An anti-heating device for a diversion plate and a power transmission line with the device

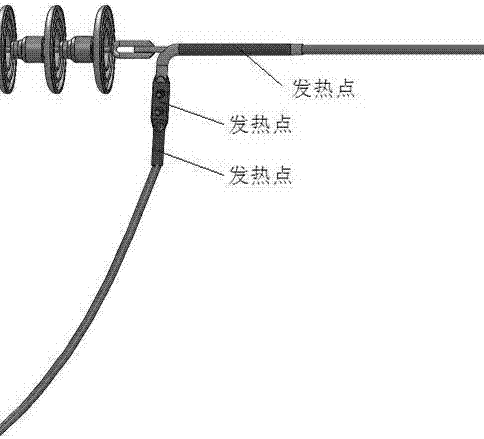

A technology for heating devices and transmission lines, which is applied to the spatial arrangement/configuration of cables, etc., which can solve the problems of increasing jumper connection point heating, increased contact resistance, and large contact resistance, so as to achieve accurate and reliable early warning indications and eliminate contact resistance. The effect of increasing and eliminating the hidden danger of fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

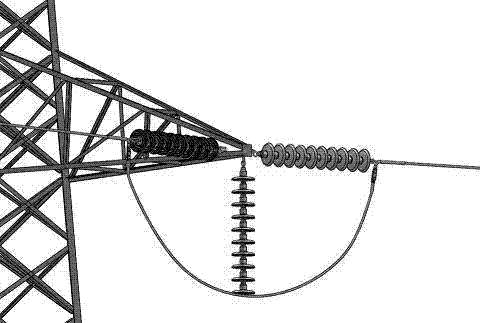

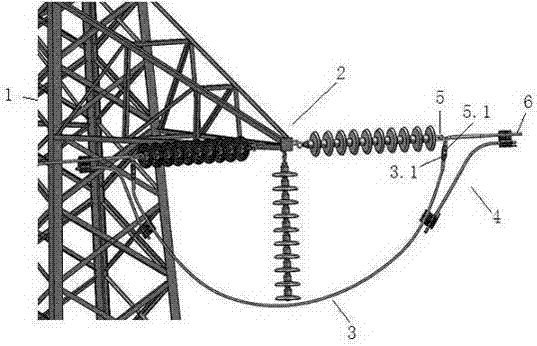

[0031] like image 3 As shown, the power transmission line with detachable diversion plate anti-heating device of the present invention includes pole tower 1, "T" shaped insulator string 2, jumper wire 3, diversion plate anti-heating device 4, strain clamp 5 and main conductor 6. Jumper wire 3 straddles the horizontal sides of the "T" shaped insulator string to image 3 Take the jumper connection structure on the right side of the horizontal as an example, the drain terminal board 5.1 at one end of the strain clamp 5 and the jumper clamp 3.1 of the jumper 3 are crimped and fixed, such as by bolt crimping; the other end of the strain clamp It is crimped and fixed with the main wire 6; the anti-heating device 4 of the drain plate is arranged on one side of the strain clamp 5, and the two ends are respectively connected and fixed with the jumper wire 3 and the main wire 6.

[0032] like Figure 4 As shown, the anti-heating device 4 of the drainage plate is composed of a bypass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com