Position sensor for throttle body

A throttle body and sensor technology, applied in the field of sensors, can solve problems such as inability to guarantee constant contact pressure and output voltage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

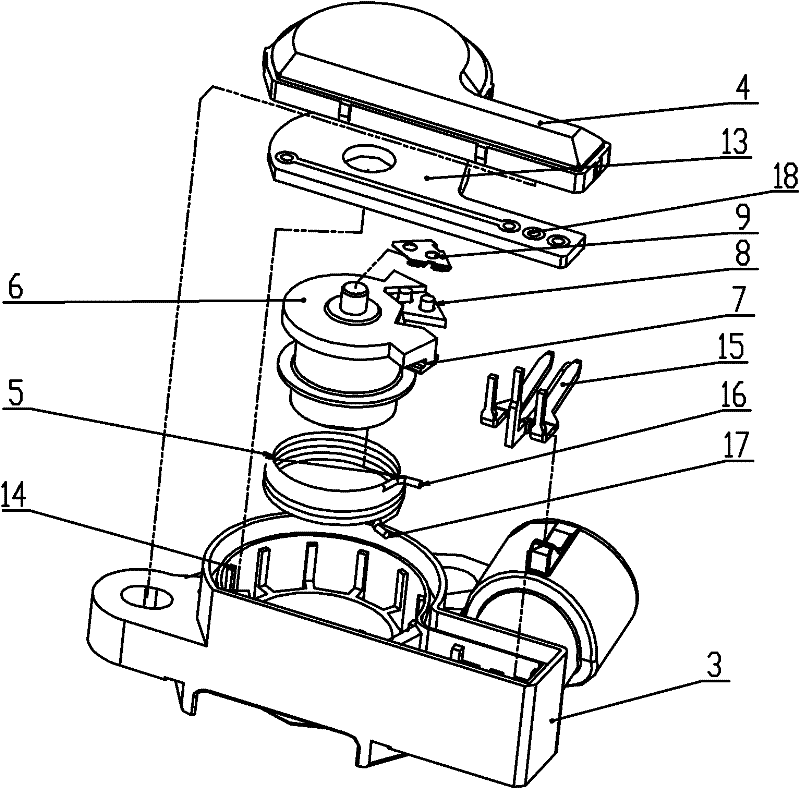

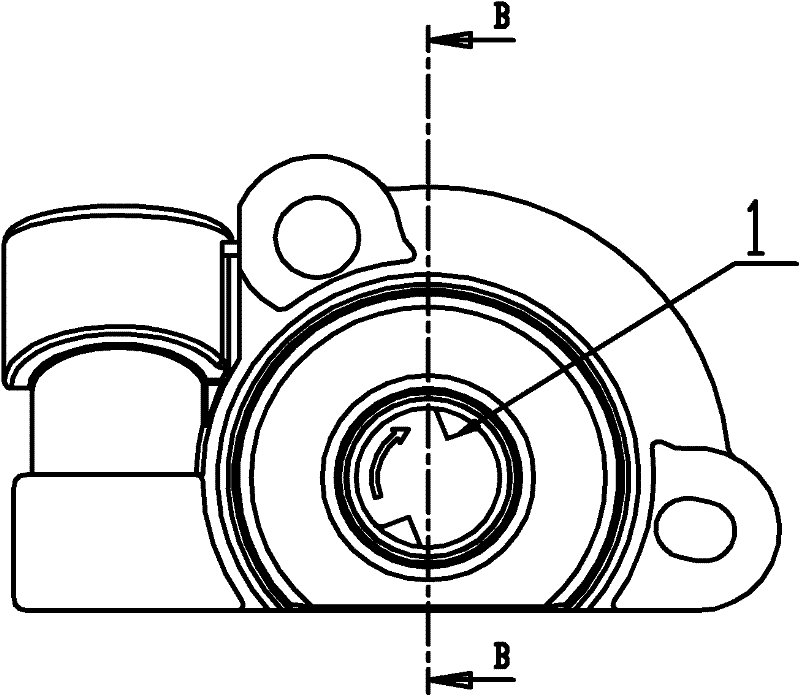

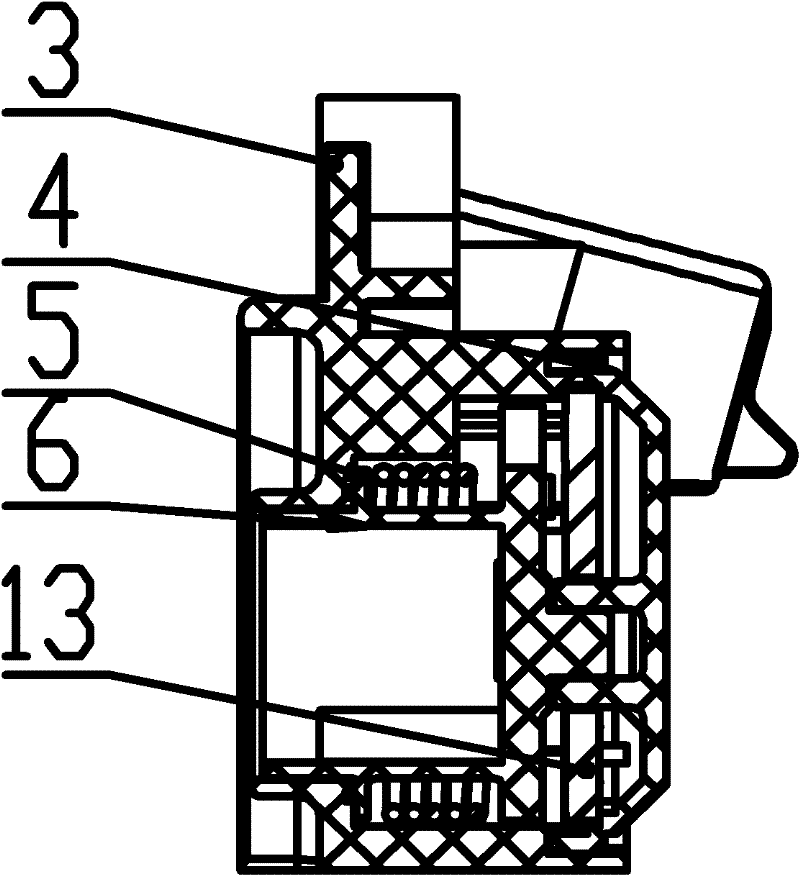

[0015] Such as Figure 1 to Figure 5 As shown, the throttle body position sensor of the present invention includes a plastic housing 3, a cover 4, a return spring 5, a brush body 6, a brush 9, a PCB substrate 13, a pillar 8, a mechanical top dead center 12, and a mechanical bottom dead center 11. The first hanging pin 7, the second hanging pin 10 and the pin 15. Pillar 8 is protruding outwards. The seal between the cover 4 and the plastic shell 3 is connected by glue. The brush main body 6 is inserted into the hole of the plastic housing 3 and is clearance-fitted with the plastic housing 3 . The electric brush 9 is connected with the post 8 with interference, and the reverse barb on the electric brush 9 is stuck on the post 8 to prevent falling off. A torsion arm 16 of the back-moving spring 5 is hung on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com