Patents

Literature

80results about How to "Ensure data accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

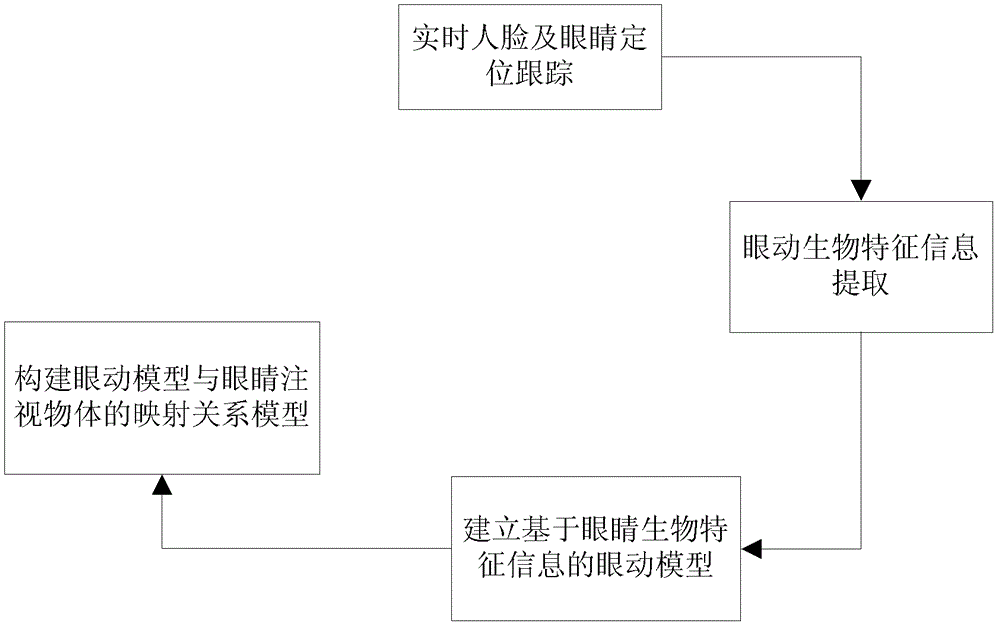

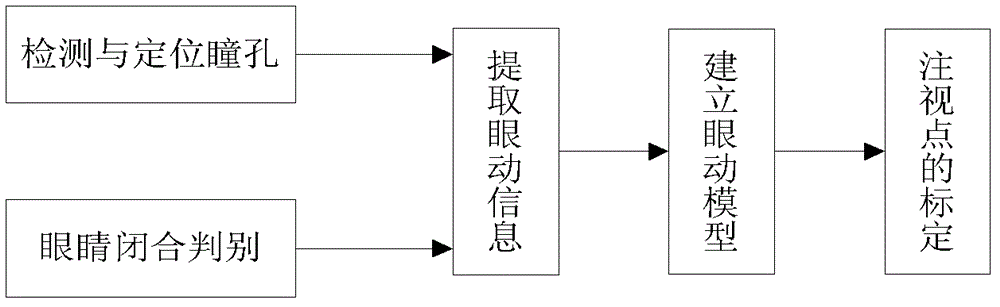

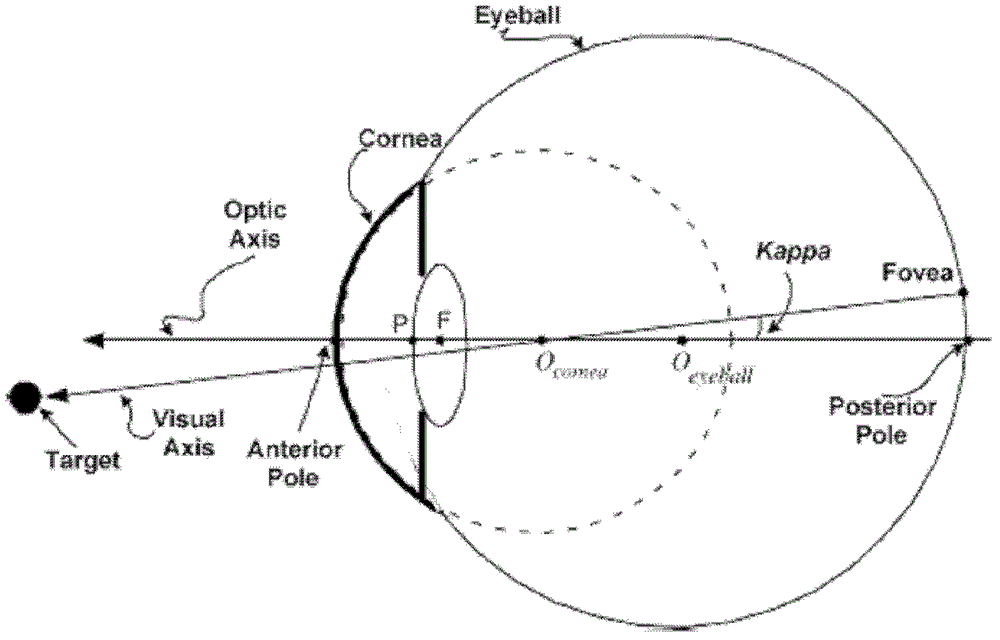

Non-contact free space eye-gaze tracking method suitable for man-machine interaction

ActiveCN102749991AAccurate detectionPrecise positioningInput/output for user-computer interactionCharacter and pattern recognitionJet aeroplaneAviation

The invention provides a non-contact free space eye-gaze tracking method suitable for man-machine interaction. The method comprises the steps of positioning and tracking a face and eyes in real time, extracting eye movement biological characteristic information, building an eye movement model based on the eye movement biological characteristic information, building a mapping relational model of the eye movement model and an eye-gazed object and the like. The non-contact free space eye-gaze tracking method suitable for the man-machine interaction relates to multiple crossed fields of image processing, computer vision, pattern recognition and the like and has wide application prospect in the fields of new-generation man-machine interaction, disabled people assisting, aerospace relating field, sports, automobile and airplane driving, virtual reality, games and the like. In addition, the method has great practical significance for improvement of the life and self-care level of disabled people, building of a harmonious society and improvement of independent innovative capability in the national high-and-new technical fields of the man-machine interaction, unmanned driving and the like.

Owner:广东百泰科技有限公司

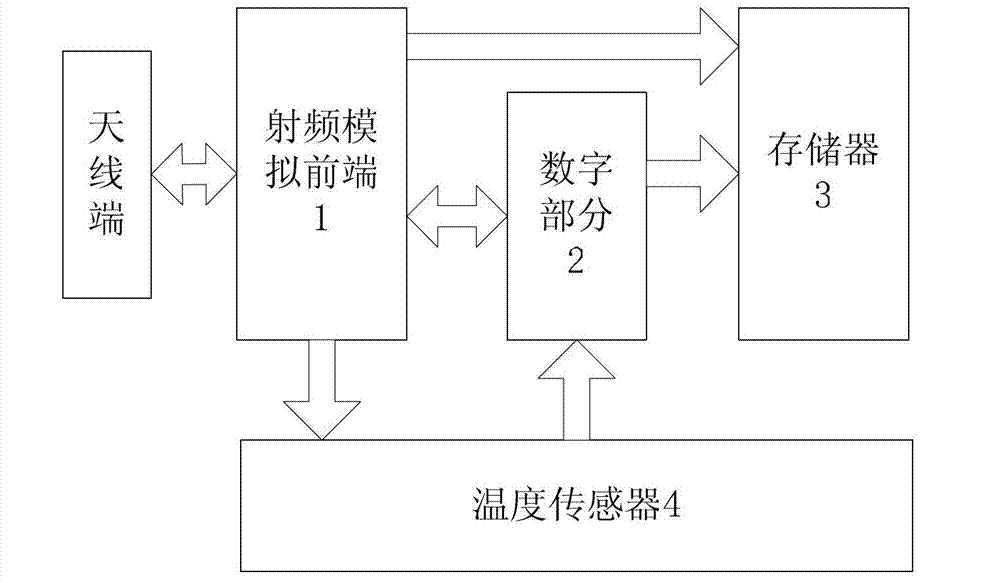

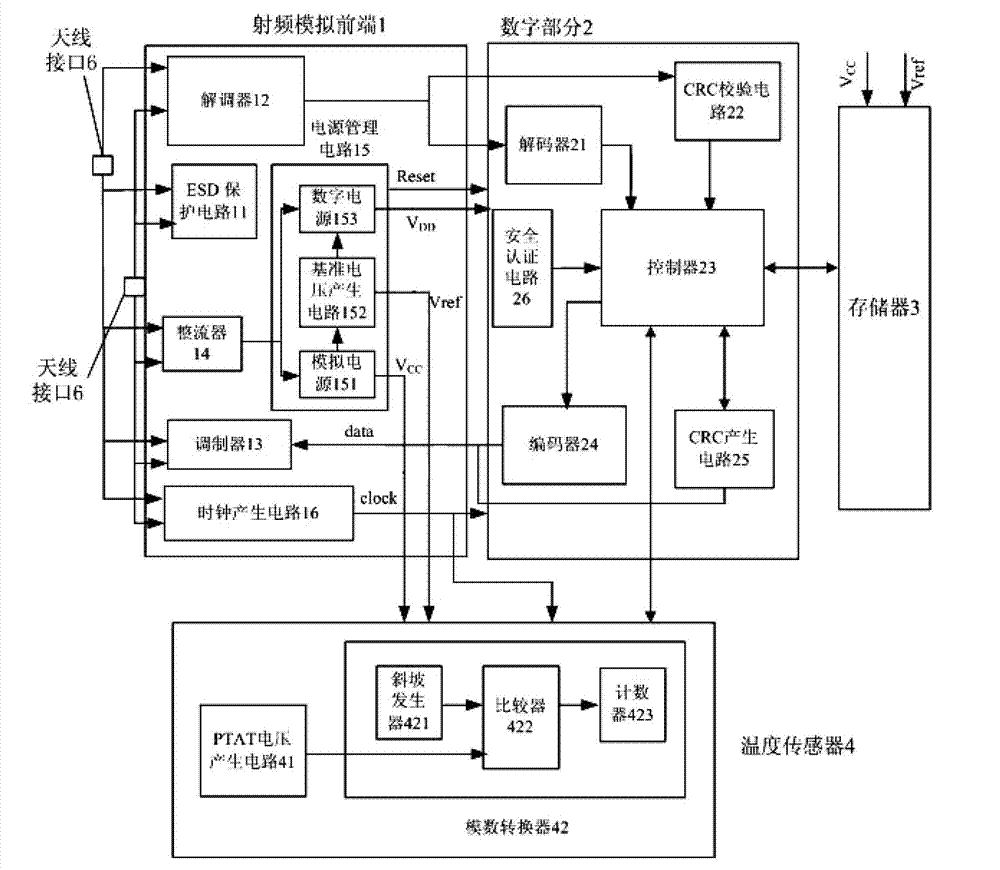

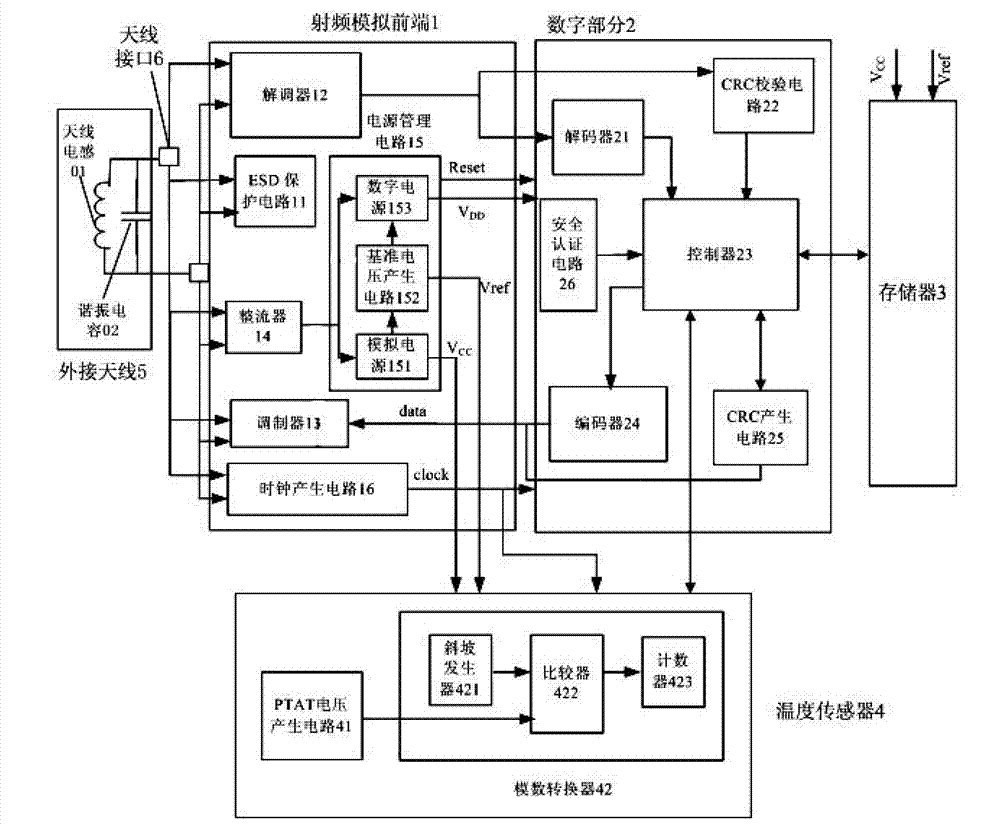

Passive RFID ((Radio Frequency Identification Device) temperature sensor label

InactiveCN102831457AReduce manufacturing costEasy to useThermometers using electric/magnetic elementsUsing electrical meansRadio frequencyElectric energy

The invention discloses a passive RFID ((Radio Frequency Identification Device) temperature sensor label. The passive RFID temperature sensor label comprises a RF analog front end, a digital part, a memory, a temperature sensor and an antenna terminal used for connecting an externally connected antenna, wherein the RF analog front end is respectively connected with an antenna end, the digital part, the memory and the temperature sensor; and the digital part is also respectively connected with the memory and the temperature sensor. The label adopts the antenna end to match with the RF analog front end to convert an RF energy sensed by the externally connected antenna into an electric energy which is enable supplied to the digital part, the memory and the temperature sensor, a built-in power source is unnecessary. The passive RFID temperature sensor label, disclosed by the invention, can efficiently reduce production cost of the label, utilize the RF energy in an inductive electromagnetic field of the externally connected antenna and convert the RF energy into the electric energy available for the label only by putting the label in the electromagnetic field, being convenient to use, and is convenient to use; and the service life of the passive RFID temperature sensor label is unnecessarily limited by the service life of the built-in power source.

Owner:广州中盈智能科技有限公司

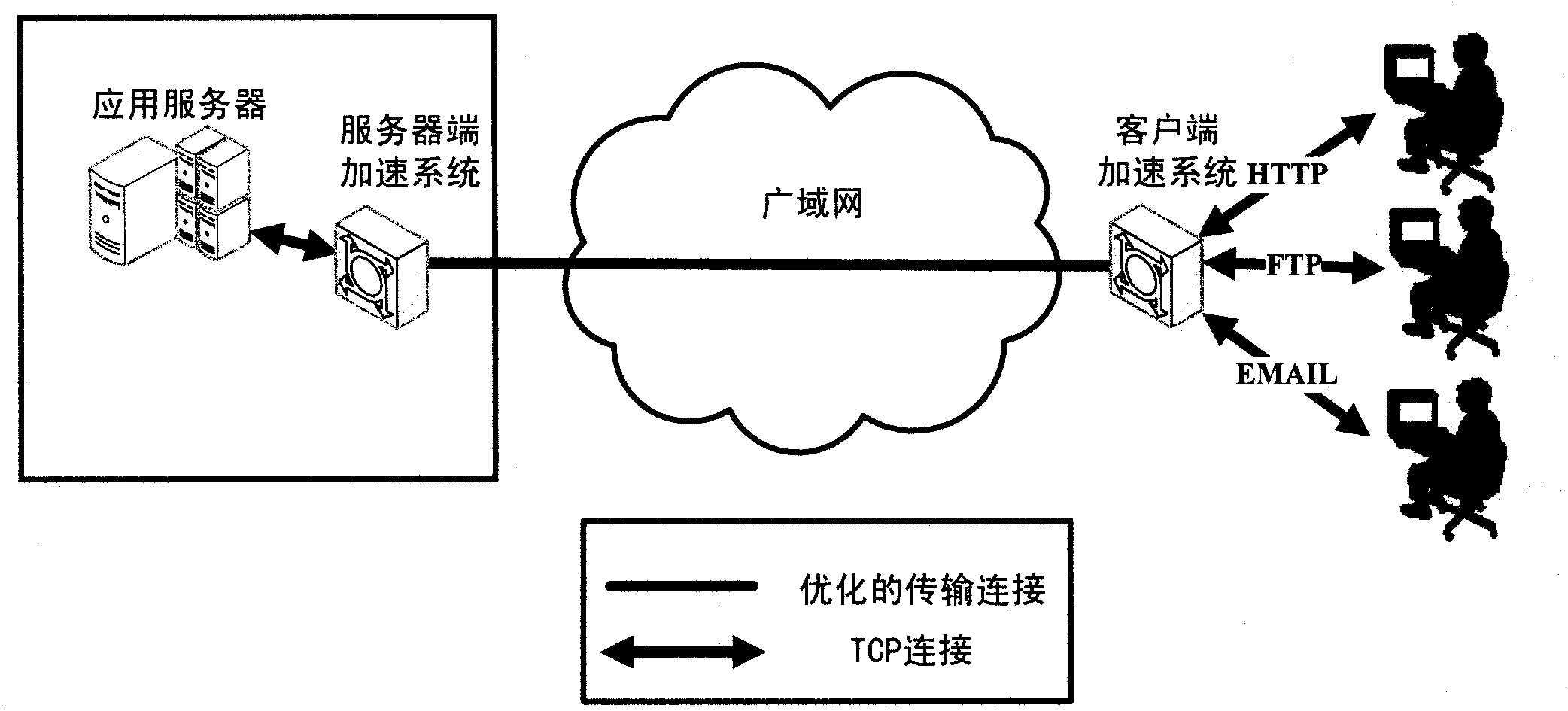

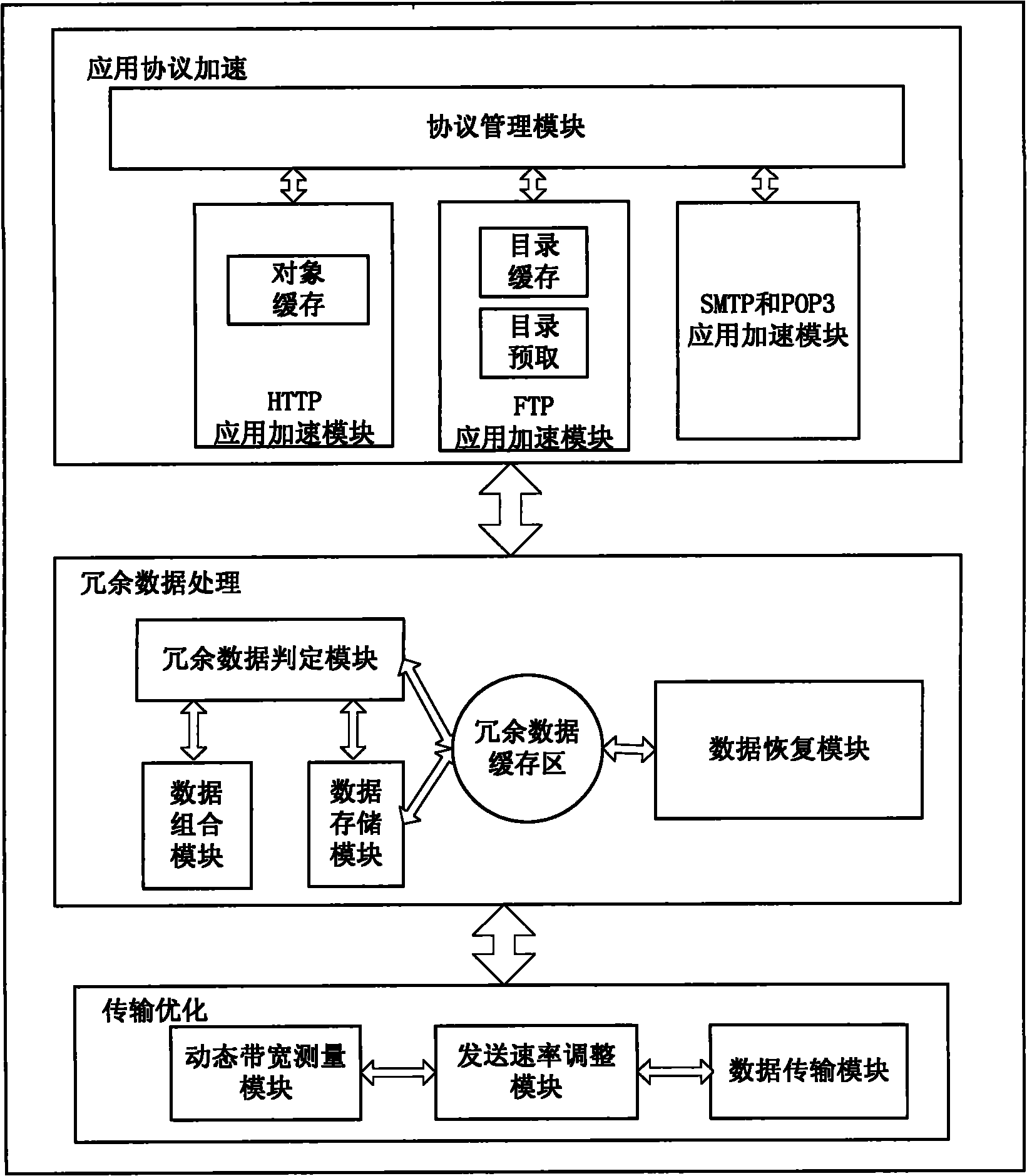

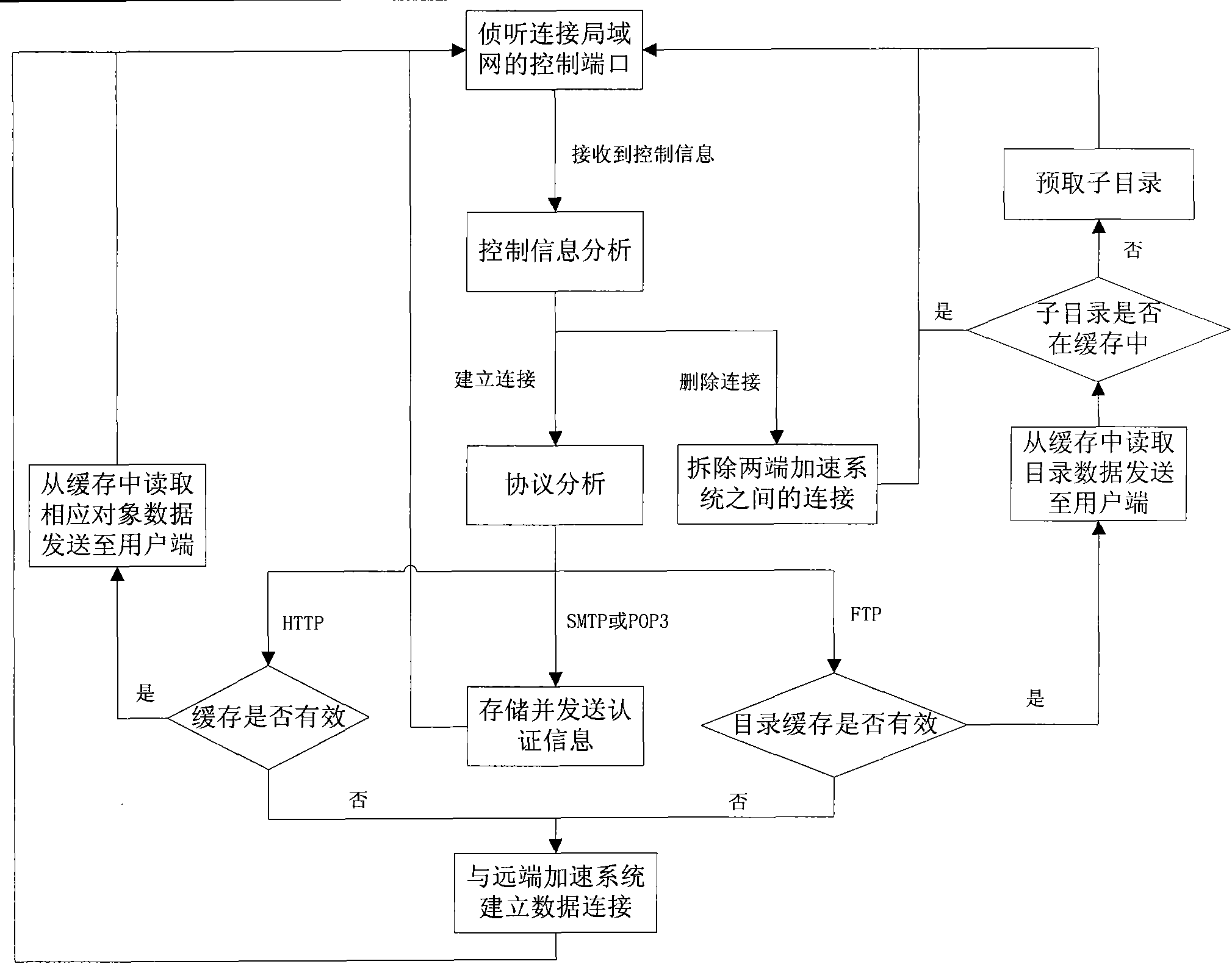

IP (Internet Protocol) network application accelerating system

ActiveCN101945103AEnsure data accuracyFast transmissionError preventionApplication serverData combination

The invention relates to an IP network application accelerating system for realizing the high-efficiency transmission of data in wide area networks. The interaction times among the wide area networks are reduced and the response time of an application server to a user is increased through optimizing four mainstream application protocols such as HTTP (Hyper Text Transport Protocol), FTP (File Transfer Protocol), SMTP (Simple Message Transfer Protocol) and POP3 (Post Office Protocol 3) in the aspects of object caching, directory prefetching, data authentication and the like; the retransmission of the same data in the networks is avoided through redundant data judgment, data combination and data recovery, and thereby, the effective use ratio of available bandwidth is improved, and simultaneously, the stability and the accuracy of redundant data processing are ensured through the storage management on a data redundancy caching zone; and the actual transmission rate of the data in the widearea networks is improved through dynamically measuring the network bandwidth and regulating the transmitting rate.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

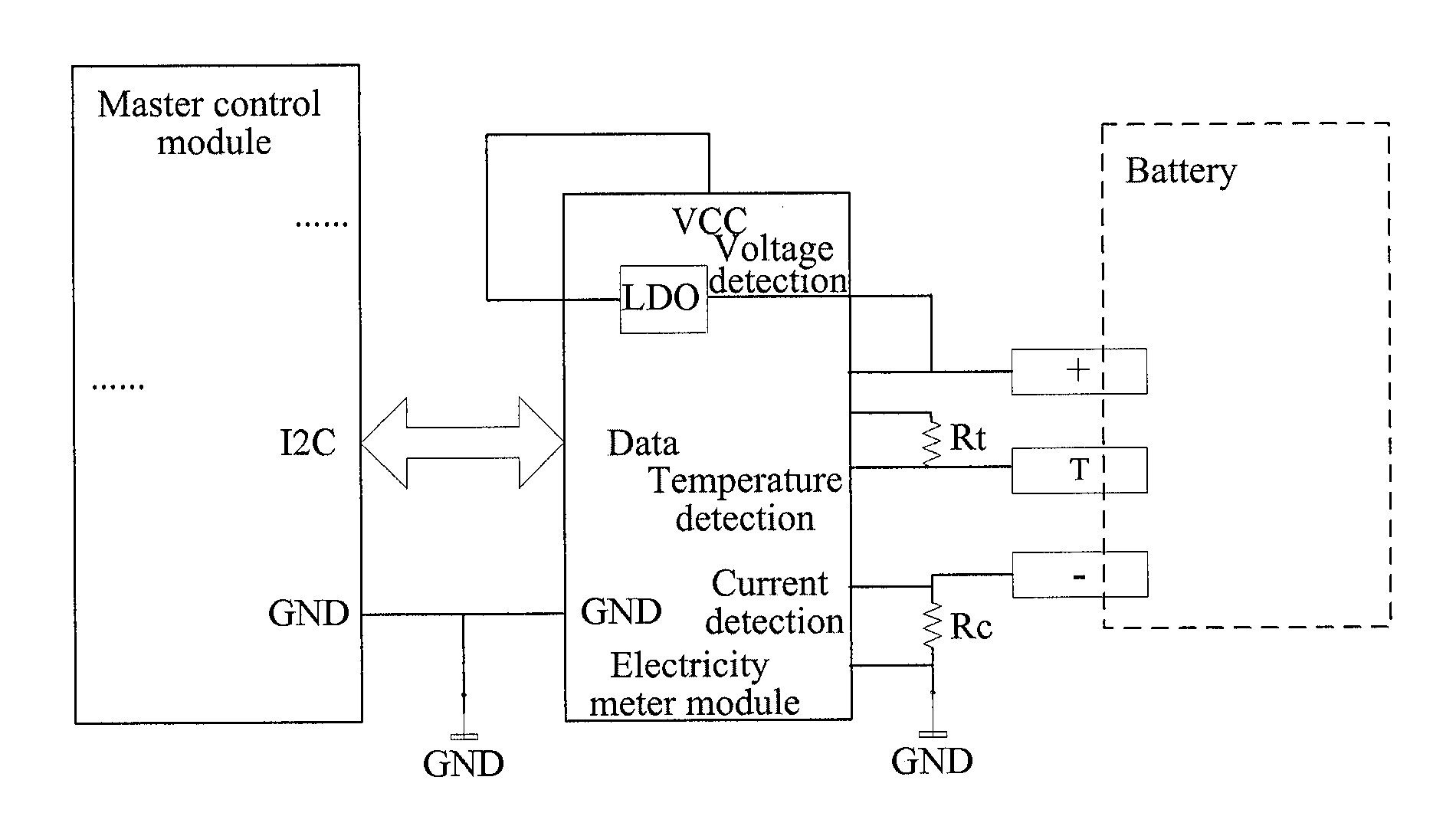

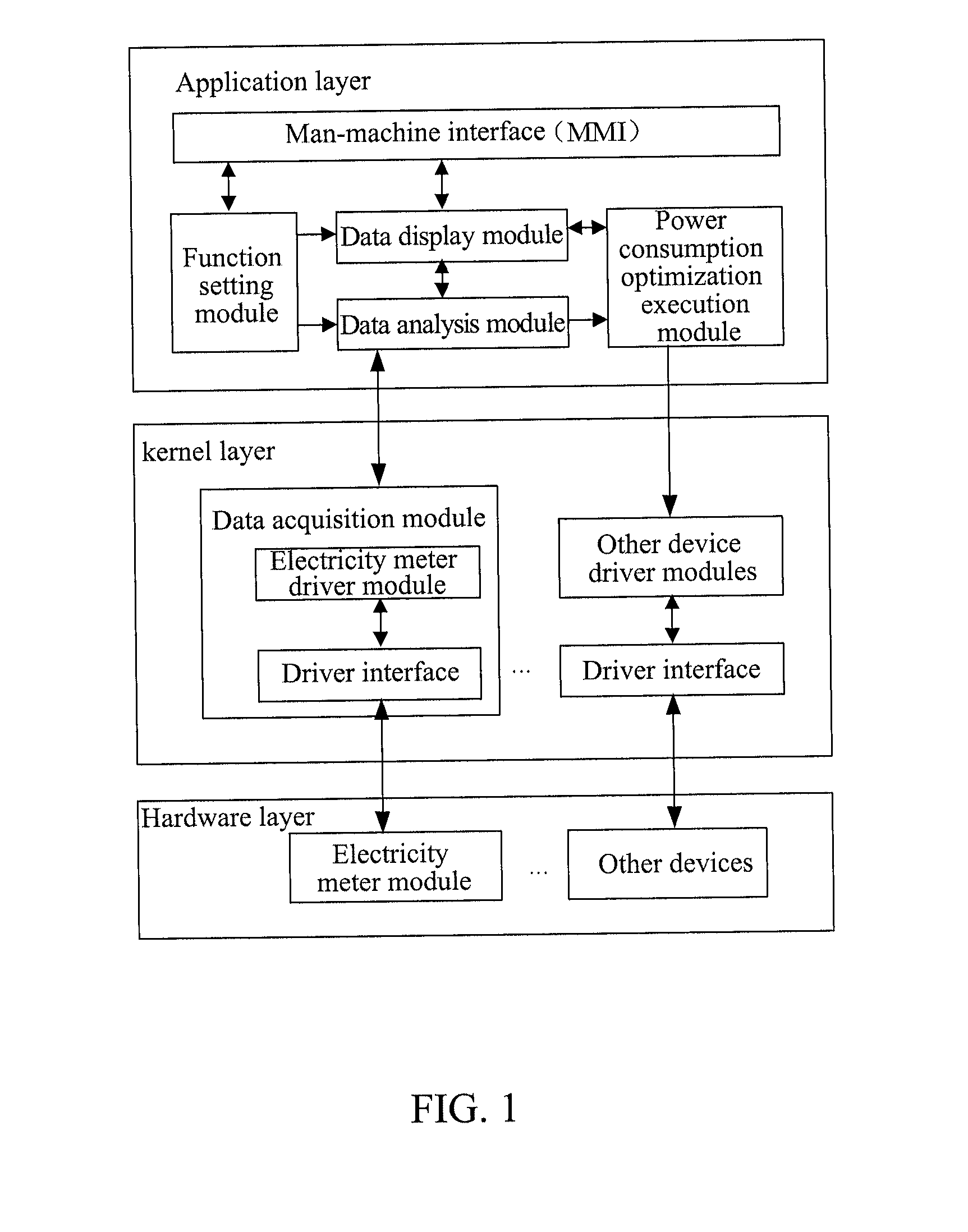

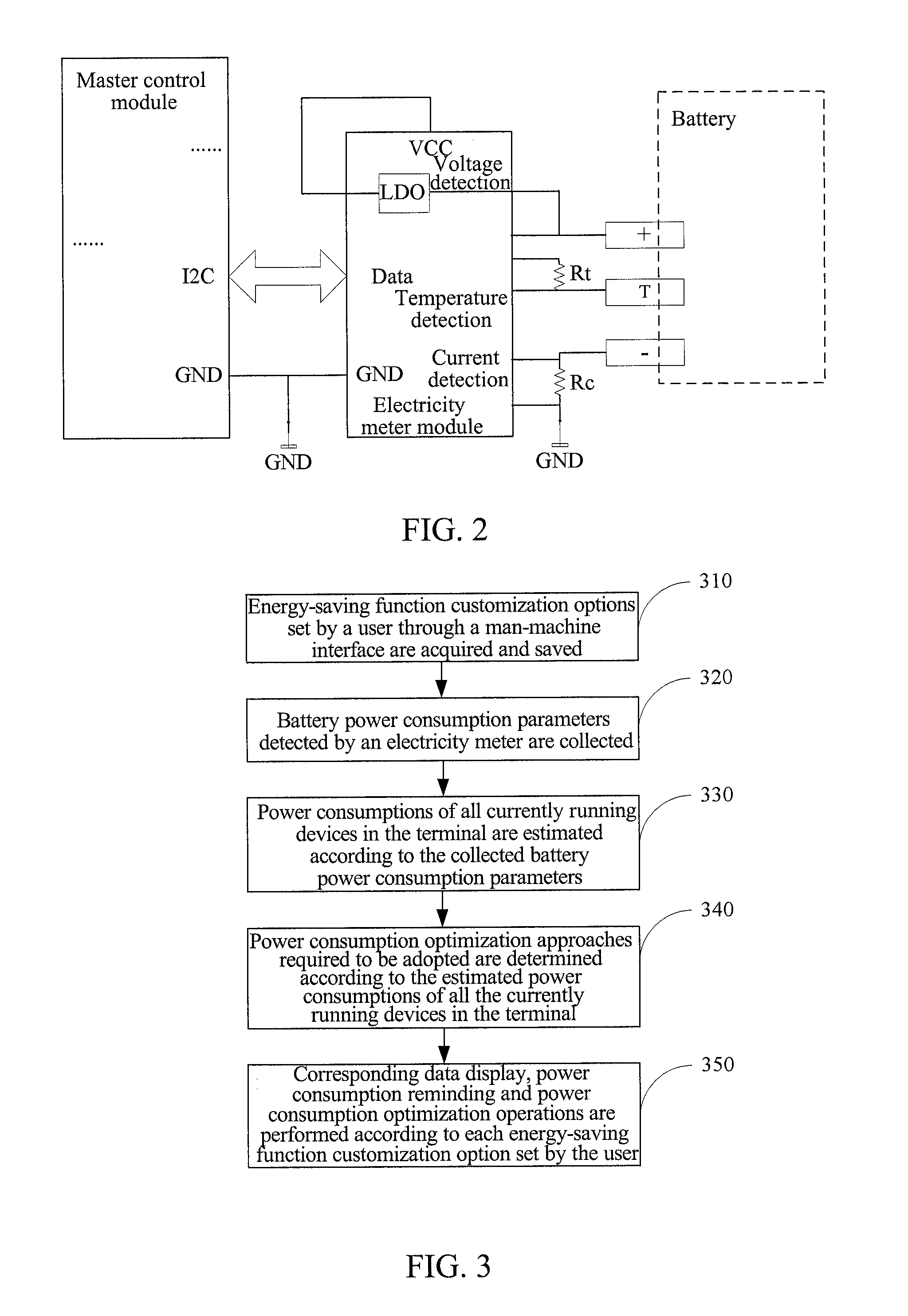

Energy-saving device and method for portable terminal

ActiveUS20130311803A1Minimum power consumptionLow costPower managementVolume/mass flow measurementElectrical batteryData acquisition module

An energy-saving apparatus and method for a portable terminal are disclosed in the present document. The apparatus includes: an electricity meter module, configured to detect battery power consumption parameters under driving of a data acquisition module; the data acquisition module, configured to drive the detection of the electricity meter module, and output the collected battery power consumption parameters to a data analysis module; the data analysis module, configured to estimate power consumptions of all running devices at present in the terminal according to the input battery power consumption parameters, and output a power consumption optimization instruction to a power consumption optimization execution module; and the power consumption optimization execution module, configured to adopt corresponding power consumption optimization approaches according to the input power consumption optimization instruction.

Owner:ZTE CORP

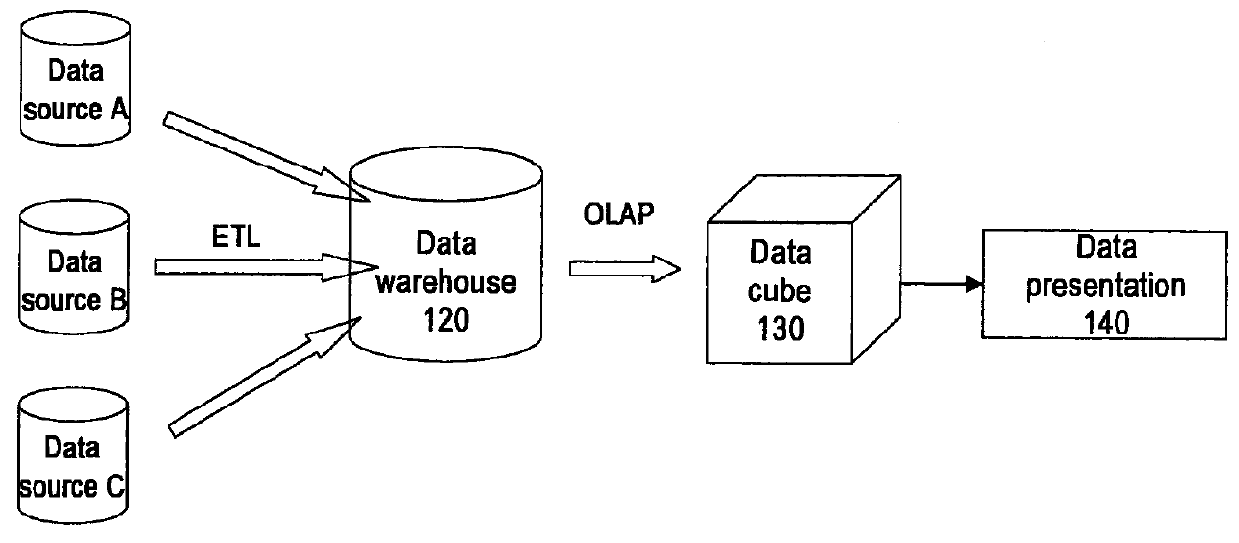

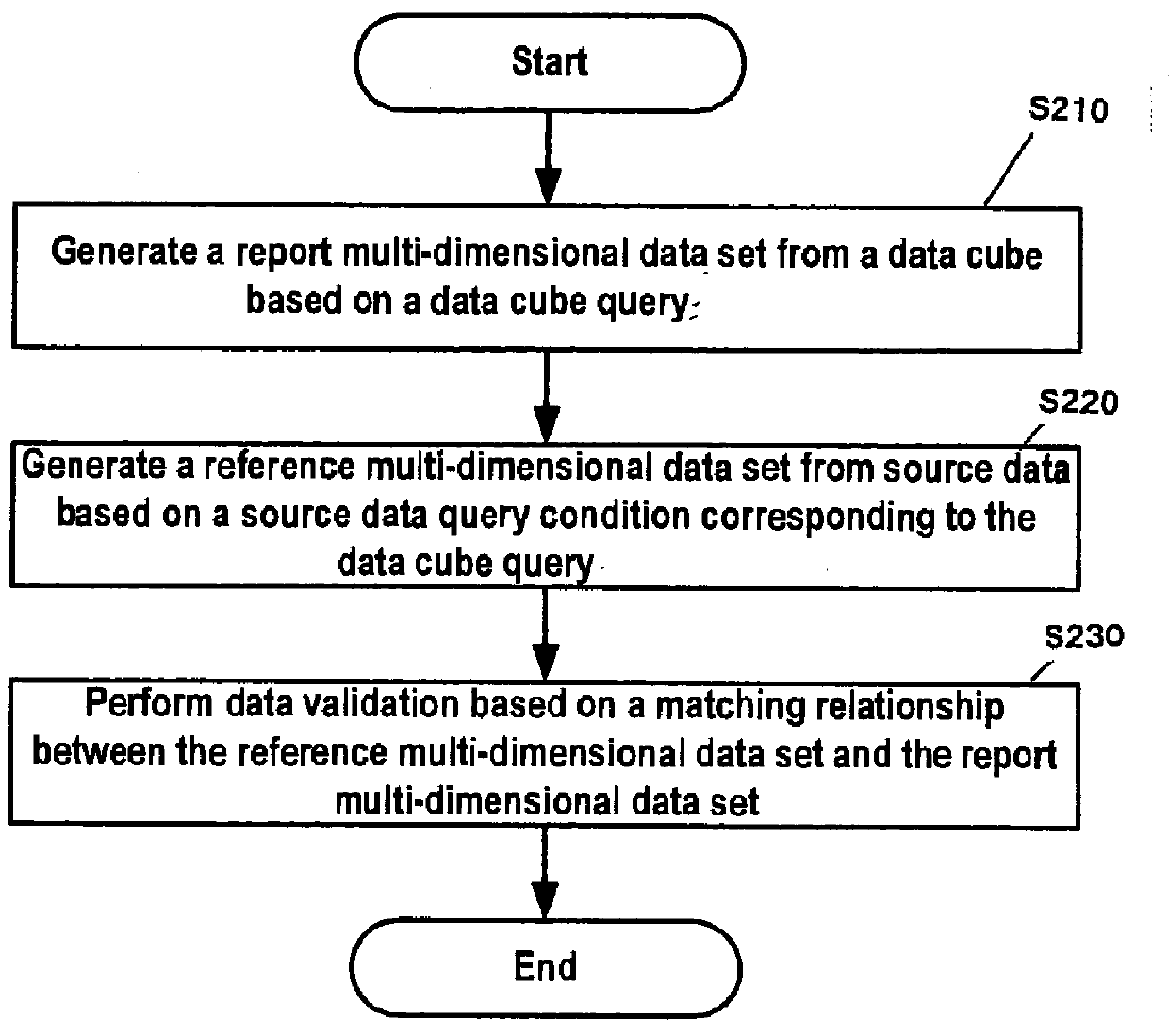

Method and system for validating data

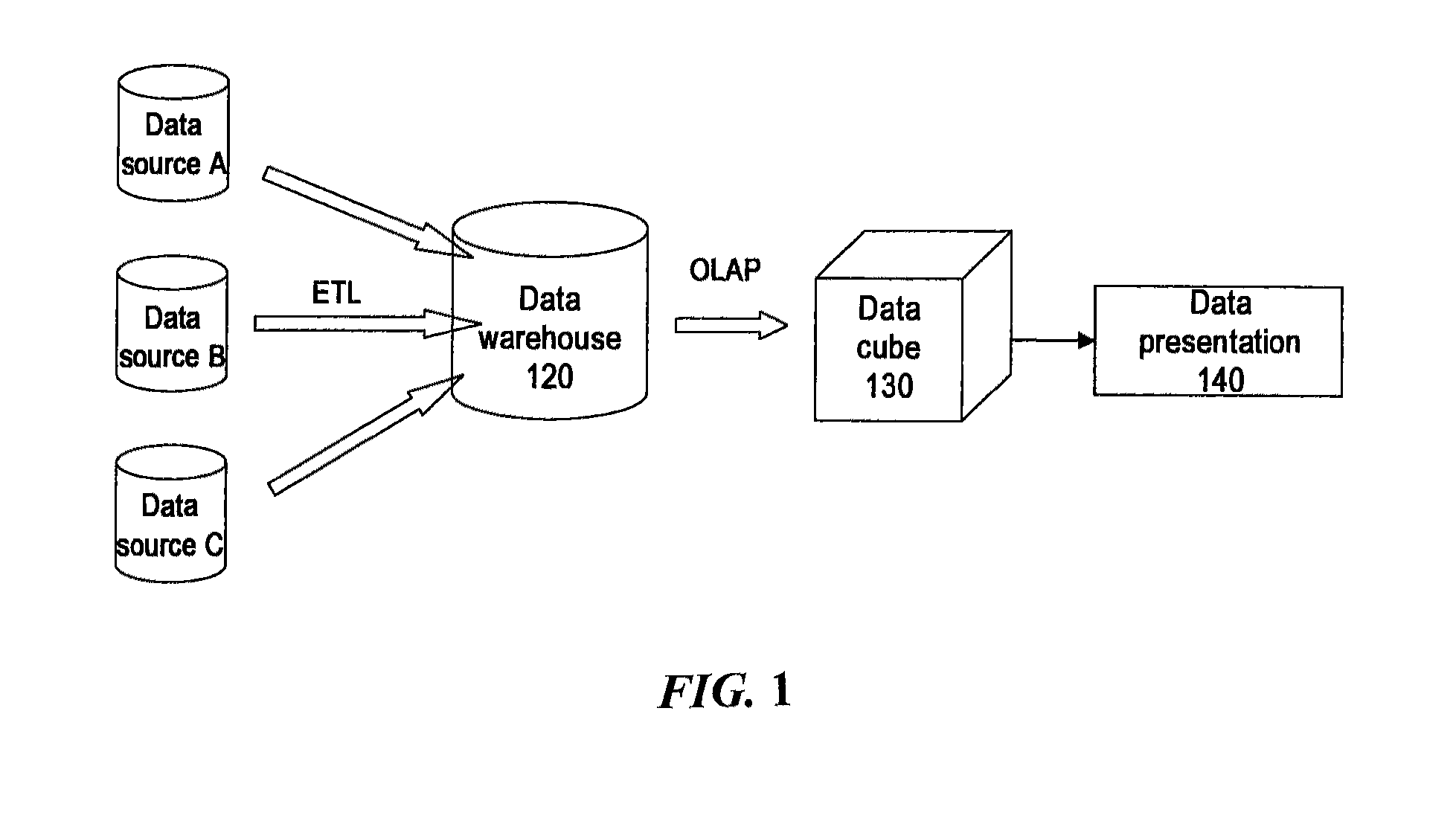

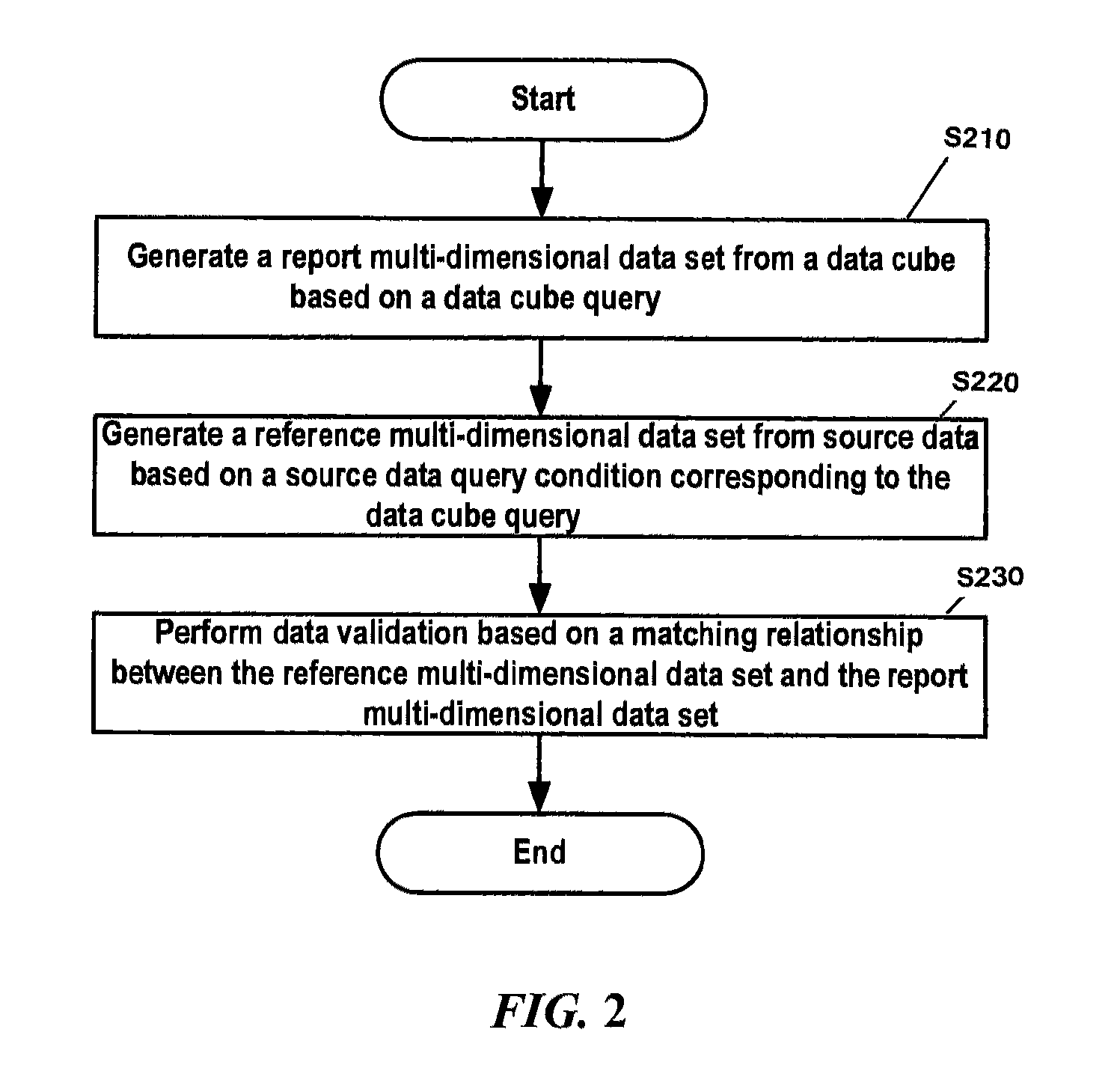

InactiveUS20120221510A1Ensure data accuracyWorkload for checking data problems is greatly reducedDigital data processing detailsMulti-dimensional databasesData validationData set

A method and system for validating data. Warehouse data is generated by transforming source data via an ETL transformation model. A data cube is generated by transforming the warehouse data via an OLAP transformation model. A report dataset (MDS1) is generated from the data cube. A reference dataset (S) is generated from the source data. A data validation is performed, the data validation being based on a matching relationship between MDS1 and S.

Owner:KYNDRYL INC

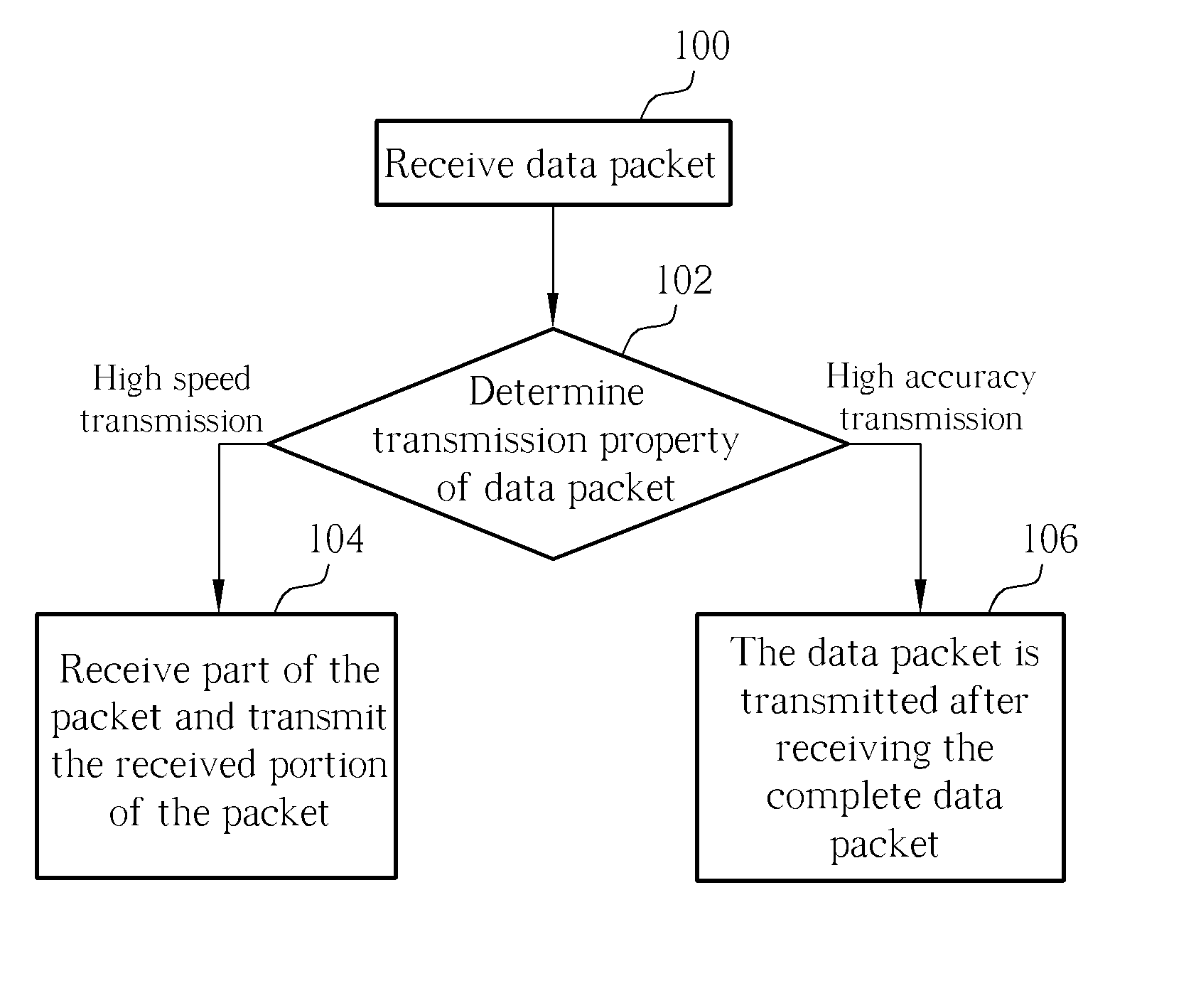

Switch capable of controlling data packet transmission and related method

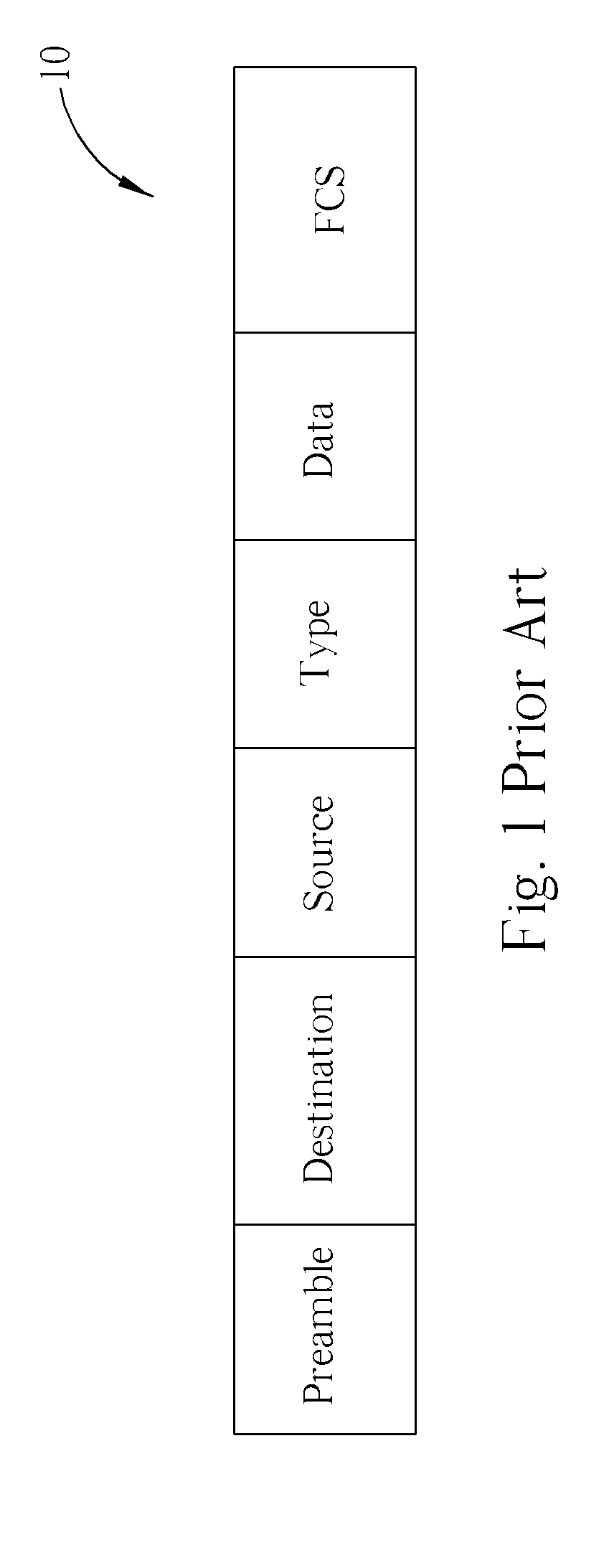

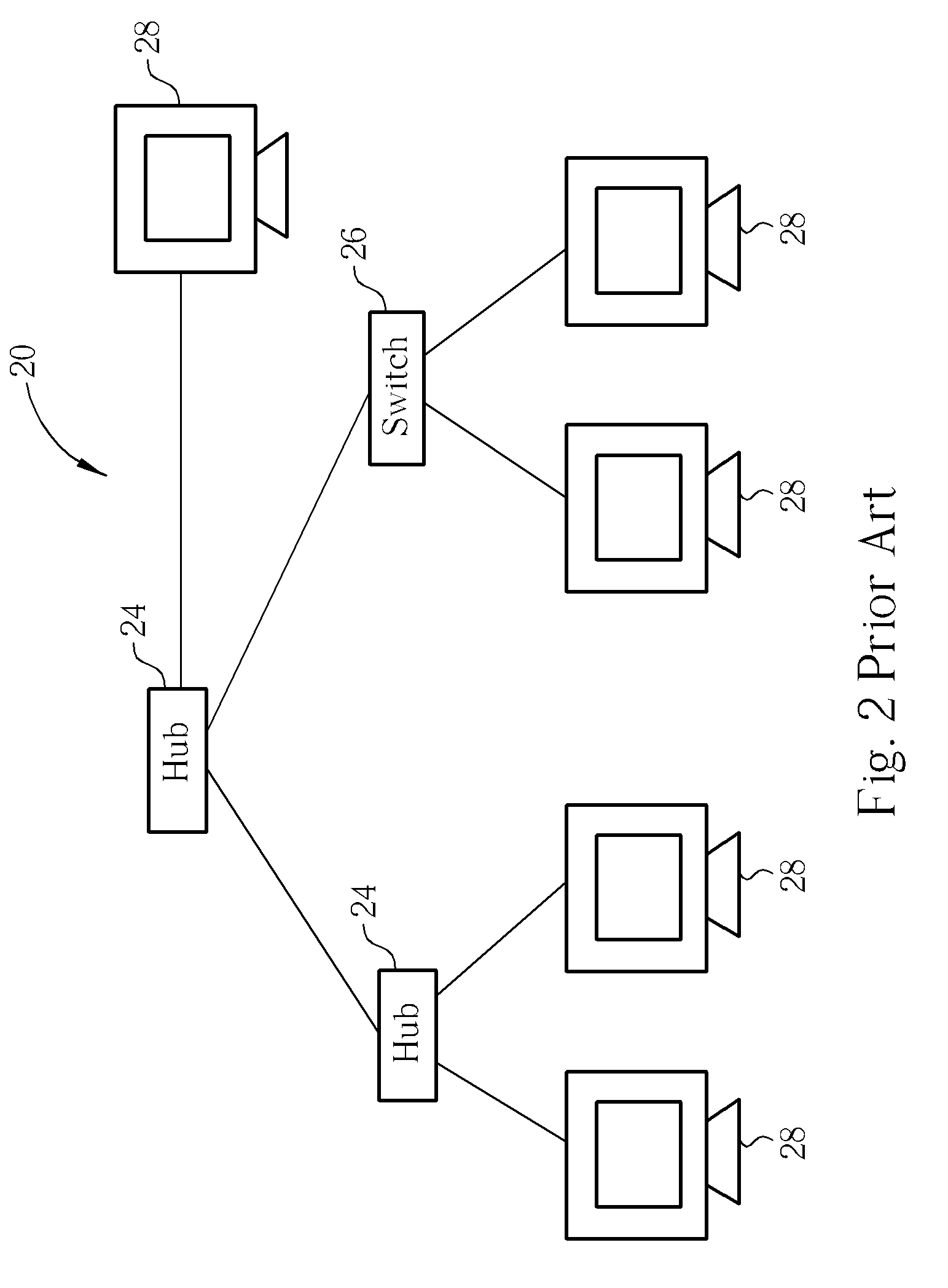

InactiveUS20050129047A1Easy to operateLow costData switching by path configurationStore-and-forward switching systemsPacket transmissionComputer science

A switch capable of controlling data packet transmission includes at least one input port for receiving a data packet, at least one output port for outputting the data packet, a queue buffer for holding the received data packet, and a analyzing-processing unit for determining how to transmit the received data packet based on a transmission requirement of the received data packet.

Owner:VIA TECH INC

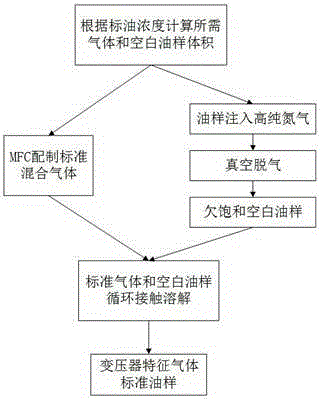

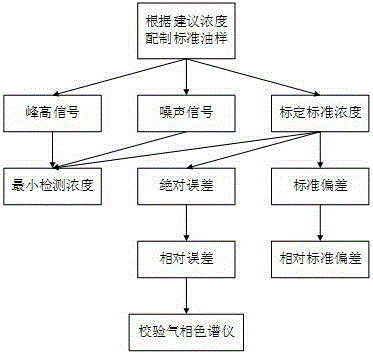

Preparation and evaluation method of transformer characteristic gas standard oil samples

ActiveCN105223286AQuality improvementGuaranteed operational reliabilityTesting dielectric strengthComponent separationGas phaseTransformer

The invention relates to a preparation and evaluation method of transformer characteristic gas standard oil samples. By preparation of standard gases with different concentrations, preparation of a blank oil sample, thorough mixing of the standard gases with the blank oil sample and other steps, the preparation method realizes preparation of the transformer characteristic gas standard oil samples. The evaluation method utilizes the standard oil samples with different concentrations prepared by the method, and evaluates the gas chromatography performance including the minimum detection concentration, data repeatability and accuracy, and evaluates a gas chromatograph, thus realizing comprehensive evaluation of the transformer characteristic gas standard oil samples. The method provided by the invention can prepare standard oil samples with set characteristic gas concentrations at one time, and also can improve the quality of the gas chromatograph so as to ensure the device operation reliability and data accuracy.

Owner:陈伟根

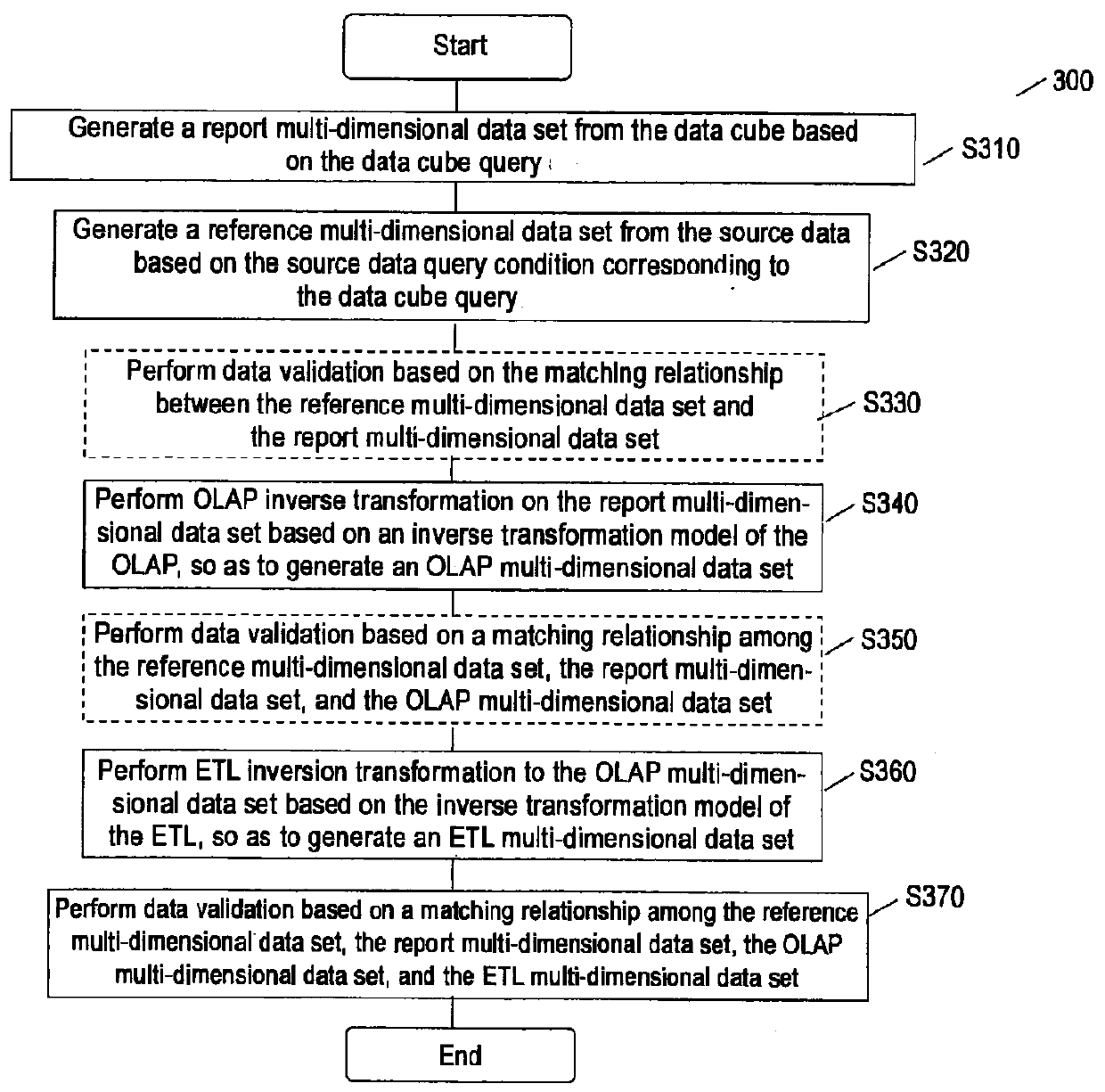

Method and system for validating data

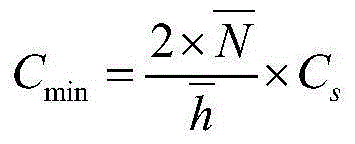

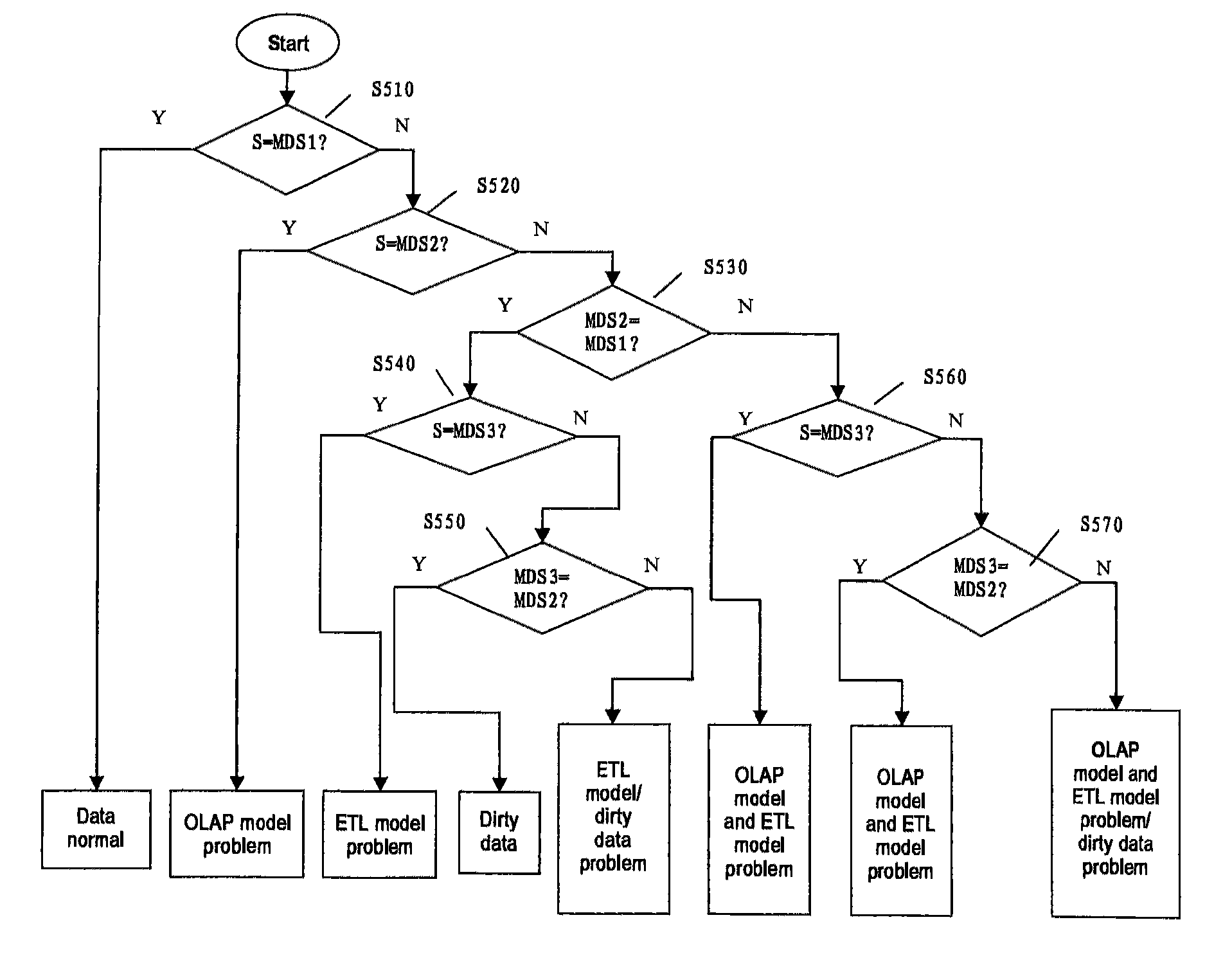

InactiveUS8219520B2Ensure data accuracyWorkload for checking data problems is greatly reducedDigital data processing detailsMulti-dimensional databasesData setData mining

A method and system for validating data. Warehouse data is generated by transforming source data via an ETL transformation model. A data cube is generated by transforming the warehouse data via an OLAP transformation model. A report dataset (MDS1) is generated from the data cube. A reference dataset (S) is generated from the source data. Whether MDS1 matches S is determined. If MDS1 doesn't match S, then an OLAP inverse transformation is performed on MDS1 to generate an OLAP dataset (MDS2) and whether MDS2 matches S is determined. If MDS1 doesn't match S and MDS2 does not match S, then an ETF inverse transformation is performed on MDS2 to generate an ETL dataset (MDS3) and whether MDS2 matches MDS1 and whether MDS3 matches S is determined. If MDS1 doesn't match S and MDS2 does not match S and MDS3 does not match S, then whether MDS3 matches MDS2 is determined.

Owner:KYNDRYL INC

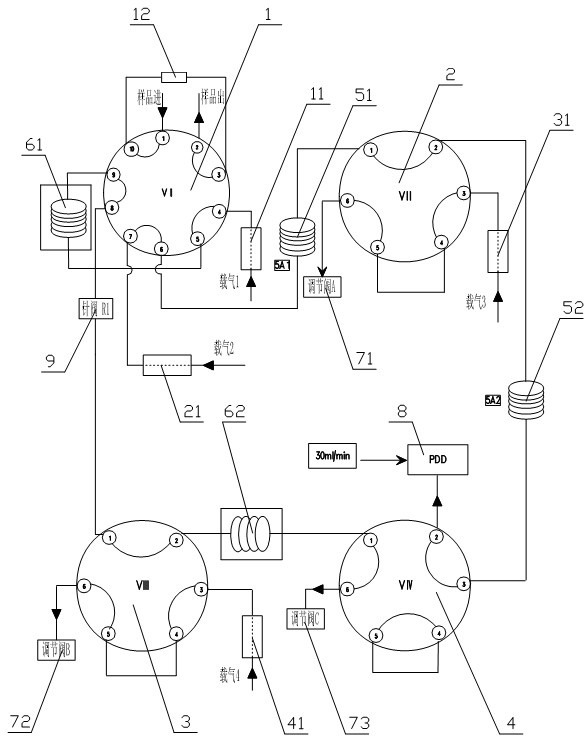

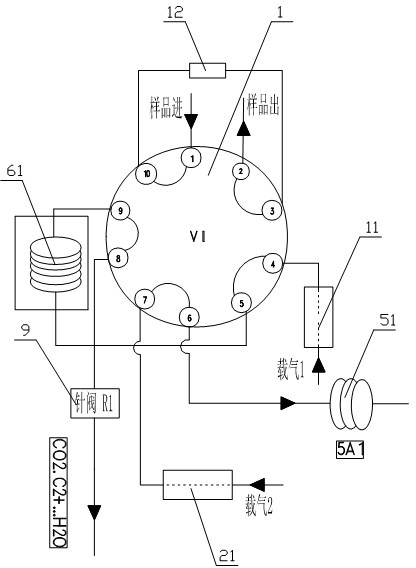

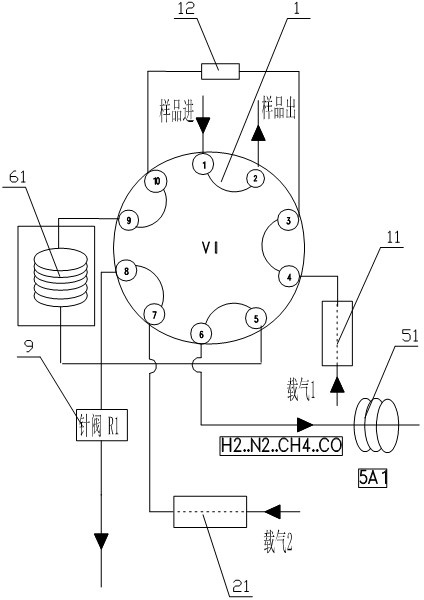

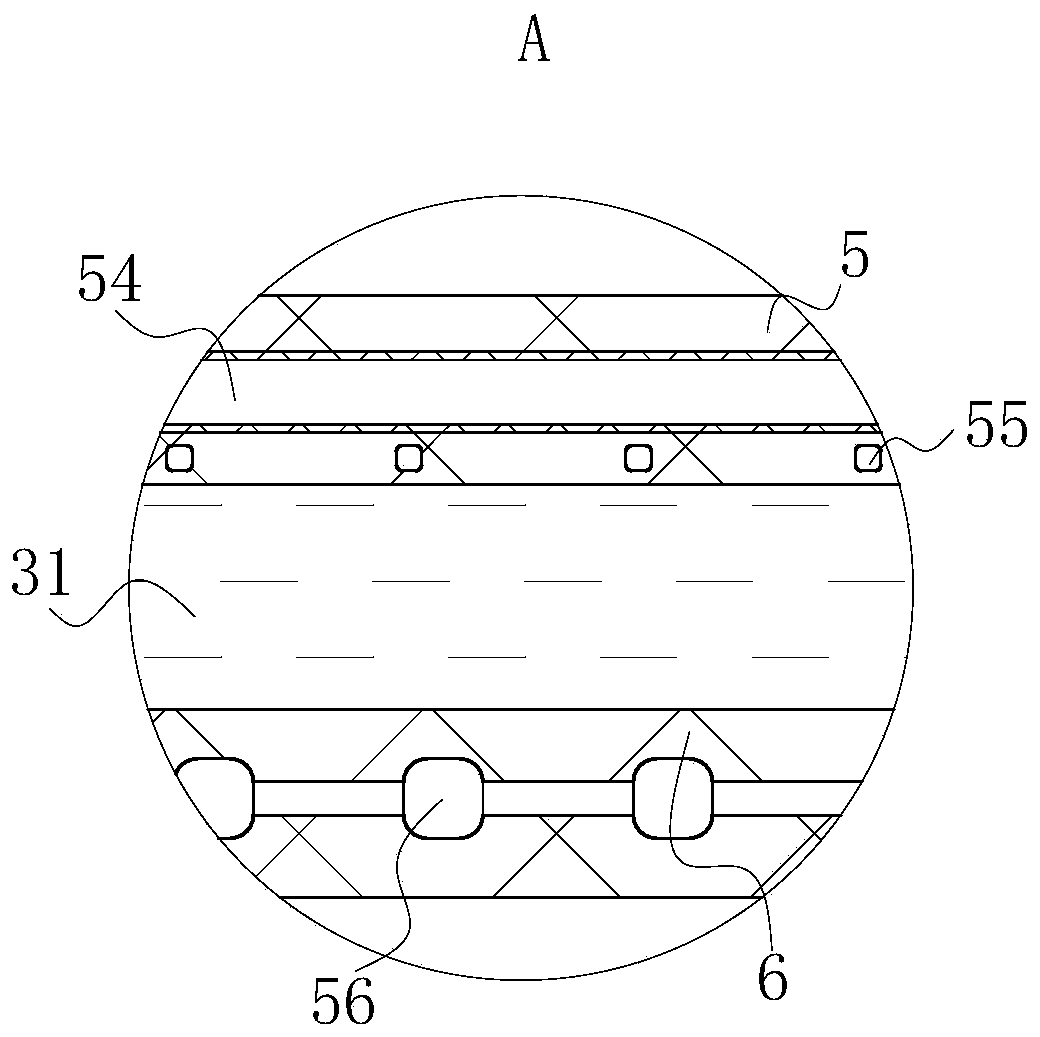

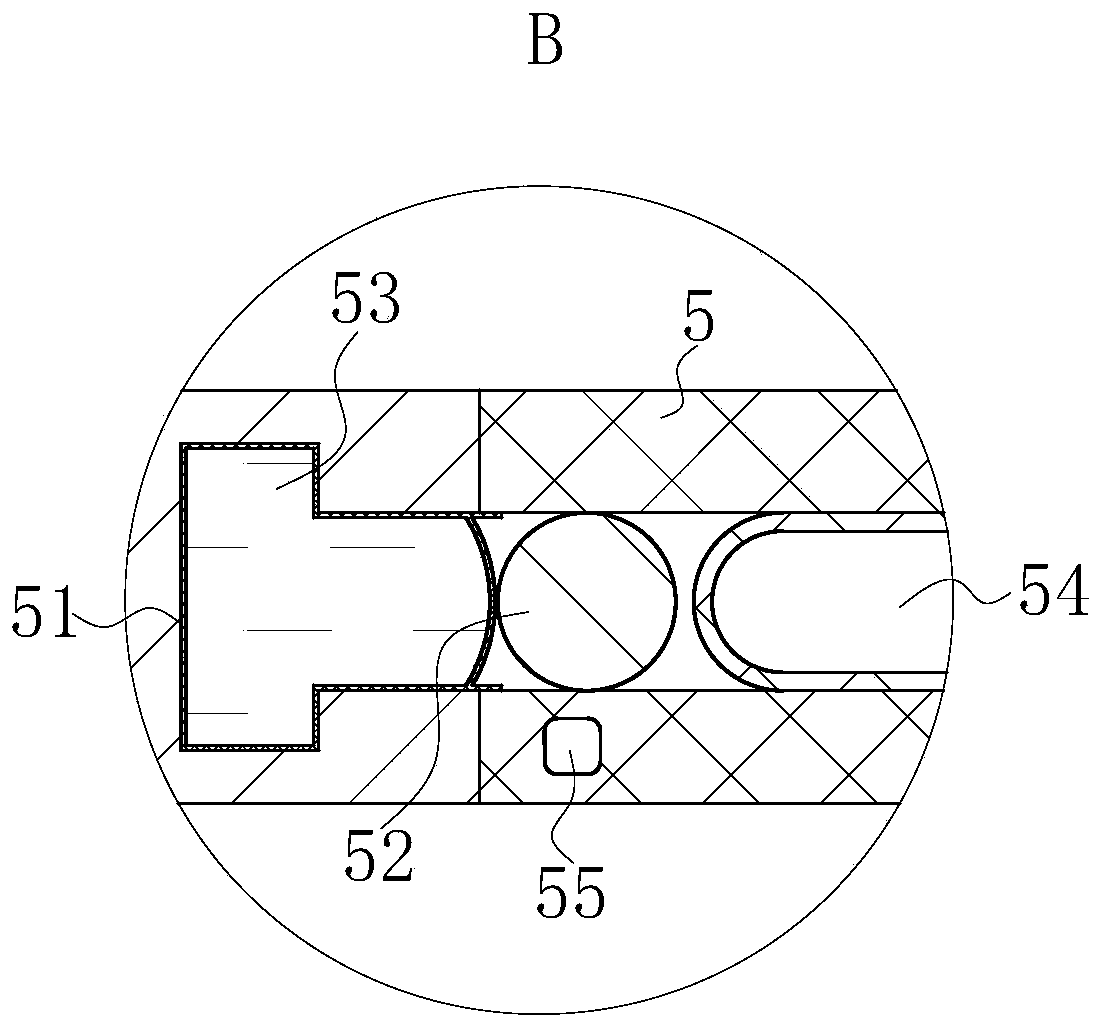

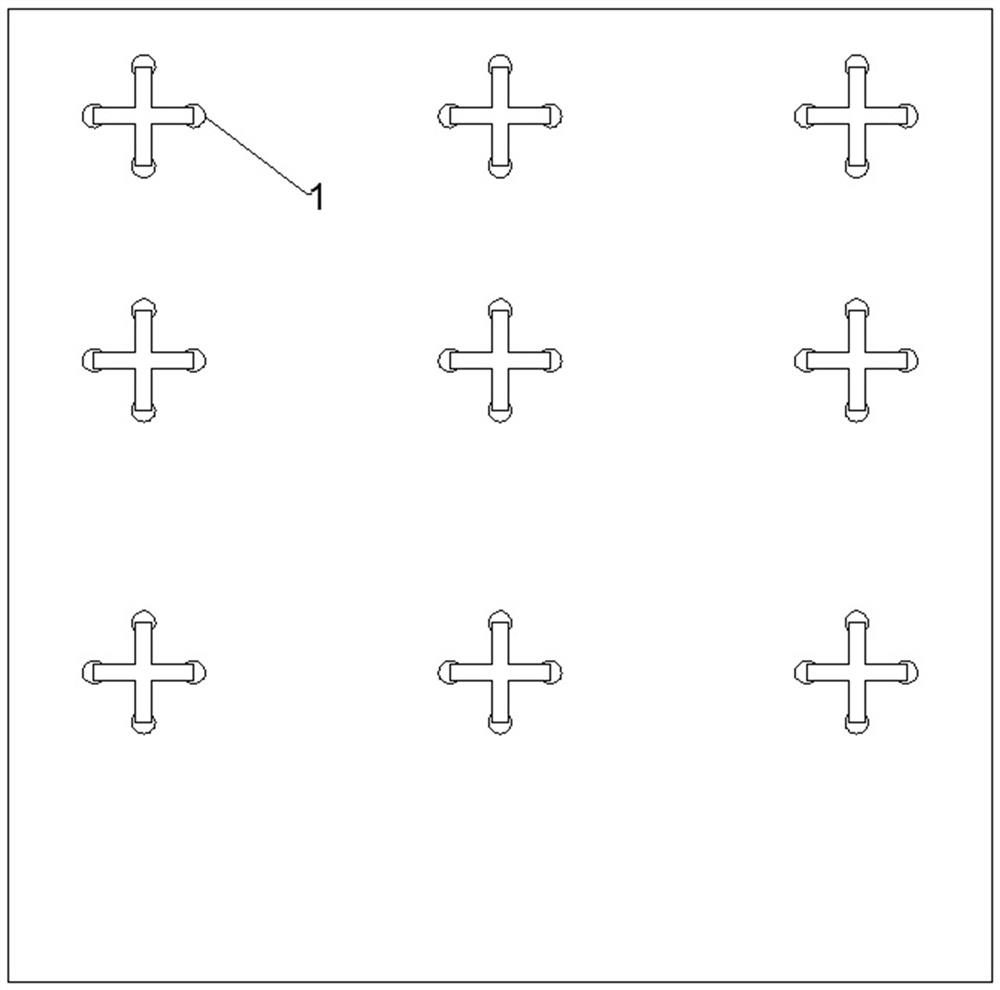

Gas chromatography detection system and method for analyzing trace impurities in ultrahigh pure gas

ActiveCN102628846AFast, consistent and reliable actionEnsure data accuracyComponent separationMolecular sieveGas liquid chromatographic

The invention relates to detection equipment and technology for a gas chromatography instrument, in particular to a gas chromatography detection system and method for analyzing trace impurities in ultrahigh pure gas. A first molecular sieve chromatographic column (51) is arranged between a switching valve VI (1) and a switching valve VII (2); a second molecular sieve chromatographic column (52) is arranged between a switching valve VII (2) and a switching valve VIV (4); and a second column separator (62) is arranged between the switching valve VIII (3) and switching valve VIV (4). A secondary sampling way is adopted for sample gas, and a main component is pre-cut during primary sample feeding of a ten-way switching valve VI (1) and subjected to back flushing during secondary sample feeding of the ten-way switching valve VI (1); and the main component is separated and switched, and enters a helium ion detector (8) for analyzing. The gas chromatography detecting system is controlled through each valve, the sequence of actions is executed by using an event draw-up program, the entire analyzing process is controlled automatically, actions are rapid, consistent and reliable, and the data repeatability and accuracy of the system are ensured through a stable flow gas channel and accurate valve switching.

Owner:HANGZHOU CHROMATOGRAPHY TECH

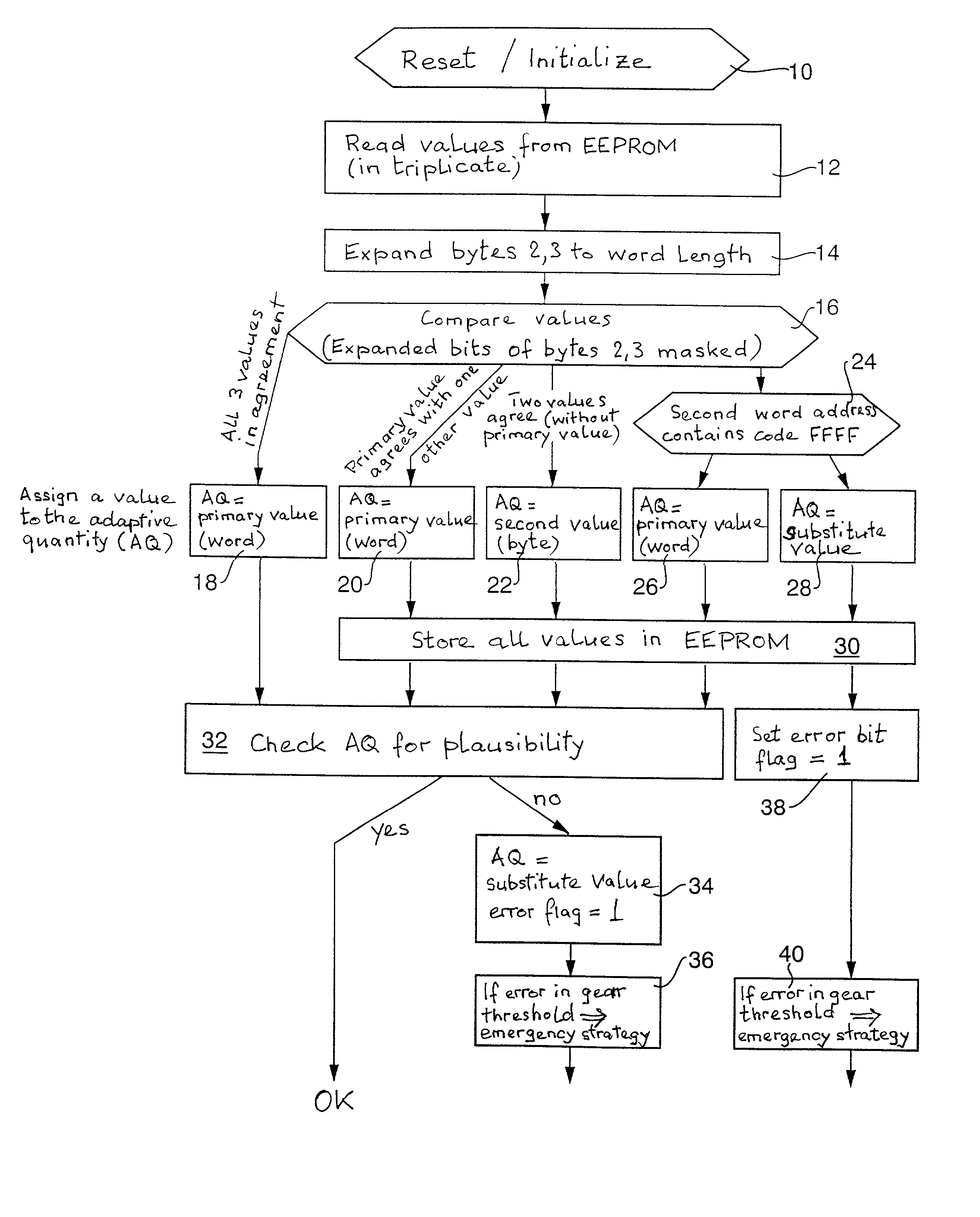

Motor vehicle

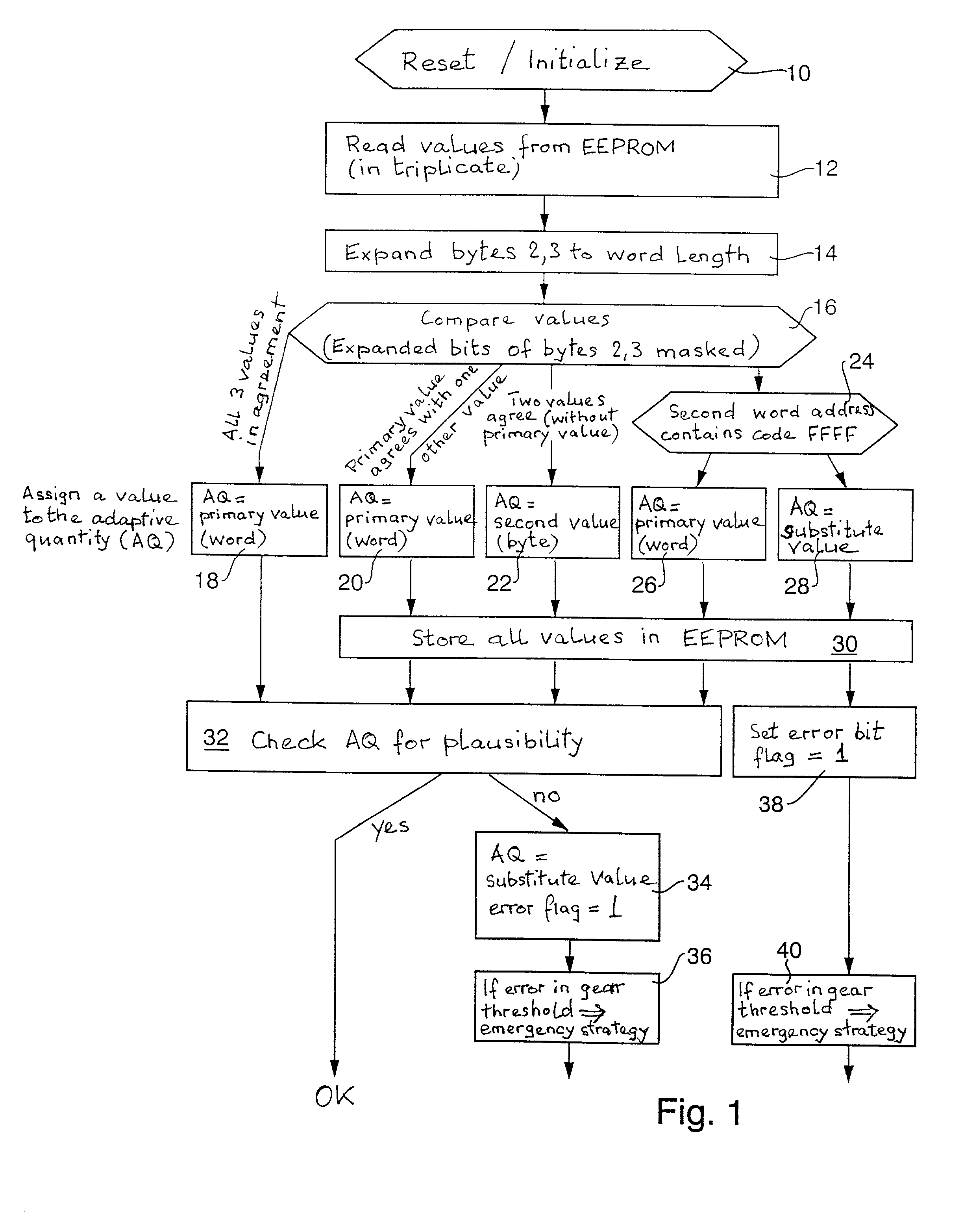

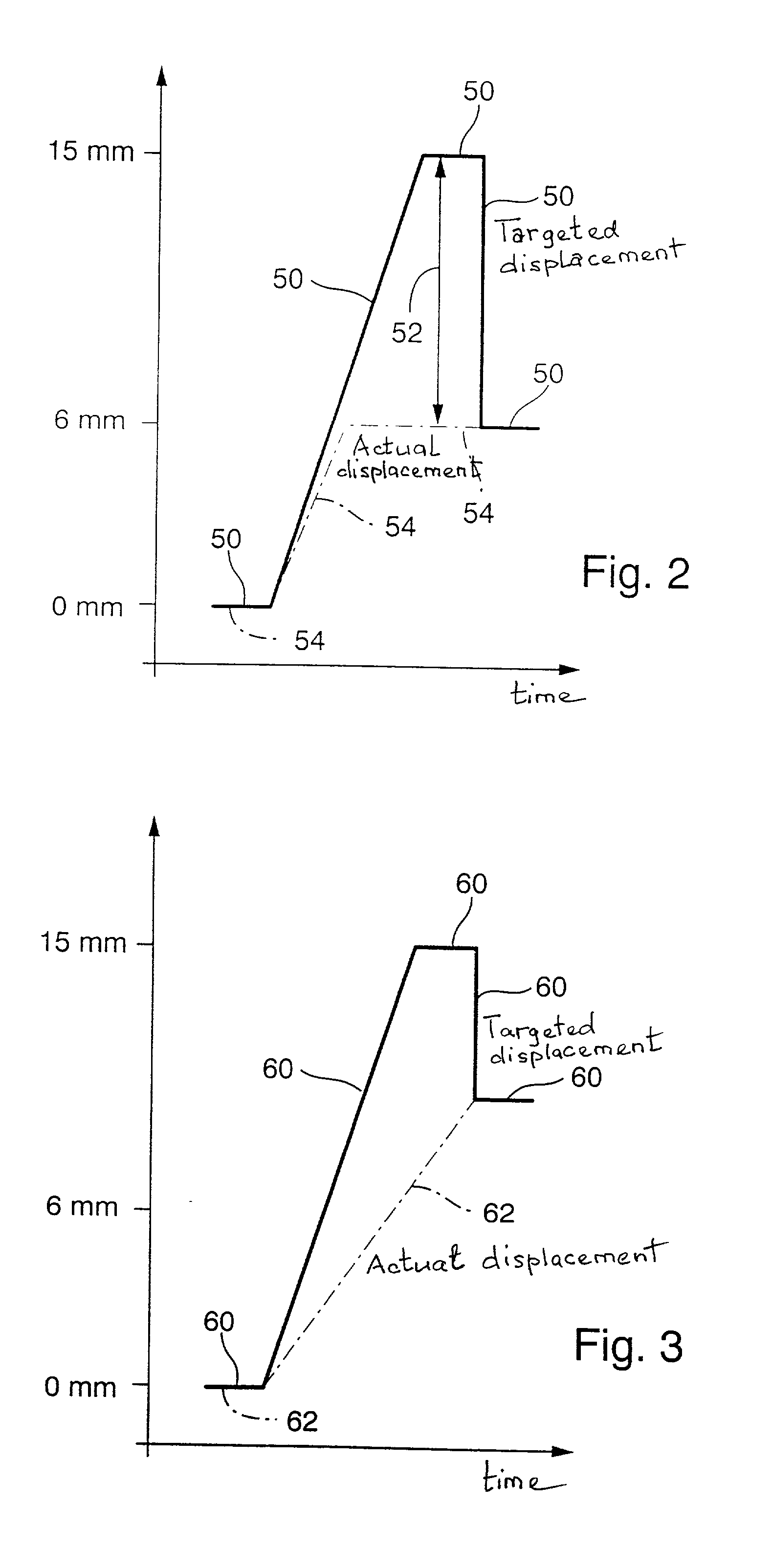

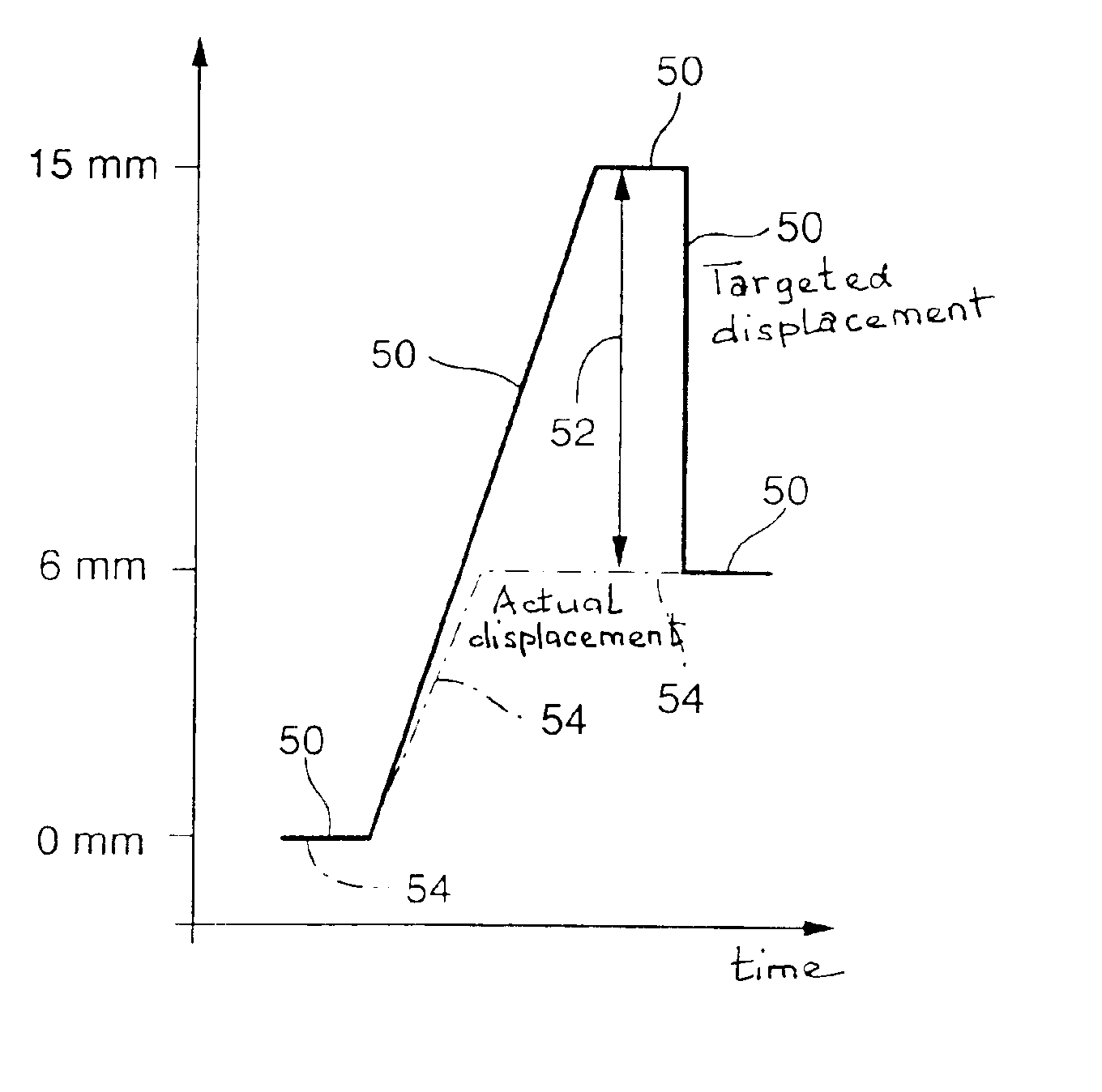

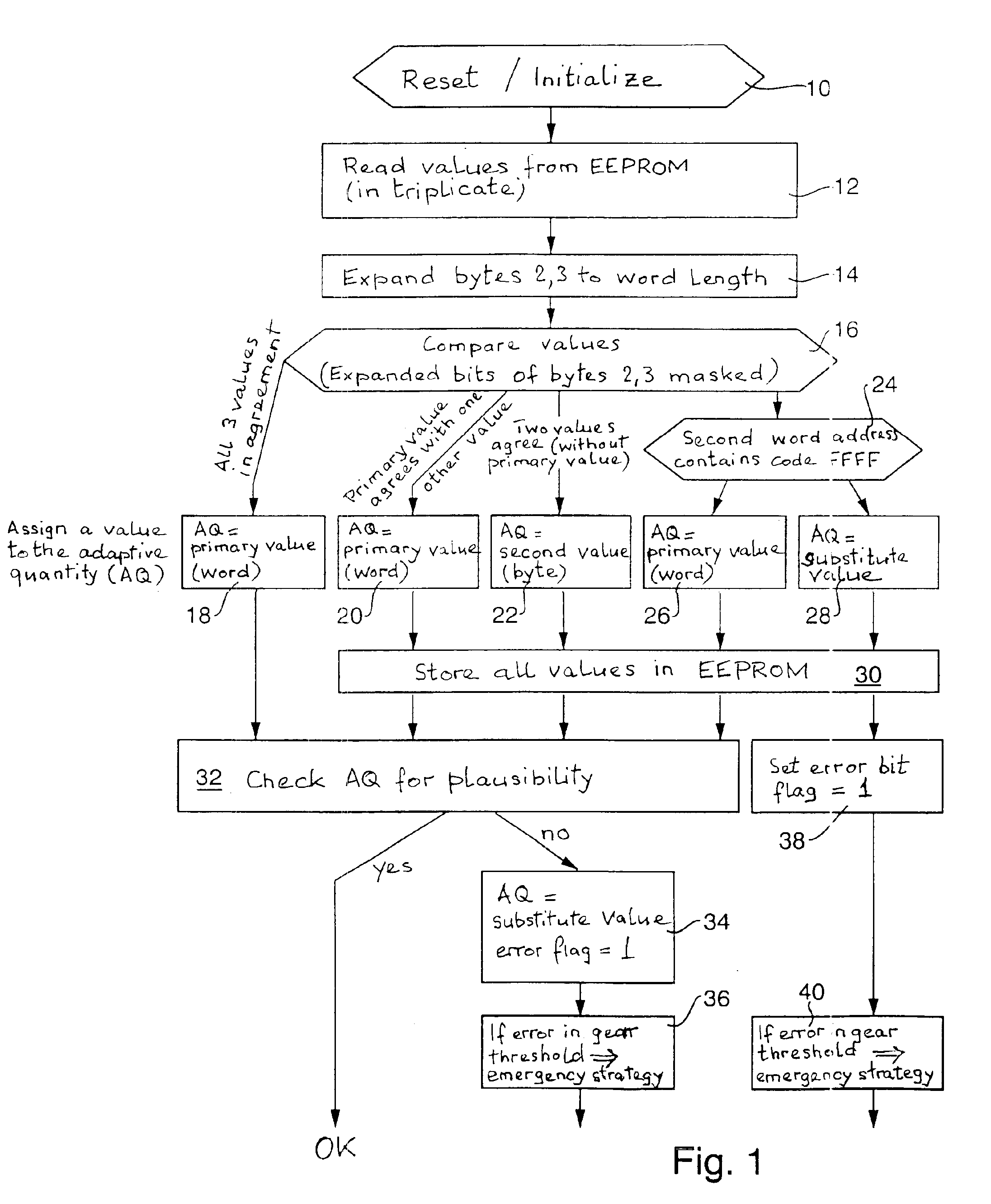

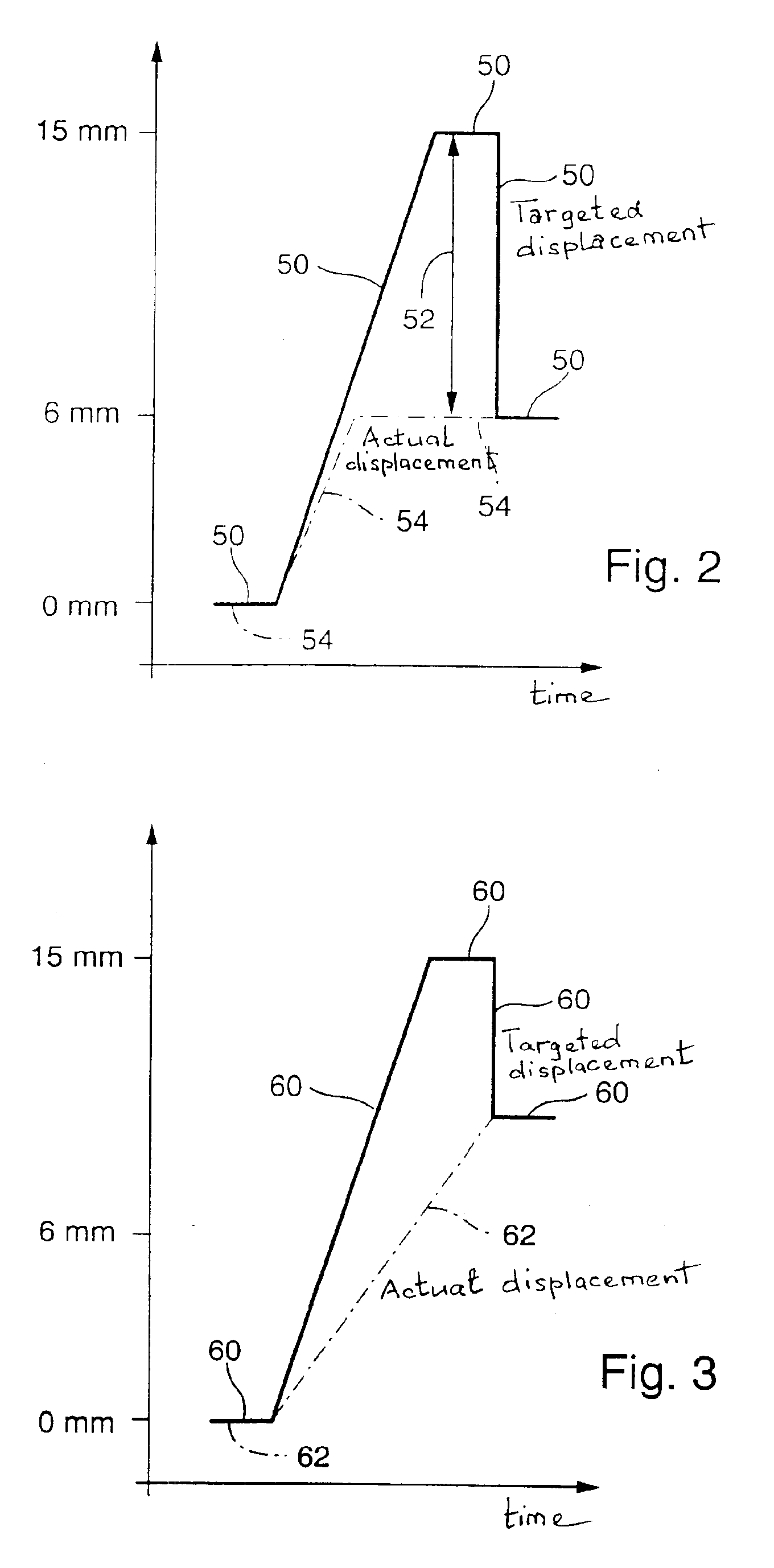

InactiveUS20020055807A1Easy to make costHigh degreeVehicle testingAnalogue computers for vehiclesMobile vehicleData storing

In a method of operating a motor vehicle with an electronically controlled automatic clutch device, a control device and one or more data-storing devices for values of operating quantities and parameters, the values are stored in at least duplicate form in the data-storing device. The data are stored in prescribed formats and the integrity of the data is checked according to prescribed criteria, to ensure that incorrect data are not used in the operation of the vehicle.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

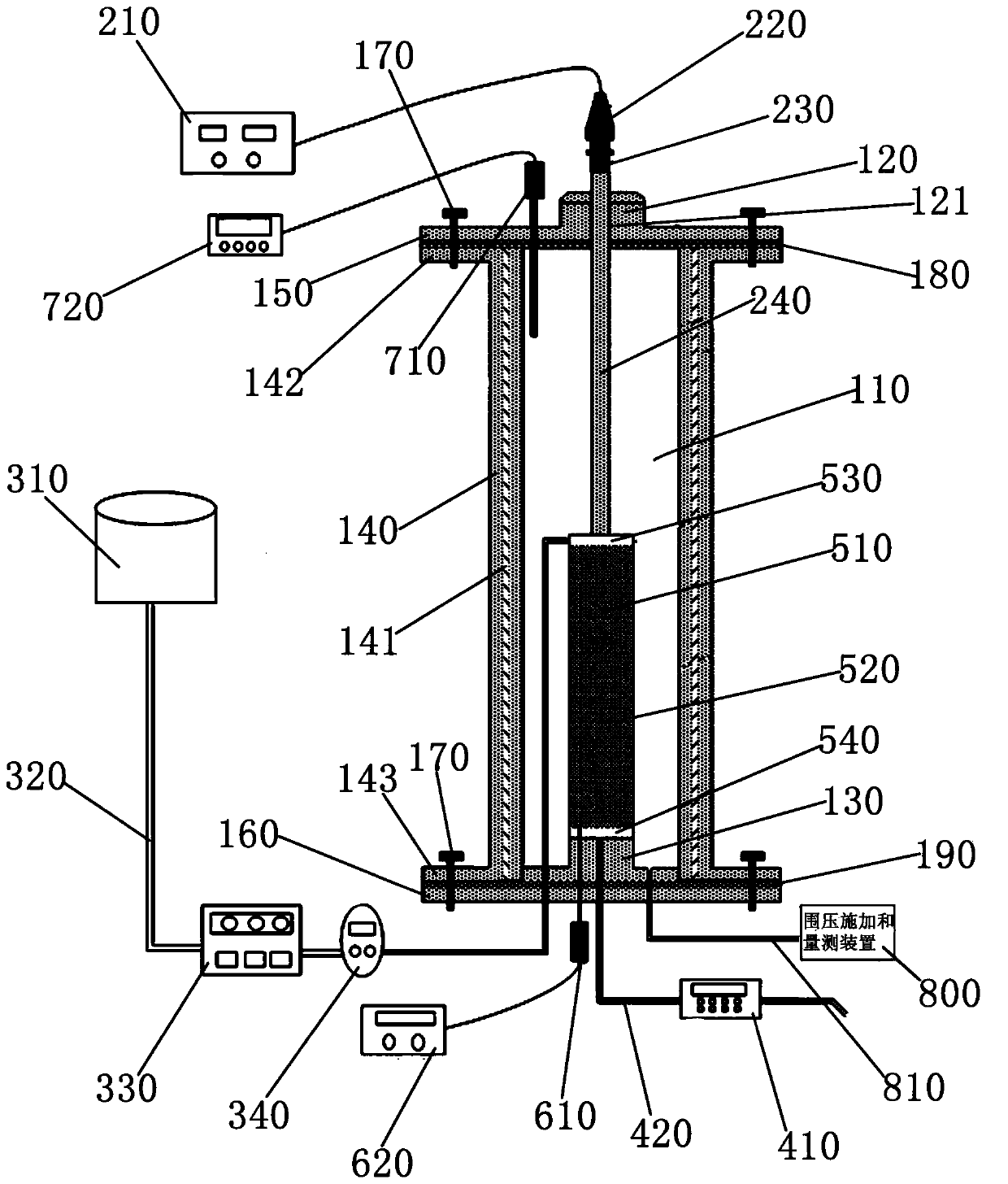

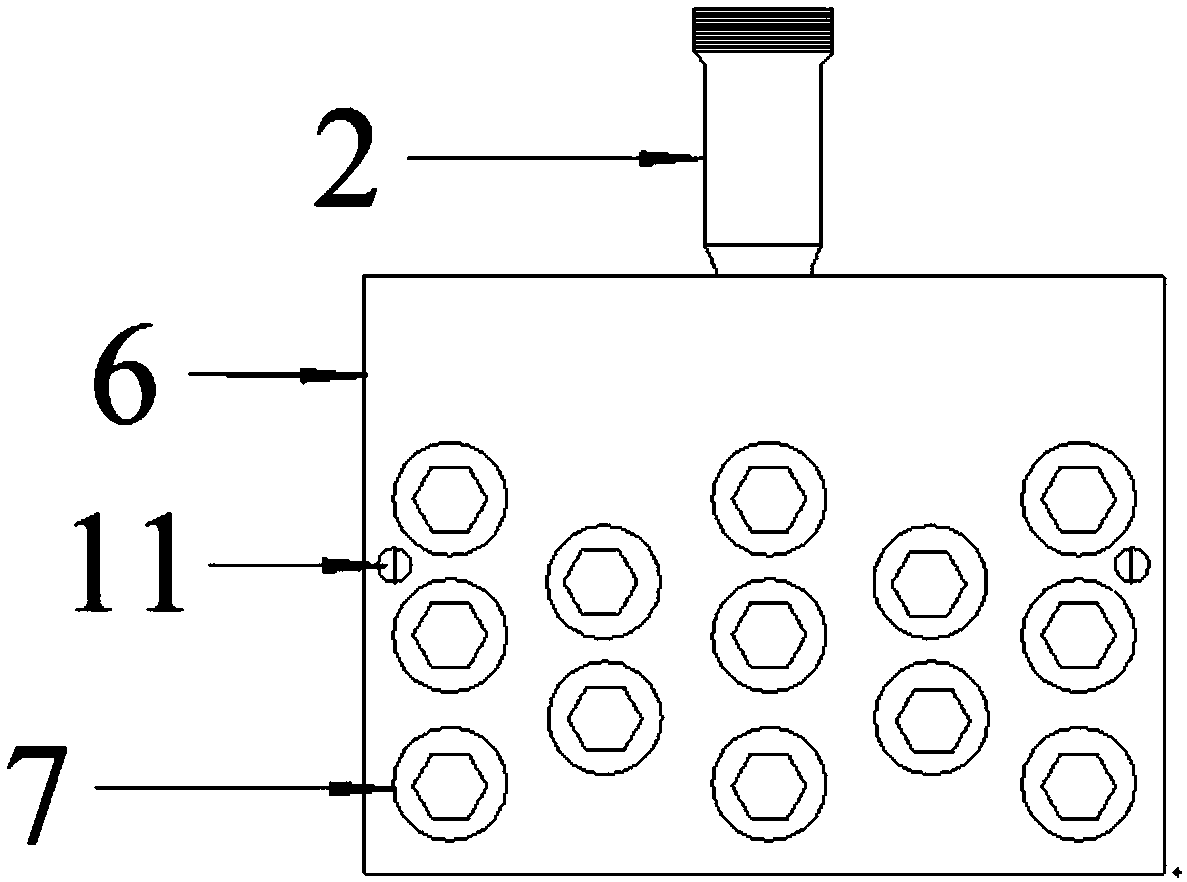

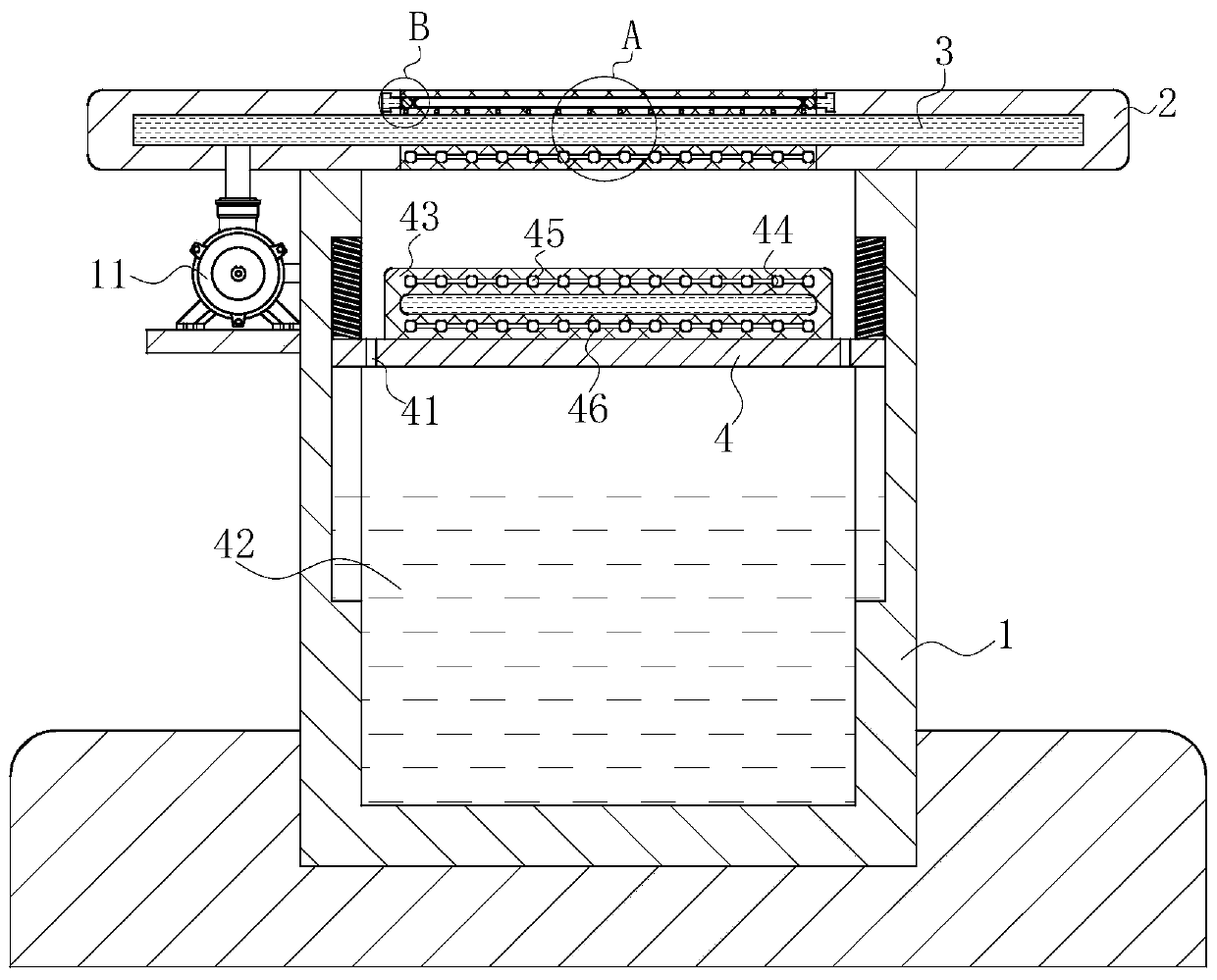

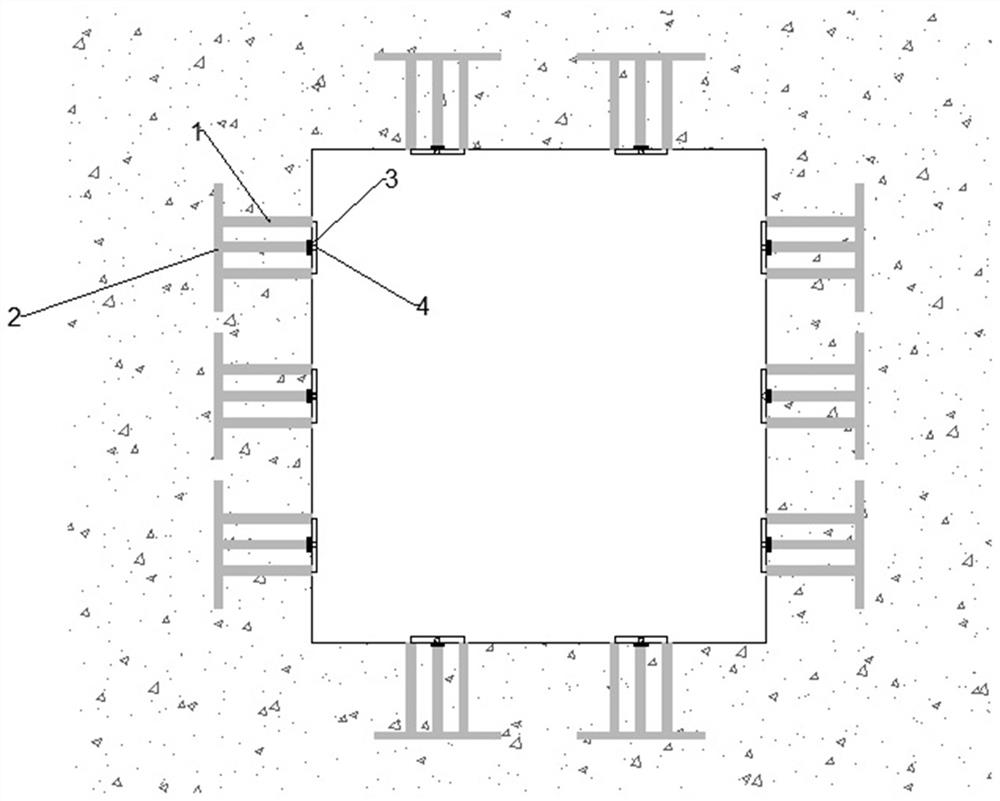

Ultrasonic control earth pillar pressure chamber system

InactiveCN104007051AMeet the requirements of the soil column testMeet testing needsMaterial analysis using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisPeristaltic pumpPorous medium

The invention discloses an ultrasonic control earth pillar pressure chamber system. The ultrasonic control earth pillar pressure chamber system comprises a pressure chamber, an earth pillar, an ultrasonic device, a liquid supply device and a liquid outlet device. The pressure chamber is provided with a cavity filled with water, and the earth pillar is arranged inside the cavity; the ultrasonic device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic amplitude-change pole and an ultrasonic emission tool head, and the ultrasonic emission tool head extends into the cavity and makes contact with the top end of the earth pillar; the liquid supply device comprises a liquid inlet pipe, a liquid storage tank, a peristaltic pump and a flowmeter; the liquid outlet device comprises a turbidimeter and a liquid outlet pipe, the turbidimeter is connected to the liquid outlet pipe, and the liquid outlet pipe extends into the cavity and is connected with the bottom end of the earth pillar. The system can accurately measure the evolution situation of rubber concentration along with time, the ultrasonic attenuation situation, the temperature change situation and the earth pillar deformation situation in the process of ultrasonic load changes, earth pillar height changes and earth pillar confining pressure changes, and then research on rubber migration and deposition characteristic in porous media under the multi-factor coupling action is carried out.

Owner:HUAQIAO UNIVERSITY

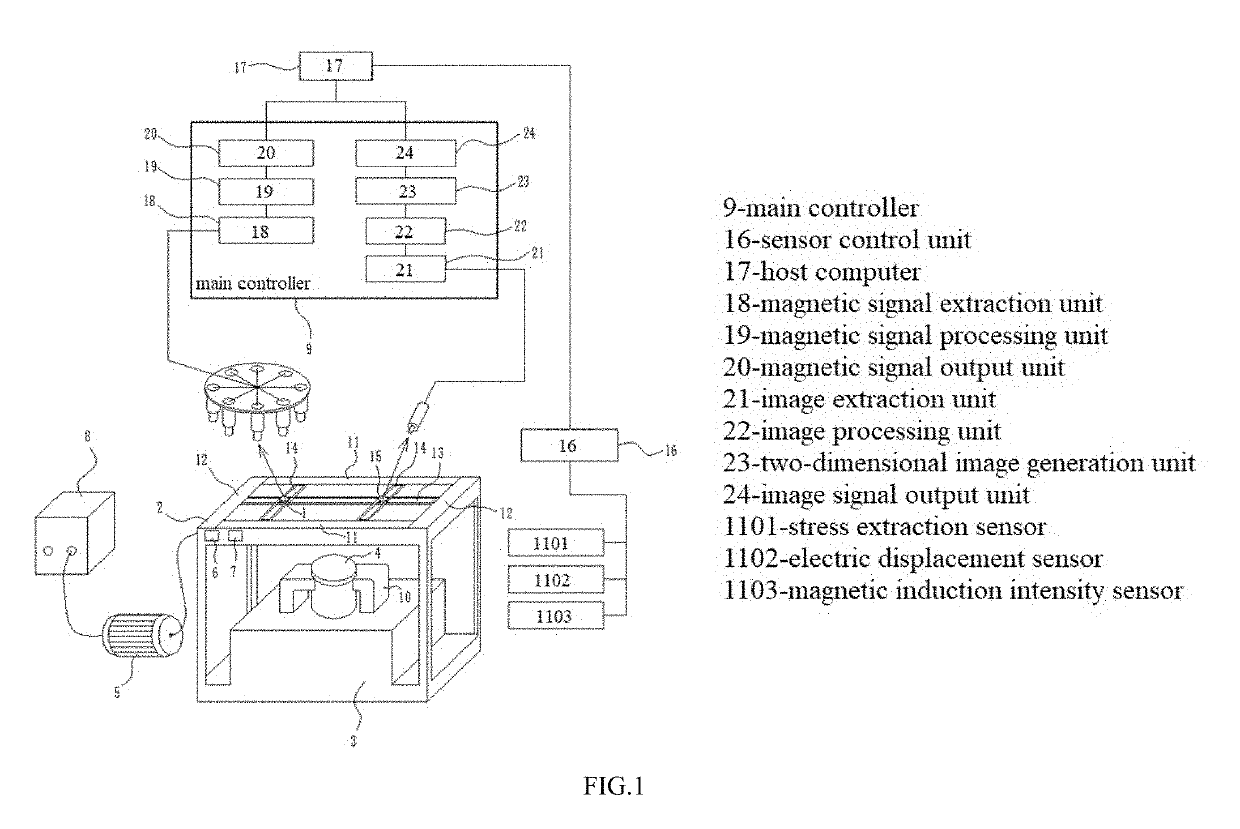

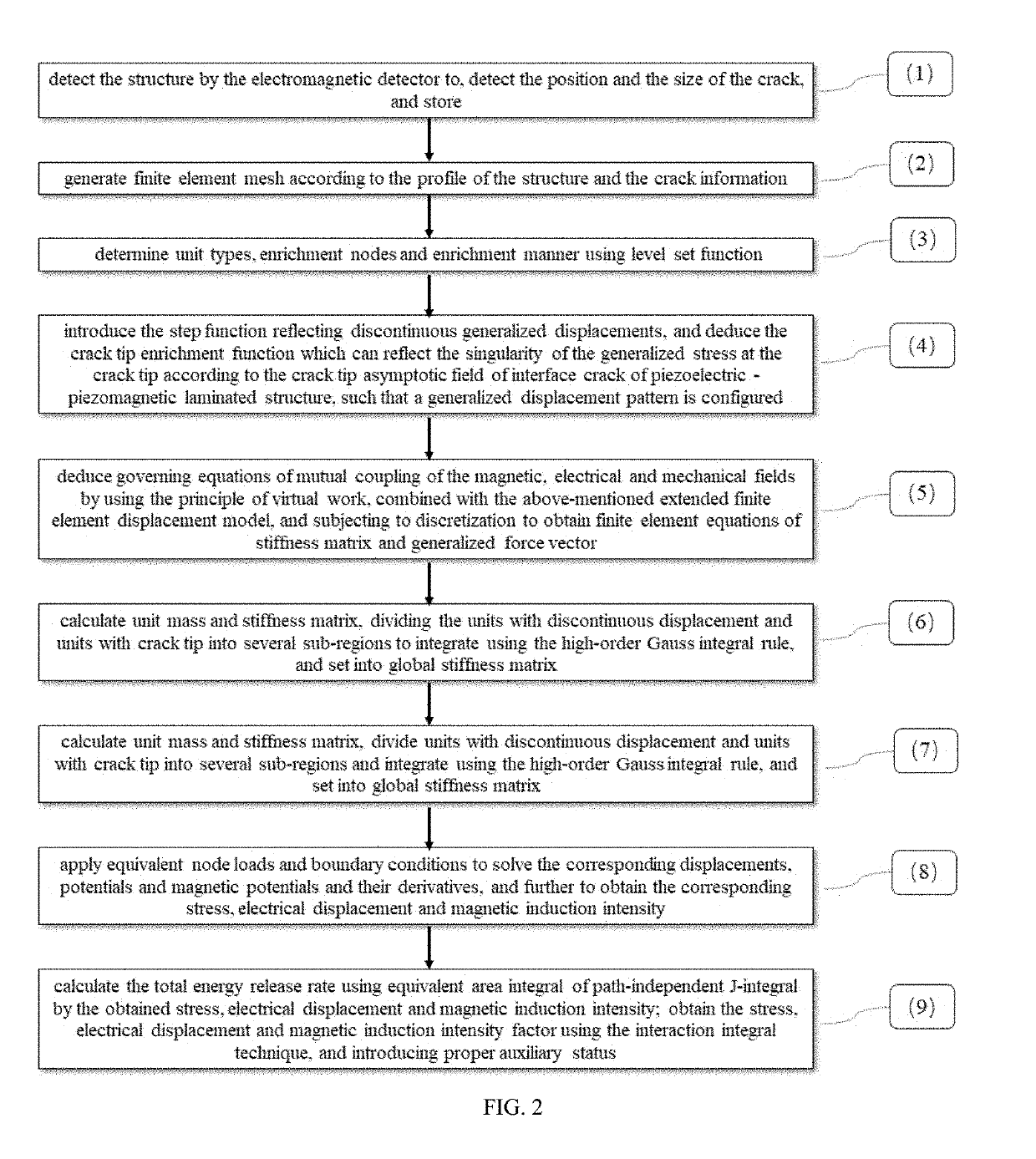

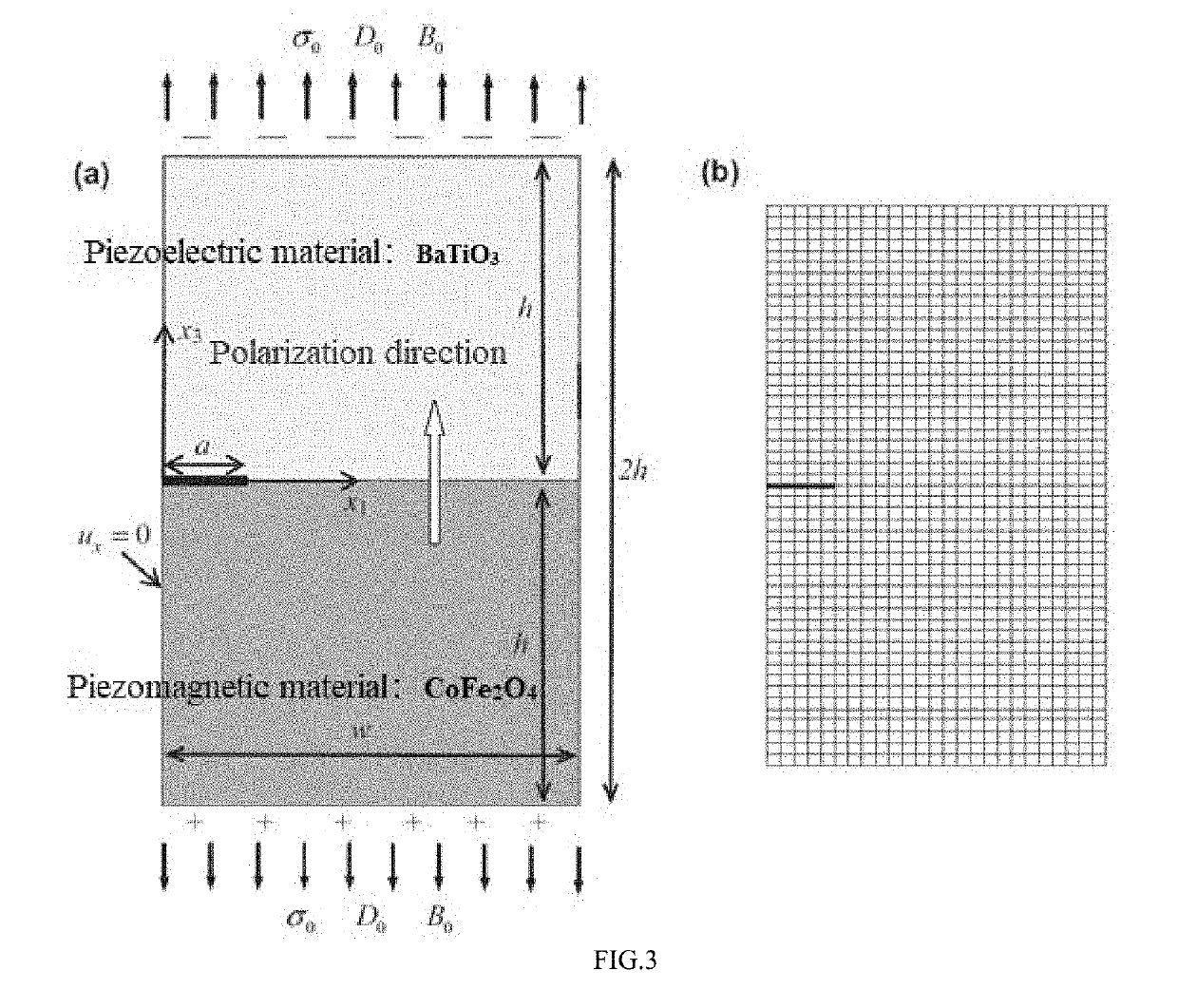

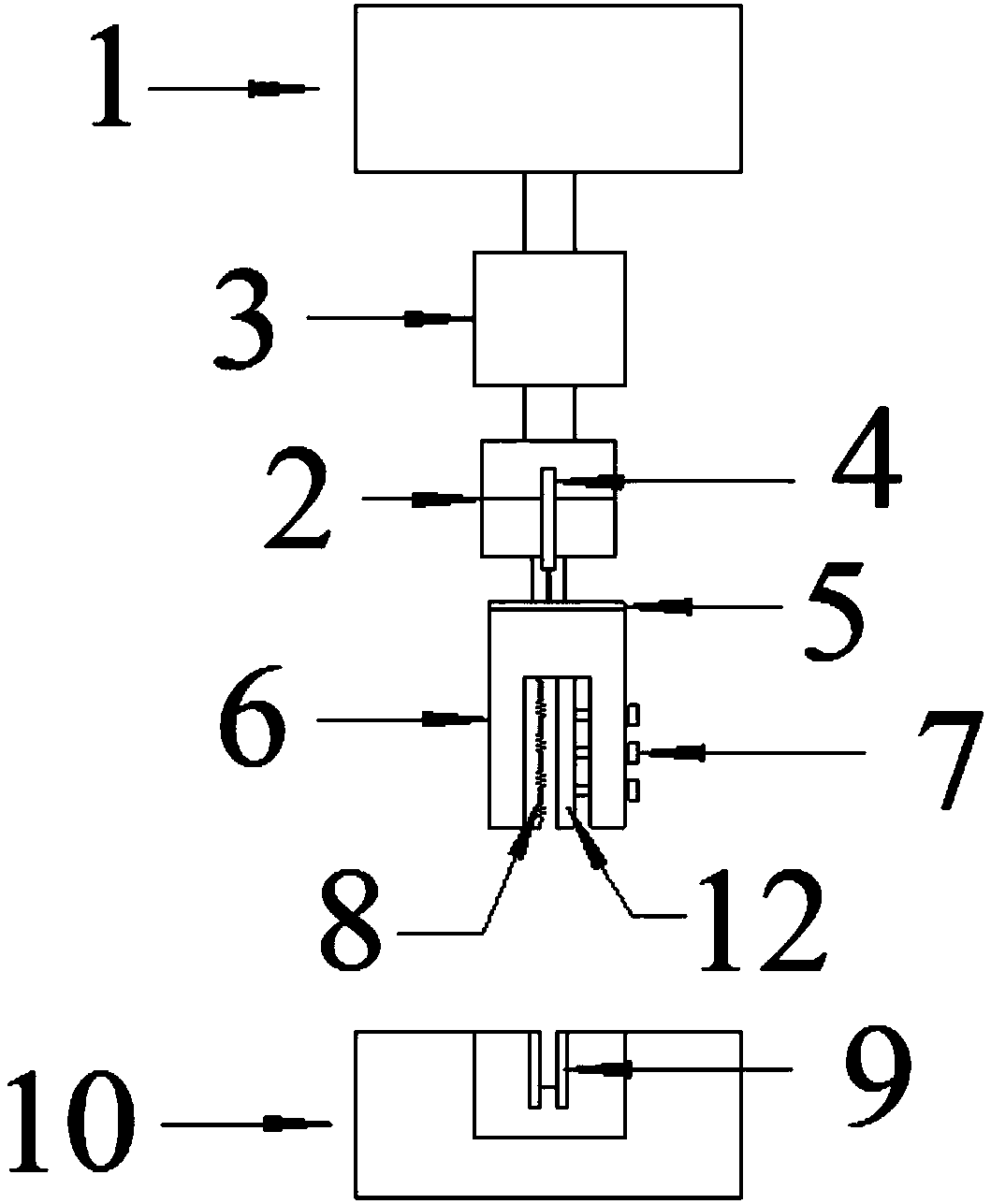

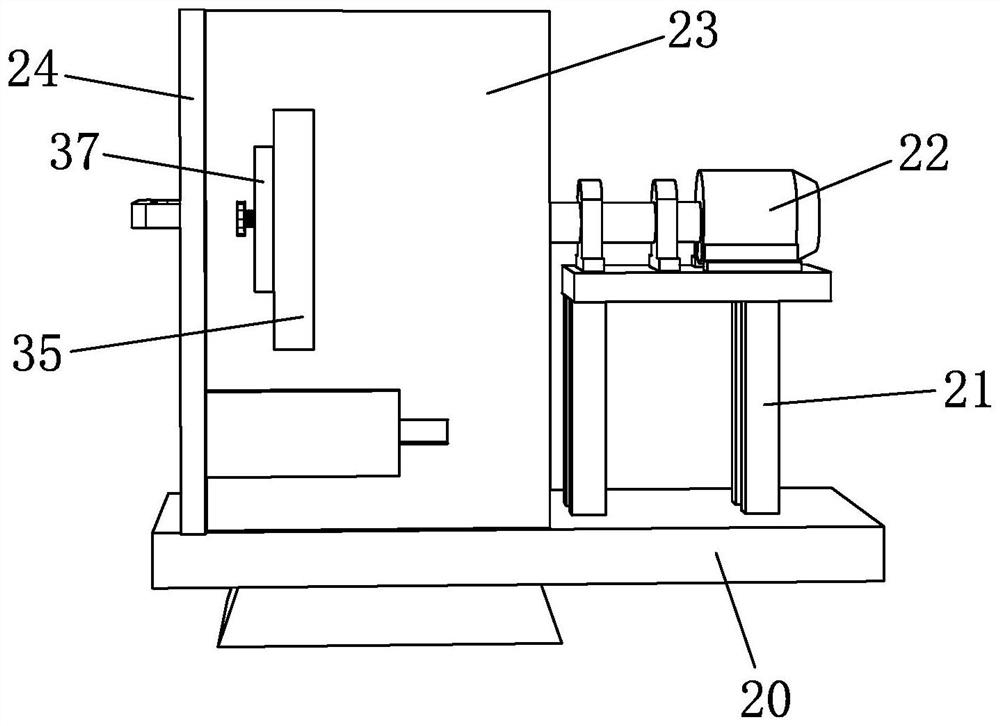

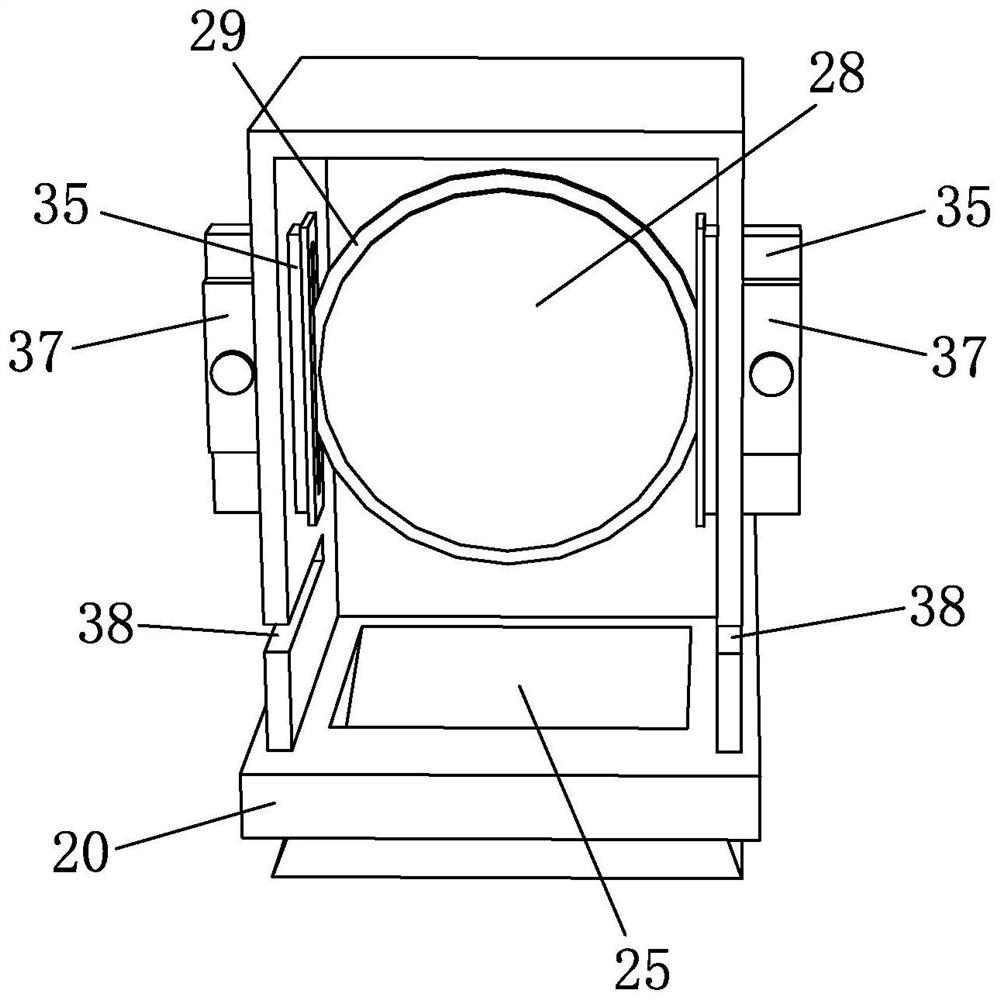

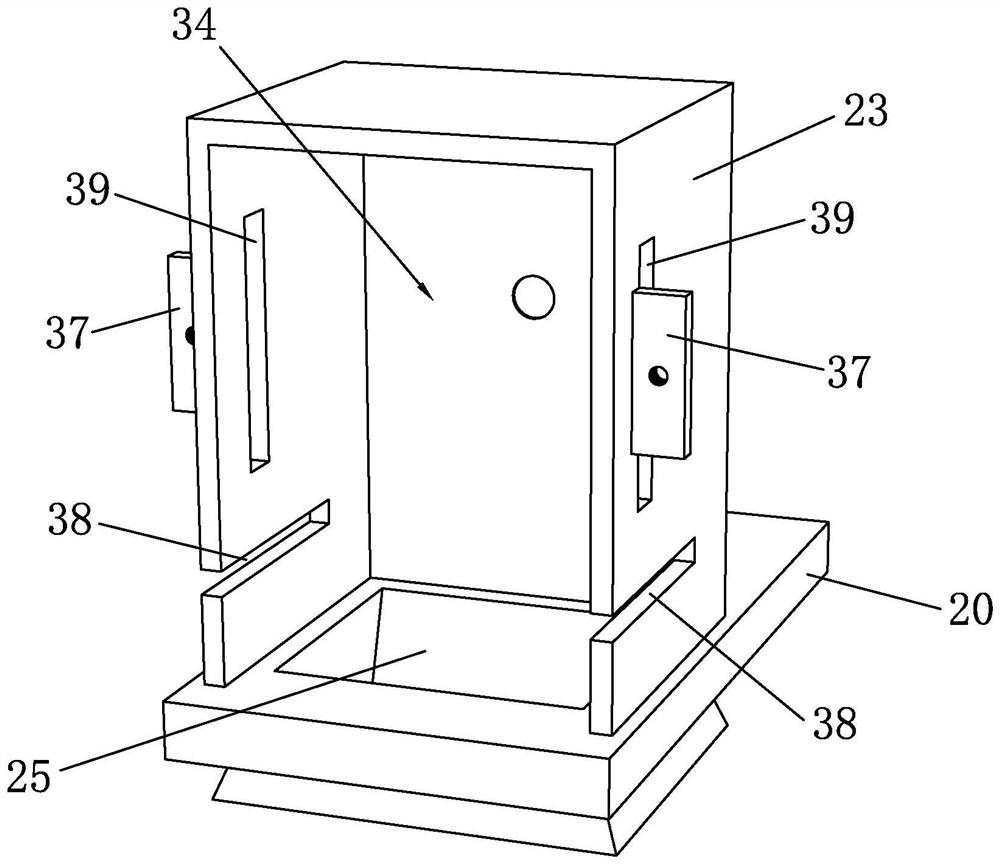

Electromagnetic detector for detection of interface cracks in a piezoelectric - piezomagnetic laminated structure

ActiveUS20190277786A1Accurately detecting informationEnsure data accuracyInductance measurementsMaterial impedanceElectricityEngineering

The present invention d iscloses an electromagnetic detector and a detection method for detection of interface cracks in a piezoelectric-piezomagnetic laminated structure. The electromagnetic detector for detection of interface crack in a piezoelectric-piezomagnetic laminated structure mainly comprises an eddy current magnetic probe assembly, an automatic scanning frame, a base, a carrier, a servomotor, an X-axis mobile frame driving controller, a Y-axis mobile frame driving controller, a power supply, and a main controller.

Owner:SHIJIAZHUANG TIEDAO UNIV

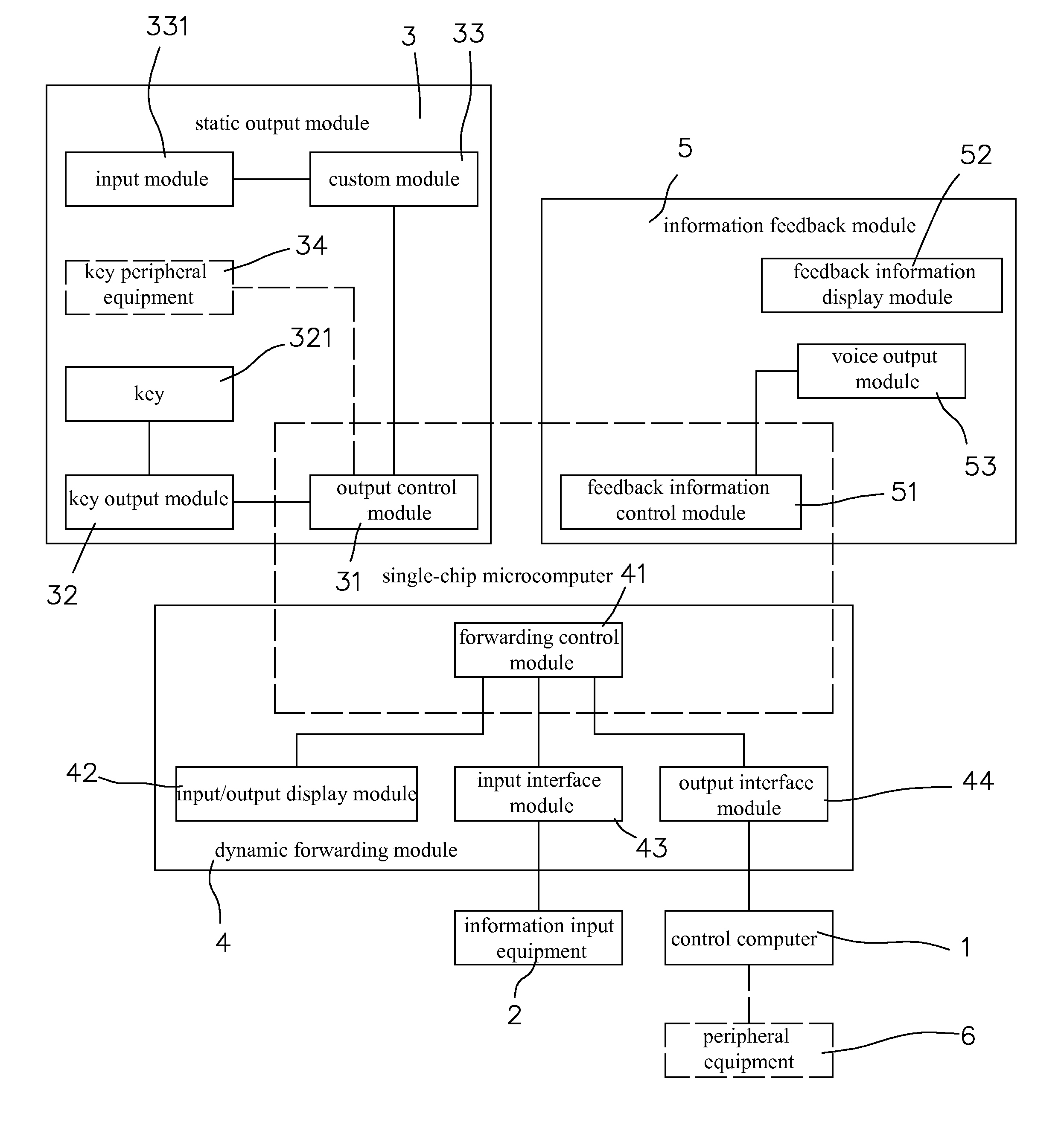

Automated network triggering-forwarding device

ActiveUS20140237146A1Easy to operateConveniently implementedProgramme control in sequence/logic controllersElectric digital data processingComputer hardwareSpeech sound

An automated network triggering-forwarding device connected with a control computer and an information input equipment by a network or a cable, respectively, is provided, which comprises a static output module, a dynamic forwarding module, and an information feedback module. A preset trigger signal is output by touching a key or combination of keys of a key output module, the output information of the information input equipment is forwarded to the control computer by the dynamic forwarding module, and the information fed back by the control computer is displayed on the feedback display module and a voice prompt is provided through the voice output module by the information feedback module. The buttons are imparted with different output definitions according to different service requirements, and tart triggering other recognizing devices to operate when needed according to operator demand. The dynamic output function can be externally connected with a plurality of non-network equipment.

Owner:ZHUHAI SUNHOME INFORMATION

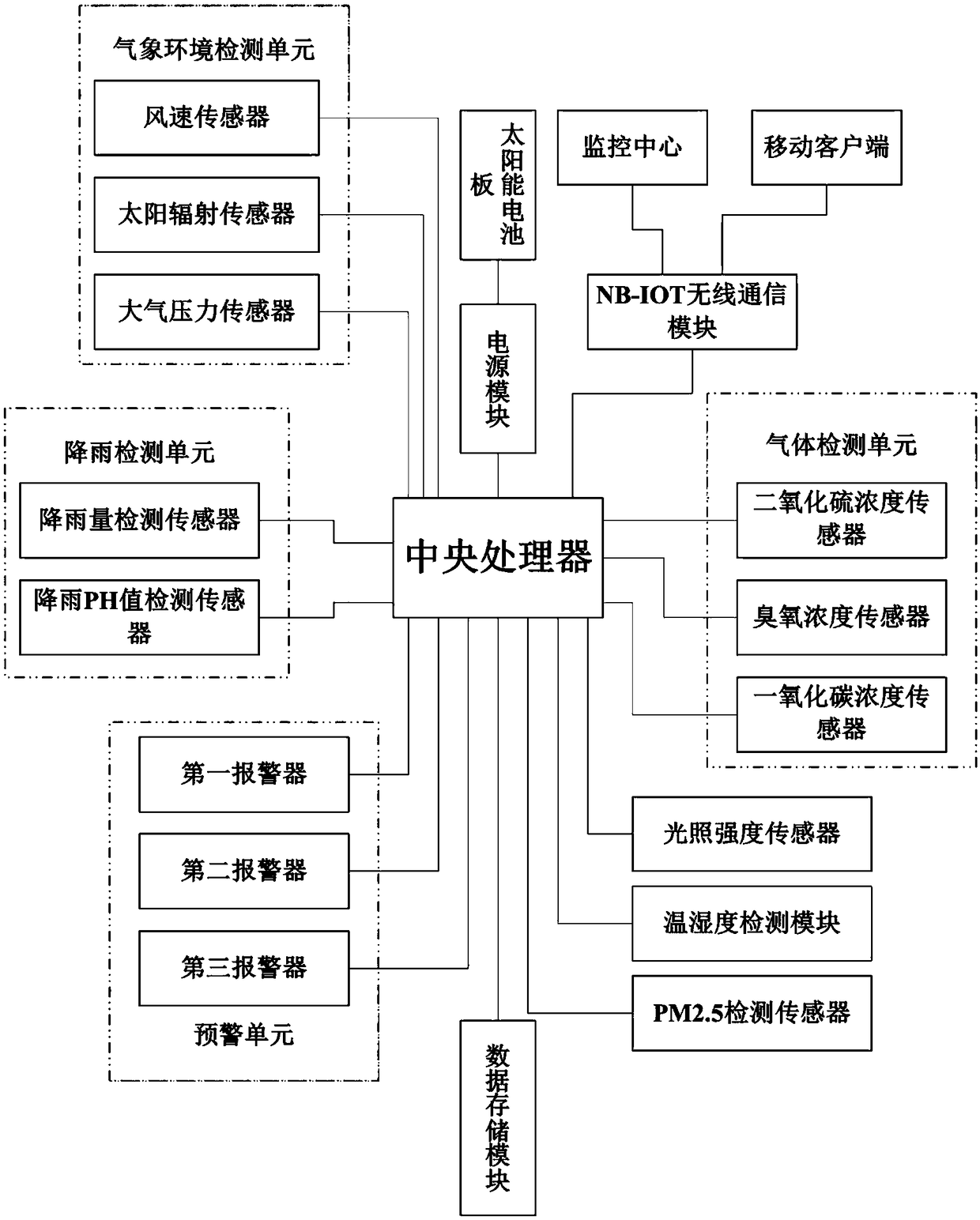

Environmental video monitoring system based on 4G mobile communication technology

InactiveCN109188563AEnsure data accuracyEnsure real-time accuracyRainfall/precipitation gaugesTransmission systemsSulfur dioxideMaterial resources

The invention discloses an environmental video monitoring system based on the 4G mobile communication technology, wherein a rainfall detecting unit is configured to detect the rainfall and a rainwaterPH value in real time; a meteorological environment detecting unit is configured to detect the wind speed, the solar radiation intensity and an atmospheric pressure value in real time; the real-timedetection of sulfur dioxide concentration, ozone concentration and carbon oxide concentration through a gas detecting unit is more intuitive when observing environmental problems; and a S3C2440A chipand a digital sensor are selected to also ensure the data accuracy, efficiency and intelligence of the system, and ensure the real-time accuracy of environmental monitoring at the same time. The environmental video monitoring system based on 4G mobile communication technology reduces manpower and material resources, and labor cost.

Owner:SHENZHEN POLYTECHNIC

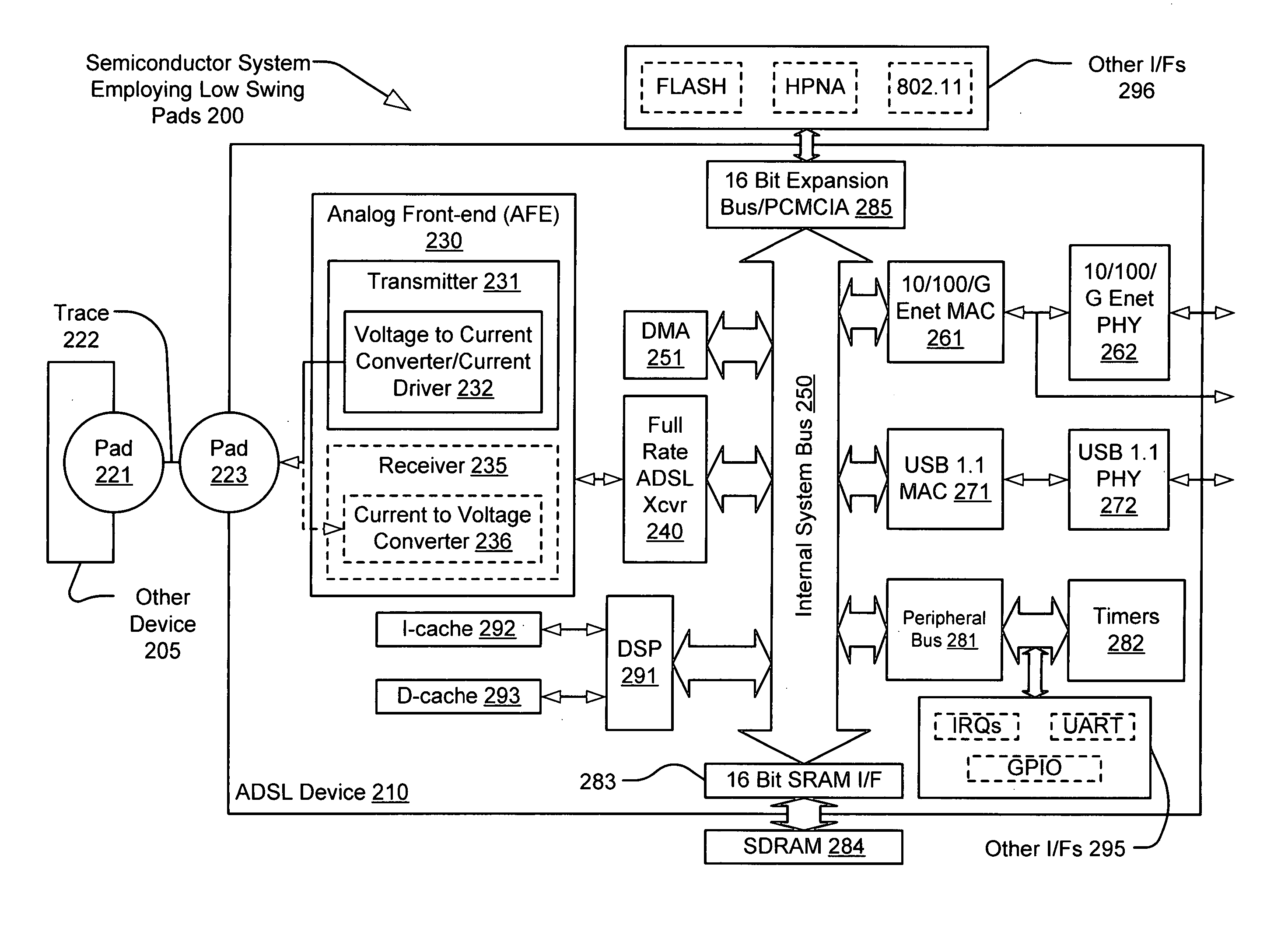

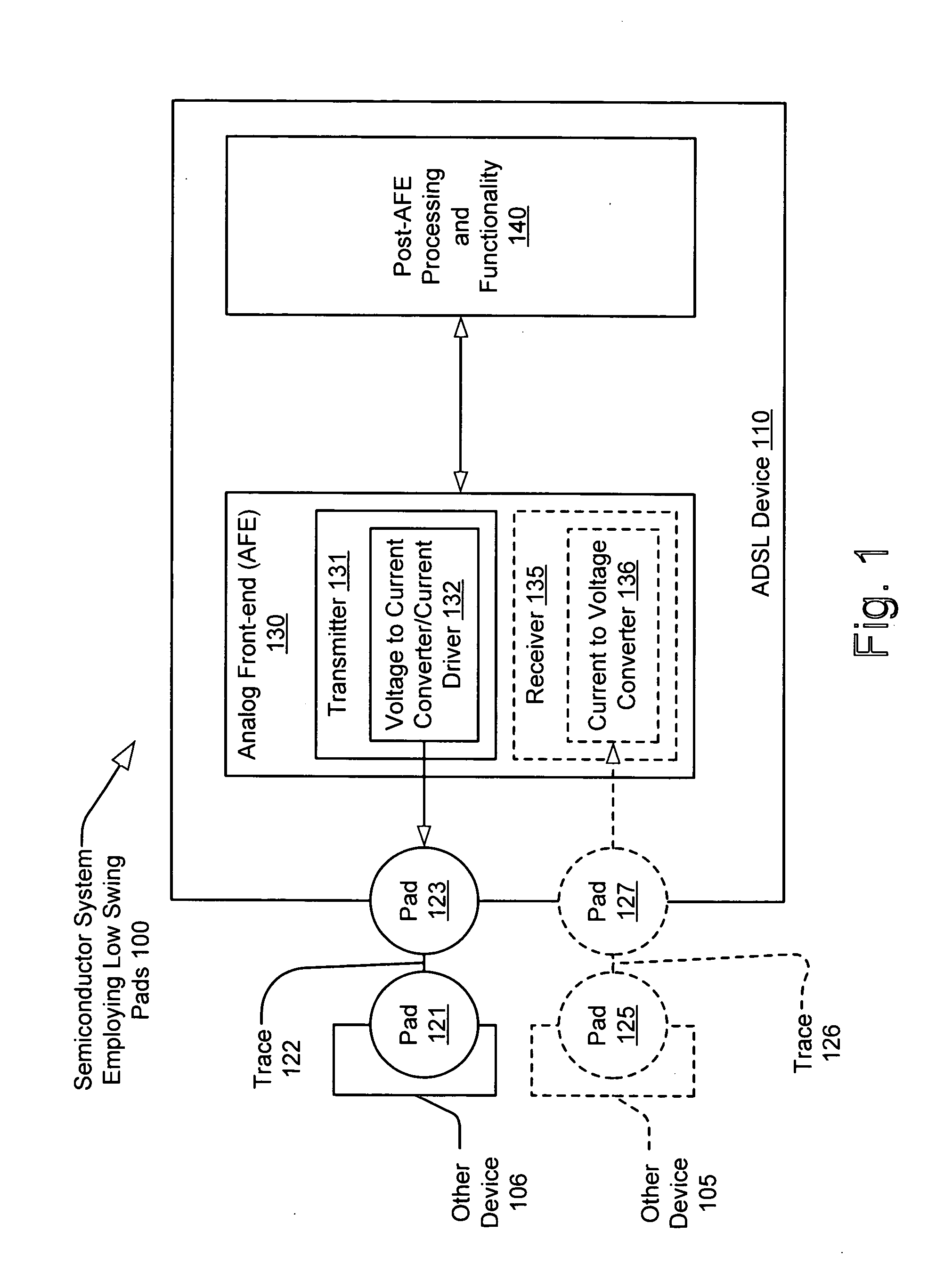

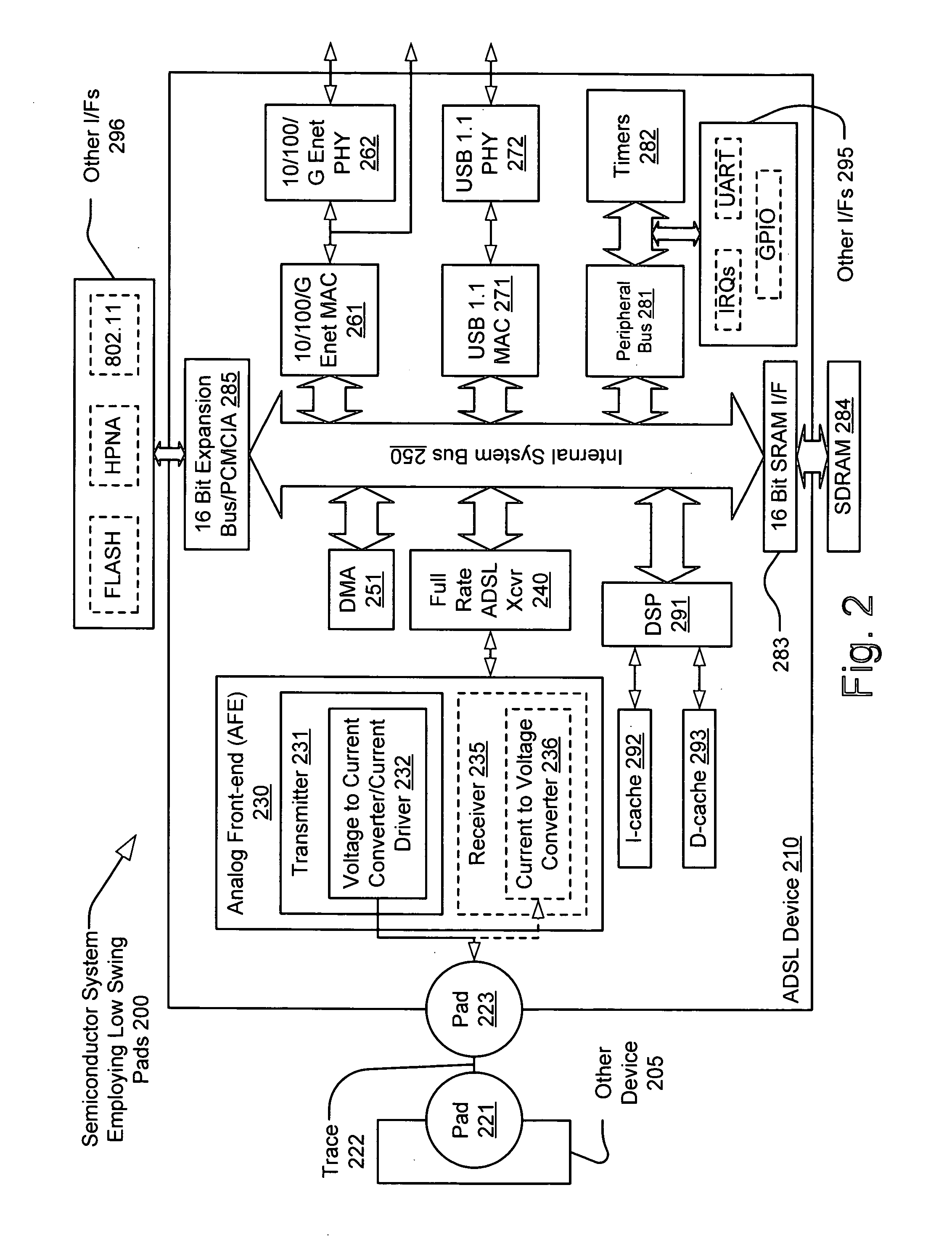

Low voltage swing pad driver and receiver

InactiveUS20050036562A1Reduce distortion problemsMinimize distortionModulation with suppressed carrierAmplitude-modulated carrier systemsEngineeringTransimpedance amplifier

Low voltage swing pad driver and receiver. A transmitter portion and a receiver portion are implemented within various devices that communicate using low voltage swing pads communicatively coupled via a trace. The transmitter portion of one device generates a current signal that is pushed / pulled to a low voltage swing pad and is then passed across the trace to another low voltage swing pad. The transmitter portion includes a current driver that outputs the current signal to the low voltage swing pads, and the receiver portion includes a trans-impedance amplifier that transforms the received current signal into a voltage signal. The low voltage swing pad driver and receiver generates a relatively low voltage swing when compared to CMOS full-scale voltage swings thereby significantly reducing the possibility of introducing any noise and / or distortion of data that is communicated via the interface.

Owner:AVAGO TECH INT SALES PTE LTD

Motor vehicle

InactiveUS6950734B2High degreeEnsure data accuracyVehicle testingAnalogue computers for vehiclesMobile vehicleData storing

In a method of operating a motor vehicle with an electronically controlled automatic clutch device, a control device and one or more data-storing devices for values of operating quantities and parameters, the values are stored in at least duplicate form in the data-storing device. The data are stored in prescribed formats and the integrity of the data is checked according to prescribed criteria, to ensure that incorrect data are not used in the operation of the vehicle.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

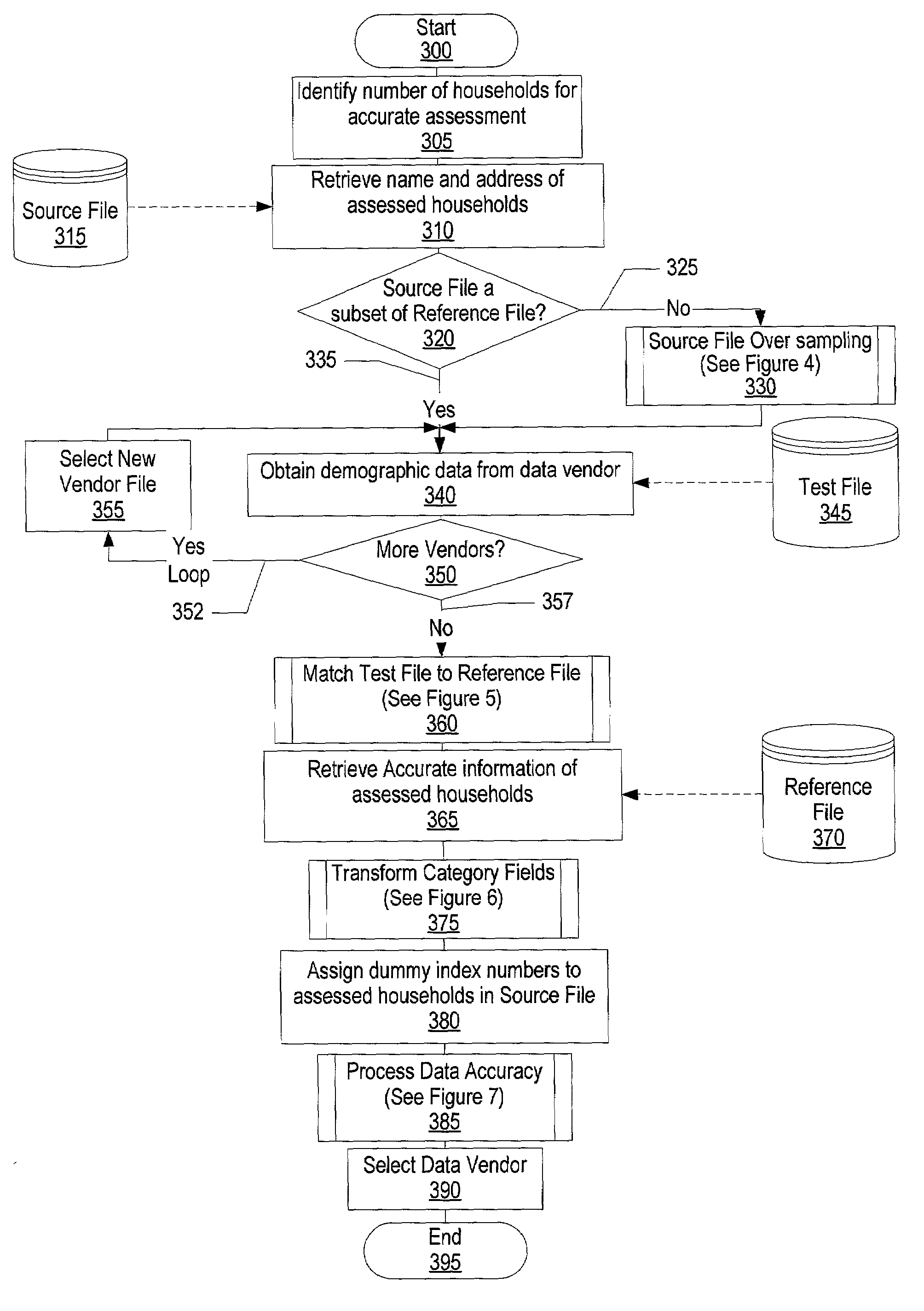

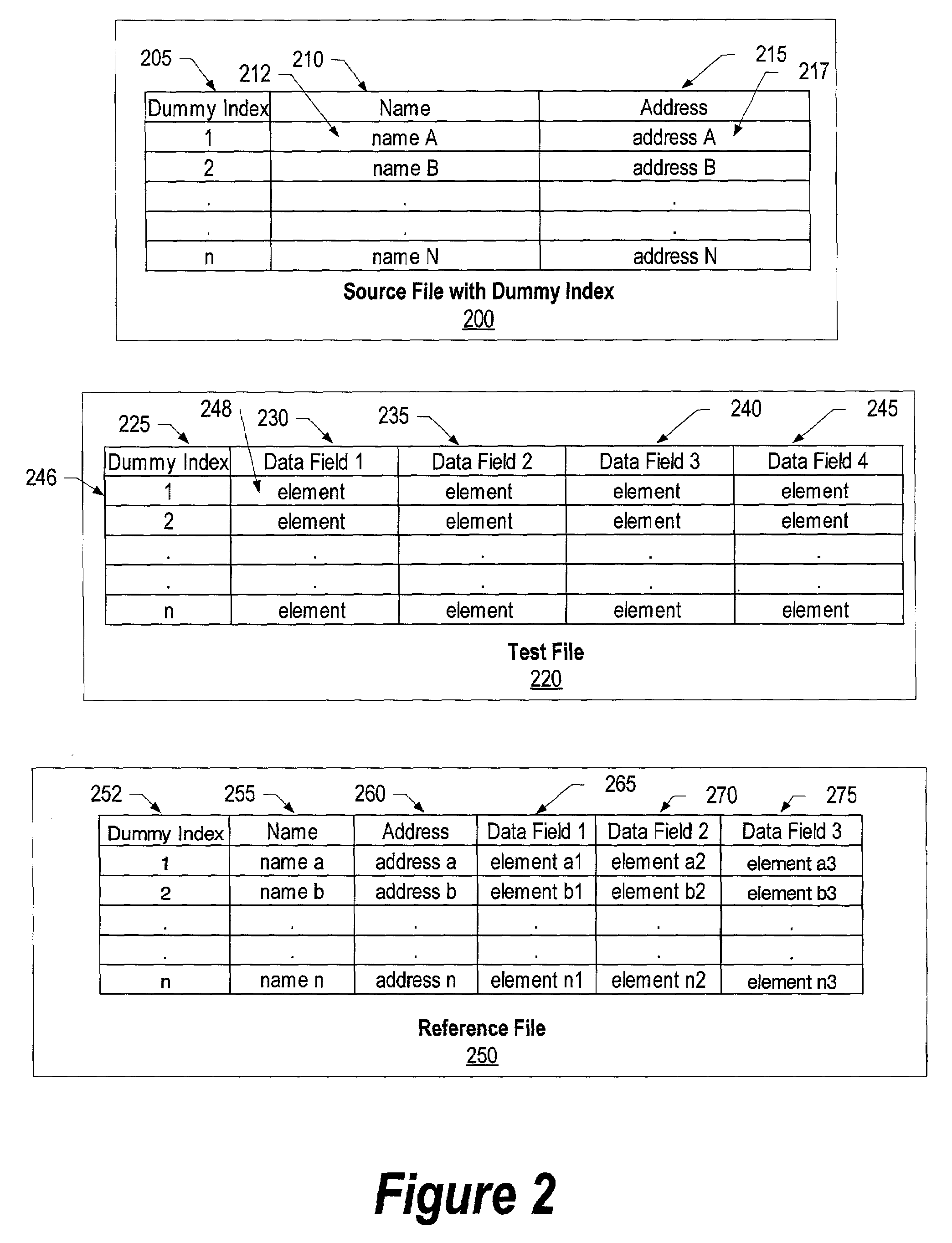

System and method for assessing demographic data accuracy

InactiveUS7197471B2Ensure data accuracyAccuracy in determiningSpecial data processing applicationsMarket data gatheringPopulationPopulation statistics

A system and method for assessing demographic data accuracy from third party data vendors is provided. Third party demographic data is compared to self-reported demographic data; hence compared to data presumed to be accurate. Analysis is done on the comparison to determine the accuracy of the data and if bias exists in the results for a particular demographic population or geographic region. Demographic data from many third parties can be analyzed in the same way, and the results can be compared to each other to determine which third party has the most accurate demographic data elements.

Owner:IBM CORP

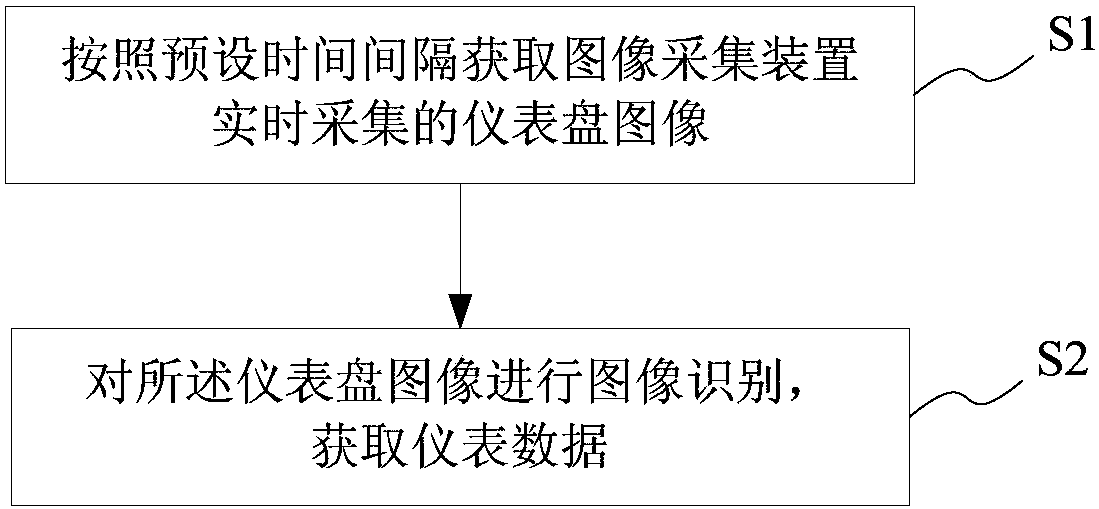

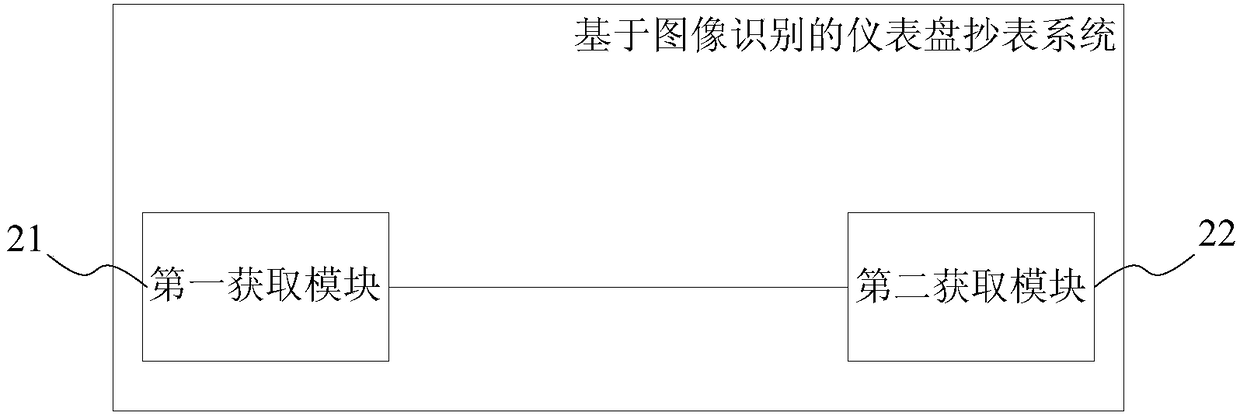

Image recognition-based instrument panel meter reading method, instrument panel meter reading system, storage medium and server

InactiveCN108600690AFully automatedHigh frequencyCharacter and pattern recognitionClosed circuit television systemsInstrument DataComputer science

The invention provides an image recognition-based instrument panel meter reading method, an instrument panel meter reading system, a storage medium and a server. The method comprises the steps of collecting the images of an instrument panel in real time by an image collecting device according to a preset time interval; recognizing the images of the instrument panel and obtaining the data of instruments. According to the image recognition-based instrument panel meter reading method, the instrument panel meter reading system, the storage medium and the server, the images of the instrument panelare collected, recognized and processed in real time. Therefore, the automatic, high-frequency and high-precision statistics and recording of instrument data are achieved.

Owner:上海东方延华节能技术服务股份有限公司

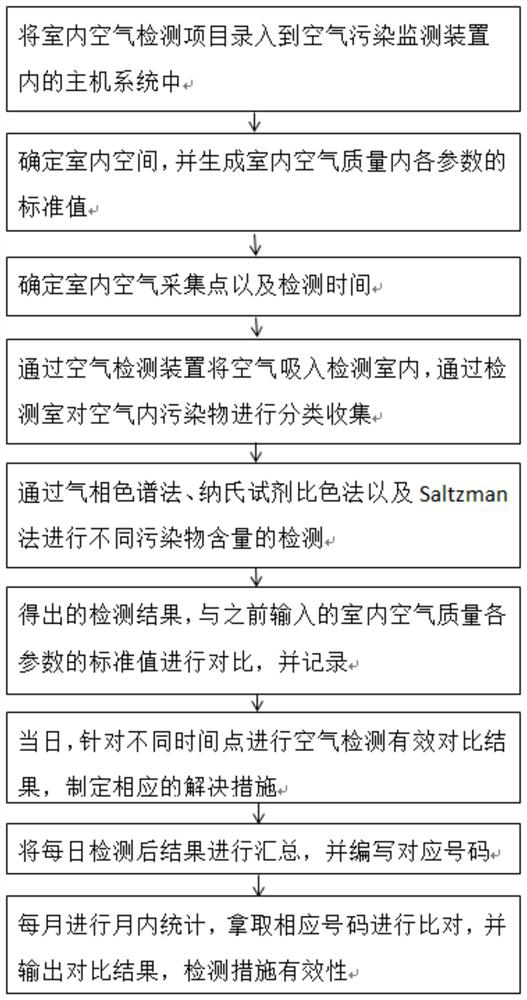

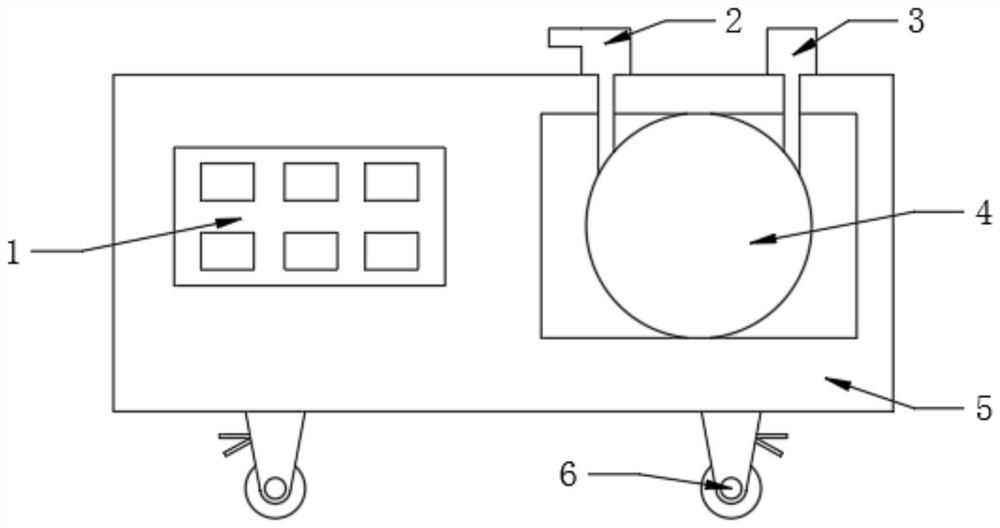

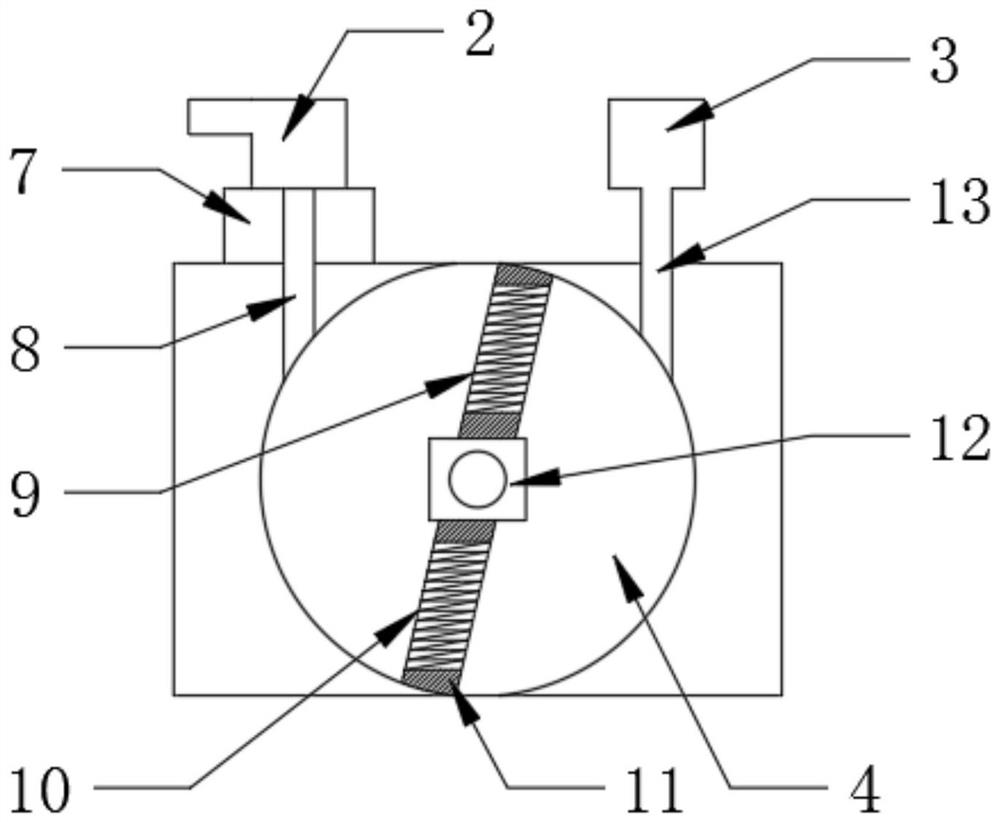

Air pollution detection device and detection method thereof

InactiveCN113188856AAccurate dataEnsure data accuracyWithdrawing sample devicesGas analyser construction detailsRotary stageMulti pollutant

The invention discloses an air pollution detection device and a detection method thereof, and belongs to the technical field of air quality detection. The invention discloses the air pollution detection device which is characterized in that air is absorbed through an air inlet to enter the detection device for detection, a rotating table is mounted below the air inlet, the air inlet is driven to rotate through the rotating table, air in different directions is absorbed, and data are more accurate; a detection chamber is installed inside the air inlet, the detection chamber can realize synchronous detection of one, two or more pollutants, the detection chamber is connected with a controller, the controller issues a command in a unified manner, and meanwhile, a detection result is synchronously displayed by the controller to confirm the content of the air pollutants; and for air at a high position, the measuring ruler can be pushed by a telescopic rod to rise, and different height positions can be determined by the measuring ruler, so that the data accuracy and completeness of overall air detection are ensured, and corresponding solution measures can be conveniently formulated.

Owner:昆山恒清净化设备科技有限公司

Power distribution network infrastructure project investment statistics and deviation correction method

PendingCN110458720AAvoid spendingImprove applicabilityData processing applicationsWeight coefficientCorrection method

The invention relates to a power distribution network infrastructure project investment statistical method. The method comprises the following steps of estimating monthly investment amount i based onmonthly investment percentages of historical similar projects in a local area; and calculating the engineering weight coefficient of each subsection based on the historical similar projects of the local area. The invention also relates to a power distribution network infrastructure project investment statistics deviation correction method. The method provided by the invention has good universalityand suits the actual condition..

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

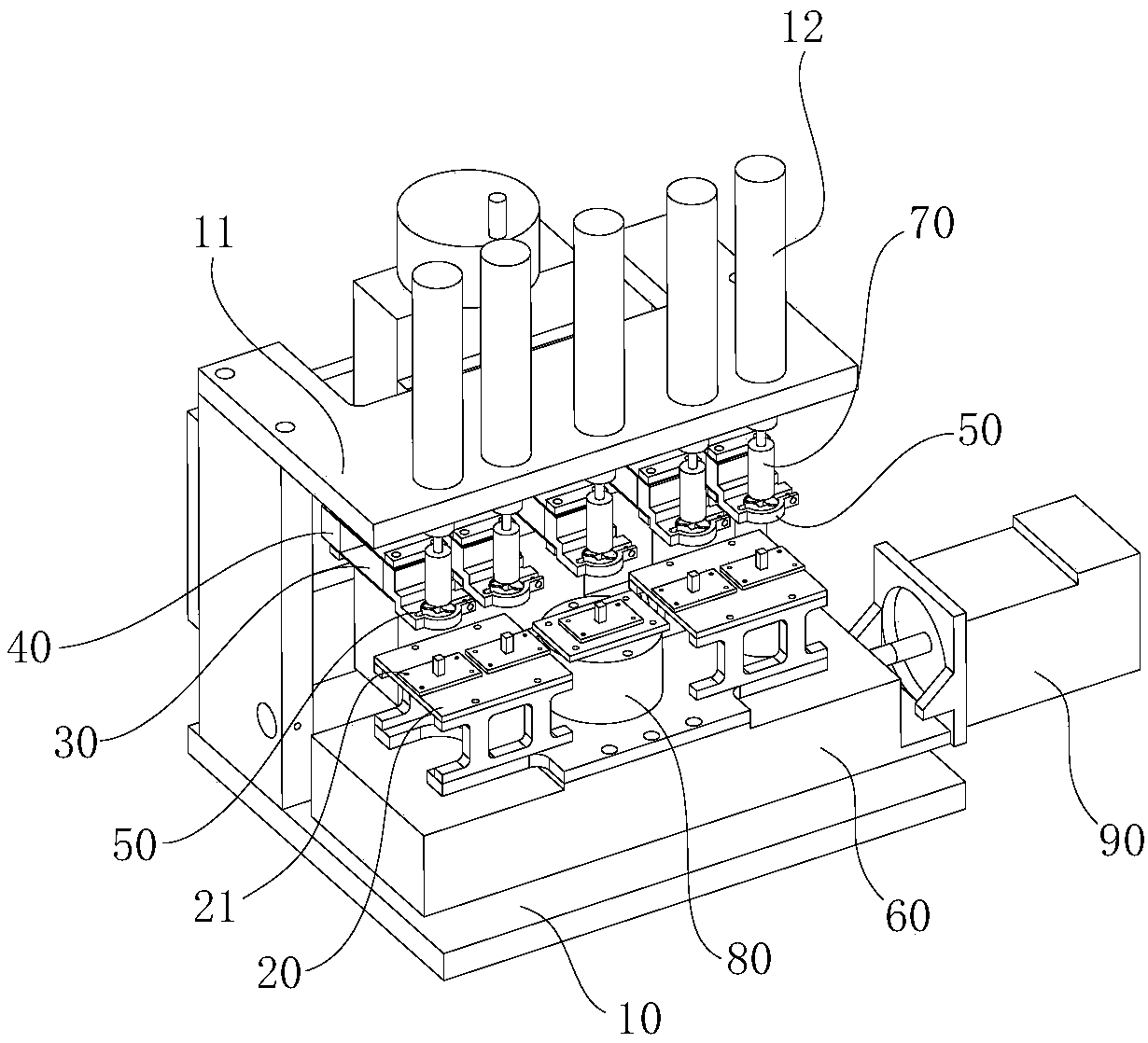

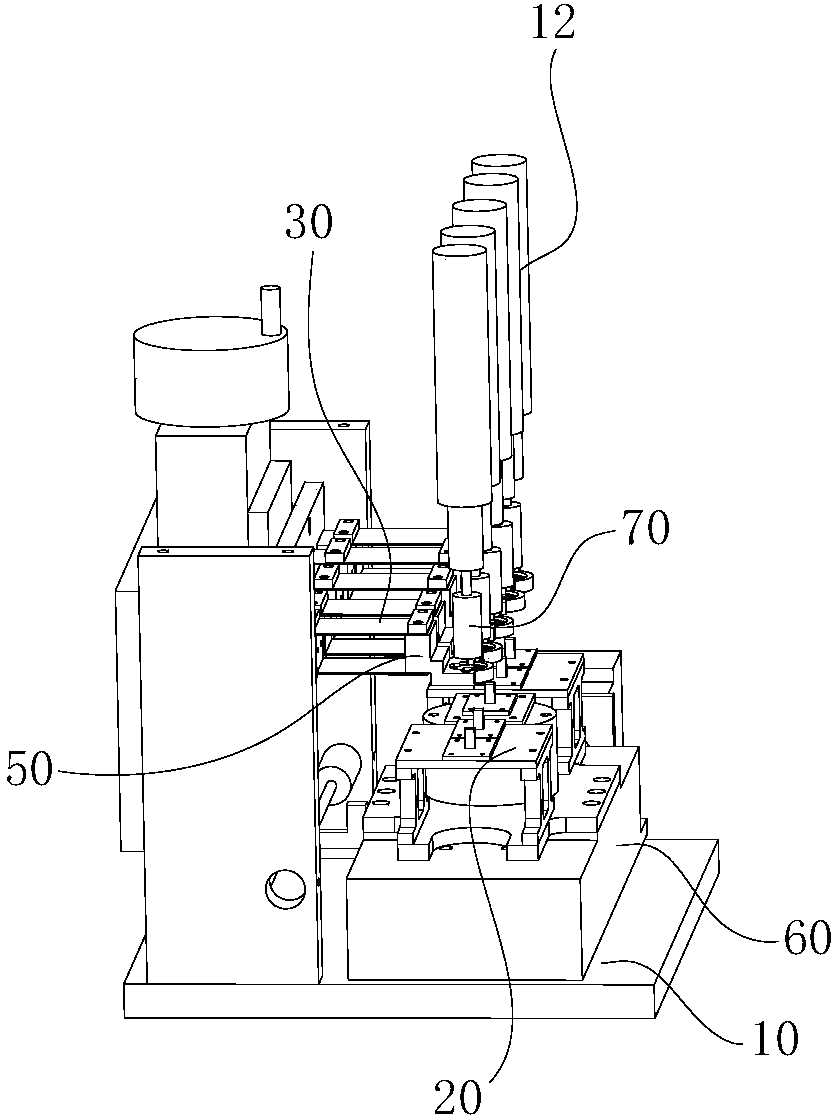

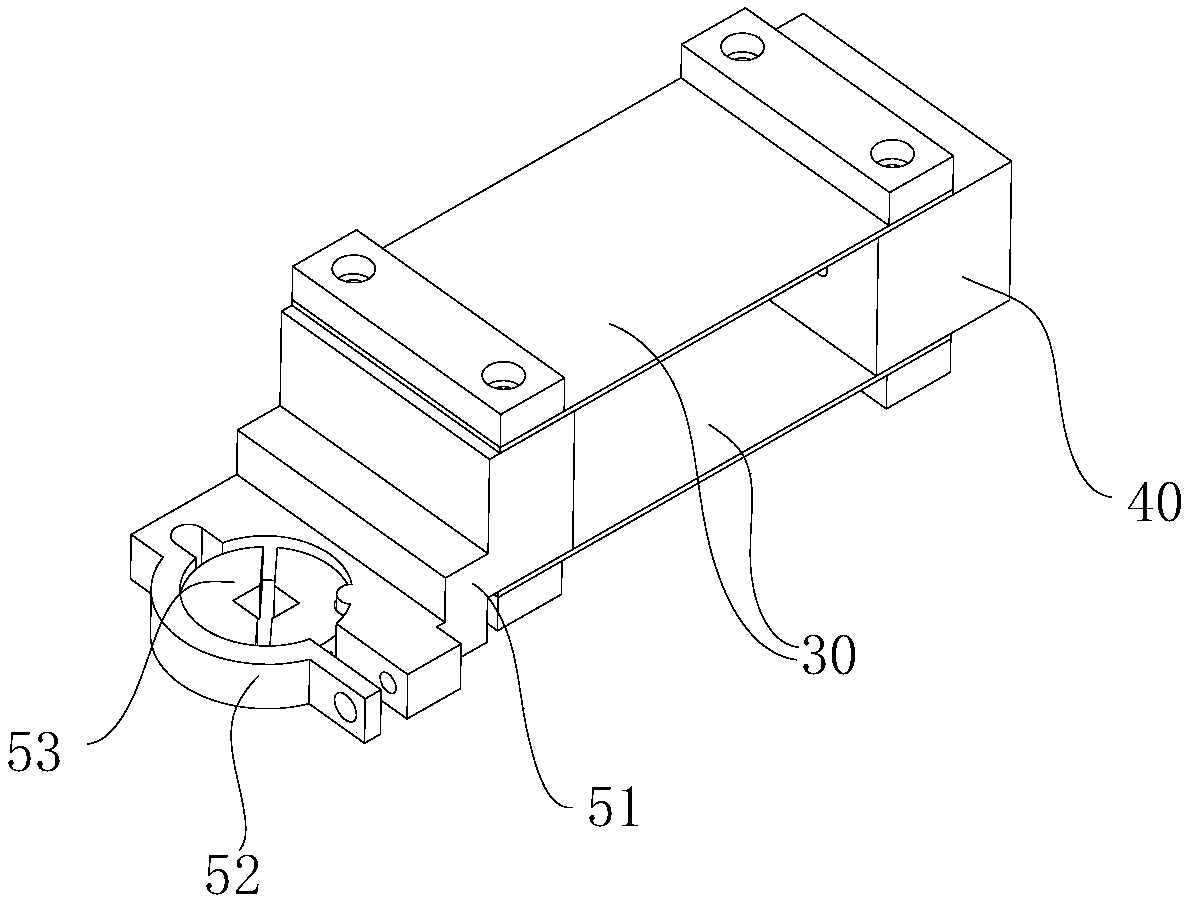

Multihead plane reciprocating friction wear testing machine

ActiveCN108088763AConstant contact pressureEnsure data accuracyInvestigating abrasion/wear resistanceFriction testTest sample

The invention relates to a multihead plane reciprocating friction wear testing machine. The multihead plane reciprocating friction wear testing machine comprises a worktable, wherein lower clamps forfixing lower to-be-tested samples are arranged on the worktable; a movable cross beam is arranged above the worktable; upper clamps are arranged on the movable cross beam; a mechanism adjusts the movable cross beam to vertically move and enables the upper clamps to be close to or separated from the corresponding lower lamps; elastic plates are horizontally arranged on the movable cross beam in a suspending manner; the plate surfaces of the elastic plates are horizontally arranged; the upper clamps are fixed at the suspending ends of the elastic plates; pressure applying heads are arranged at the upper ends of the upper clamps; a three-way force sensor is arranged on the lower clamps and is used for detecting applying pressure of the pressure applying heads; a driving mechanism drives the lower clamps to do reciprocating motion in the horizontal direction; the upper clamps are fixed at the ends of the elastic plates; when the pressure applying heads prop against upper to-be-tested samples, the upper to-be-tested samples can be always kept vertical, further friction surfaces of the upper to-be-tested samples and the lower to-be-tested samples are always planes, the constancy of the contact pressure of the friction surfaces is kept and data accuracy of a friction test is ensured.

Owner:HEFEI UNIV OF TECH

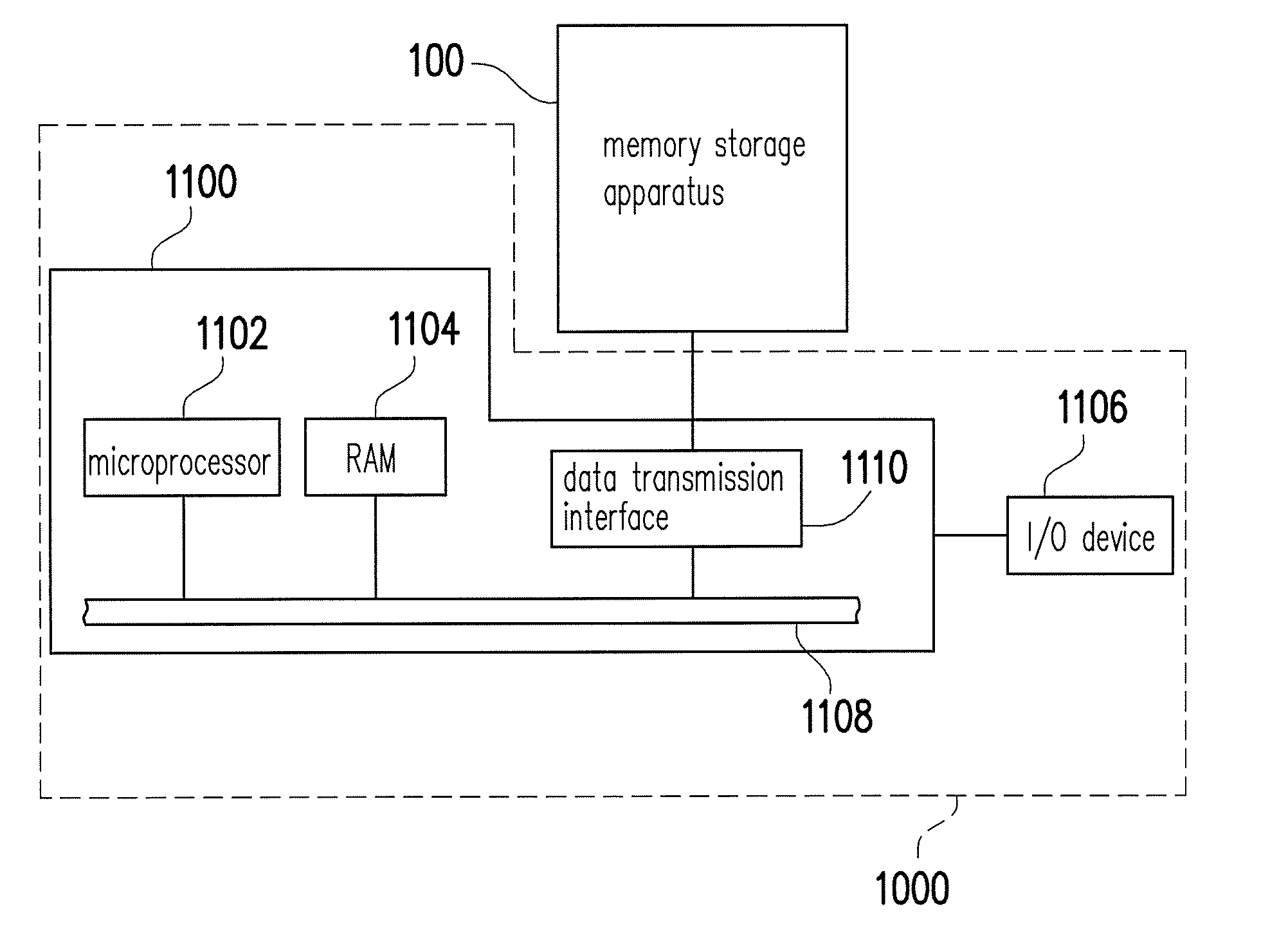

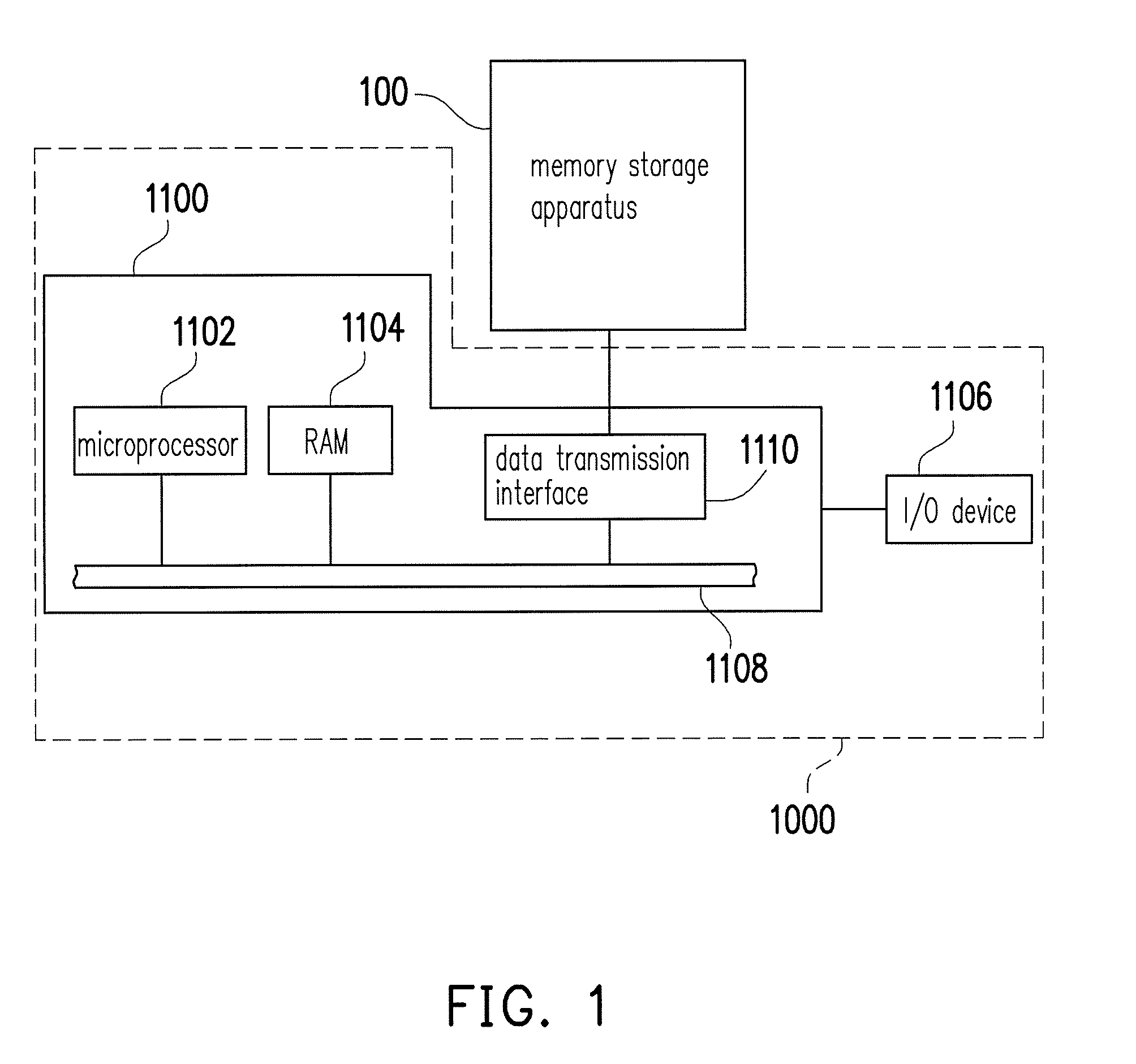

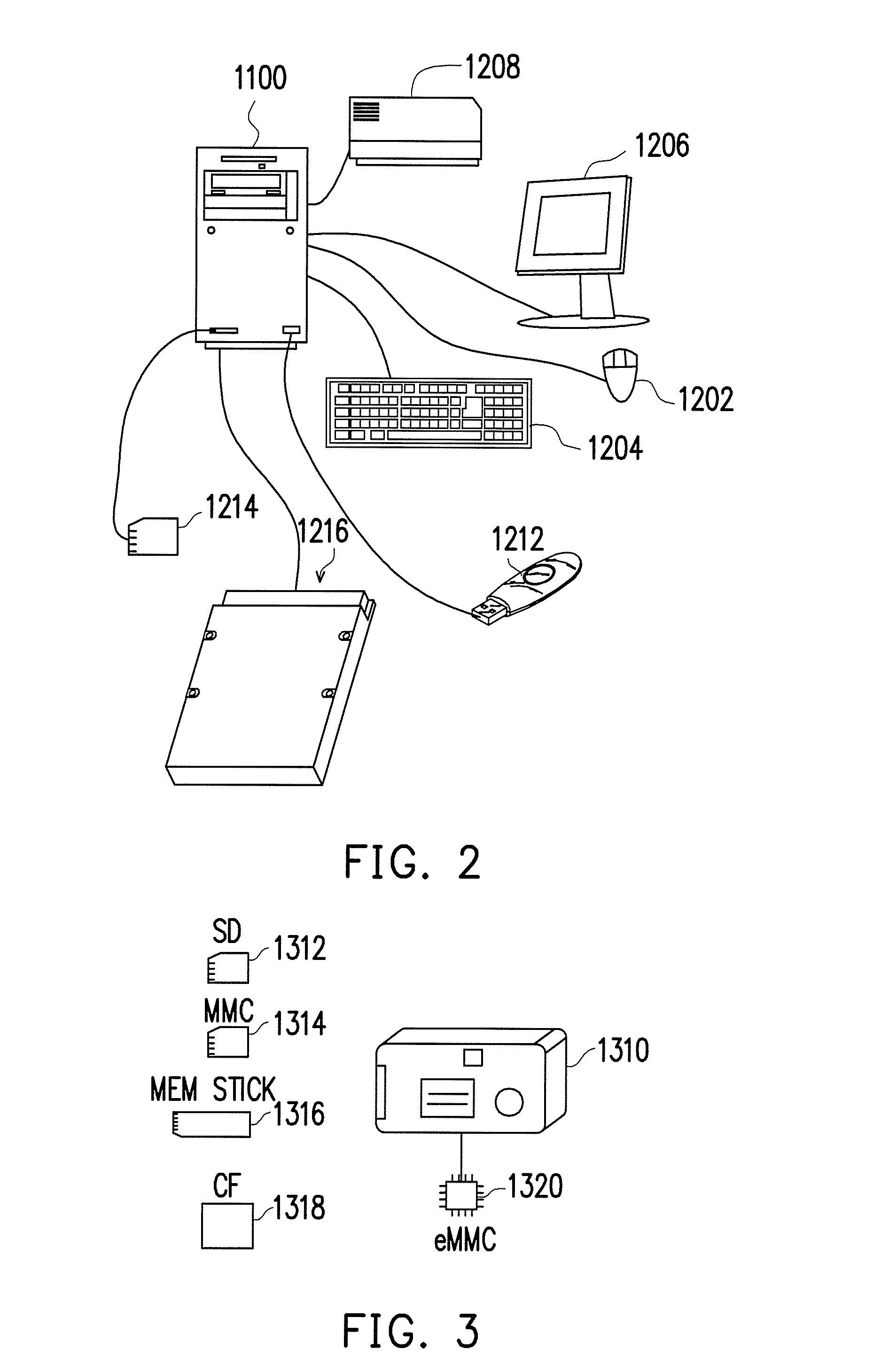

Data accessing method, memory controlling circuit unit and memory storage apparatus

ActiveUS20160314040A1Efficient verificationEnsure data accuracyInput/output to record carriersCode conversionData setData stream

A data accessing method for a memory storage apparatus is provided. The method includes using a first check code circuit to generate a first check code corresponding to a first data stream and generating a first data set based on the first data stream and the first check code. The method also includes using a second check code circuit to obtain the first data stream and the first check code from the first data set and check the first data stream according to the first check code. The method still includes using a third check code circuit to generate a second check code according to the checked first data stream and generating a data frame based on the checked first data stream and the second check code and thereby programming the data frame into a physical programming unit.

Owner:PHISON ELECTRONICS

Vertical tensile test device containing novel fibre cloth clamp

PendingCN107831064AAvoid stress concentrationImprove usageMaterial strength using tensile/compressive forcesFiberSteel ball

The invention belongs to the technical field of tensile test devices, and particularly relates to a vertical tensile test device containing a novel fibre cloth clamp. The vertical tensile test devicecontaining the novel fibre cloth clamp comprises the fibre cloth clamp, a testing machine clamping head, a load sensor and displacement meters; the fibre cloth clamp comprises a main body steel shell,high-strength bolts, small bolts, a spherical hinge and a steel clamping plate; the testing machine clamping head comprises an upper testing machine clamping head and a lower testing machine clampinghead; an inner testing machine clamp is fixed to the centre of the lower testing machine clamping head, is integrally placed below the main body steel shell, and is used for fixing other small test devices or fibre cloth. According to the vertical tensile test device containing the novel fibre cloth clamp, the defects that most existing single shear test devices are loaded transversely and forcetransfer of the fibre cloth clamp is non-uniform are overcome; and uniform stress of the fibre cloth at an end part can be ensured, so that the acquisition of accurate and stable test data is facilitated.

Owner:DALIAN UNIV OF TECH

Intelligent shoemaking method based on three-dimensional data of soles

The invention belongs to the technical field of shoemaking, in particular to an intelligent shoemaking method based on three-dimensional data of soles. The intelligent shoemaking method comprises a main frame body, a connecting plate, a No.1 cavity, a carrying plate, a No.1 rubber film and a No.2 rubber film, wherein the connecting plate is fixedly arranged at the upper end of the main frame body;the No.1 cavity is formed in the connecting plate; the No.1 rubber film is arranged above the middle part of the No.1 cavity; the No.2 rubber film is arranged below the middle part of the No.1 cavity; the No.1 cavity is filled with liquid silicon rubber; the No.1 rubber film is arranged in the upper wall of the connecting plate; the No.2 rubber film is fixedly arranged in the lower wall of the connecting plate; the carrying plate is connected in the inner walls of the two ends of the main frame body in a sliding way through springs; the two ends of the carrying plate are provided with deflector holes in a through way; the lower side of the carrying plate is provided with hot water; and the lower end of the inside of the main frame body is filled with the hot water. The intelligent shoemaking method is mainly used for solving the problem that the problems of disabled people as well as people with different foot sizes and foot deformity cannot be solved with a shoemaking method in the prior art.

Owner:瑞安市天驰鞋业有限公司

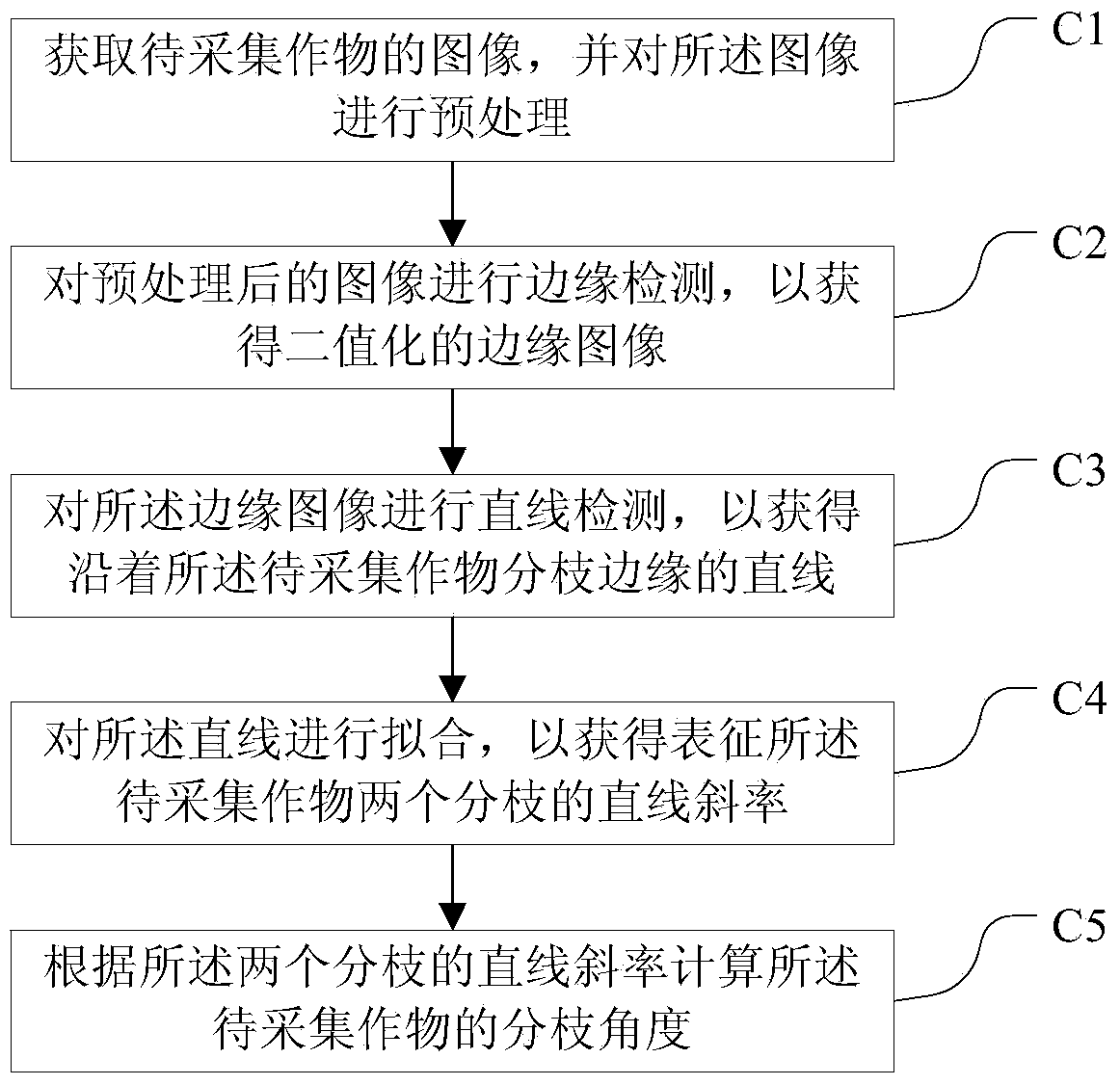

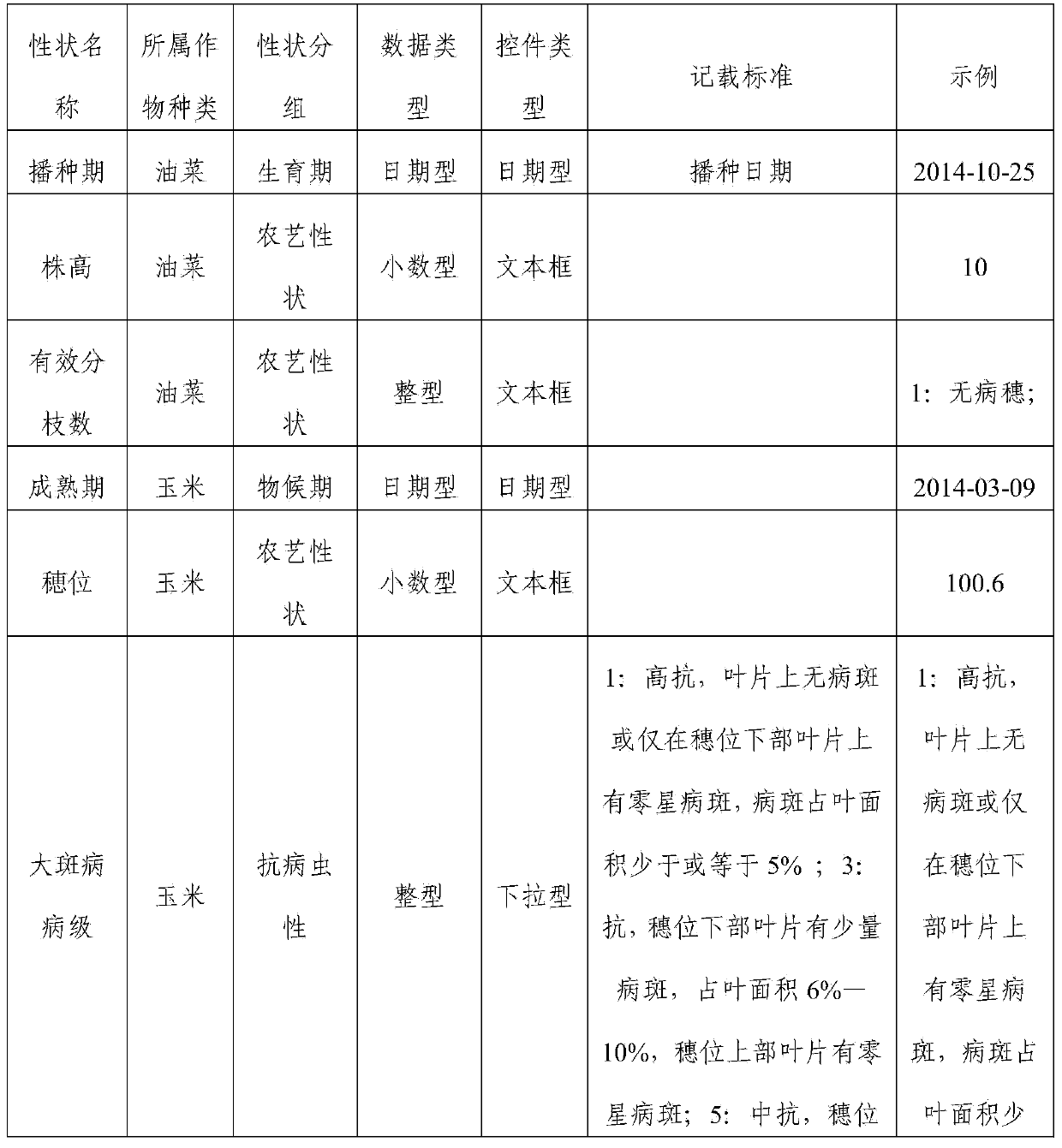

Character collecting method and system

InactiveCN103996197AImprove accuracyImprove collection efficiencyImage analysisTransmissionPattern recognitionBranching angle

The invention discloses a character collecting method and system, and relates to the technical field of character collecting of crops. The method comprises the following steps that C1, images of corps to be collected are obtained and preprocessed; C2, the images after preprocessing are subjected to edge detection to obtain binary edge images; C3, all edge images are subjected to linear detection to obtain straight lines along the edges of branches of the crops to be collected; C4, the straight lines are subjected to fitting to obtain straight slopes representing two branches of the crops to be collected, and C5, according to the straight slopes of the two branches, branch angles of the crops to be collected are calculated. According to the character collecting method and system, partial characters are automatically collected, and accuracy of character collecting is improved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

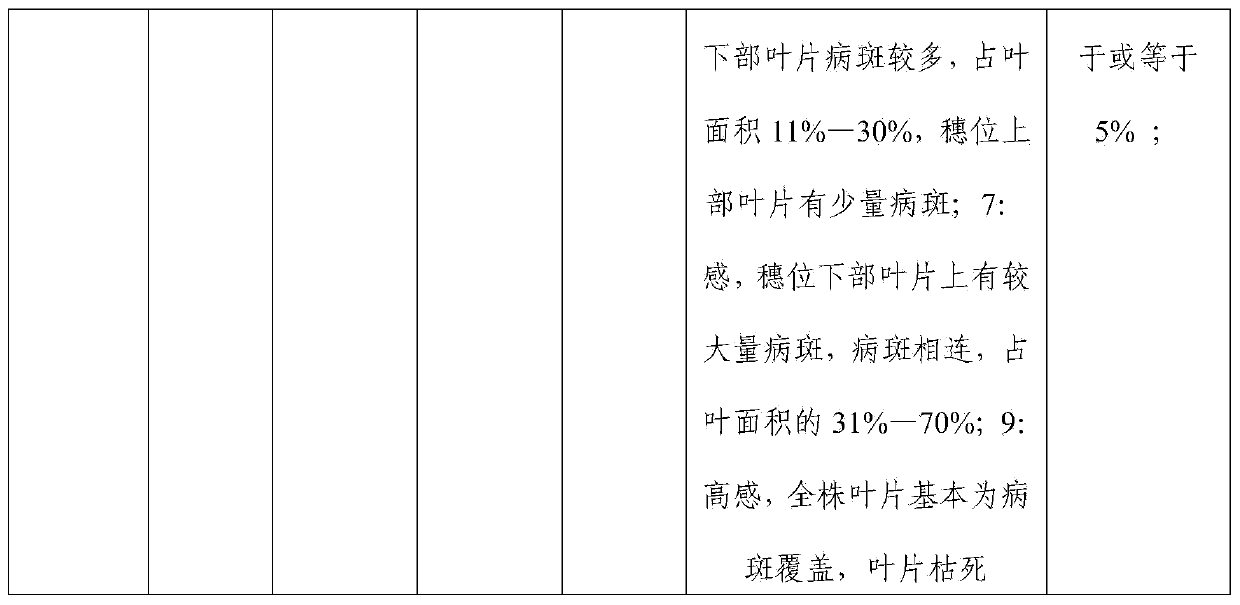

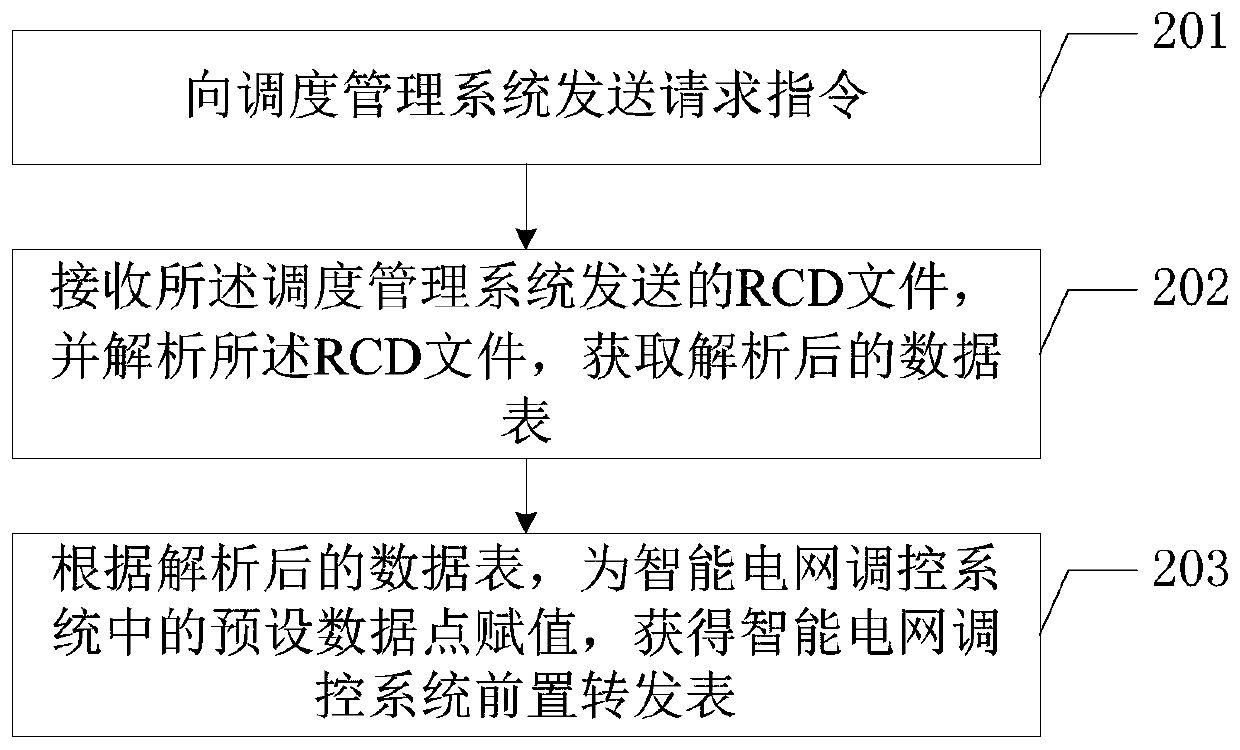

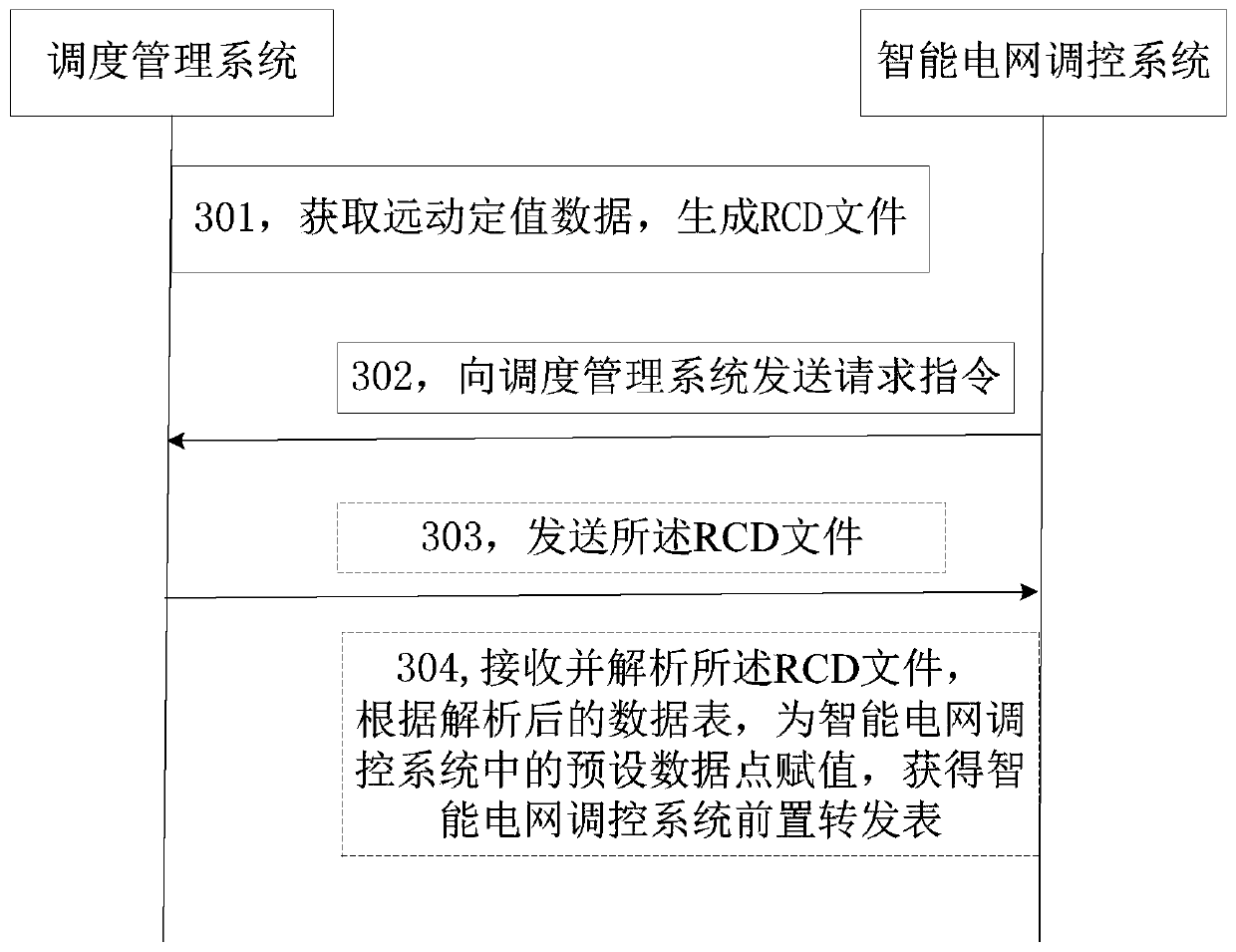

Automatic information processing method and terminal equipment

ActiveCN109918353AEnsure data accuracyAvoid legacy problemsData processing applicationsFile system typesSmart gridManagement system

The invention is applicable to the technical field of information processing, and provides an automatic information processing method and terminal equipment, and the method comprises the steps: sending a request instruction to a scheduling management system, using the request instruction for requesting to acquire an RCD file; receiving an RCD file sent by the scheduling management system, analyzing the RCD file, and obtaining an analyzed data table; And according to the analyzed data table, assigning values to preset data points in the smart power grid regulation and control system to obtain afront forwarding table of the smart power grid regulation and control system, so that the problems of long time and low accuracy caused by the fact that manual operation is adopted to debug the plant-station access of the automatic system in the prior art can be solved.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Geographic big data three-dimensional visualization rendering method

InactiveCN113744380AReduce storageShorten the timeDetails involving 3D image data3D-image renderingComputer graphics (images)Big data

The invention relates to the technical field of visual rendering, and discloses a geographic big data three-dimensional visual rendering method. The method comprises the following steps: 1, layering a map visual area, so that the map visual area is divided into at least two or more data layers, each data layer is positioned according to own latitude and longitude coordinates, and the representation number of each data layer is S1, S2, S3... Sn; 2, firstly analyzing the data of each data layer and then screening the data; 3, respectively calling out the data of each data layer and loading the data into a data storage unit; and 4, rendering the data corresponding to each data layer in the data storage unit, and rendering each data layer in a one-to-one manner by a data rendering unit. According to the geographic big data three-dimensional visualization rendering method, the data of the geographic position does not need to be directly called, the data storage and pollution time is shortened, and then the rendering efficiency of mass geographic position data is improved.

Owner:南京国诚土地整治研究院有限公司

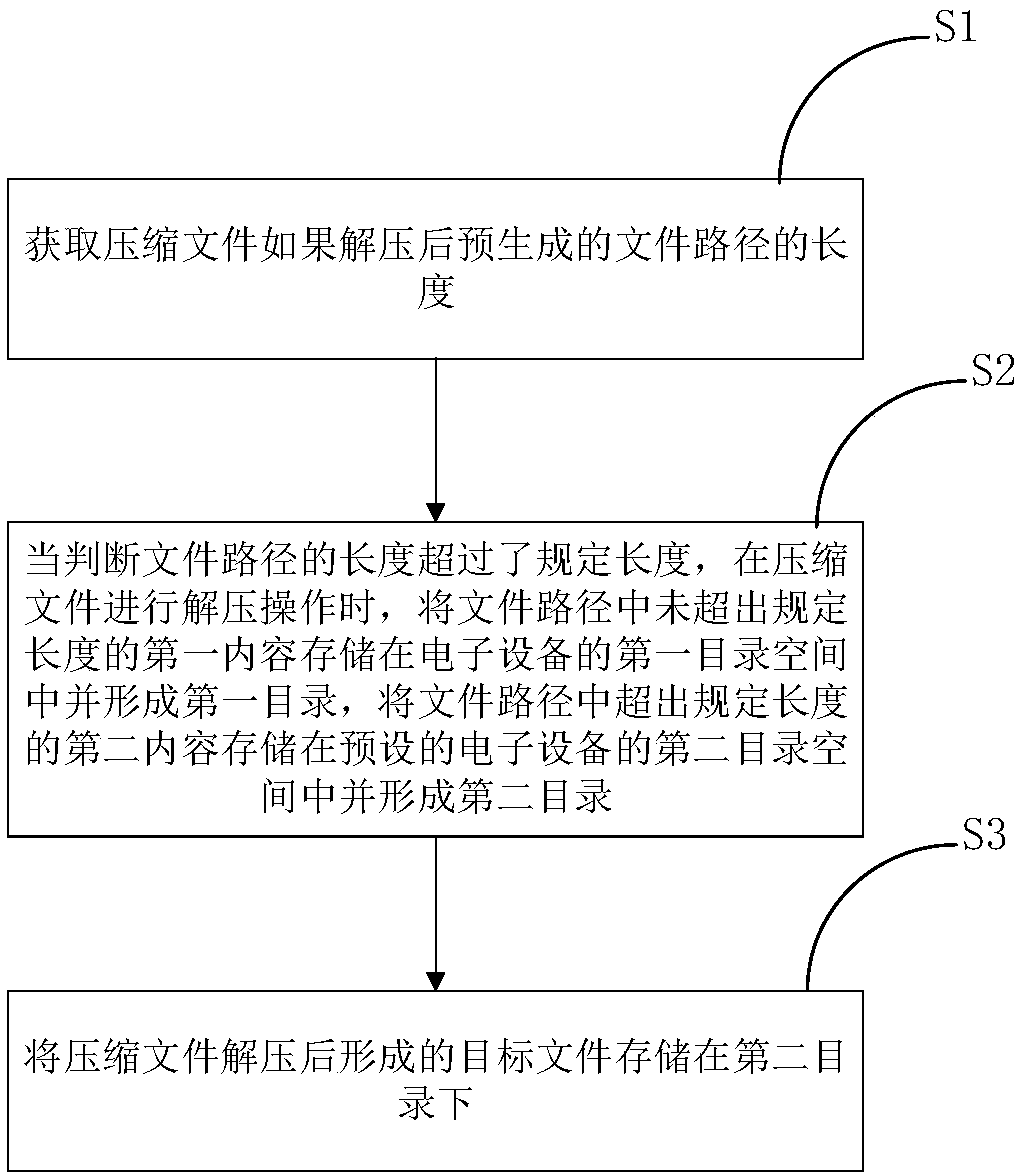

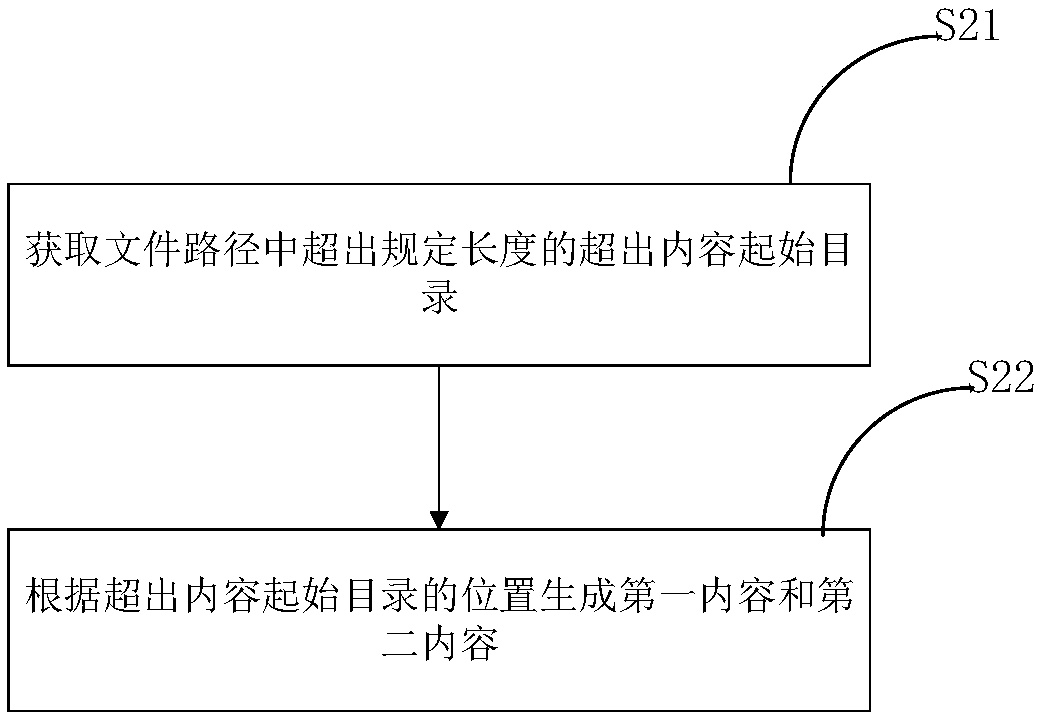

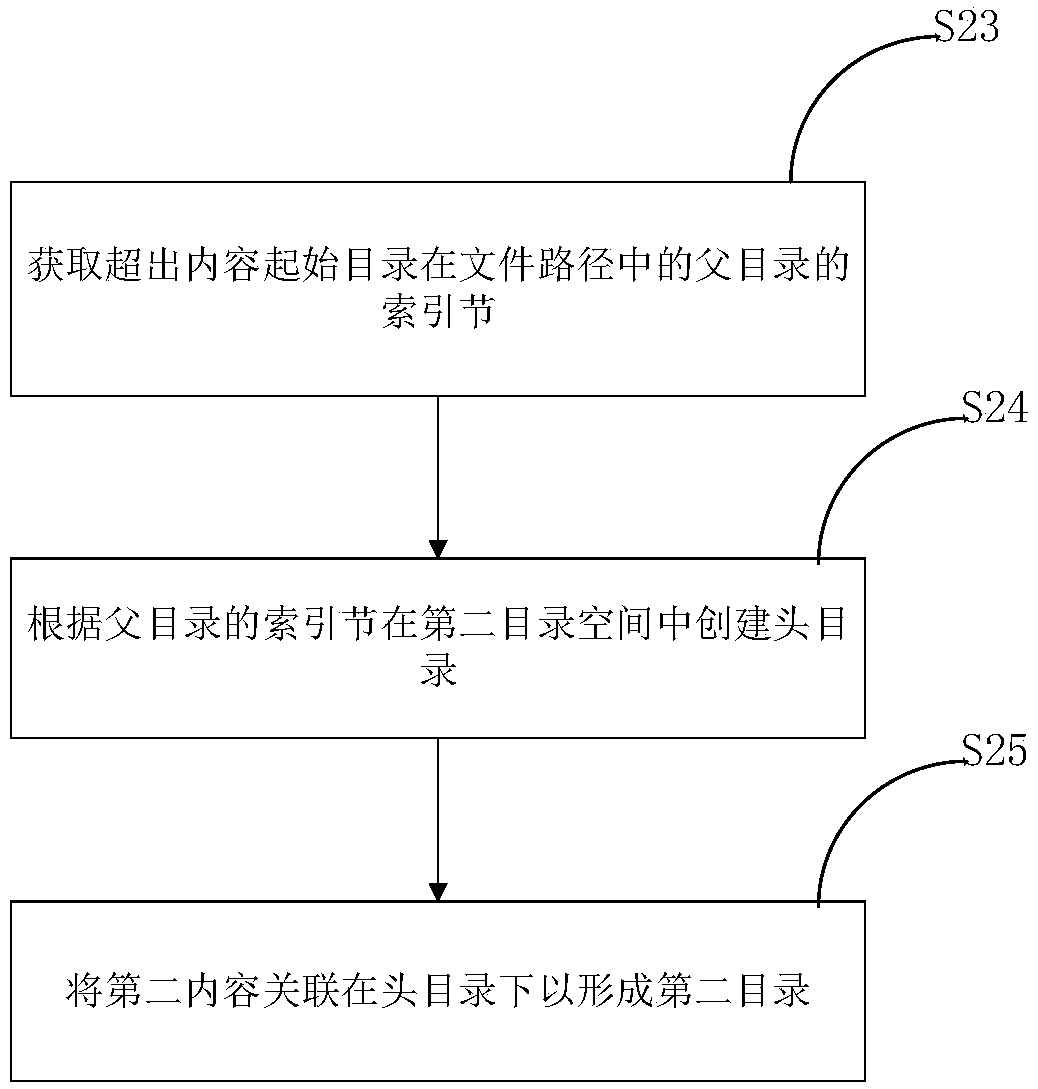

Data processing method and apparatus

ActiveCN107609072ANormal decompression operationEfficient storageSpecial data processing applicationsPath lengthDefining length

The invention discloses a data processing method and apparatus. The method is applied to a process of processing a compressed file in an electronic device. The method comprises the steps of obtainingthe length of a file path pre-generated after decompression of the compressed file; when it is judged that the length of the file path exceeds the defined length, during decompression operation of thecompressed file, storing first contents, which do not exceed the defined length in the file path, in a first directory space of the electronic device, forming a first directory, storing second contents, which exceed the defined length in the file path, in a preset second directory space of the electronic device, and forming a second directory; and storing a target file formed after decompressionof the compressed file in the second directory. According to the method, the compressed file with the file path length, formed after decompression, exceeding the defined length can be normally decompressed; and the target file formed after the decompression of the compressed file is effectively stored, so that the data accuracy of the target file is ensured.

Owner:LENOVO (BEIJING) LTD

Bio-based degradable film blowing master batch and production process thereof

ActiveCN114106444AReduce pollutionImprove stabilityPlastic recyclingCentrifugesPolymer scienceAnoxomer

The invention discloses a bio-based degradable film blowing master batch and a production process thereof. The bio-based degradable film blowing master batch comprises the following components: biological refined starch, polyethylene resin, a compatilizer, a coupling agent, an antioxidant and a lubricant. The process comprises the following steps: a, obtaining biological refined starch; b, removing impurities from the biological refined starch obtained by refining; c, heating and dehydrating the biological refined starch; d, mixing the polyethylene resin, the biological refined starch, the lubricant, the compatilizer, the coupling agent and the antioxidant; e, feeding the materials into an automatic feeding device; f, sealing the automatic feeding device and the double-screw extruder; g, extruding to form master batches; and h, the material conveying pipe, the first hose and the second hose are cleaned. The obtained master batch can be degraded in the natural environment, so that the environmental pollution is reduced. Meanwhile, the material conveying stability is good, the prepared materials can be uniformly and continuously fed into the double-screw extruder through the automatic feeding device, and the production efficiency of the master batch is improved.

Owner:浙江绿禾生态科技股份有限公司

Method, system and device for measuring horizontal displacement of foundation pit

PendingCN113513050AEasy to measureEliminate errorsFoundation testingExcavationsMonitoring siteData transformation

The invention relates to a method, a system and a device for measuring horizontal displacement of a foundation pit. Monitoring points are arranged on the inner wall of the foundation pit in a layered mode by using optical fibers, so that errors caused by reference points are eliminated, and the scheme omits a mode of using the monitoring reference points as reference points for measurement and calculation, so that the measurement process is more simplified, and meanwhile, errors caused by displacement changes of the monitoring reference points are eliminated, data conversion does not need to be conducted through the monitoring reference points, the calculation process is further saved, the inclination angles of the monitoring points are directly measured through the optical fibers, the real-time performance and accuracy of the data are guaranteed, and the measurement precision is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com