Probe assembly of control rod guiding cylinder cotter pin of nuclear power station

A technology of control rods and guide cylinders, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. Achieve the effect of repeatability and self-adaptive positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

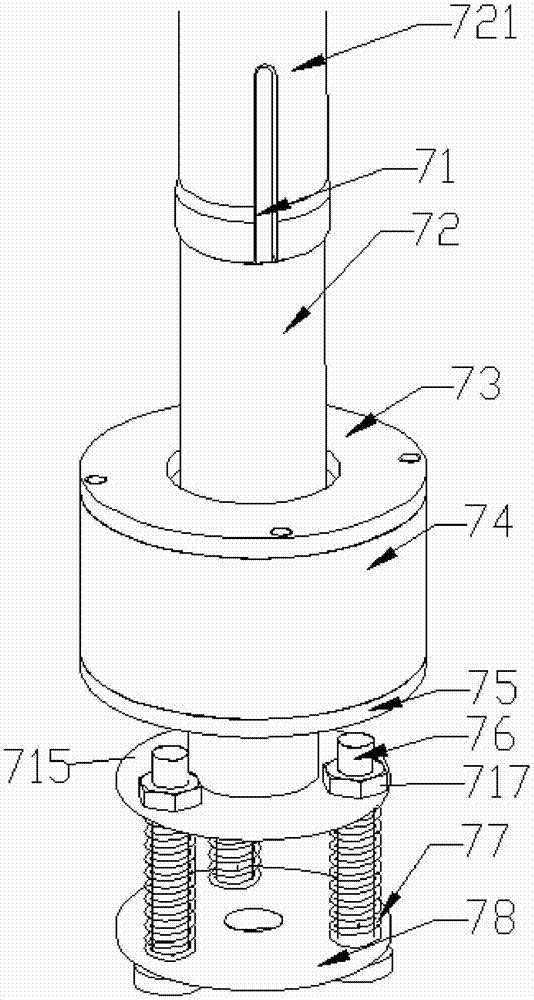

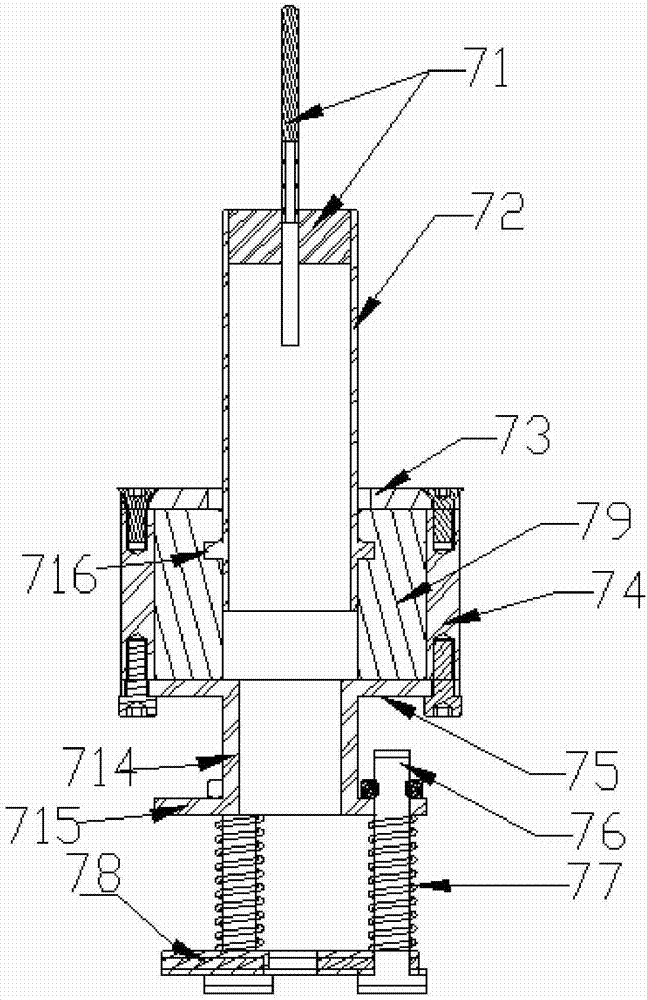

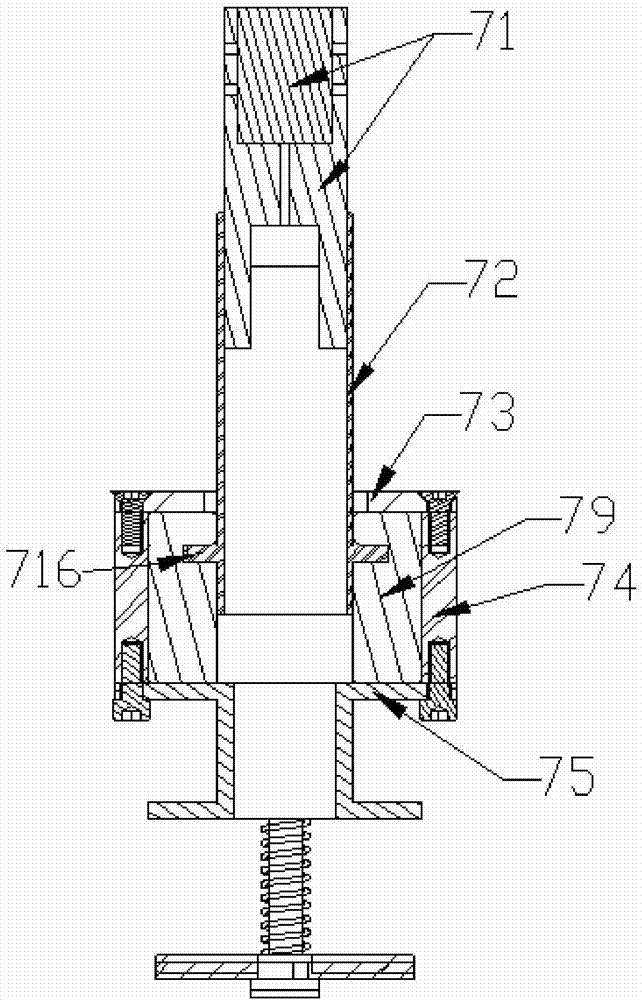

[0017] Such as figure 1 , 2 , 3, the nuclear power plant control rod guide cylinder cotter pin probe assembly includes a probe wafer 71, a wafer holder 72 for fixing the probe wafer 71, a base plate 78, and is connected between the base plate 78 and the wafer holder 72. Between the first buffer assembly and the second buffer assembly disposed between the first buffer assembly and the wafer holder 72 .

[0018] The second buffer assembly includes a middle plate 75 connected to the first buffer assembly, a cylinder 74 sleeved on the middle plate 75, an elastic rubber ring 79 fixed inside the cylinder 74 and a seal. The cover plate 73 that is covered on the cylinder body 74 and sleeved on the wafer holder 72, the wafer holder 72 is fixedly inserted in the elastic rubber ring 79 and exists between the middle plate 75 Gap, the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com