Power distribution unit and movable type elastic busbar for the same

A power distribution device, mobile technology, applied in the direction of coupling devices, circuits, electrical components, etc., can solve the problems of adding terminal blocks, circuit virtual connections, inconvenient system adjustments in the later stage, etc., to ensure contact pressure, ensure stability, Ease of replacement and system maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

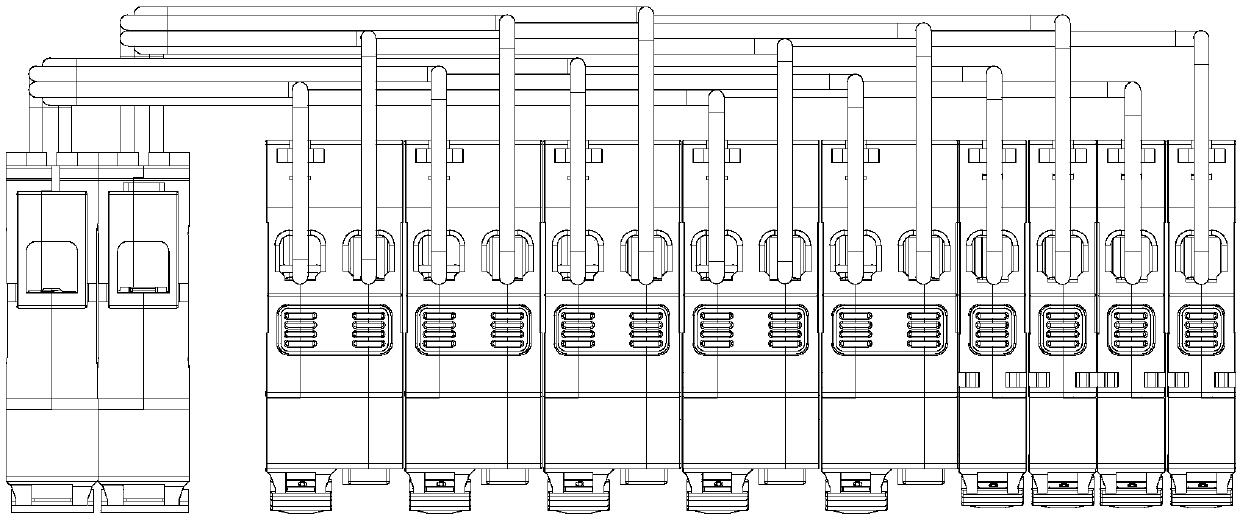

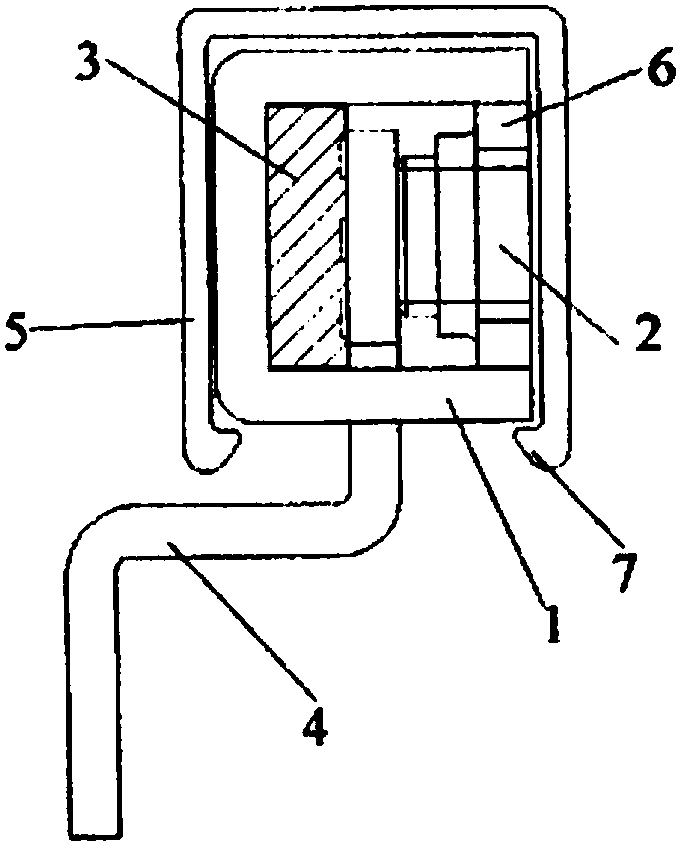

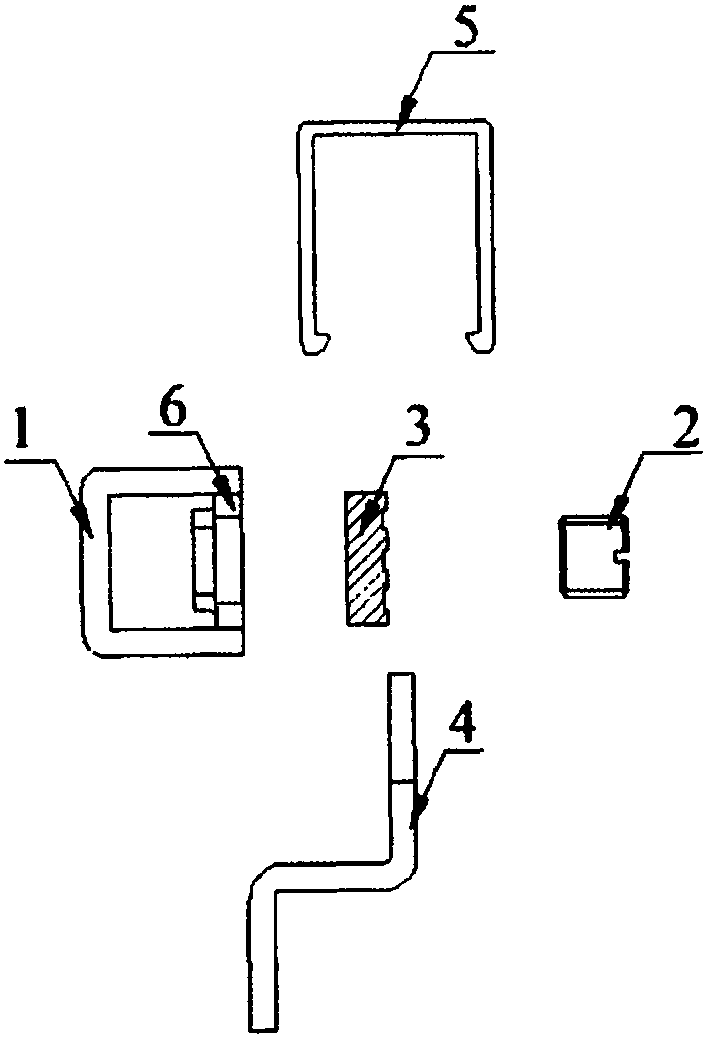

[0101] Such as Figure 4 to Figure 31 As shown, the present invention provides a mobile elastic busbar for power distribution devices, which includes: a main conductor 200, one end of which is connected to the main switch 500 of the power distribution device; at least two sub-conductors 300, the sub-conductors One end of the sub-conductor 300 is connected to the sub-switch 600 of the power distribution device, and the other end of the sub-conductor 300 can be fixed on the main conductor 200 with a predetermined clamping force. The junction of the conductor 300 and the general conductor 200 is collinear.

[0102] Specifically, the main conductor 200 is used to flow out from the main switch 500 or sink current into the main switch 500, and the sub-conductors 300 are used to flow in or flow out current to each sub-switch 600, and the length and shape of the sub-conductors 300 are Conductors of different shapes and lengths are made according to the number of poles of the sub-swit...

example

[0121] (1) When the sub-conductor 300 is made of non-elastic material, the conductive part is provided with a metal elastic part, and the elastic part is covered with an insulating cover 320, the material of each part and the coating on the main conductor 200 and the sub-conductor 300 can be as follows Setting (823 refers to DJB-823 solid film protective agent, 6μ refers to the thickness), wherein, the elastic part is blackened, and the insulating cover 320 is not treated:

[0122]

[0123]

[0124] For example, the rated current of each sub-switch 600 is 16A~25A, the conductivity of carbon spring steel or carbon steel after copper plating is greatly enhanced, and there are two points of contact, the contact resistance is very good, and it has anti-corrosion after coating 823. Wear resistance, the service life can reach 20 years. When the material is copper, its electrical conductivity is better, and it has anti-wear performance after tin or 823 is coated. When the materi...

Embodiment approach 2

[0135] Such as Figure 5 , Figure 8 and Figure 11 As shown, the present invention also provides a power distribution device, which includes a housing 100, a main switch 500, at least two sub-switches 600, and a mobile elastic busbar for power distribution devices as described above, the main switch 500 and at least two The two sub-switches 600 are fixed in the housing 100, specifically on the rear wall of the housing 100, and the movable elastic busbar is connected between the main switch 500 and the sub-switch 600. The structure, working principle and beneficial effect of the mobile elastic busbar for the power distribution device are the same as those of the first embodiment, and will not be repeated here, wherein, each sub-conductor 300 is vertically connected through an adjustable conductive part With respect to the main conductor 200 , the vertical includes being perpendicular to a plane parallel to the rear wall of the housing 100 or perpendicular to a plane perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com