Bio-based degradable film blowing master batch and production process thereof

A bio-based, masterbatch technology, applied in the field of plastic products, can solve the problems of ecological environment pollution, poor material transportation stability, poor sealing, etc., to reduce environmental pollution, improve efficiency, and ensure data accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The bio-based degradable blown film masterbatch disclosed by the invention includes the following components: bio-refined starch, polyethylene resin, compatibilizer, coupling agent, antioxidant and lubricant, and the bio-refined starch is made of potatoes and corn. The refined starch made of raw materials is 800-1200 mesh.

[0057] The production method of bio-based degradable blown film masterbatch of the present invention comprises the following steps:

[0058] a. Thinning potatoes and corns as raw materials to obtain bio-refined starch, which can be refined to 800-1200 meshes, can make the obtained masterbatch degrade in the natural environment, thereby reducing environmental pollution.

[0059] b. Use an impurity separation device to perform impurity removal operations on the bio-refined starch obtained by refining, remove impurities, and improve the quality of masterbatch production in the later stage.

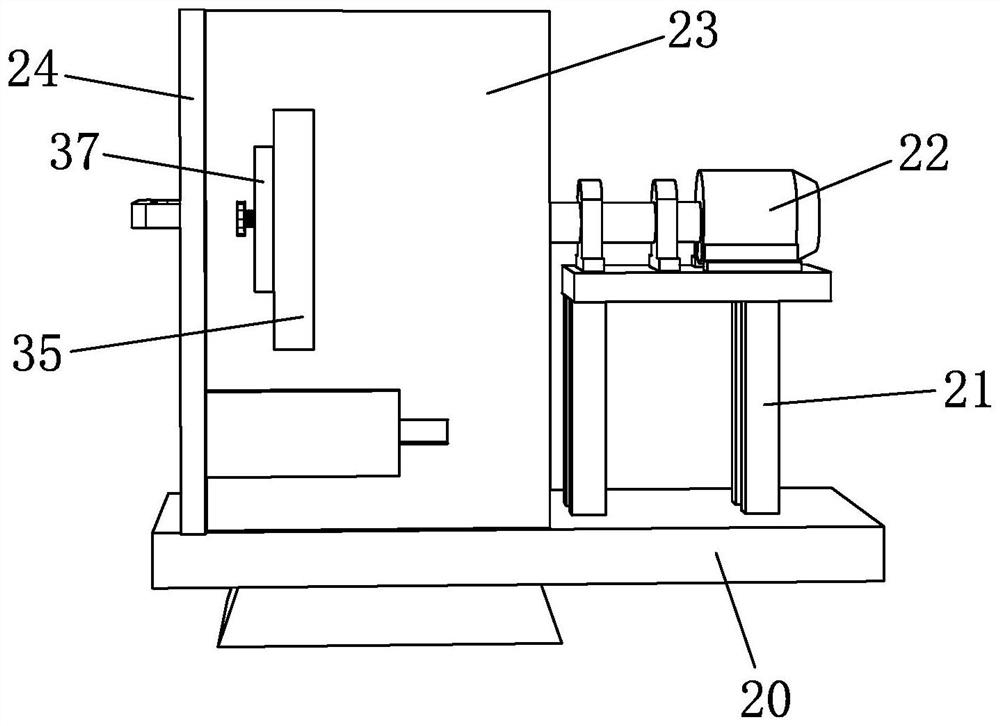

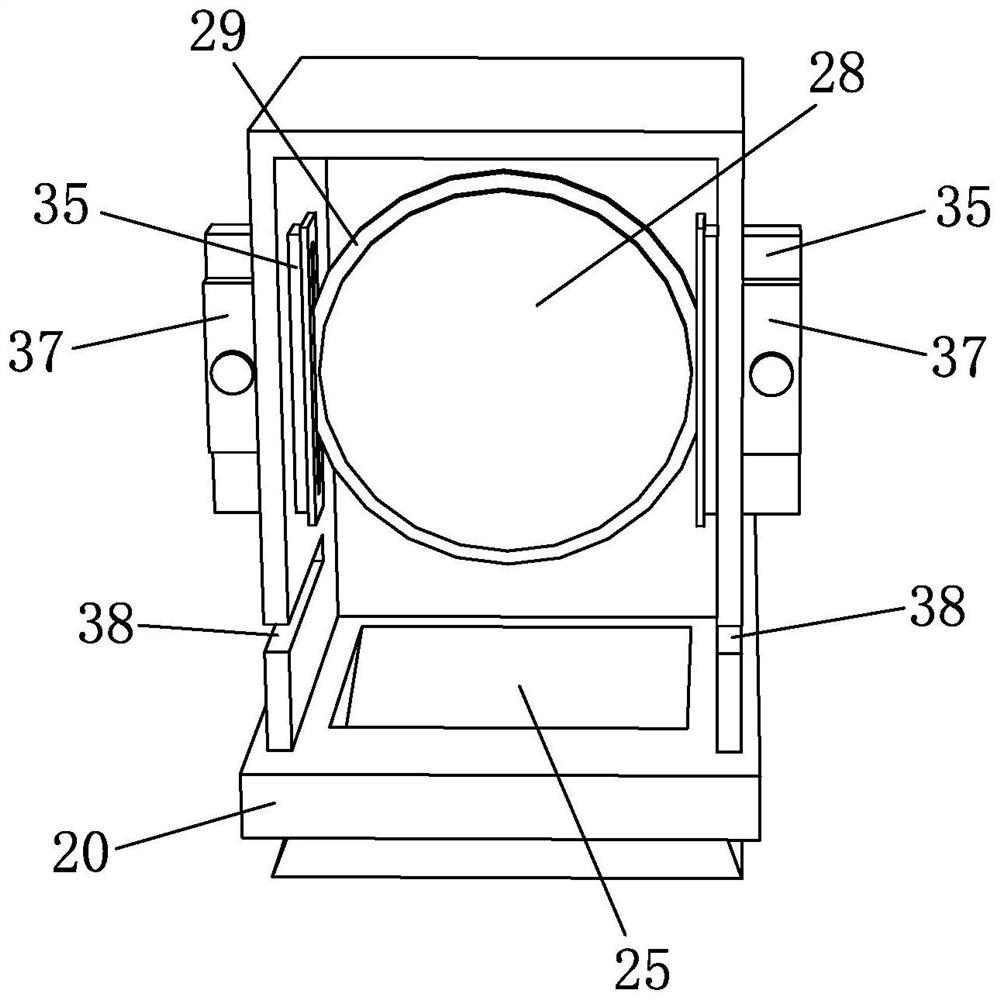

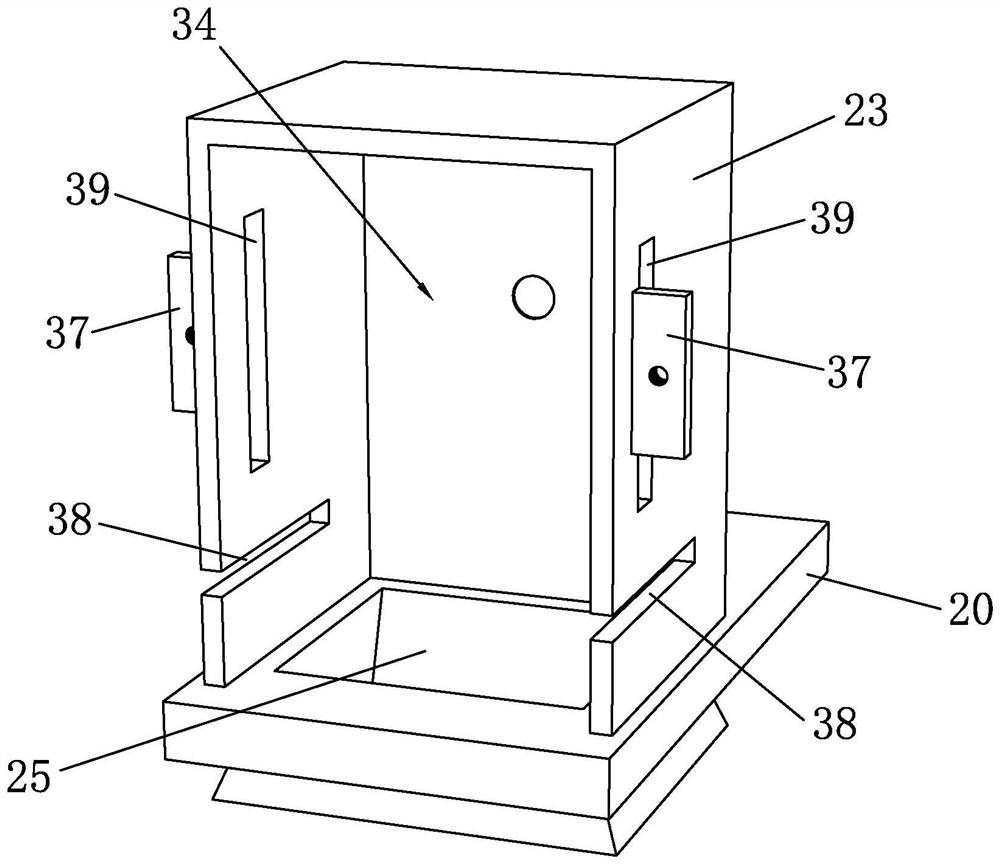

[0060] Such as Figure 1 to Figure 10 As shown, the impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com