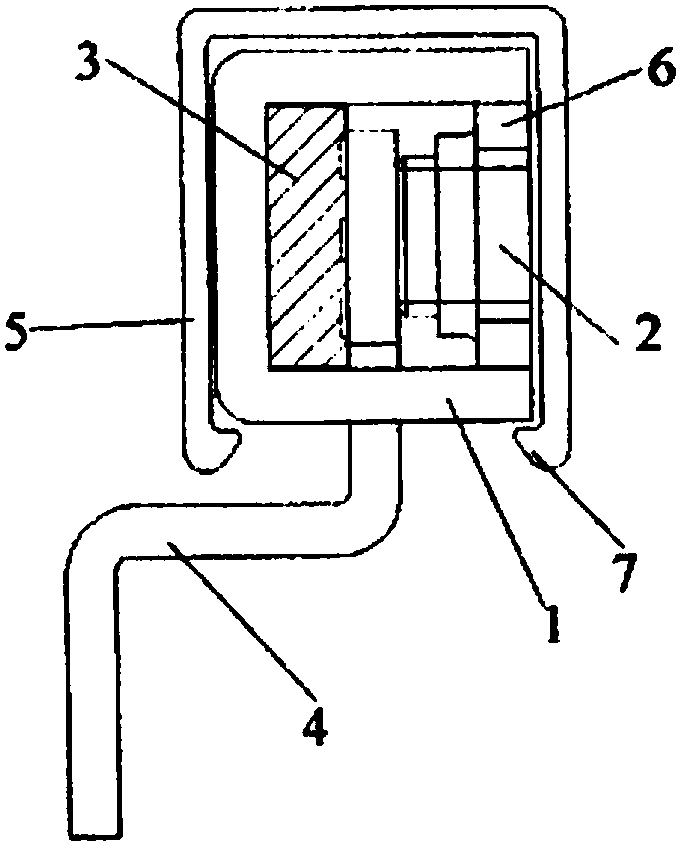

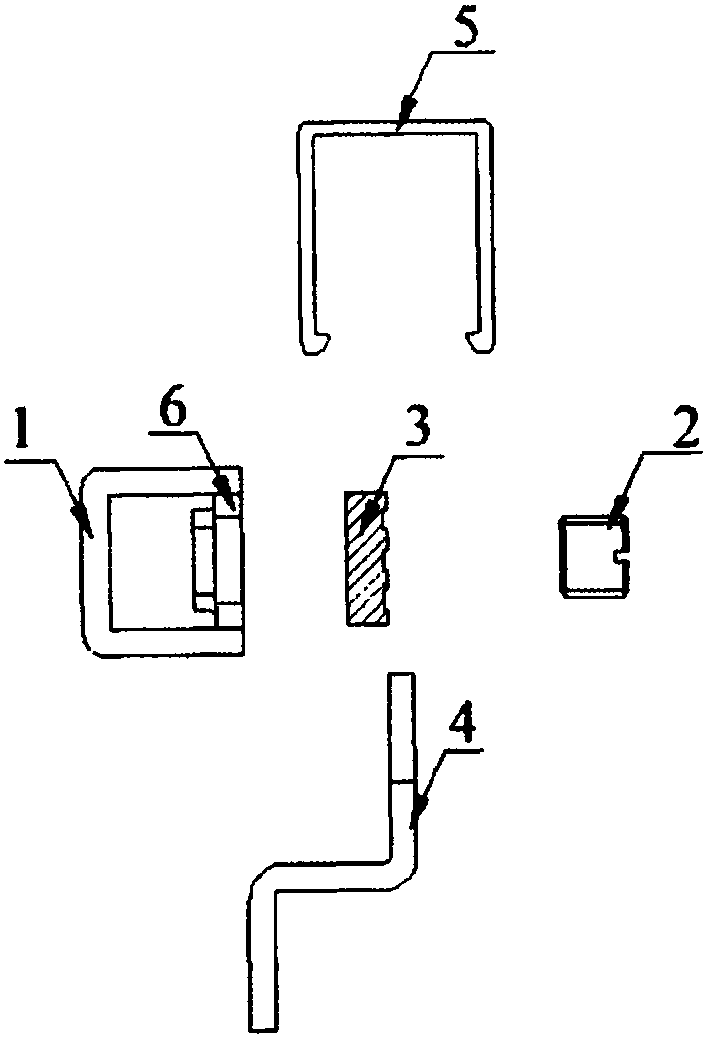

Mechanical switching contact

InactiveCN101080793AReduce contact bounceIncrease contact pressureElectric switchesMechanical engineering

Owner:MASCHFAB REINHAUSEN GEBR SCHEUBECK GMBH & CO KG

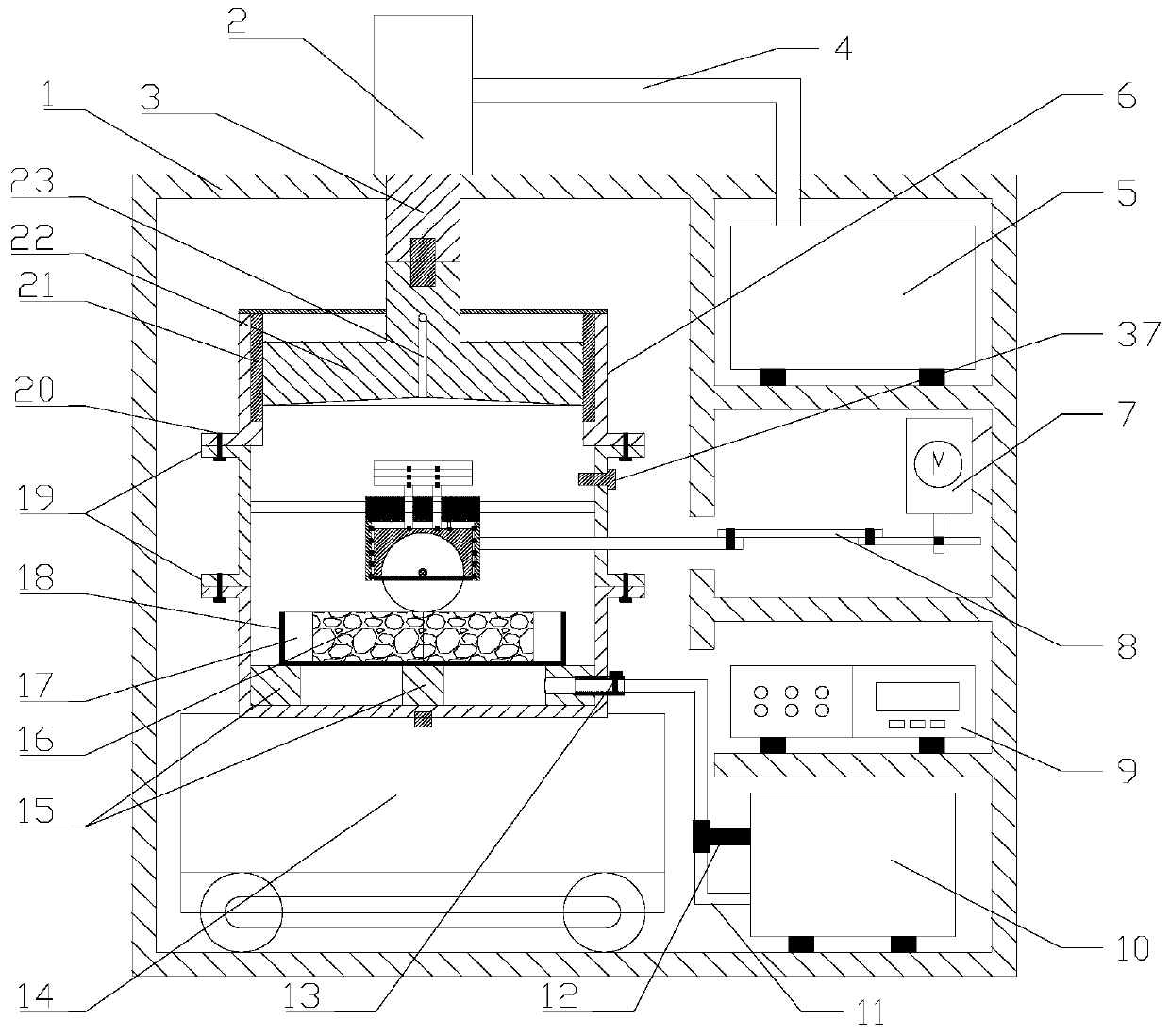

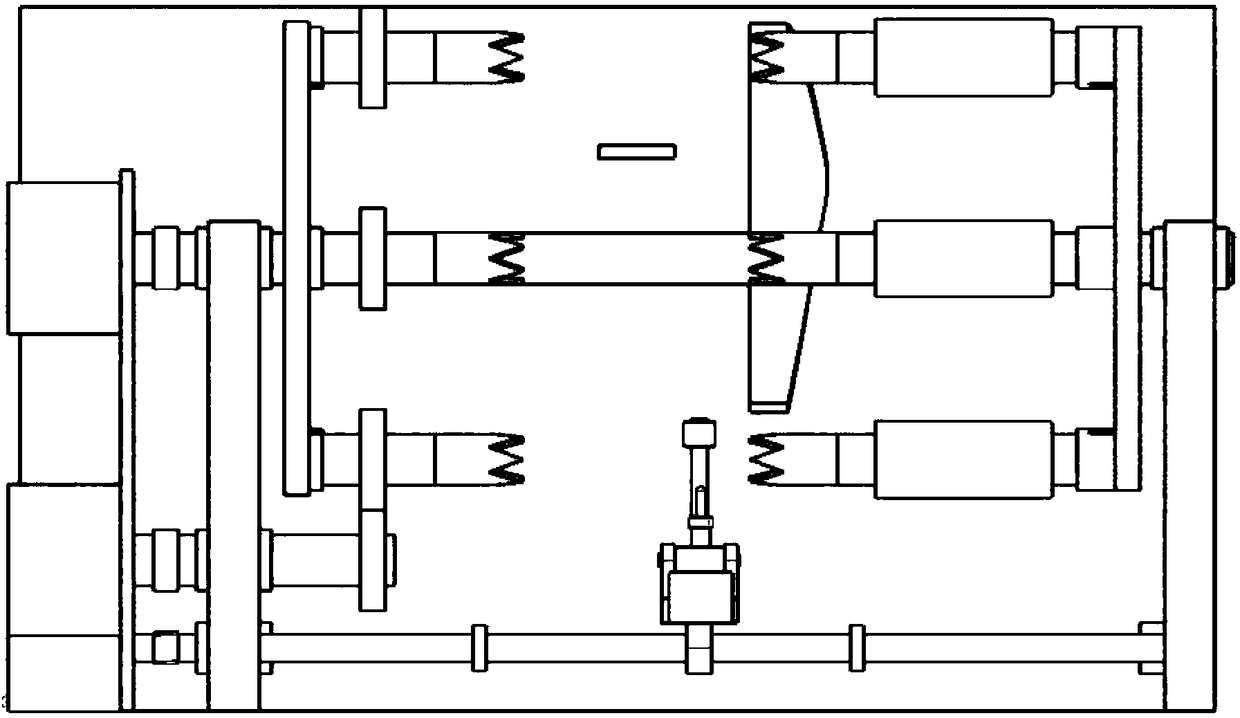

Temperature-variable abrasion instrument capable of studying rolling and sliding friction behaviors of rubber simultaneously

InactiveCN110501249AExpand the scope of applicationConstant contact pressureInvestigating abrasion/wear resistanceRubber ringGrinding wheel

The invention relates to a temperature-variable abrasion instrument capable of studying the rolling and sliding friction behaviors of rubber simultaneously. The instrument comprises a grinding wheel and an abrasion wheel contacting the grinding wheel. The circumferential direction of the abrasion wheel contacts the end face of the grinding wheel. The rotation of the grinding wheel drives the rotation of the abrasion wheel. The abrasion wheel and the grinding wheel generate rolling friction and sliding friction at the same time. According to the invention, the abrasion instrument can simultaneously measure the rolling friction and sliding friction behaviors of rubber, so as to acquire the abrasion amount under two friction situations; with the gradual increase of the amount of depressionof a cylinder, the friction behavior of the rubber ring of the outer ring of the abrasion wheel on the grinding wheel is changed from sliding-based friction to rolling-based friction; and the application range of the instrument is greatly expanded.

Owner:QINGDAO UNIV OF SCI & TECH

Collecting vehicle for detecting small-angle intersecting-line weld seam

ActiveCN105699496ALower the altitudeConstant distanceAnalysing solids using sonic/ultrasonic/infrasonic wavesContact pressureEngineering

The invention discloses a collecting vehicle for detecting a small-angle intersecting-line weld seam. The collecting vehicle comprises a base, wherein the base is in a U shape. A walking mechanism capable of being attracted to and walking on the surface of a to-be-detected pipe is arranged at the bottom of the base; a probe capable of being attached to the surface of the to-be-detected pipe and used for detecting the intersecting-line weld seam is arranged on the base, and is fixed to the front of the base through an angle adjusting mechanism; a height adjusting mechanism for adjusting ascending and descending of the base is arranged on the back side of the base. As the collecting vehicle for detecting the small-angle intersecting-line weld seam comprises the U-shaped base, the height of the collecting vehicle is reduced, and the collecting vehicle can enter narrow and small space; as the walking mechanism capable of being attracted to and walking on the surface of the to-be-detected pipe is arranged at the bottom, the collecting vehicle can stay on any curved surface and walk along any path of the curved surface; as the angle adjusting mechanism and the height adjusting mechanism are arranged, the constant distance, the constant angle and the constant contact pressure between the probe and the weld seam can be invariably kept.

Owner:SENSE ENG SERVICES

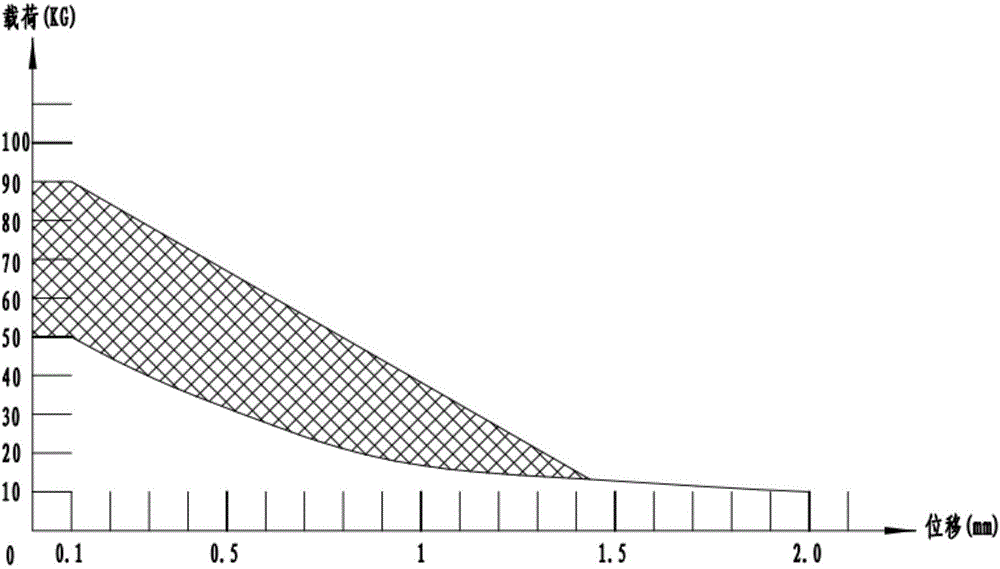

Roller cone bit and method for installing roller cone bearing sealing system of roller cone bit

InactiveCN104165028ASolution to short lifePrecise control of contact pressureConstructionsContact pressureWell drilling

The invention relates to the technical field of drilling tools, in particular to a roller cone bit and a method for installing a roller cone bearing sealing system of the roller cone bit. The roller cone bit comprises a roller cone, a roller palm shaft and positioning steel balls used for fixing the roller cone and the roller palm shaft, wherein a roller cone bearing hole is formed in the root of the roller cone, the bearing sealing system is arranged in the roller cone bearing hole and is composed of a metal roller cone sealing ring, a metal roller palm sealing ring, a metal and rubber roller cone sealing ring and a wave spring used for supplying power to a metal roller cone ring, the metal and rubber roller cone sealing ring is located on one side of the metal roller cone sealing ring and is used for sealing the gap between the metal roller cone sealing ring and the roller cone bearing hole. According to the roller cone bit and the method for installing the roller cone bearing sealing system of the roller cone bit, through the metal end face sealing system mainly powered by the crest-to-crest wave spring or is completely powered by the crest-to-crest wave spring, the specific contact pressure of a sealed end face can be accurately controlled, and the specific contact pressure is high, lasting and constant.

Owner:TIANJIN LILIN BIT

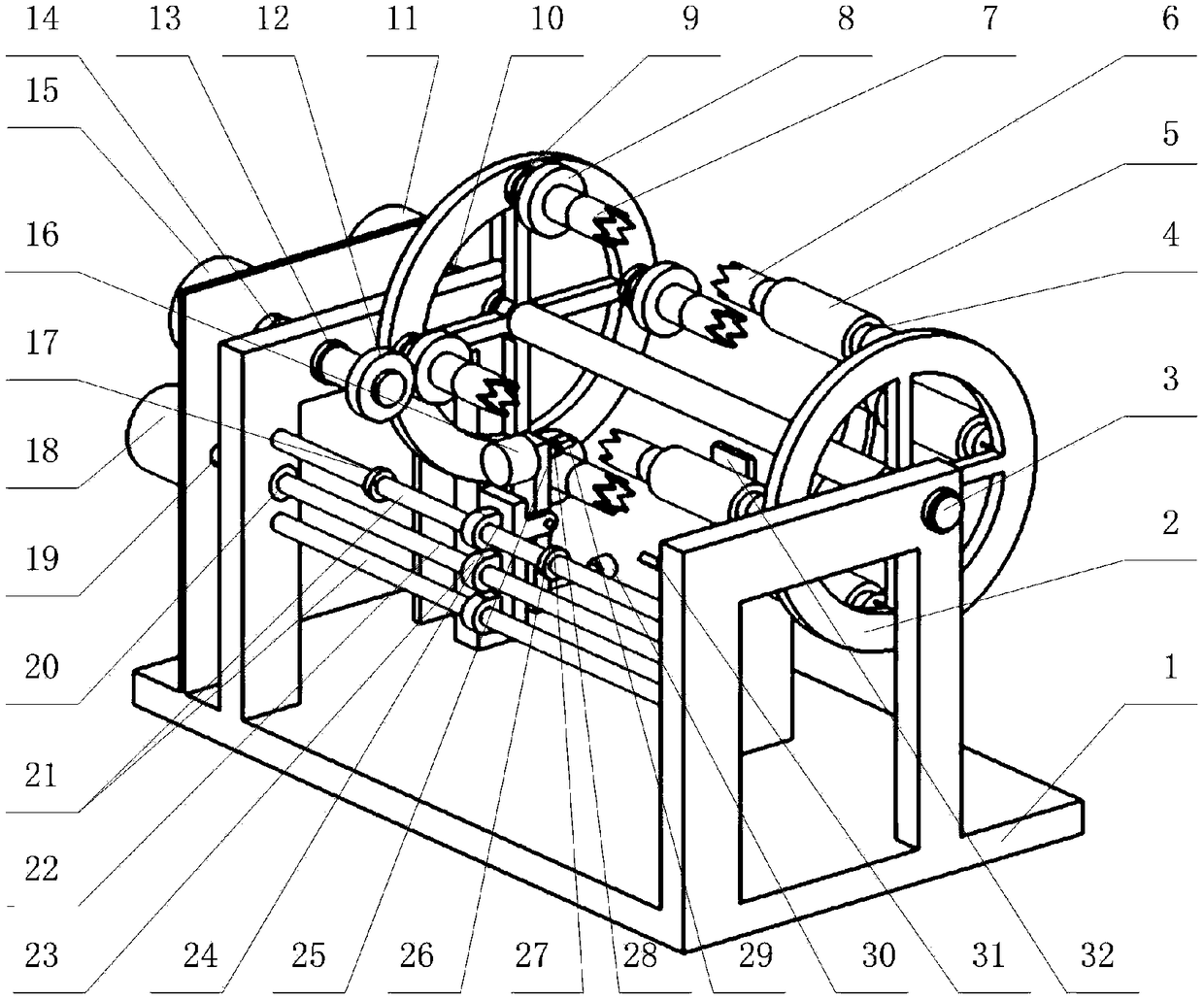

Multihead plane reciprocating friction wear testing machine

ActiveCN108088763AConstant contact pressureEnsure data accuracyInvestigating abrasion/wear resistanceFriction testTest sample

The invention relates to a multihead plane reciprocating friction wear testing machine. The multihead plane reciprocating friction wear testing machine comprises a worktable, wherein lower clamps forfixing lower to-be-tested samples are arranged on the worktable; a movable cross beam is arranged above the worktable; upper clamps are arranged on the movable cross beam; a mechanism adjusts the movable cross beam to vertically move and enables the upper clamps to be close to or separated from the corresponding lower lamps; elastic plates are horizontally arranged on the movable cross beam in a suspending manner; the plate surfaces of the elastic plates are horizontally arranged; the upper clamps are fixed at the suspending ends of the elastic plates; pressure applying heads are arranged at the upper ends of the upper clamps; a three-way force sensor is arranged on the lower clamps and is used for detecting applying pressure of the pressure applying heads; a driving mechanism drives the lower clamps to do reciprocating motion in the horizontal direction; the upper clamps are fixed at the ends of the elastic plates; when the pressure applying heads prop against upper to-be-tested samples, the upper to-be-tested samples can be always kept vertical, further friction surfaces of the upper to-be-tested samples and the lower to-be-tested samples are always planes, the constancy of the contact pressure of the friction surfaces is kept and data accuracy of a friction test is ensured.

Owner:HEFEI UNIV OF TECH

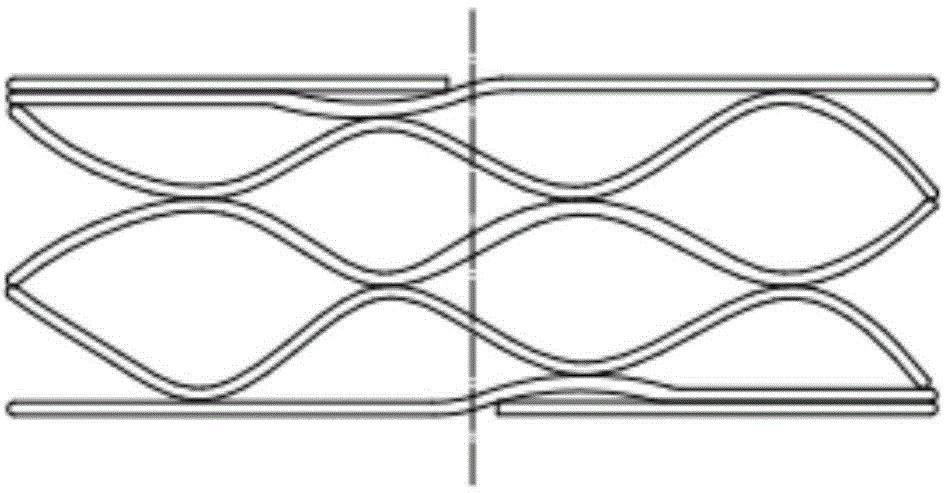

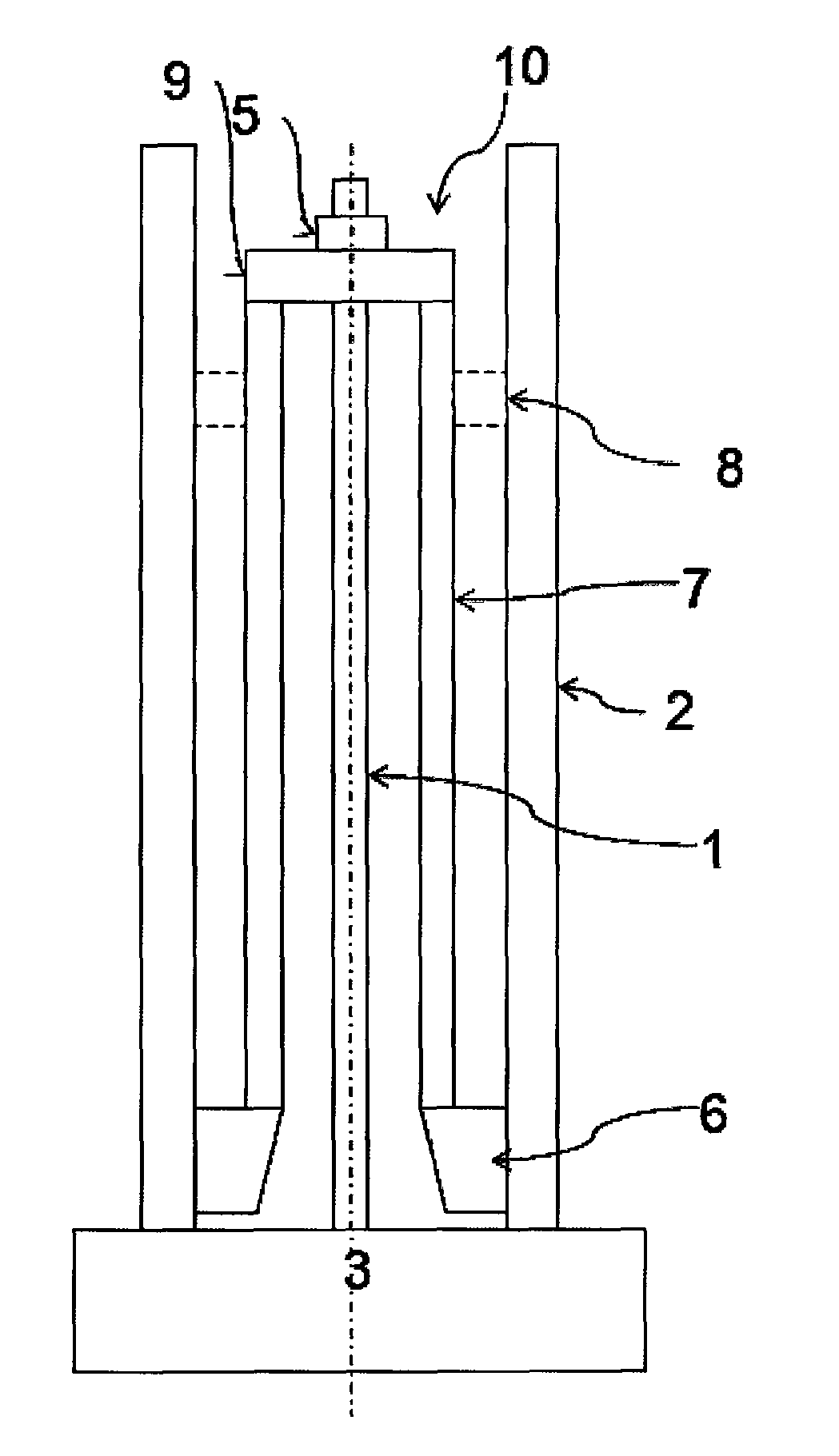

Grind-stone-mount of honing head

InactiveUS20120094583A1Smoothly follow inside shapeConstant contact pressureGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A plurality of grind-stone-mounts 12 each having a grind stone 15 on its outer side are attached to a holder 11 of a honing head 10 expandably along a radial direction. Each of the grind-stone-mounts 12 is provided with a support part 13 disposed inside along the radial direction, and a grind part 14 including the grind stone 15 and disposed outside along the radial direction. The grind part 14 is swingably attached to the support part 13 through one or more spring members 16 disposed at intervals along an axial direction of the holder 11.

Owner:HONDA MOTOR CO LTD

Cover plate, door covering and aircraft or spacecraft

InactiveUS20130105630A1Prevent developmentConstant contact pressureAircraft doorsFuselagesAirplaneSpacecraft

The present invention provides a cover plate for covering at least portions of a door gap formed between a door covering and a fuselage cell of an aircraft or spacecraft, comprising: a fastening portion by which the cover plate can be mounted on an outer surface of the door covering; a contact portion which rests in a contacting manner against an outer skin of the fuselage cell when the door covering is closed; at least one corner portion associated with a corner of the door covering; and a side portion associated with a side of the door covering, the at least one corner portion and the side portion being configured to press the contact portion with a constant contact pressure against the outer skin of the fuselage cell when the door covering is closed. The present invention further provides a door covering for an access opening in a fuselage cell of an aircraft or spacecraft having a cover plate of this type as well as an aircraft or spacecraft having a cover plate of this type and / or having a door covering of this type.

Owner:AIRBUS OPERATIONS GMBH

Method for cutting protective tape of semiconductor wafer and apparatus for cutting the protective tape

InactiveUS8042441B2Good accuracy and precisionStable maintenanceAutomatic control devicesSemiconductor/solid-state device manufacturingContact pressureEngineering

A cutter blade movably in a radial direction of a wafer is pressed for biasing to an outer circumferential edge of the semiconductor wafer. Simultaneously, the pushing biasing force of the cutter blade is controlled constant with automatic regulation corresponding to a traveling speed variation of the cutter blade, so that effect of a centrifugal force that works at the time of rotating travel of the cutter blade may not vary a pushing biasing force of the cutter blade. As a result, a contact pressure of the cutter blade to the outer circumferential edge of the semiconductor wafer is maintained stable.

Owner:NITTO DENKO CORP

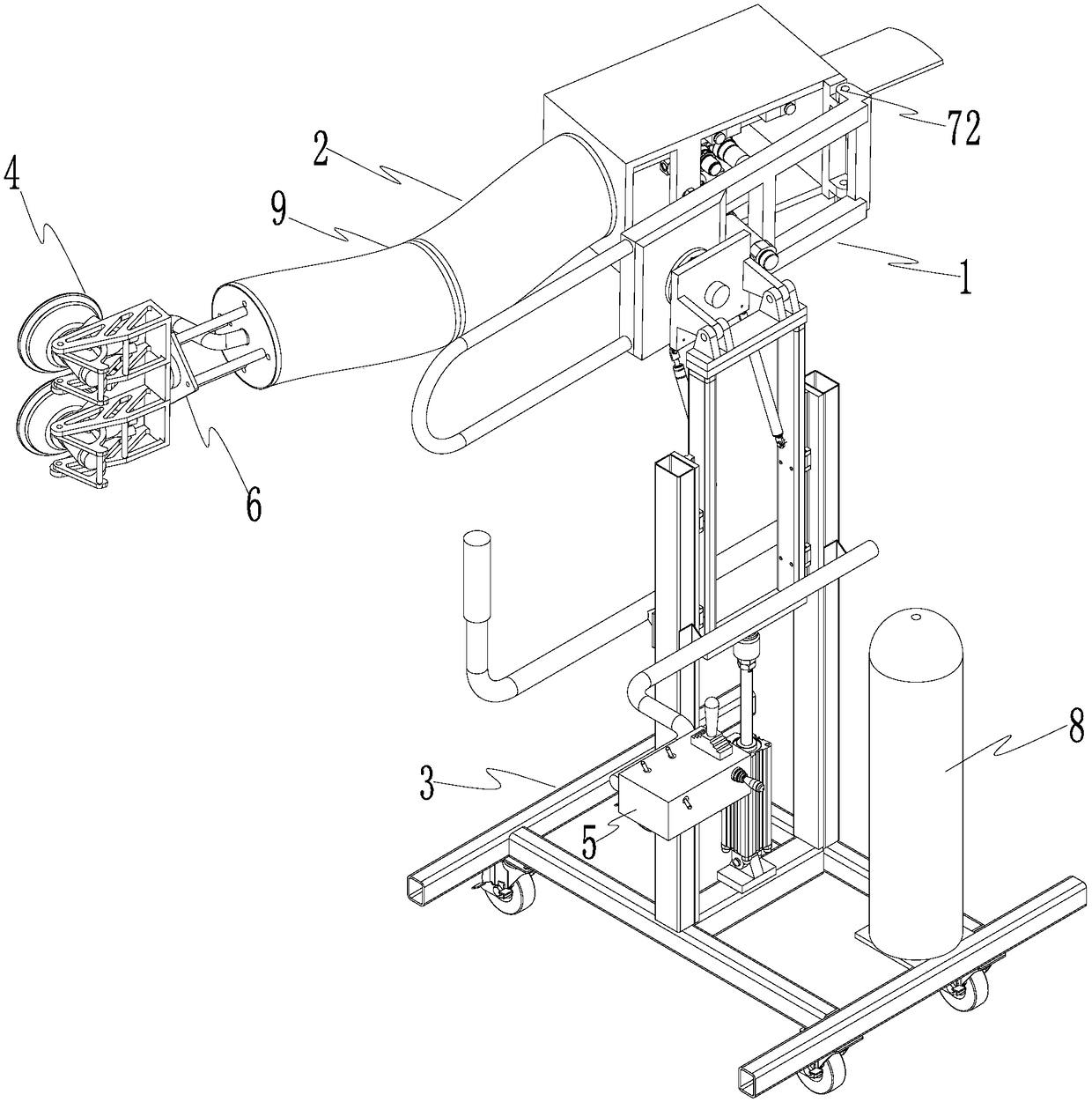

Mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment

ActiveCN108544375AAvoid permanent damageCompact structureGrinding carriagesGrinding drivesEngineeringFuselage

The invention discloses a mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment. The mobile self-dust-suction continuous grinding and polishing machine comprises a mobile base, a pneumatic mechanical arm and a self-dust-suction eccentric grinding machine; the pneumatic mechanical arm is movably assembled on the mobile base and comprises an assembling and positioning assembly and a pneumatic swinging arm assembly; and the self-dust-suction eccentric grinding machine is installed at one end of the pneumatic mechanical arm through a connecting rack structure. According to the mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment, the pneumatic swinging arm and the self-dust-suction eccentricgrinding machine are installed on the mobile base, one person operates the machine to enable the machine to move along the outer contour of a machine body, the grinding process of various shape and hook face coherent portions of the machine body is continuously completed, the structure is simple and compact, programming is not needed, operation is flexible and convenient, standardized production is facilitated, the production efficiency and the machine body grinding surface quality are improved, environmental pollution is reduced to the maximum limit, and sufficient technical guarantees are provided for grinding and polishing of complex and irregular hook faces of the large machine body.

Owner:广东博科数控机械有限公司

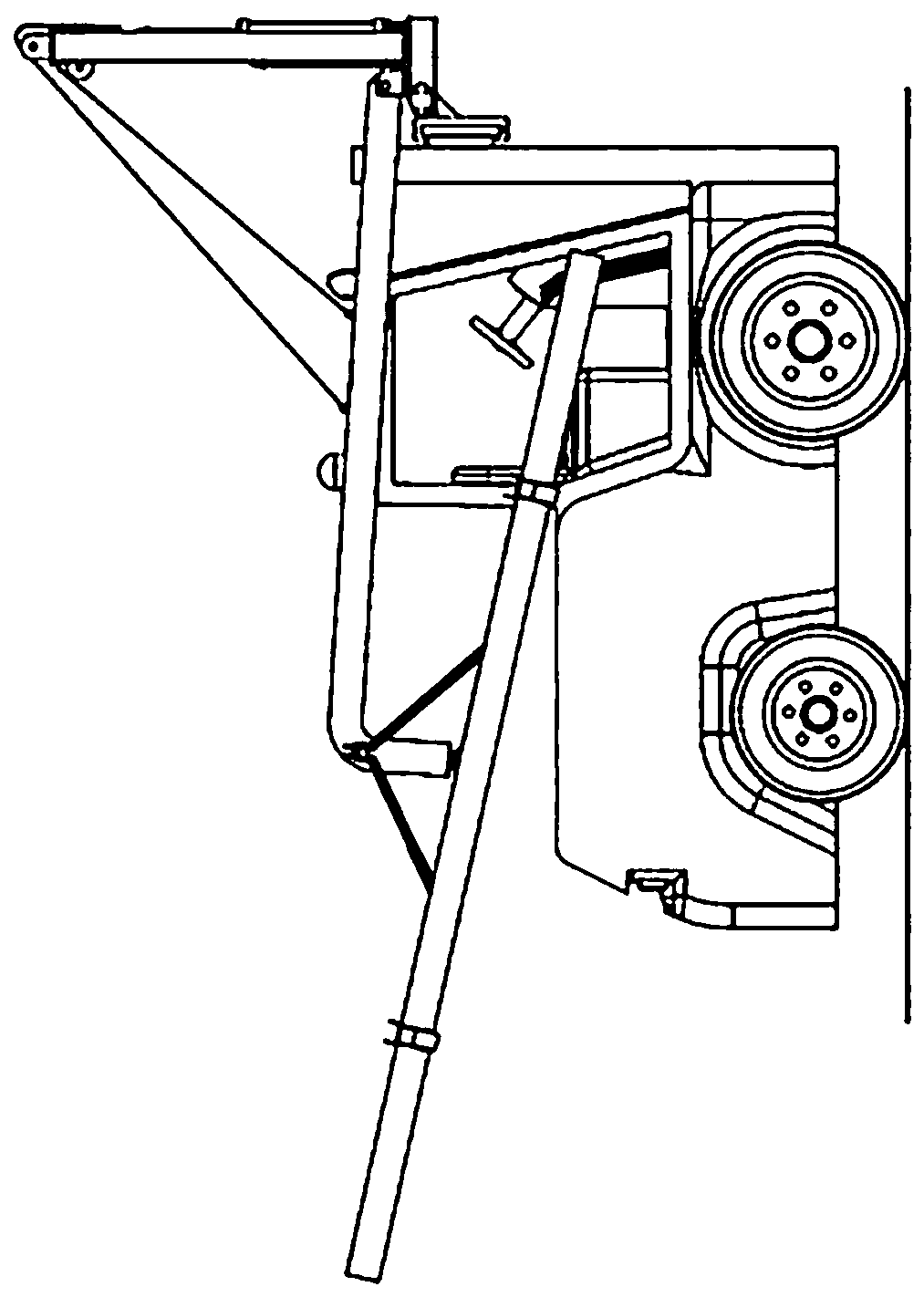

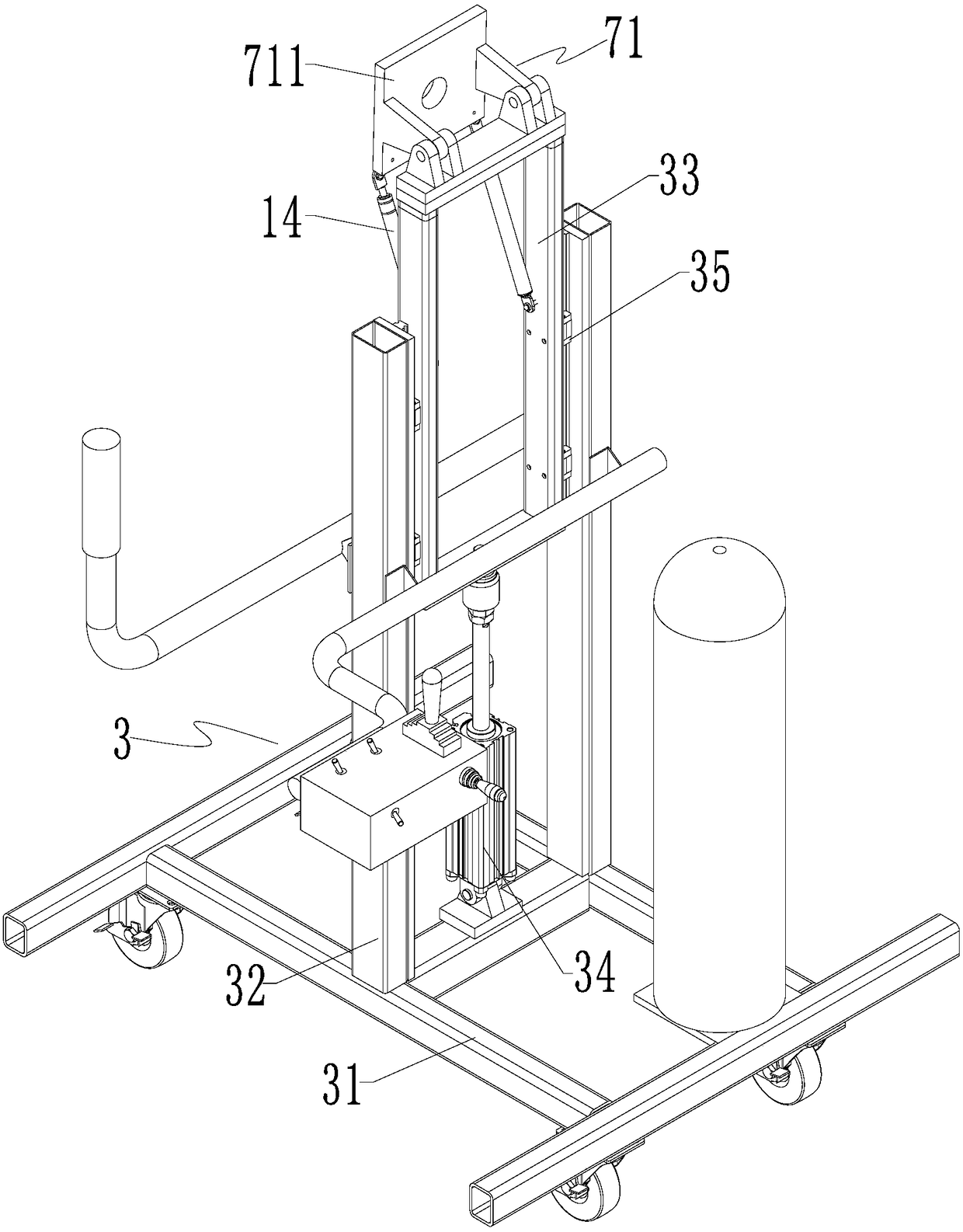

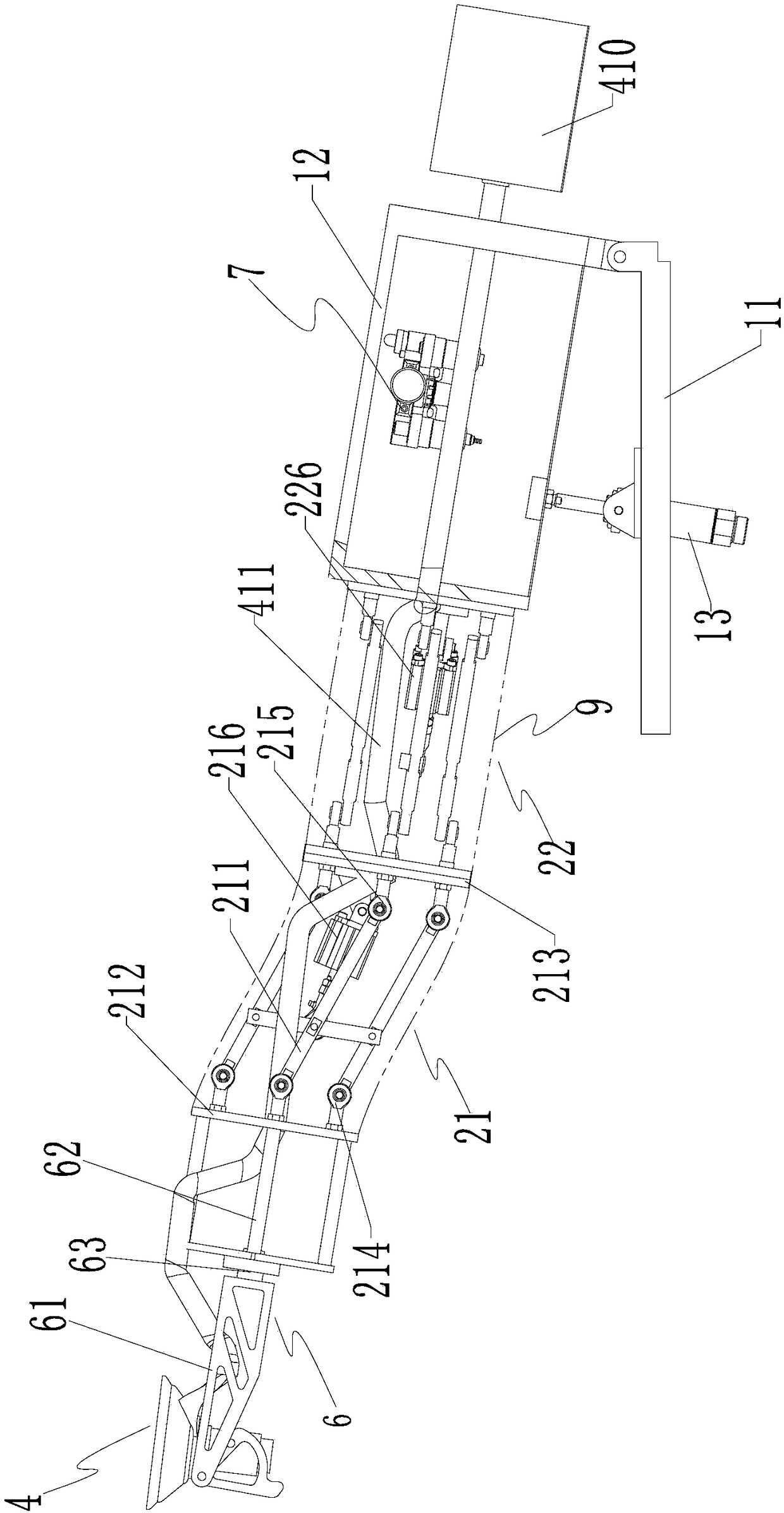

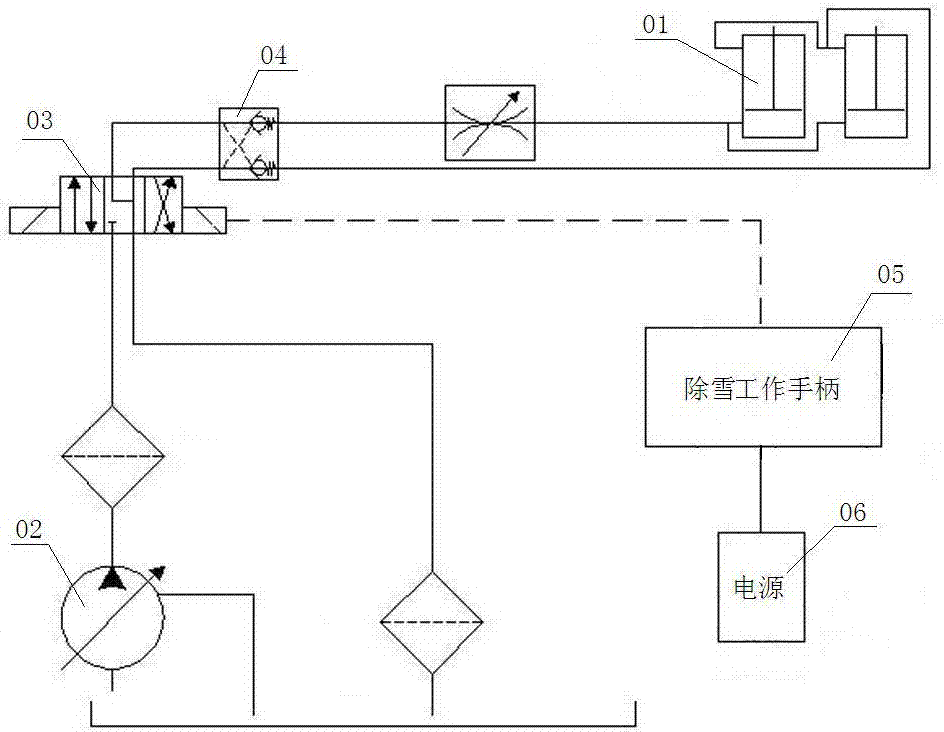

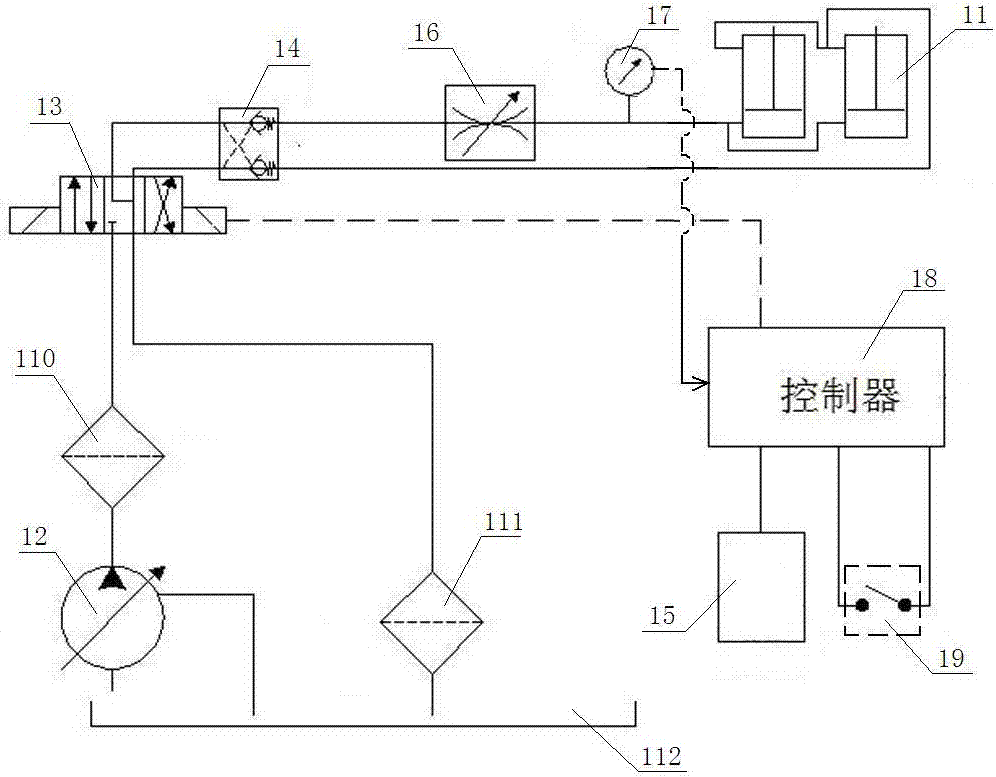

Rolling brush regulating device for snow sweeper

The invention discloses a pressing control device for a rolling brush of a snow sweeper and belongs to the technical field of engineering machinery. The device comprises a lifting cylinder and a hydraulic pump, wherein the lifting cylinder is used for driving the rolling brush to press down; the hydraulic pump is used for supplying pressure oil to the lifting cylinder; a solenoid directional valve is arranged between the lifting cylinder and the hydraulic pump; a sensor used for sensing the abrasion of the rolling brush is also arranged on the device; the sensor is connected with an electric control end of the solenoid directional valve through a controller; an automatic pressing switch for the rolling brush and a snow sweeping operation handle are arranged at a control end of the controller. The pressing control device is capable of solving the problem of easy abrasion of the rolling brush or incomplete snow sweeping caused by the difficulty in controlling the contact pressure between the rolling brush of the snow sweeper and the ground within the optimal scope.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

Overtuned charging bipole contact device for electric bus

InactiveCN1994778ASimple structureAvoid uncontrollablePower current collectorsElectricityEngineering

The invention relates to a bus turnover dual-pole trigger, wherein cylinder pushes the large turnover plate on one chassis and the small turnover plate hinged to the large plate, to drive the trigger and electrode that mounted on the small plate, to contact the fixed conductive track to charge quickly.

Owner:马建华

Temperature compensated bushing design

ActiveUS8748757B2Improves prior art bushingsEnsure contact pressurePipesTransformers/inductances detailsElectrical conductorContact pressure

A bushing including a bottom contact, and a tubular conductor, having a lower part having an end in electrical and mechanical contact with the bottom contact, and a draw rod arrangement, inside the conductor, arranged to exert sufficient contact pressure between the bottom contact and the conductor, and the draw rod arrangement includes a member in mechanical contact with the conductor and draw rod having a second end, fixedly connected to the bottom contact, and a first end in connection to the member and clamping means, the clamping means is adapted to apply a force, urging the member in the direction of the bottom contact to generate sufficient contact pressure between the bottom contact and the conductor. The member of the draw rod arrangement is arranged to apply the force to the lower part of the conductor.

Owner:HITACHI ENERGY LTD

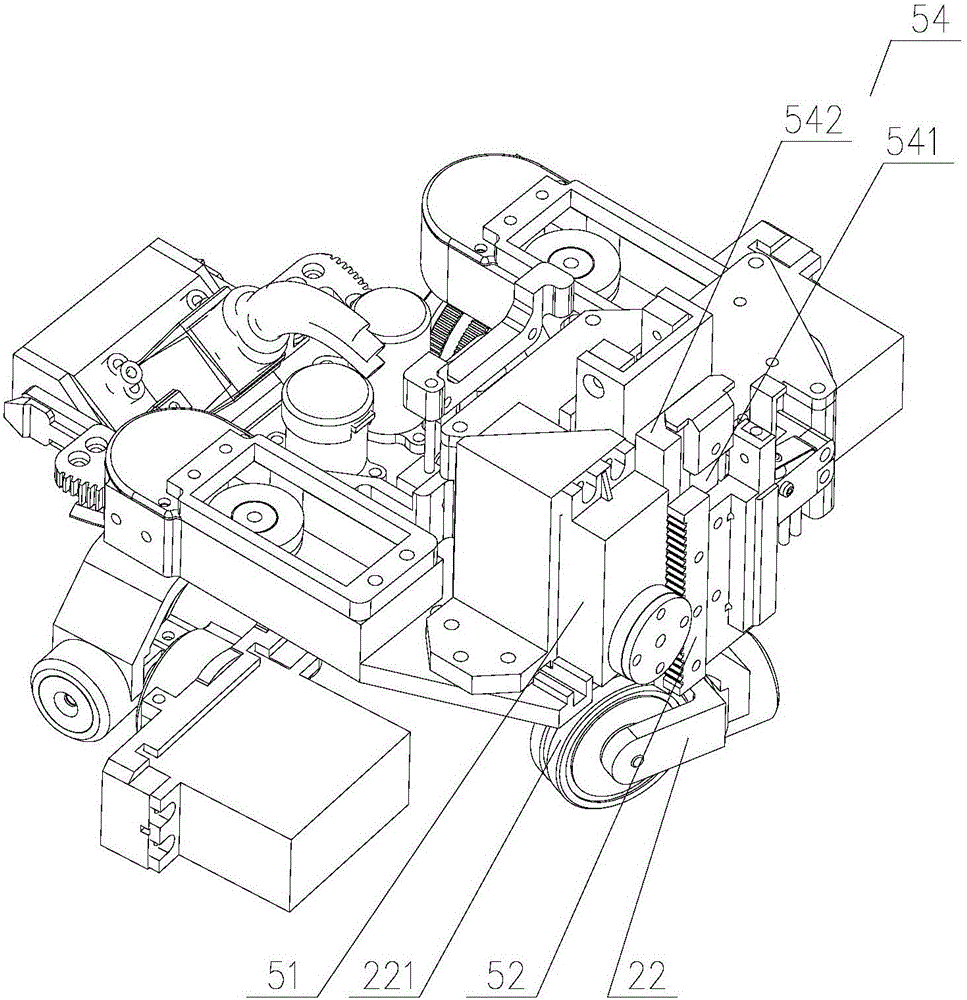

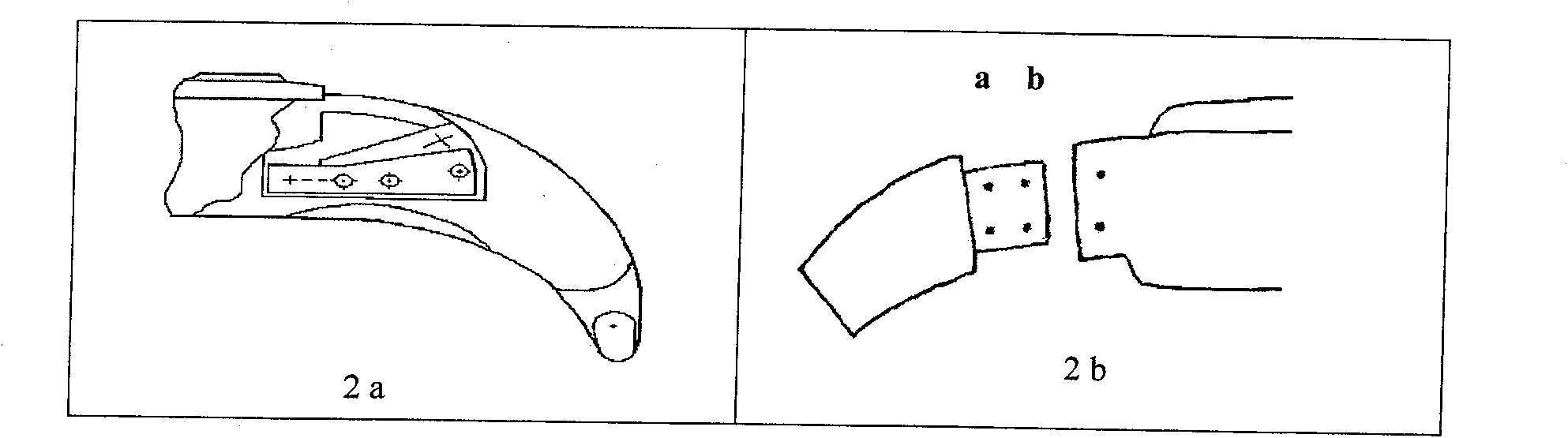

Probe assembly of control rod guiding cylinder cotter pin of nuclear power station

ActiveCN107976486AConstant contact pressureGood repeatabilityMaterial analysis using sonic/ultrasonic/infrasonic wavesRubber ringContact pressure

The invention discloses a probe assembly of a control rod guiding cylinder cotter pin of a nuclear power station. The probe assembly comprises a probe wafer, a wafer fixing frame for fixing the probewafer, a bottom plate and a first buffering assembly connected between the bottom plate and the wafer fixing frame; a second buffering assembly is further arranged between the first buffering assemblyand the wafer fixing frame; the second buffering assembly comprises a middle plate connected with the first buffering assembly, a cylinder body which sleeves the middle plate and an elastic rubber ring fixed in the cylinder body; the wafer fixing frame is fixedly inserted into the elastic rubber ring and a gap is formed between the elastic rubber ring and the middle plate; the height, which is higher than the second buffering assembly part, of the probe wafer and the wafer fixing frame is greater than the distance between the deepest part of a cotter pin groove and the lower end face of an upper grid plate and the distance is a compression distance. The probe assembly disclosed by the invention can be self-adaptive to positioning errors and mounting errors; the contact pressure between anultrasonic probe and the cotter pin is constant and the repeatability of ultrasonic examination is easy to realize.

Owner:CGNPC INSPECTION TECH +3

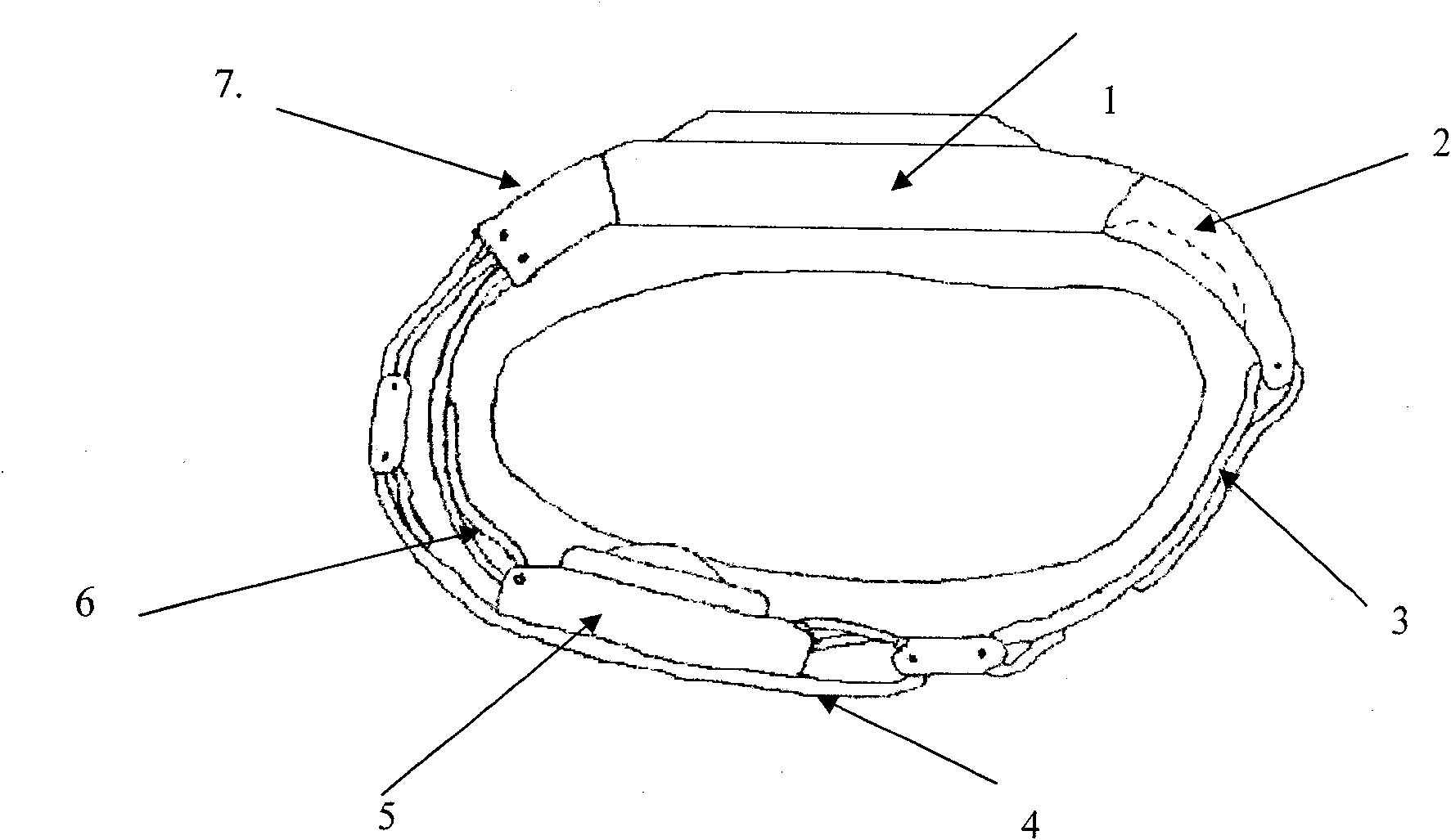

Watch strap human blood pressure non-invasive continuous detection device

InactiveCN100586366CConvenient and comfortable continuous blood pressure measurementEasy to wear and detectEvaluation of blood vesselsAngiographyElectricityHuman body

The invention belongs to general electronic blood pressure measuring apparatuses, aiming at providing a wristlet typed human body blood pressure trauma-free continuous checkout gear for realizing theconvenient and comfortable continuous blood pressure measurement. The technical scheme adopted by the invention is that the wristlet typed human body blood pressure trauma-free continuous checkout gear consists of two parts of a wristwatch and a human body pulse wave checkup gear, and the two parts are connected by a wristlet and an electric signal wire; the human body pulse wave checkup gear consists of a piezoresistive pulse wave sensor and a base of the pulse wave sensor; a pulse wave signal processor unit is attached to the inside of the wristwatch of the wristlet typed human body blood pressure continuous checkout gear; the wristlet consists of a pressing belt of the pulse wave sensor, a sensor location adjustment strip, a length size regulating mass used for regulating the length ofthe wristlet, a camber regulating mass used for regulating the measuring point locating relation between the wristlet and the pulse and a fastening belt. The checkout gear is mainly used for manufacturing blood pressure continuous monitoring and measuring apparatuses.

Owner:胡梦辰

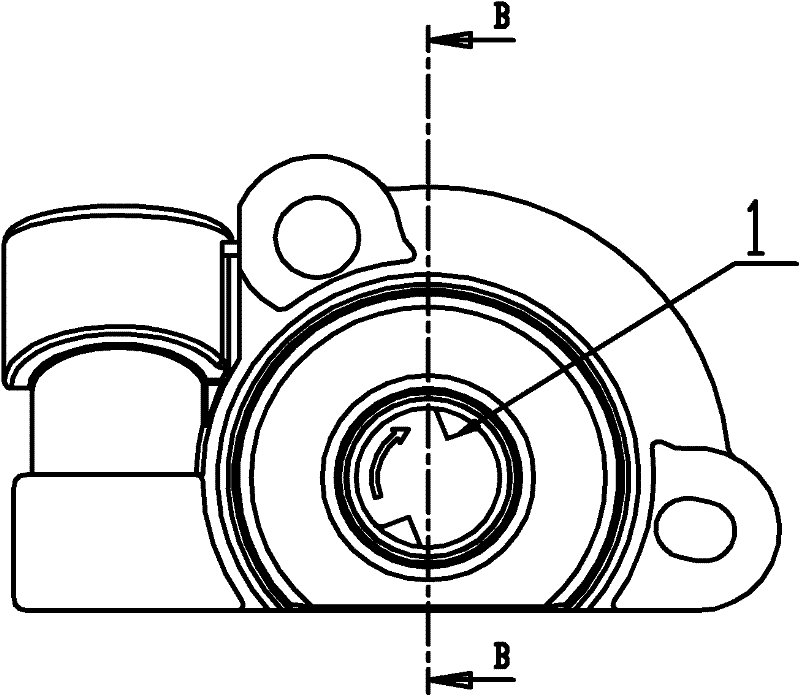

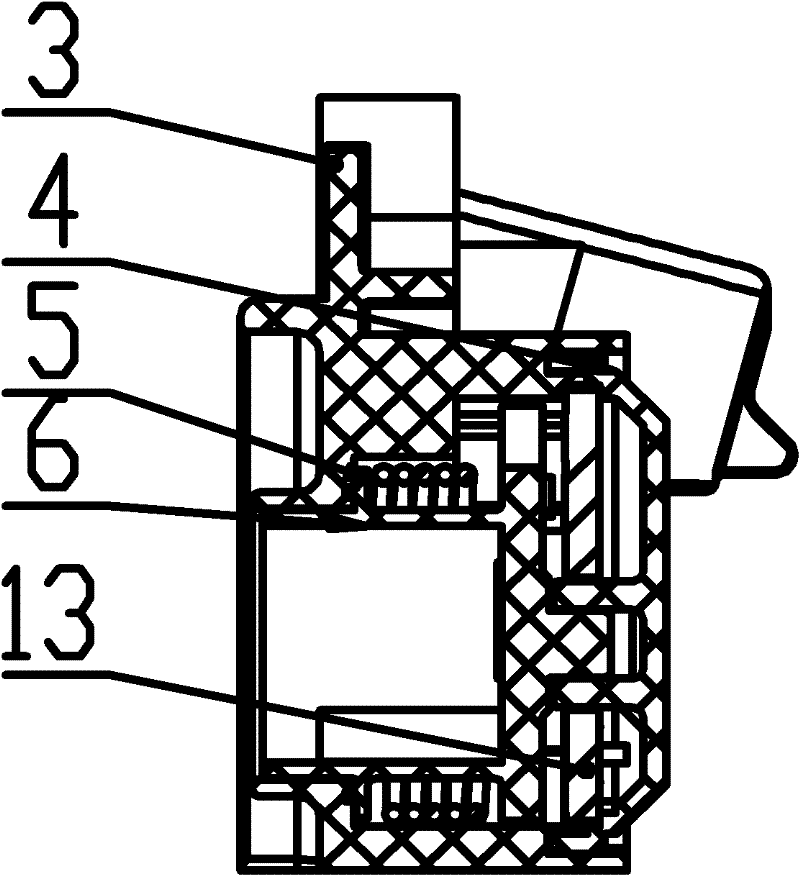

Position sensor for throttle body

InactiveCN102175272AGuaranteed stabilityConstant contact pressureConverting sensor output electrically/magneticallyElectrical resistance and conductanceContact pressure

The invention discloses a position sensor for a throttle body. The position sensor for the throttle body comprises a plastic shell, a sealing cover, a return spring, an electric brush main body, an electric brush, a print circuit board (PCB) substrate, a post, a first hanging foot and a second hanging foot. The sealing cover and the plastic shell are sealed and connected in a bonding way; the electric brush main body is inserted into a hole of the plastic shell and is in clearance fit with the plastic shell; the electric brush is in clearance fit with the post; one torsion arm of the return spring is hung on the first hanging foot, and the other torsion arm of the return spring is hung on the second hanging foot; and the PCB substrate is arranged on one side of the plastic shell and pressed against the upper part of the electric brush main body. The PCB substrate is pressed against the upper part of the electric brush main body and keeps a certain distance with the electric brush; and the electric brush is always tightly attached to a resistive layer of the PCB substrate, so that a constant contact pressure is kept and the stability of an output voltage is ensured.

Owner:SHANGHAI AUZONE AUTO PARTS MFG CO LTD

Sensing element for determining a physical property of a gas mixture

InactiveUS7124622B2Low elastic modulusLow costAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansDecreased elasticityCombustion

A sensing element for determining a physical property of a gas mixture, in particular the exhaust gas of internal combustion engines, includes a sensor element, arranged in a housing and connected to at least one electrical cable, as well as a molded piece, which seals the housing and is made of an elastically deformable material, which encloses the at least one cable in a gas-tight manner by radial compression. To ensure the gas-tightness of the cable feed-through also under a higher temperature load, which results in decreased elasticity of the molded piece, a spring element is arranged inside the molded piece, which is able to be tensioned by the radial compression and in the tensioned state generates a force component that acts on the cables in a radial direction.

Owner:ROBERT BOSCH GMBH

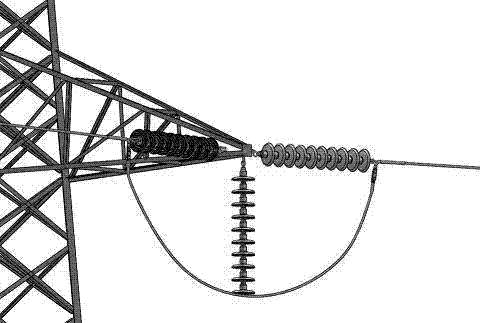

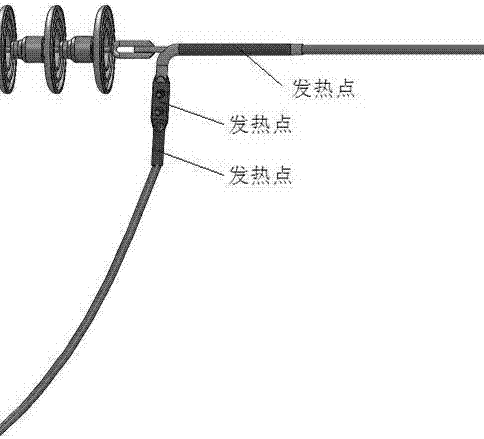

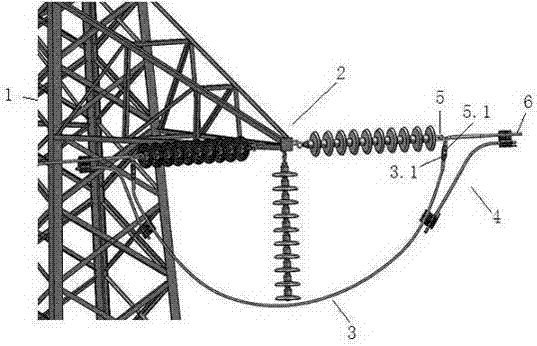

An anti-heating device for a diversion plate and a power transmission line with the device

ActiveCN106207928BEliminate heat hazardsConstant contact pressureSpatial arrangements/dispositions of cablesEngineeringTower

Owner:广州开能电气技术有限公司

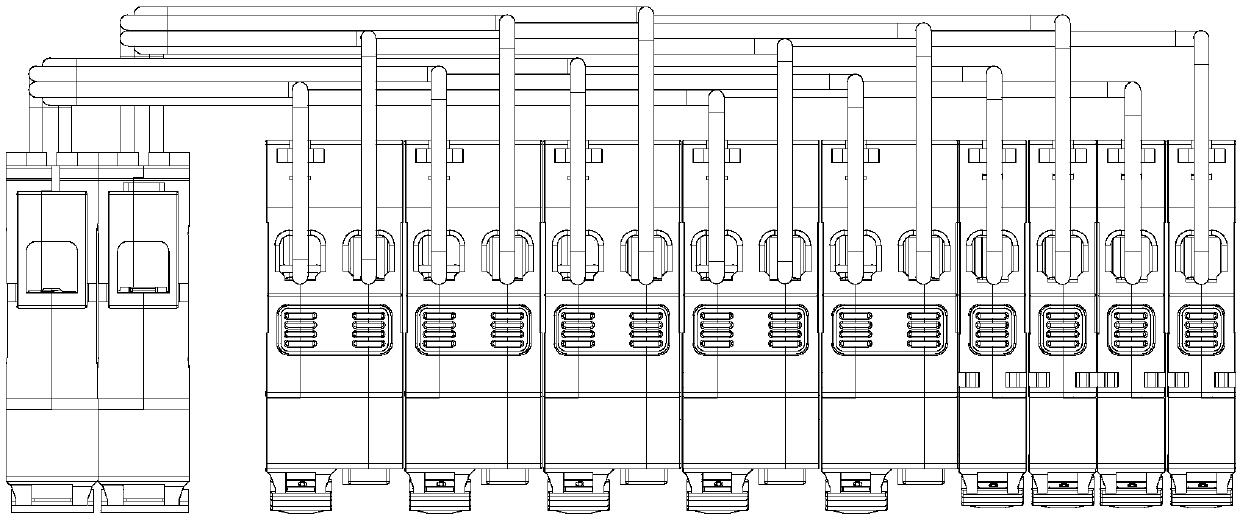

Power distribution unit and movable type elastic busbar for the same

PendingCN107785676AEasy to adjust the positionEasy to replaceCoupling device connectionsClamped/spring connectionsElectrical conductorBusbar

The invention provides a movable type elastic busbar for a power distribution unit, comprising a master conductor with one end being connected to a master switch of the power distribution unit. The movable type elastic busbar also comprises at least two slave conductors. One end of each slave conductor is connected to a slave switch of the power distribution device, and the other end of each slaveconductor can be clamped in the master conductor with a predetermined clamp force, and each slave conductor at the same phase share the line with the connecting part of the master conductor. The invention also provides a power distribution unit, comprising a housing, a master switch, at least two slave switches, and the movable type elastic busbar. The master switch and the slave switches are fixedly disposed in the housing, and the movable type elastic busbar is connected between the master switch and the slave switches. The invention also provides a power distribution unit, comprising a master switch, at least two slave switches, and the movable type elastic busbar connected between the master switch and the slave switches. The invention is advantageous in that the position adjustment of the slave conductors can be conducted based on the demand of a wiring port, and the contact is stable and reliable, and the mounting and dismounting are simple.

Owner:SOOAR TIANJIN ELECTRICAL EQUIP CO LTD

Multi-head plane reciprocating friction and wear testing machine

ActiveCN108088763BGuaranteed accuracyConstant contact pressureInvestigating abrasion/wear resistanceWear testingContact pressure

The invention relates to a multihead plane reciprocating friction wear testing machine. The multihead plane reciprocating friction wear testing machine comprises a worktable, wherein lower clamps forfixing lower to-be-tested samples are arranged on the worktable; a movable cross beam is arranged above the worktable; upper clamps are arranged on the movable cross beam; a mechanism adjusts the movable cross beam to vertically move and enables the upper clamps to be close to or separated from the corresponding lower lamps; elastic plates are horizontally arranged on the movable cross beam in a suspending manner; the plate surfaces of the elastic plates are horizontally arranged; the upper clamps are fixed at the suspending ends of the elastic plates; pressure applying heads are arranged at the upper ends of the upper clamps; a three-way force sensor is arranged on the lower clamps and is used for detecting applying pressure of the pressure applying heads; a driving mechanism drives the lower clamps to do reciprocating motion in the horizontal direction; the upper clamps are fixed at the ends of the elastic plates; when the pressure applying heads prop against upper to-be-tested samples, the upper to-be-tested samples can be always kept vertical, further friction surfaces of the upper to-be-tested samples and the lower to-be-tested samples are always planes, the constancy of the contact pressure of the friction surfaces is kept and data accuracy of a friction test is ensured.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com