Mechanical switching contact

A contact point, mechanical technology, applied in the direction of electrical components, electrical switches, circuits, etc., to achieve the effect of reducing contact bounce and high contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

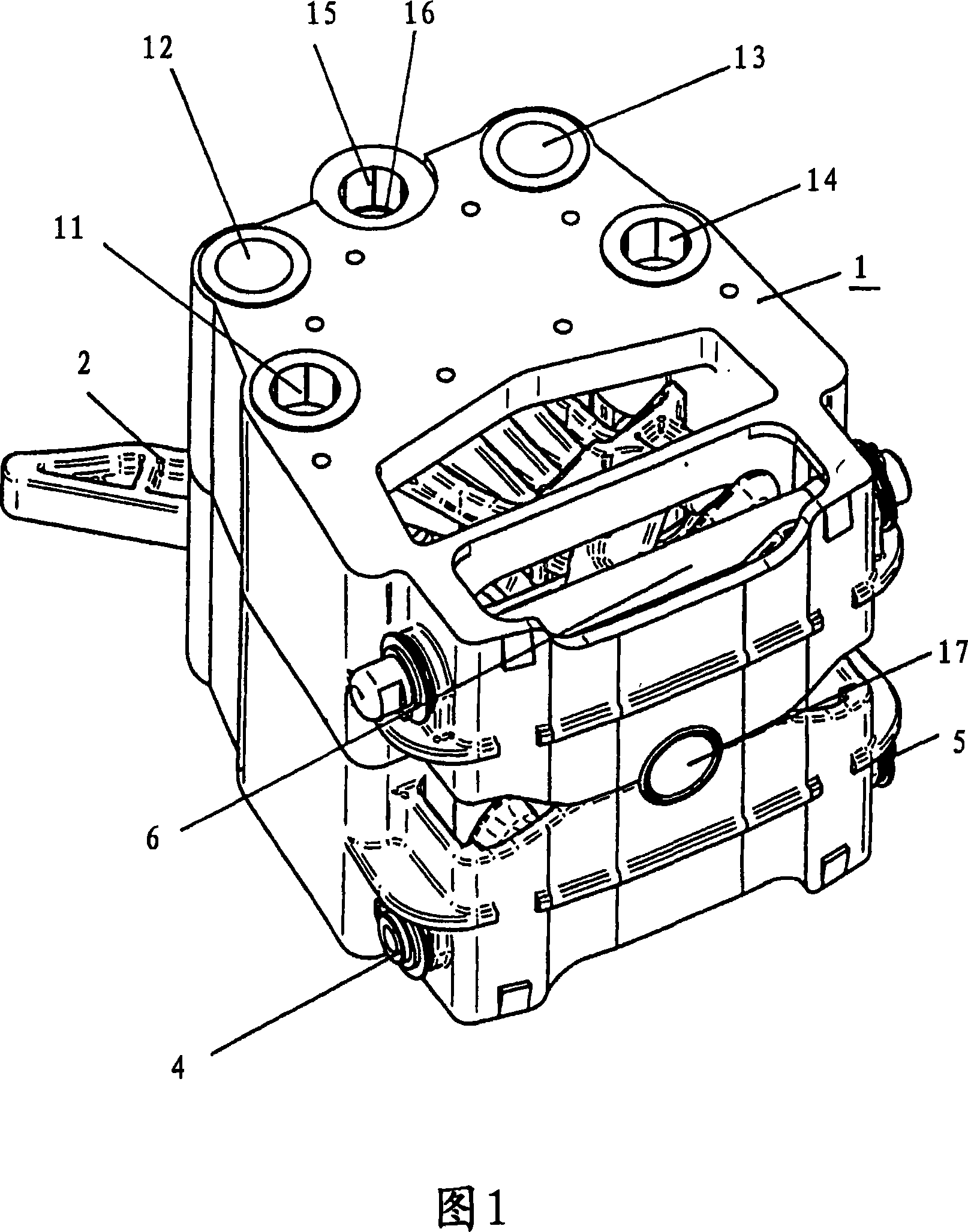

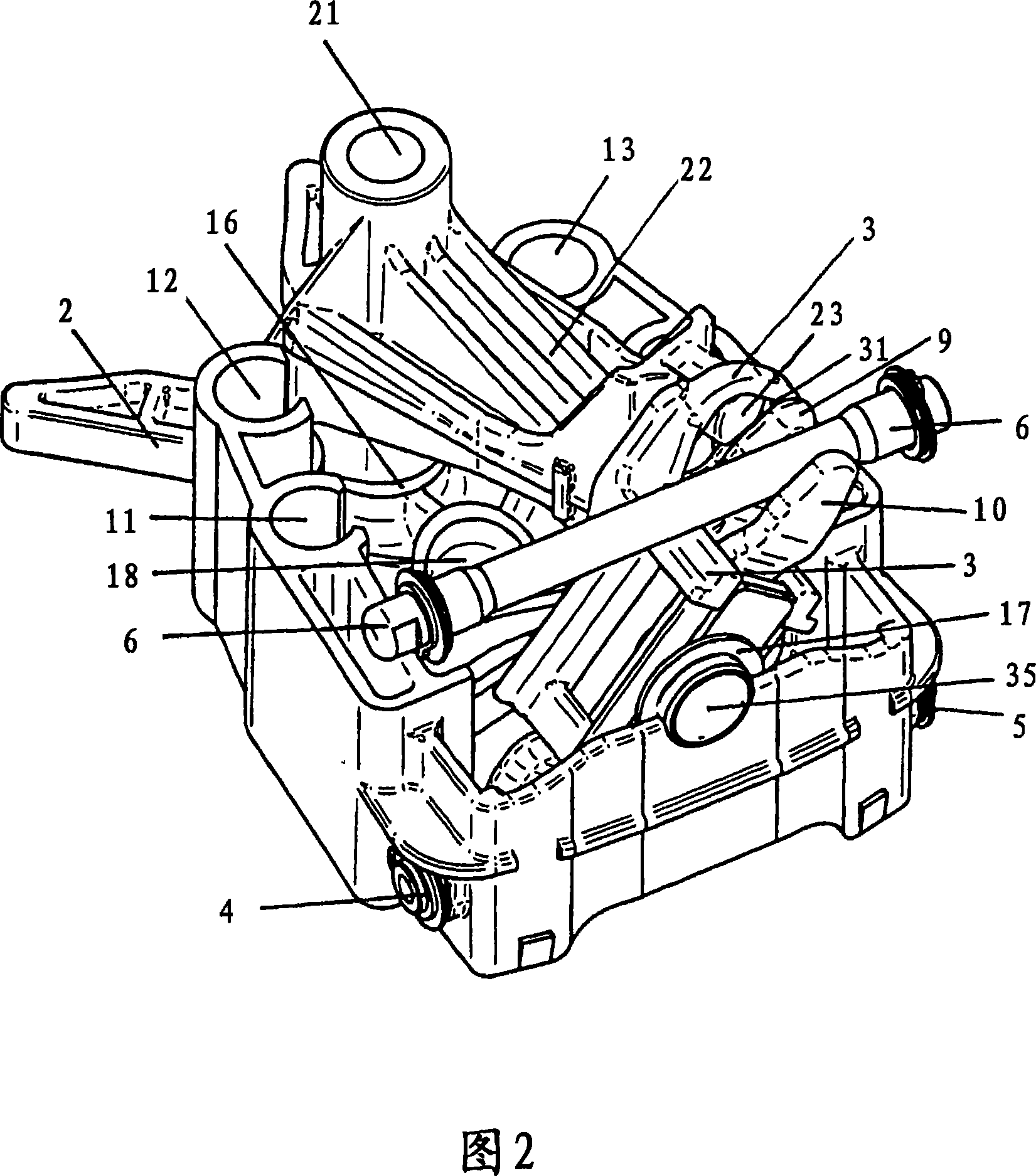

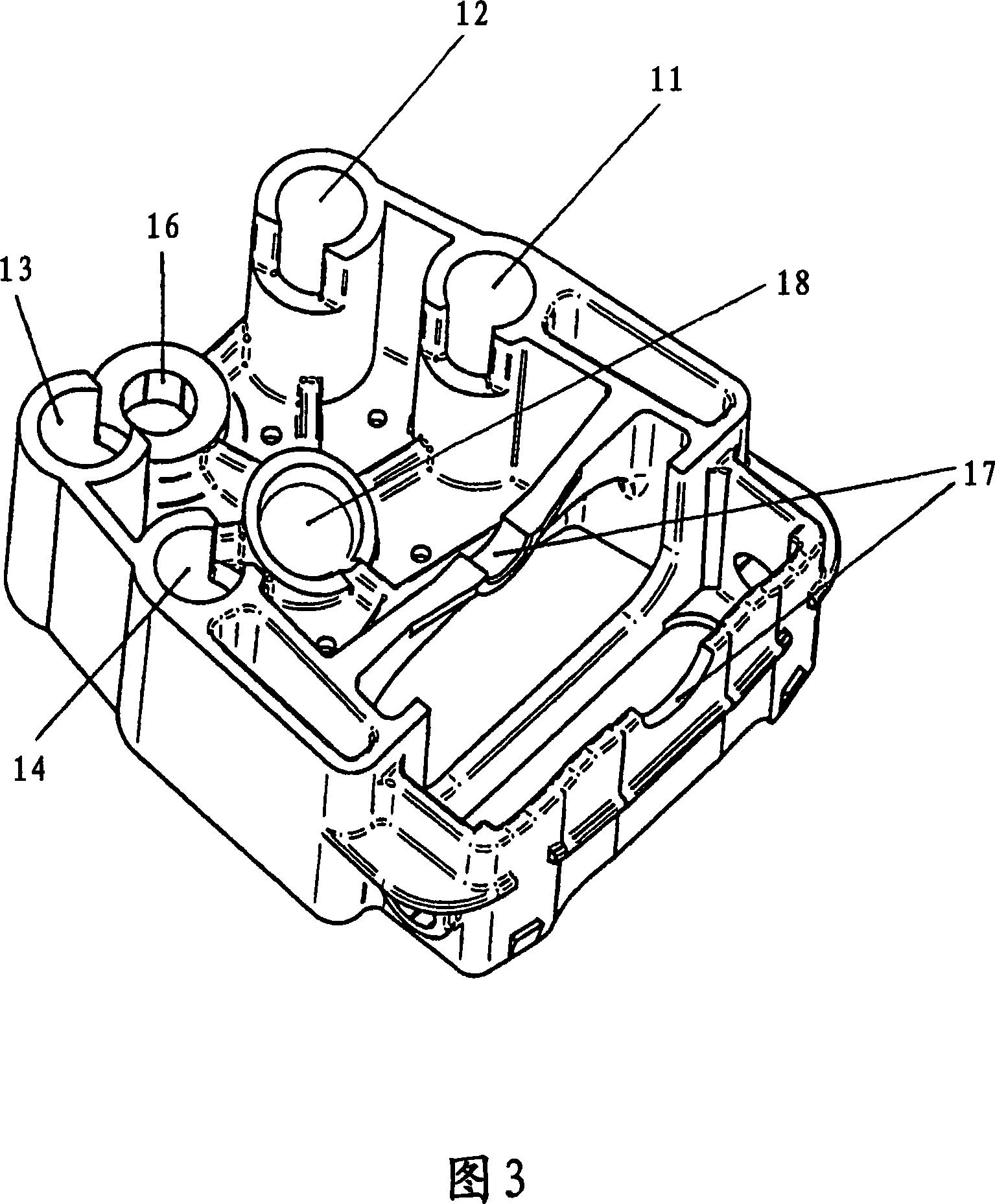

[0016] First, the mechanical switching contact according to the invention shown in FIGS. 1 and 2 will be explained in detail. It has a two-part insulating material carrier 1 which accommodates the other components explained below and encloses the entire arrangement. In FIG. 2 the upper part of the insulating material carrier 1 is omitted in order to better illustrate the internal components. The insulating material support 1 is provided with longitudinal holes 11 to 14 extending in each profiled rod, which will be explained in more detail below. In the region of the other longitudinal bore 15 is arranged a bearing 16 in which the actuating rod 2 is mounted rotatably by means of a bearing cap screw (not shown). A further bearing 17 is arranged laterally, which accommodates a contact housing 3 which will be explained in more detail below. Finally, a spherical segment-shaped receptacle 18 is also provided on the insulating material carrier 1 , in which the compression spring 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com