Roller cone bit and method for installing roller cone bearing sealing system of roller cone bit

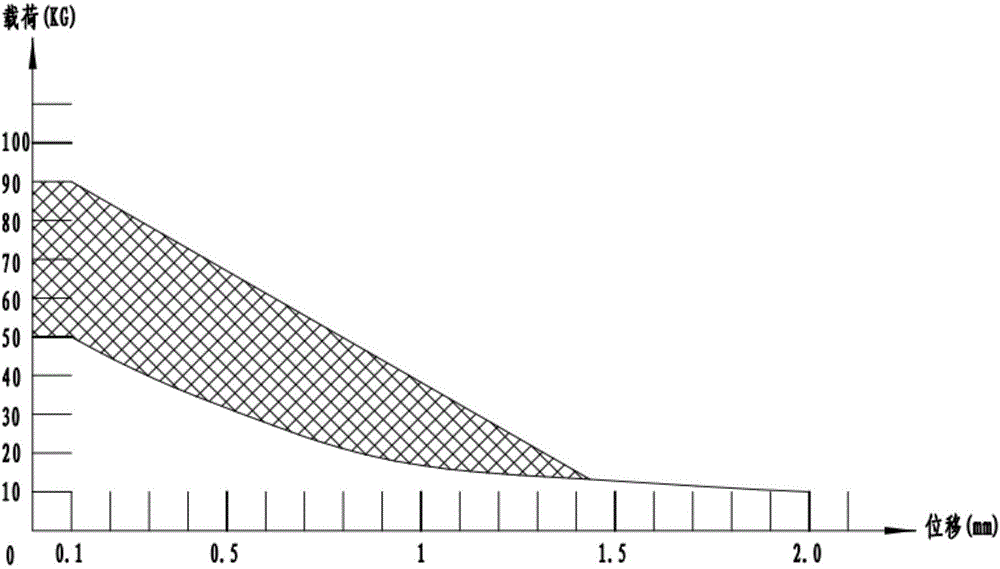

A roller cone bit and bearing sealing technology, which is applied in construction and other directions, can solve the problem of inability to accurately control the contact specific pressure of the sealing system, and achieve the effects of large contact specific pressure, smooth rigidity curve, and large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

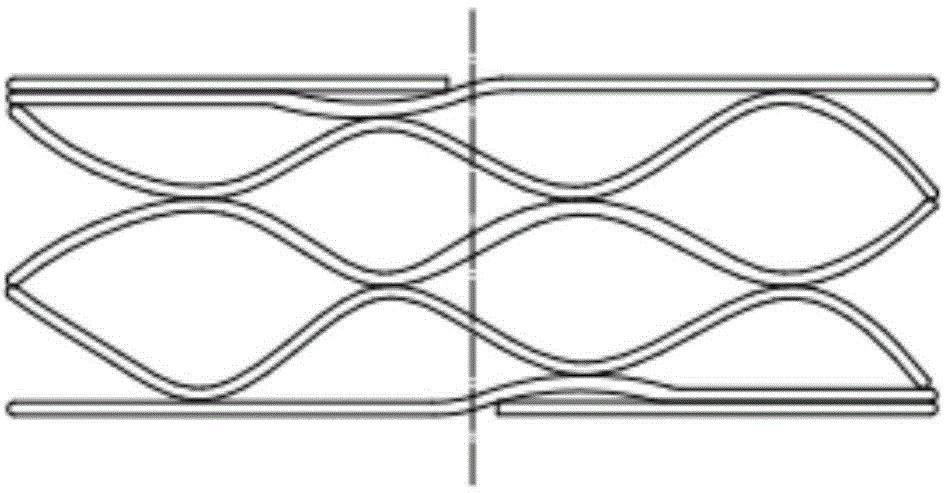

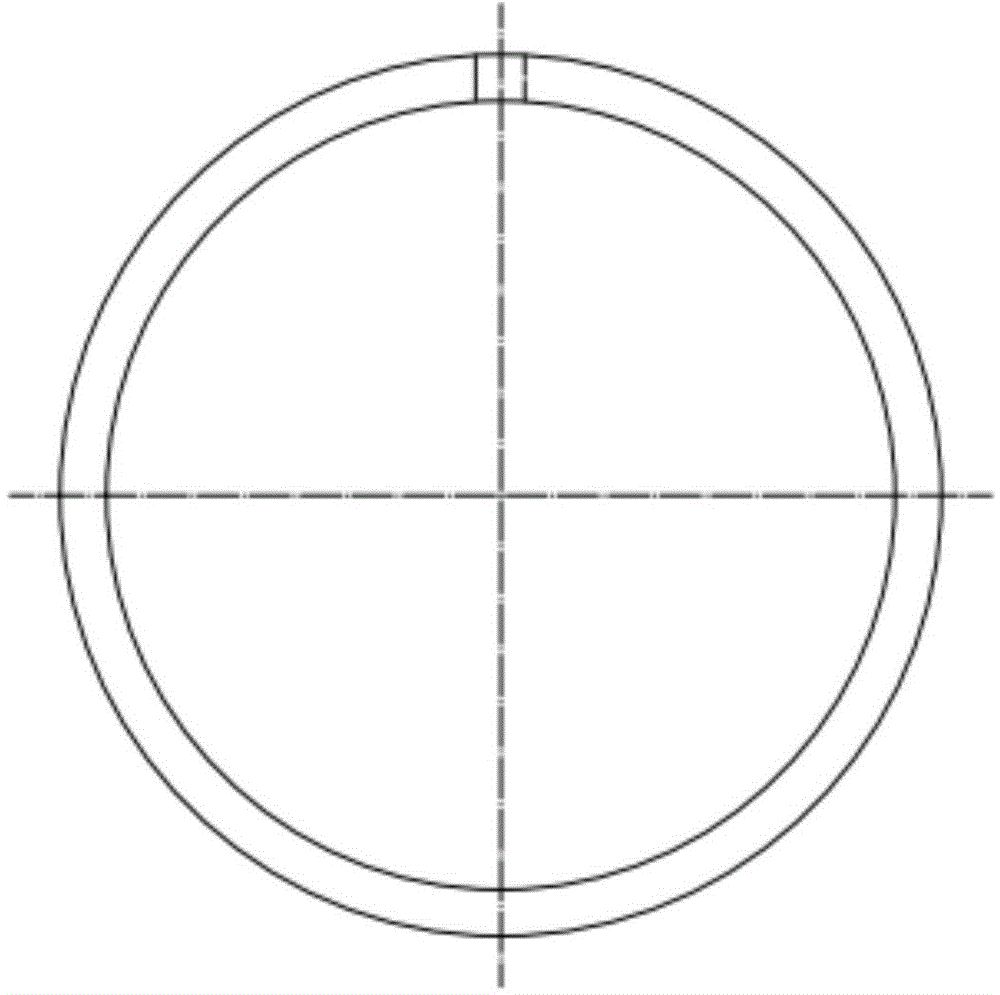

[0031] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 7 with Figure 8 Shown, a kind of roller cone bit, comprise cone, tooth palm 2 and be used for the positioning steel ball 9 that described cone and tooth palm are fixed, the root of described cone is provided with cone bearing hole 1, described A bearing sealing system is arranged in the cone bearing hole, and the bearing sealing system is composed of a cone metal seal ring 3, a tooth palm metal seal ring 4, a cone metal rubber seal ring 6, and a wave spring 7 for energy supply of the cone metal ring The metal sealing ring of the gear cone and the metal sealing ring of the tooth palm are in contact to form an end face sealing structure. There is a groove in the middle of the metal sealing ring of the gear cone, and the wave spring for the metal gear cone is placed in the groove In the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com