Gas chromatography detection system and method for analyzing trace impurities in ultrahigh pure gas

A trace impurity and gas chromatography technology, which is applied in the field of gas chromatography detection systems for trace impurities analysis in ultra-high-purity gas, can solve the problems of reduced detection sensitivity of the system, and achieve the effect of fast, consistent and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

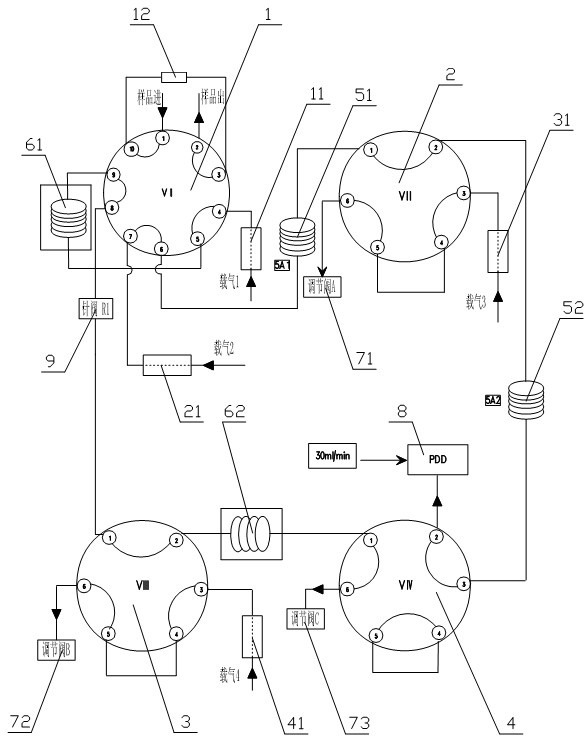

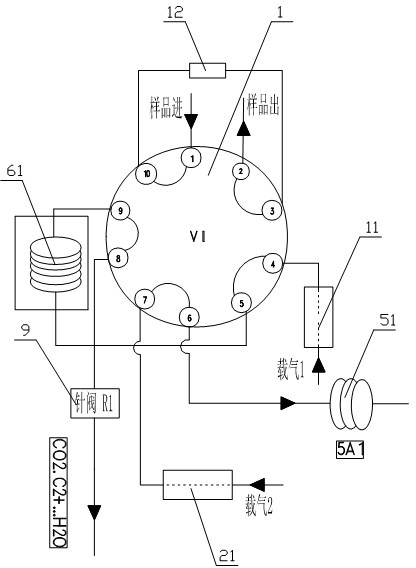

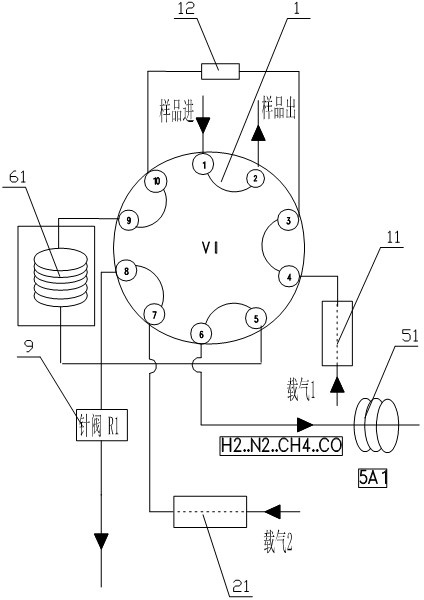

[0038] Gas chromatography detection system for trace impurity analysis in ultra-high-purity gas, including carrier 1, carrier 2, carrier 3, carrier 4 gas circuits, switching valve VI1, switching valve VII2, switching valve VIII3 and switching valve VIV4, ten-way purge pneumatic A first molecular sieve chromatographic column 51 is set between the switching valve VI1 and the six-way purge pneumatic switching valve VII2; a second molecular sieve chromatographic column 52 is set between the switching valve VII2 and the switching valve VIV4; between the switching valve VI1 and the switching valve VIII3 A needle valve 9 is provided, and a second column separator 62 is provided between the switching valve VIII3 and the switching valve VIV4. Carrier gas 1, carrier gas 2, carrier gas 3, and carrier gas 4 are all damped by microporous tubes, and then the length of the pipeline is calculated to determine the flow rate in practice. This way, the flow rate of the gas path is stable and accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com