Intelligent shoemaking method based on three-dimensional data of soles

A three-dimensional data, intelligent technology, applied in footwear, foot or shoe last measuring device, clothing, etc., can solve the problems of people who cannot be disabled, people with deformed feet, etc., and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

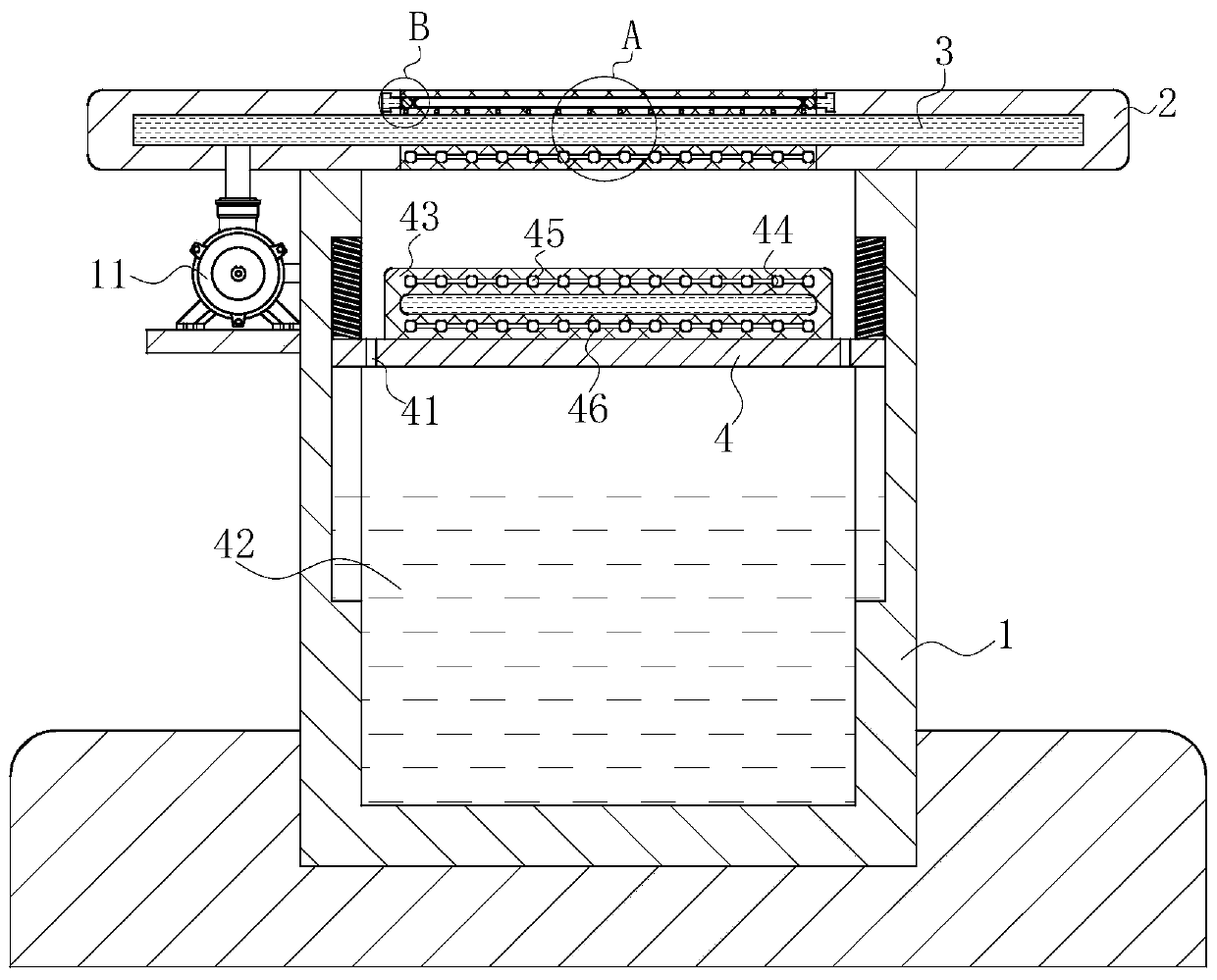

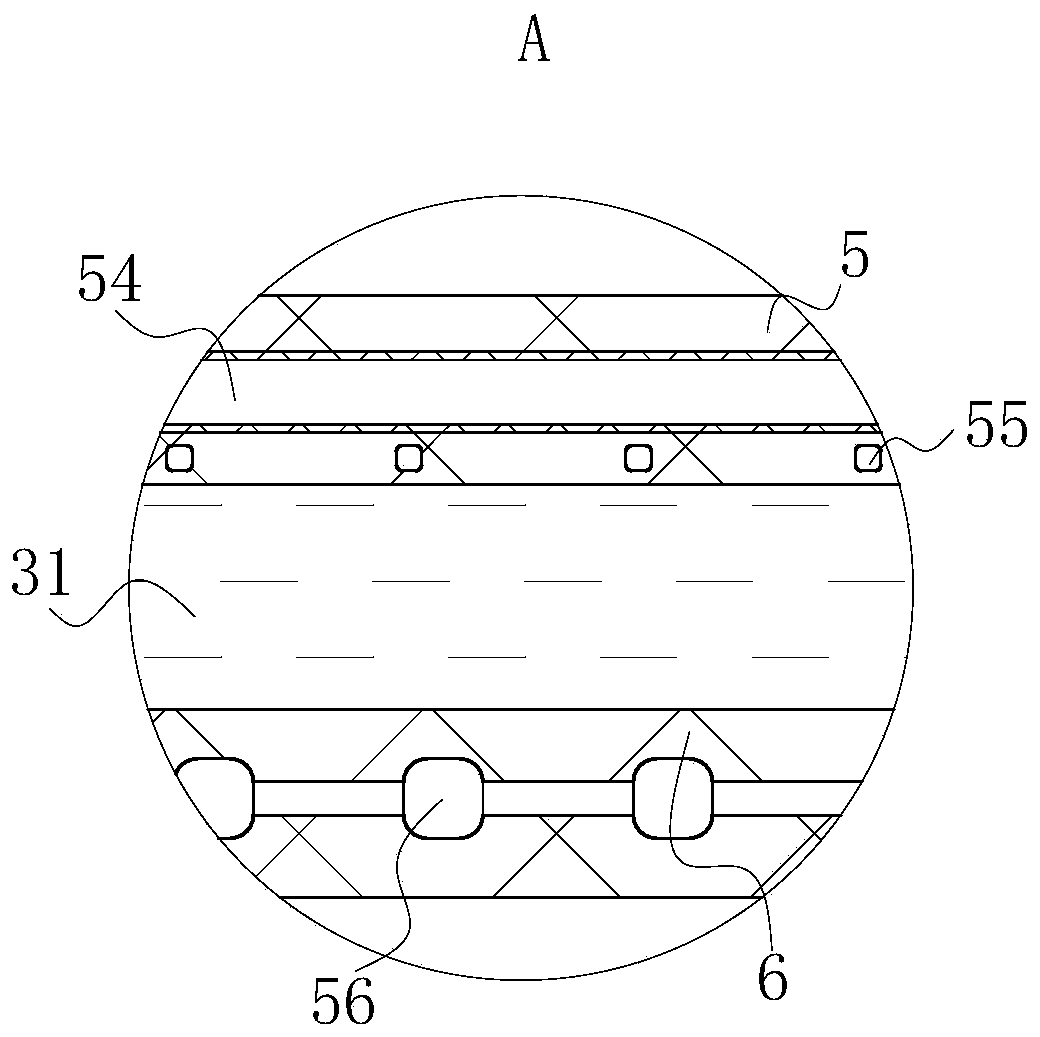

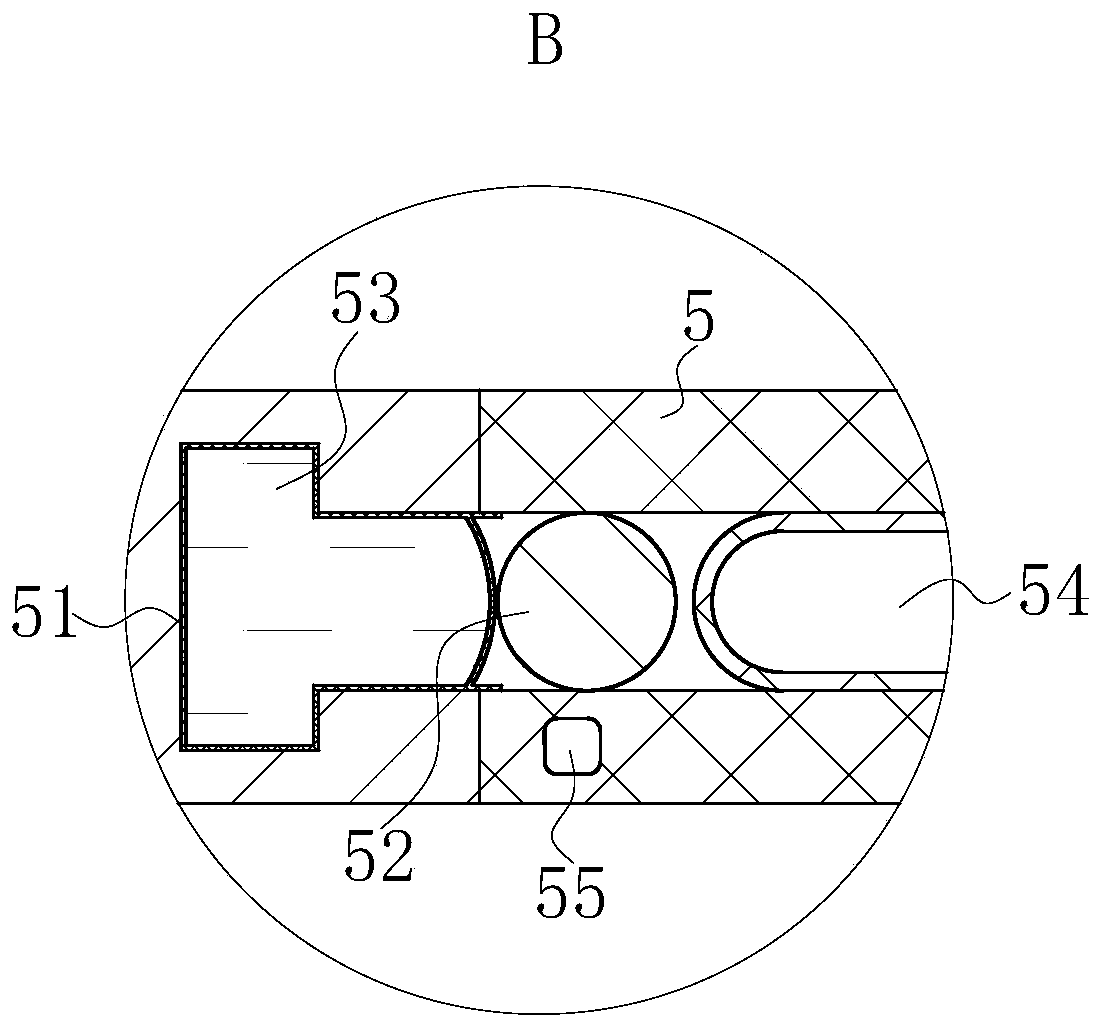

[0018] use Figure 1-Figure 3 An intelligent shoe-making method based on three-dimensional data of soles according to an embodiment of the present invention is described as follows.

[0019] Such as Figure 1-Figure 3As shown, the intelligent shoe-making method based on the three-dimensional data of the soles of the present invention includes a main frame body 1, a connecting plate 2, a cavity 3, a load-bearing plate 4, a rubber film 5 and a rubber film No. 2 Membrane 6; the connection plate 2 is fixedly installed on the upper end of the main frame body 1, and a No. 1 cavity 3 is provided in the connection plate 2; No. 1 rubber membrane 5 is arranged above the middle part of the No. 1 cavity 3, and the No. 1 cavity No. 2 rubber film 6 is provided below the middle part of 3, and liquid silicone rubber 31 is filled in the No. 1 cavity 3; the No. 1 rubber film 5 is installed in the upper wall of the connecting plate 2; the No. 2 rubber film 6 is fixed Installed in the lower wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com