Vertical tensile test device containing novel fibre cloth clamp

A tensile test, fiber cloth technology, used in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as uneven force transmission of fiber cloth fixtures, and achieve data accuracy, guarantee Stability, the effect of improving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

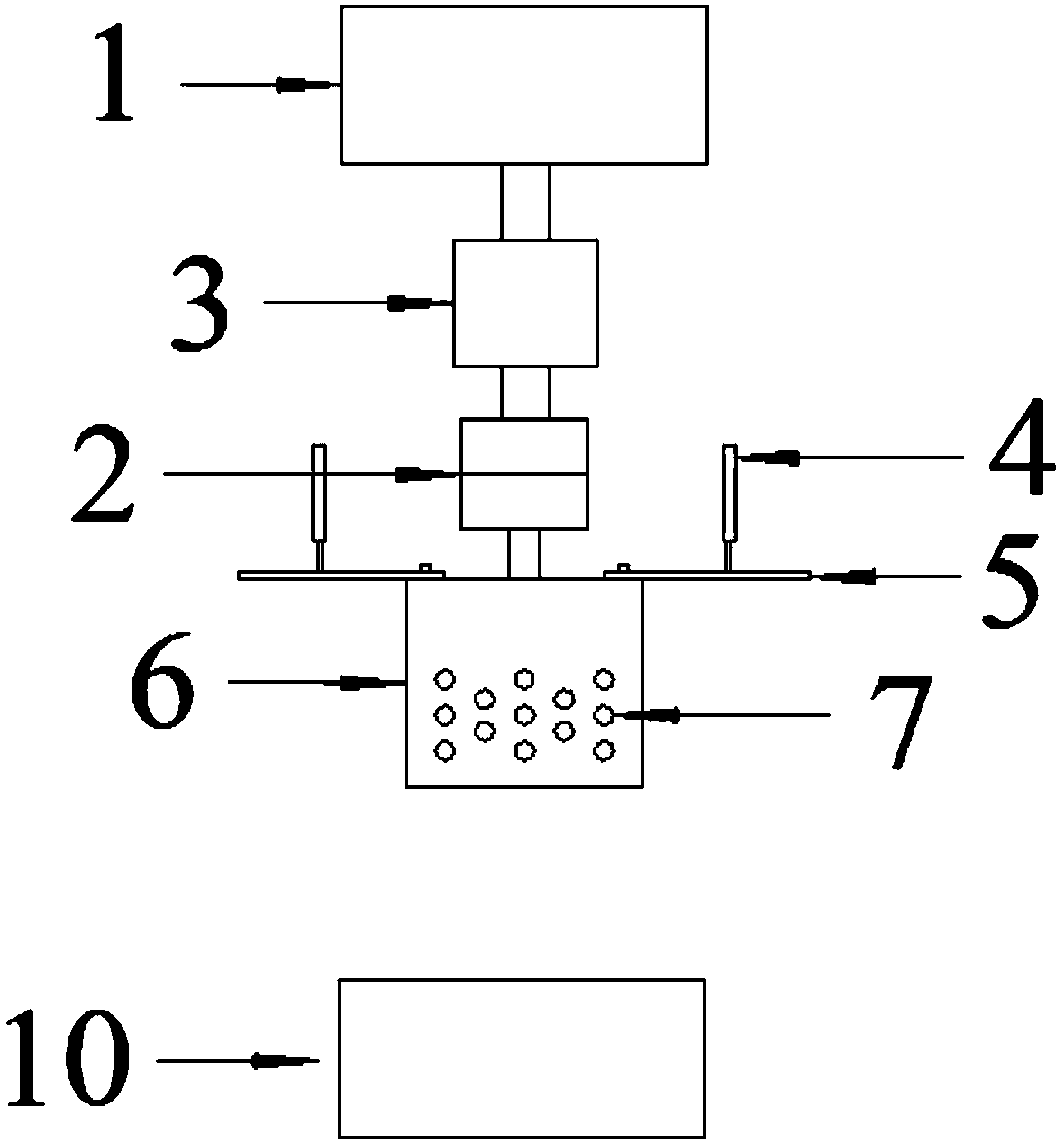

Embodiment 1

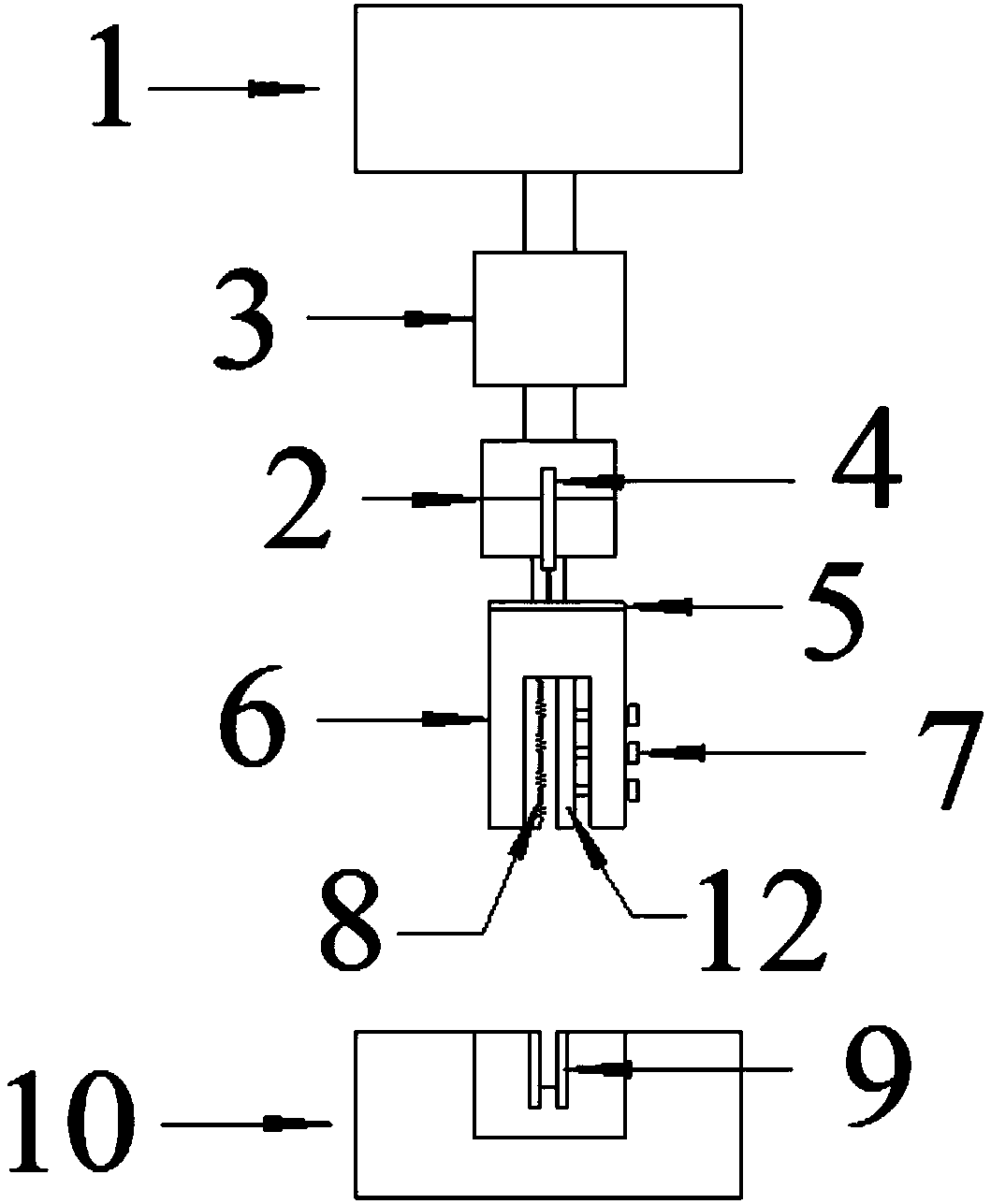

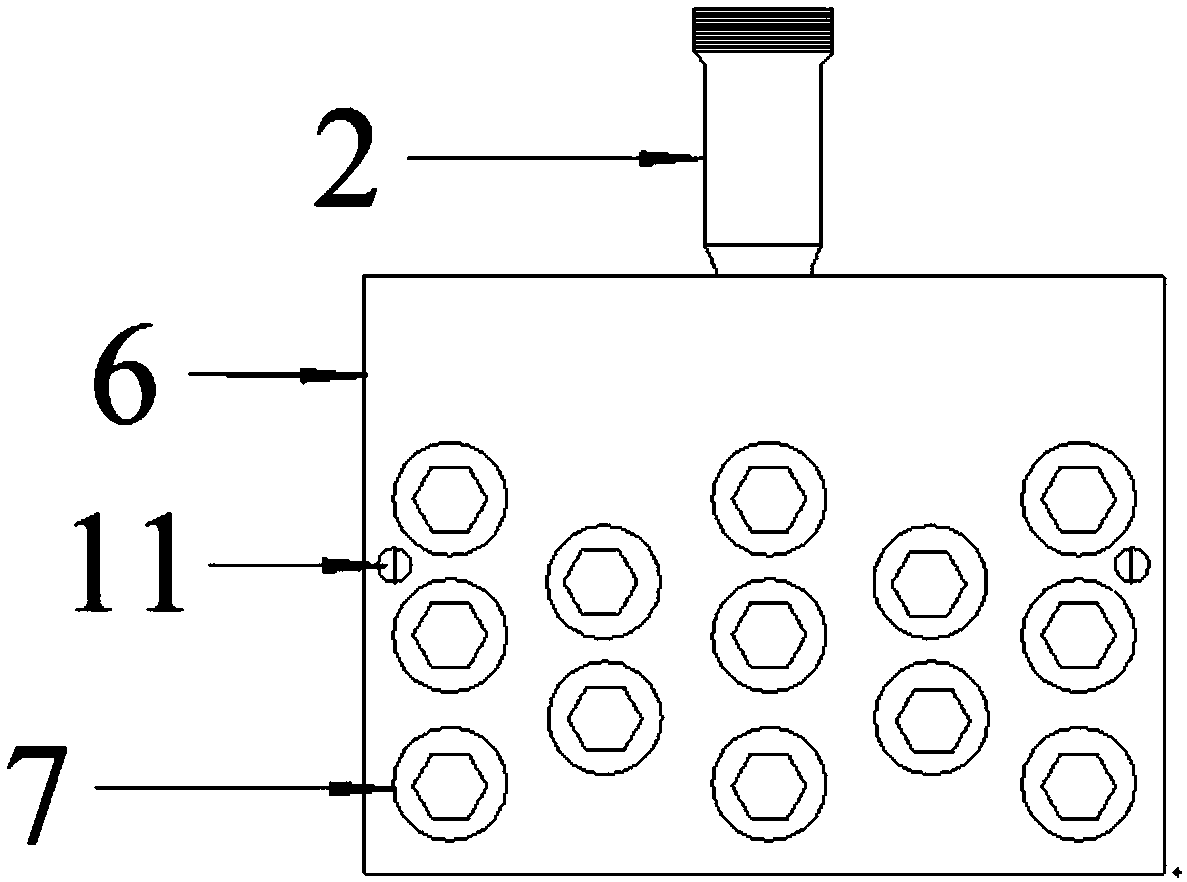

[0034] Image 6 It is a schematic diagram of the vertical tensile test device containing the novel fiber cloth clamp applied to the unidirectional tensile test of the fiber cloth, which is to directly insert the upper part of the FRP sheet 13 into the steel splint 12 with sawtooth 8, and then use The small bolts 11 are pre-tightened, and 13 high-strength bolts 7 are fastened in turn at the same time to ensure that the final force of the FRP sheet 13 is uniform, and the lower part of the FRP sheet 13 is directly placed in the fixture 9 of the testing machine and tightened. During the test, the lower chuck 10 of the testing machine remains stationary, and the upper chuck 1 of the testing machine moves upward continuously according to the displacement loading mode. The load sensor 3 located on the upper part of the ball joint 2 is used to record the real-time change of the load, and is installed on the main body of the fixture. Two displacement gauges (LVDT) 4 on the steel sheet ...

Embodiment 2

[0036] Figure 7It is a schematic diagram of the single-sided shear test of the vertical tensile test device containing the new fiber cloth clamp applied to the FRP-concrete interface. The upper pressing plate 14, the fixing screw 16 and the bottom plate 19 for fixing the concrete are first combined into a frame and then passed through The lower chuck 10 of the testing machine is directly fixed, and then the FRP sheet 13 is pasted on the surface of the concrete specimen 17 with epoxy resin glue in advance, and then placed on the bottom plate 19 as a whole, and the concrete upper plate 14 is fixed and the concrete side is fixed. The plate 15 is fixed, and then the concrete front screw 18 is locked and fixed to ensure that the lower end of the concrete specimen 17 does not have a large displacement outside the loading surface, and the upper part of the FRP sheet 13 is directly inserted into the steel splint 12 with sawtooth 8 Then use small bolts 11 for pre-tightening, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com