Multihead plane reciprocating friction wear testing machine

A friction and wear test, reciprocating technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of sample deflection, inability to ensure, difficult to analyze the friction surface, etc., to achieve constant contact pressure, ensure data The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

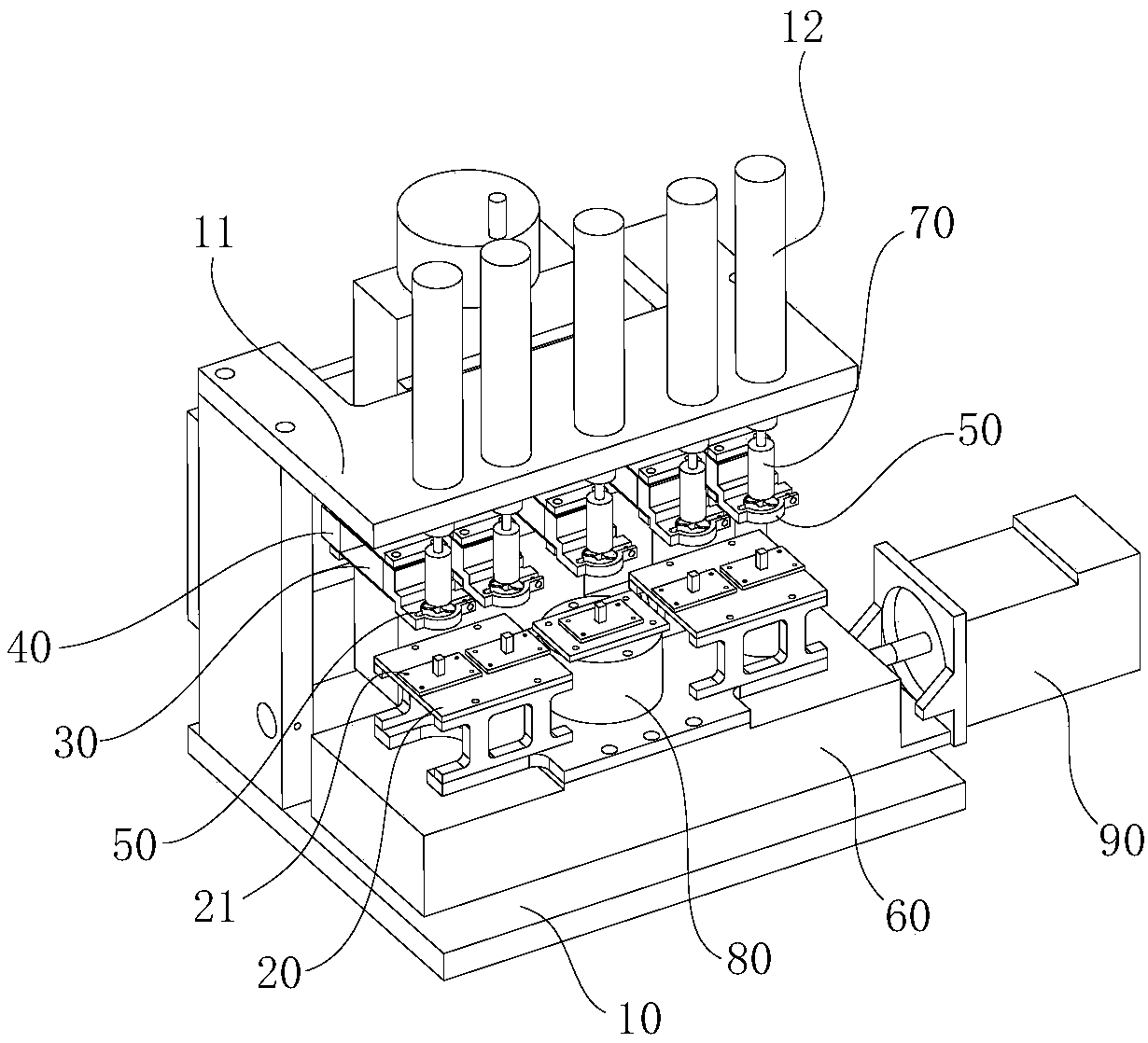

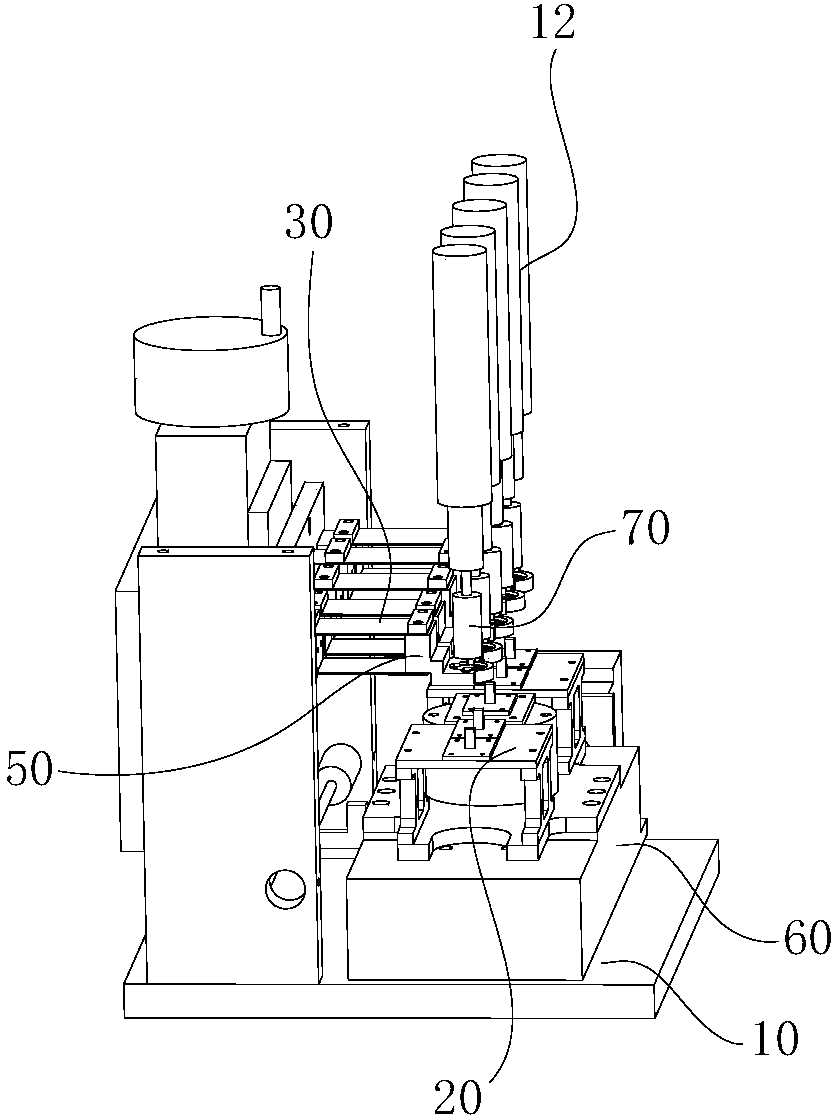

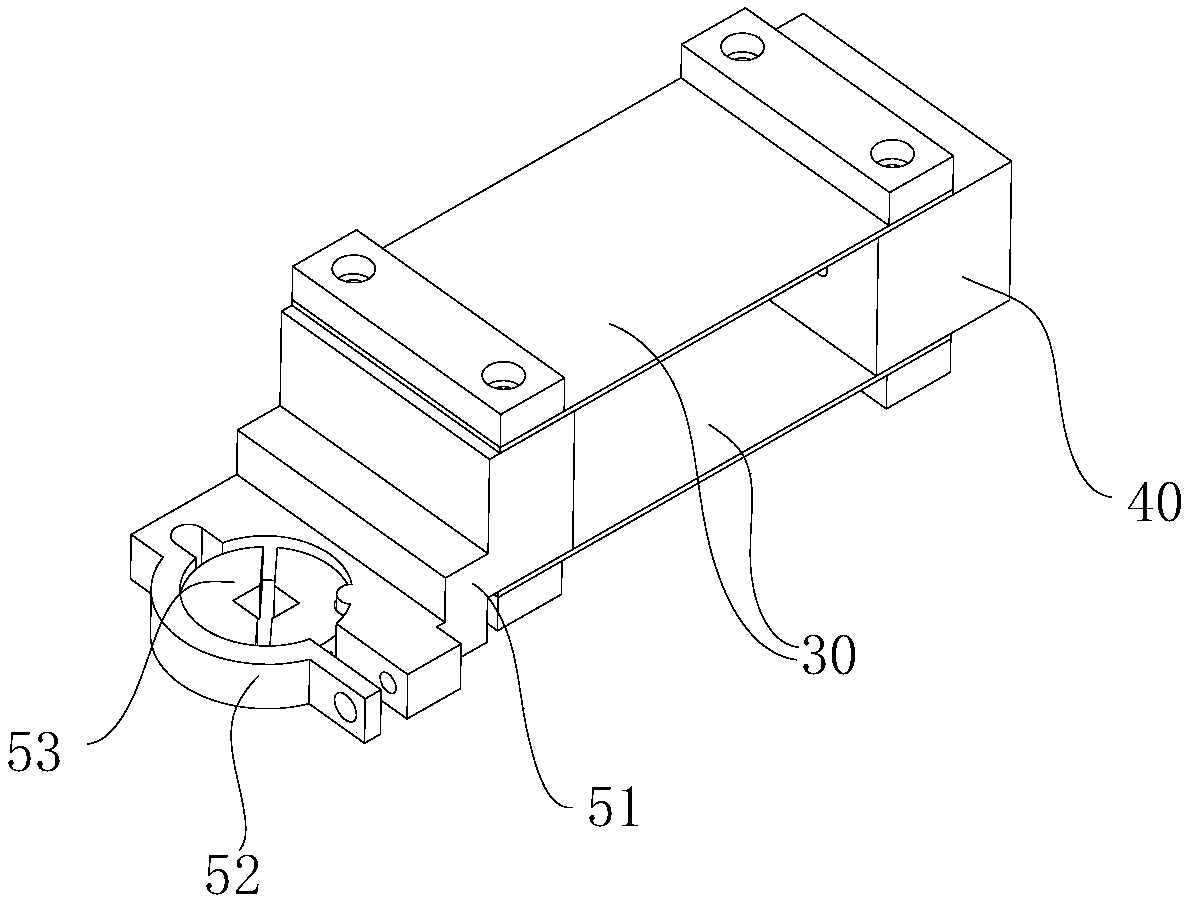

[0022] combine Figure 1 to Figure 6 , the present invention is further described:

[0023] The multi-head plane reciprocating friction and wear testing machine comprises a workbench 10, on which a lower clamp 20 for fixing the sample to be tested is arranged, and a movable beam 40 is arranged above the workbench 10, and the movable beam 40 An upper clamp 50 for clamping the sample to be tested is arranged on the top, and the adjustment mechanism adjusts the movable beam 40 to move up and down and makes the upper clamp 50 and the lower clamp 20 approach or move away from each other. The movable beam 40 is horizontally suspended and set There is an elastic plate 30, the surface of the elastic plate 30 is arranged horizontally, the upper clamp 50 is fixed on the overhanging end of the elastic plate 30, the upper end of the upper clamp 50 is provided with a pressure head 70, and the pressure head 70 is vertical direction reciprocating movement and abut against or separate from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com