Ultrasonic control earth pillar pressure chamber system

An ultrasonic and pressure chamber technology, applied in the field of colloid migration and deposition characteristics, can solve the problems of inability to measure and control the colloid migration and deposition characteristics, the inability to adjust the height of the soil column, and the application of ultrasonic load and confining pressure to the soil column, etc., to achieve Reduce residence time, prevent deposition, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

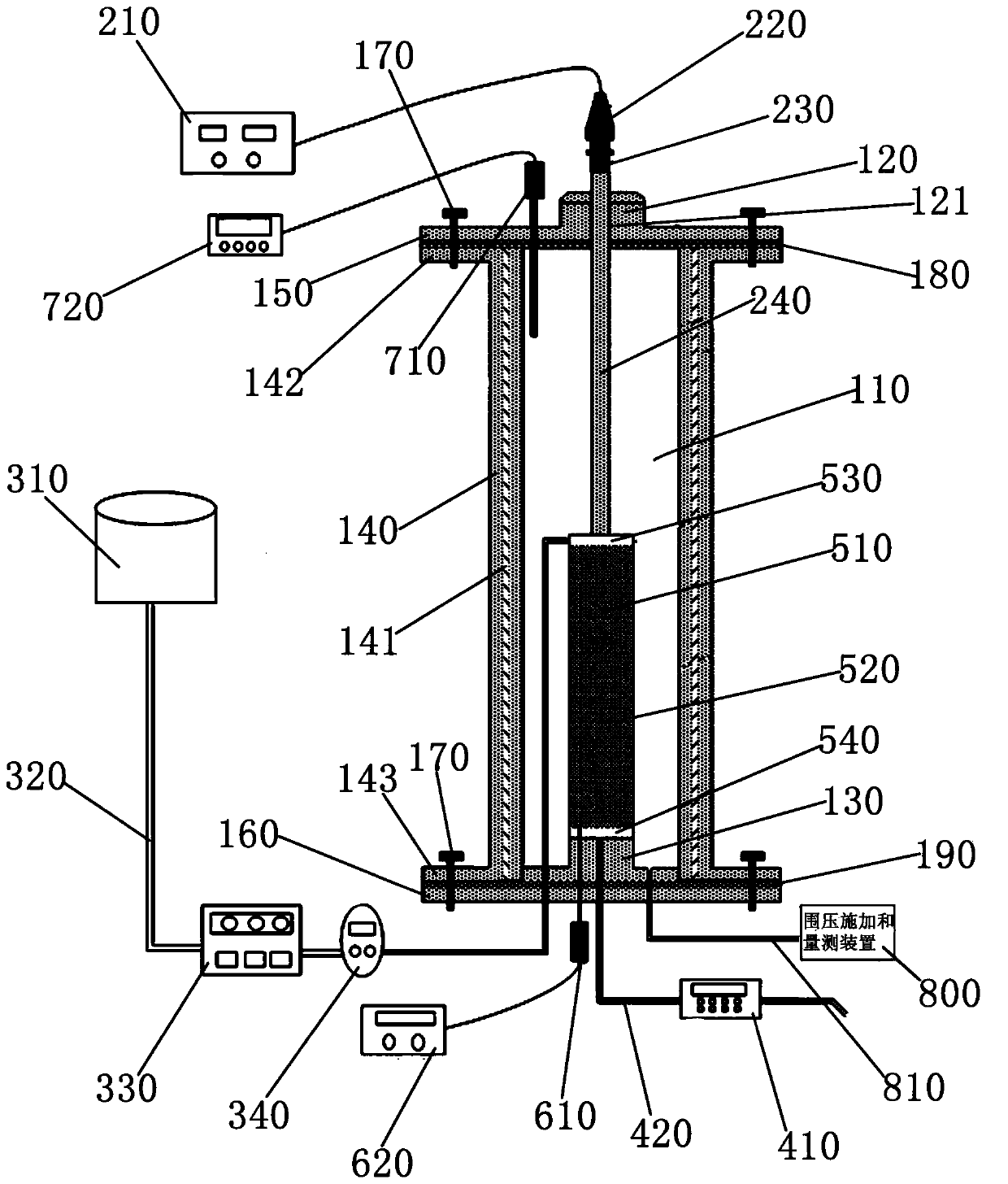

[0036] Please check figure 1 , a preferred embodiment of the ultrasonically controlled soil column pressure chamber system, the ultrasonically controlled soil column pressure chamber system includes a pressure chamber, a soil column, an ultrasonic device, a liquid supply device, a liquid outlet device, and a vibration measuring device , a temperature measuring device and a confining pressure applying and measuring device 800 .

[0037] A pressure chamber, which has a cavity 110 filled with water.

[0038] In this embodiment, the pressure chamber includes a cylindrical body 140, a top cover 150, and a bottom cover 160. The surrounding wall of the body 140 is a hollow double-layer structure, and a nano-based insulating soft felt 141 is provided. The hot soft felt 141 is attached to the peripheral wall of the body 140; the top of the body 140 is provided with an upper edge 142, the bottom of the body 140 is provided with a lower edge 143, and the top cover 150 is connected betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com