Waste heat recovery device for high-temperature aluminum oxide roasting furnace

A high-temperature alumina and waste heat recovery technology, applied in furnace control devices, waste heat treatment, furnaces, etc., can solve the problems of deteriorating the operating environment of the staff, waste of energy in the shell of the roasting furnace, etc., and achieves the removal of high-temperature danger sources and improvement of the working environment. , the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be noted that, in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other, and the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

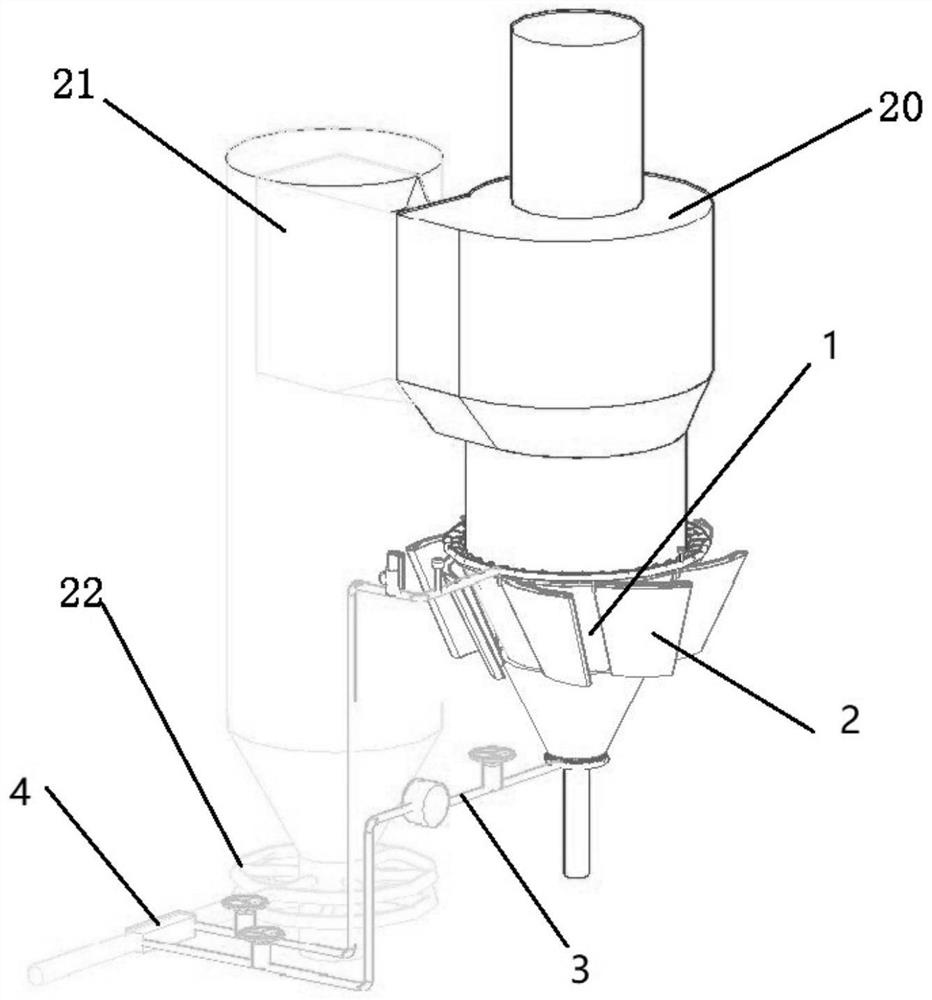

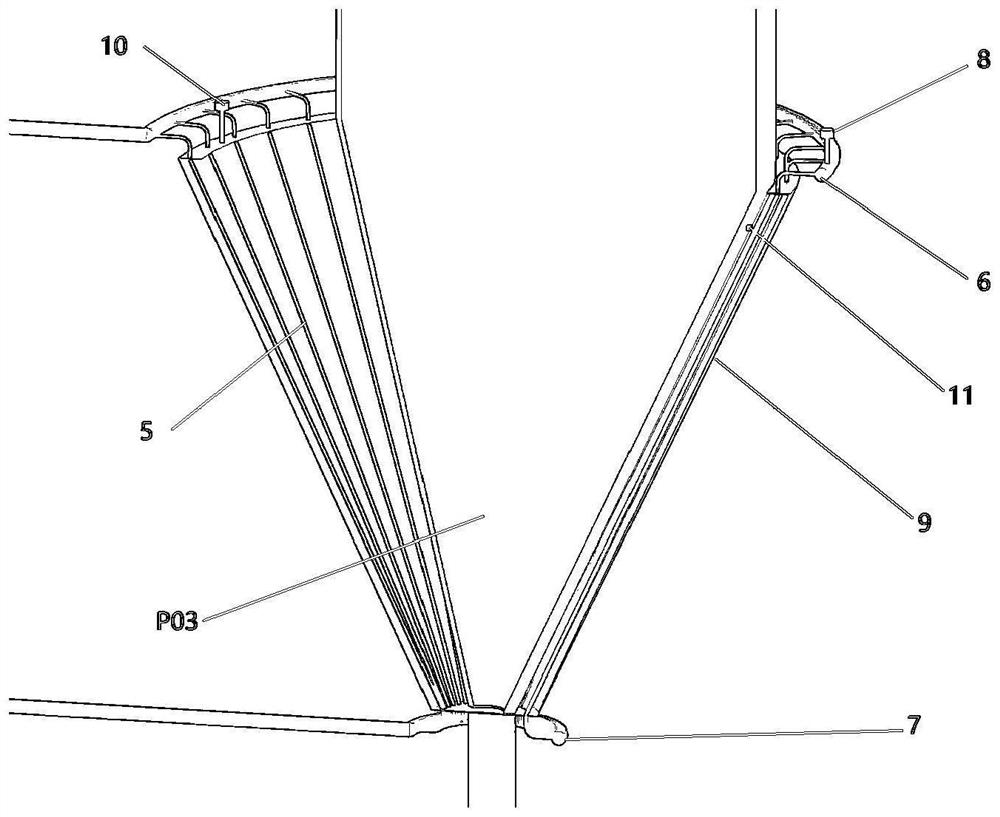

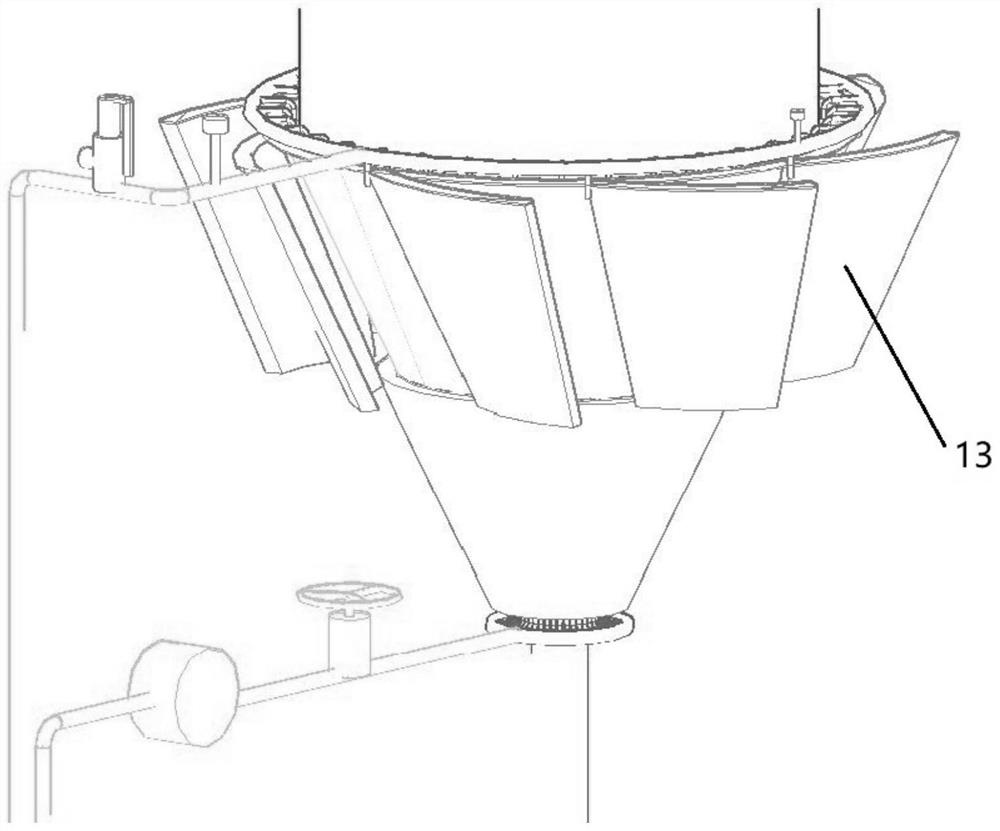

[0027] see Figure 1-5 To illustrate this embodiment, the shell heat conduction device 1 is arranged outside the position of the lower cone of the first roasting furnace 20, and the two ends of the circulation pipeline system 3 are respectively fixedly connected and communicated with the shell heat conduction device 1 and the heat user 4. The outside of the shell heat conduction device 1 is provided with an insulating layer, and the first roasting furnace 20 can no longer dissipate heat outwards in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com