Rut test system for asphalt mixture in hydrodynamic pressure environment and test method

A technology of asphalt mixture and hydrodynamic pressure, which is applied in the application of stable tension/pressure to test the strength of materials, analyze materials, and use repetitive force/pulse force to test the strength of materials, etc. It can solve the limited actual effect of hydrodynamic pressure, etc. problems, to achieve the effects of rich test evaluation indicators, reasonable and reliable test results, and convenient and fast test operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The invention provides a rutting test system and a test method in an asphalt mixture hydrodynamic pressure environment.

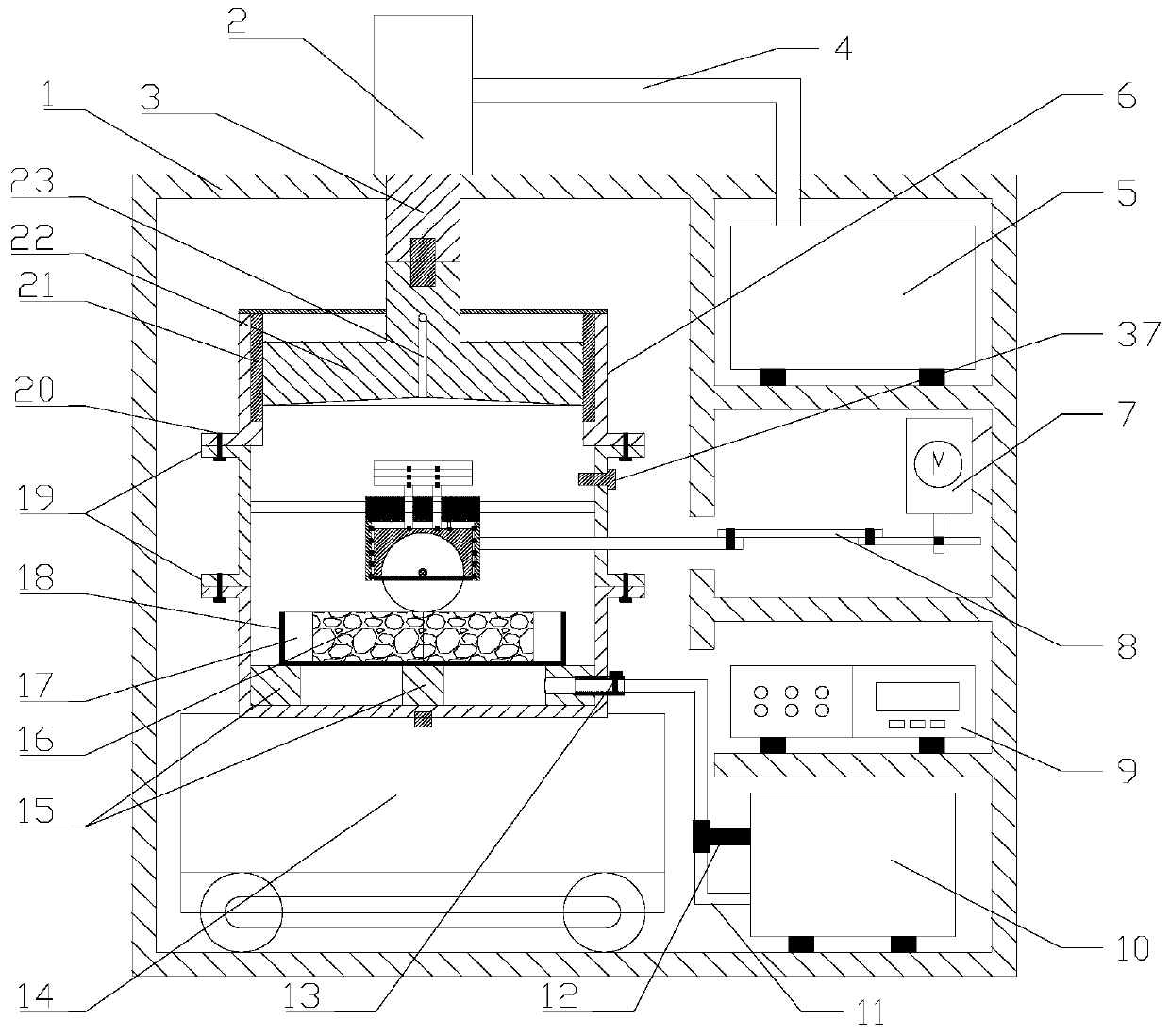

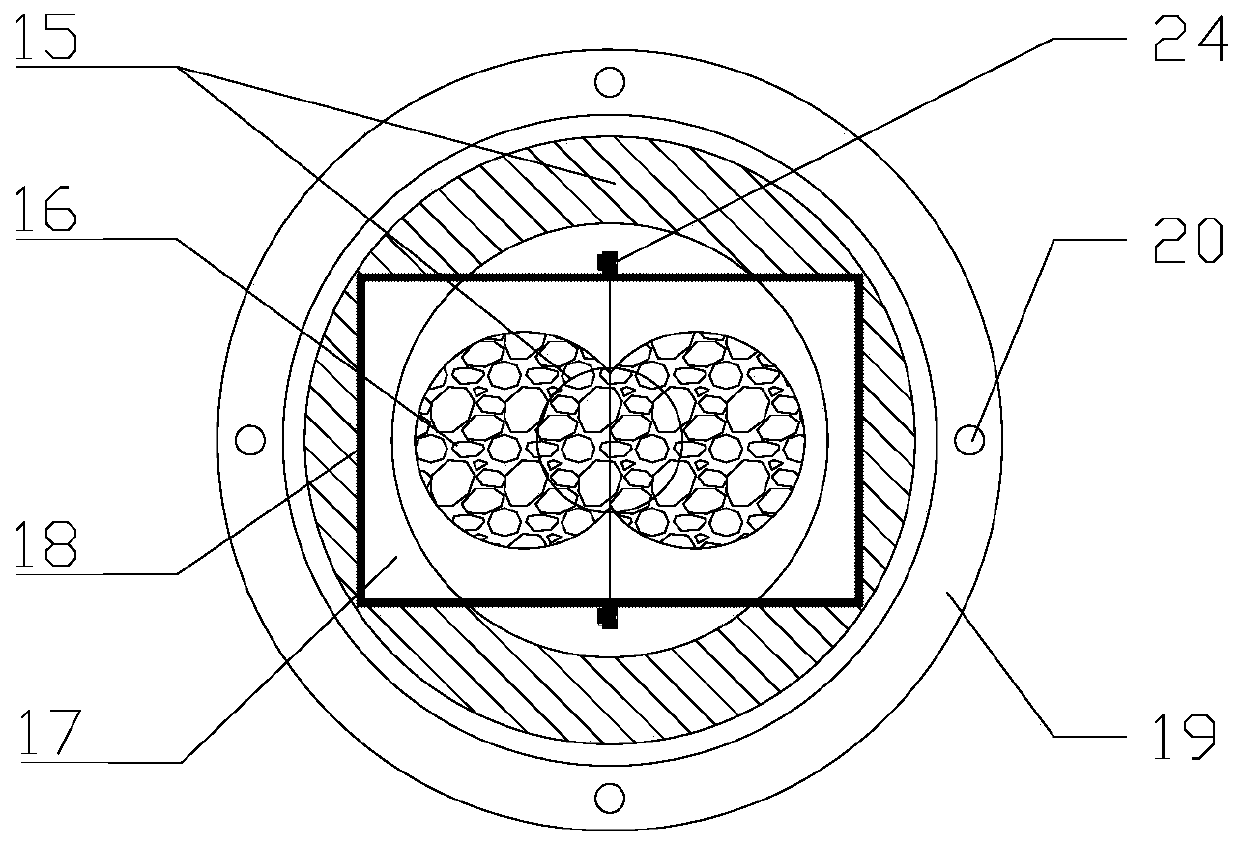

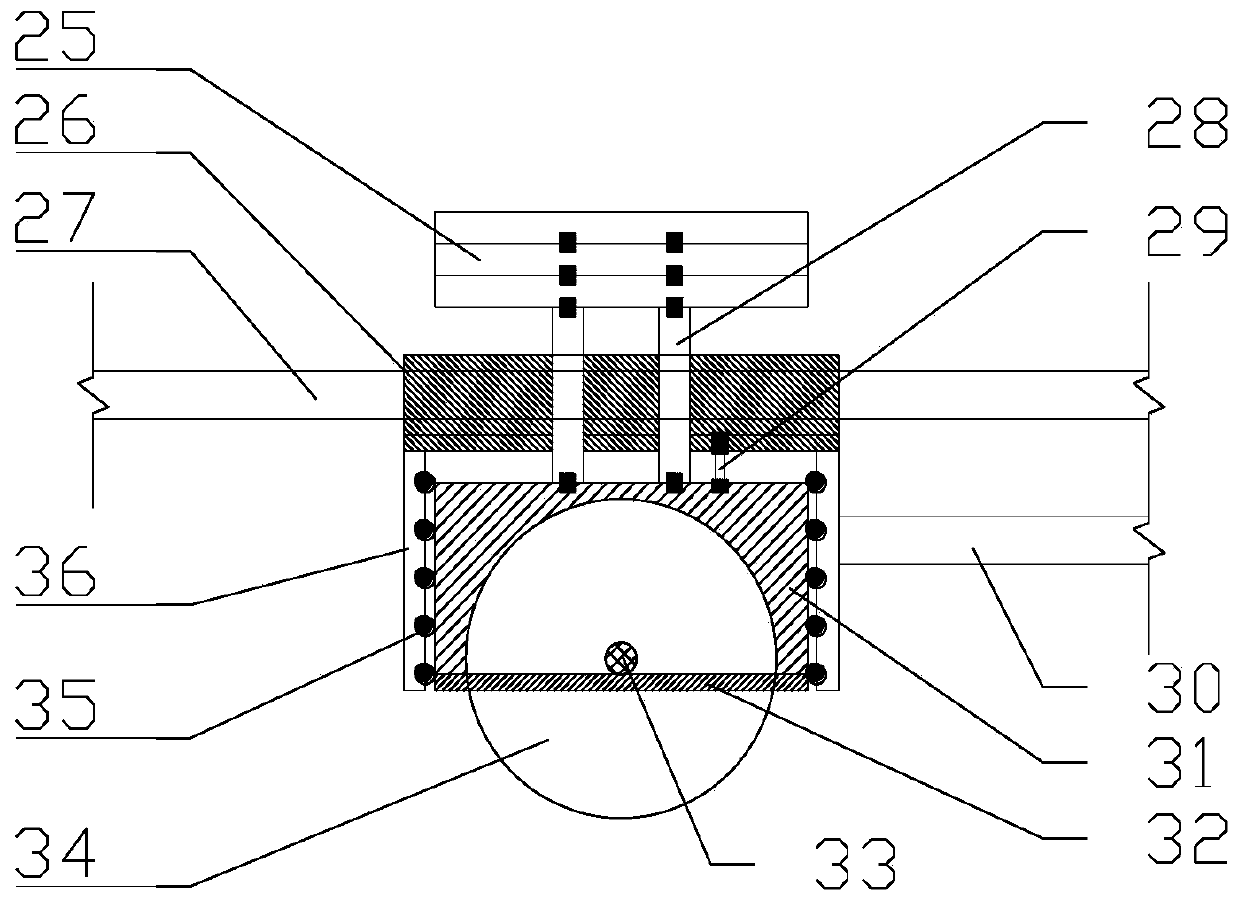

[0032] like figure 1 As shown, the test system includes four parts: hydrodynamic pressure generating device, wheel system loading device, asphalt mixture specimen fixing device and temperature-controlled water bath device, in which the hydrodynamic pressure generating device, wheel system loading device, asphalt mixture specimen The fixing device and the temperature-controlling water bath device are connected and fixed to the system frame 1 in order from top to bottom, and the dynamic water pressure generating device, the wheel system loading device and the asphalt mixture specimen fixing device are connected to each other thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com