Use method of automatic peeling machine

A kind of peeling machine, automatic technology, applied in application, peeling of vegetables or fruits, food science, etc., can solve the problems of waste polluting the environment, unsafe production operation, unable to achieve peeling, etc., to reduce cutting force , peeling thickness is stable, and the effect of improving the yield of pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

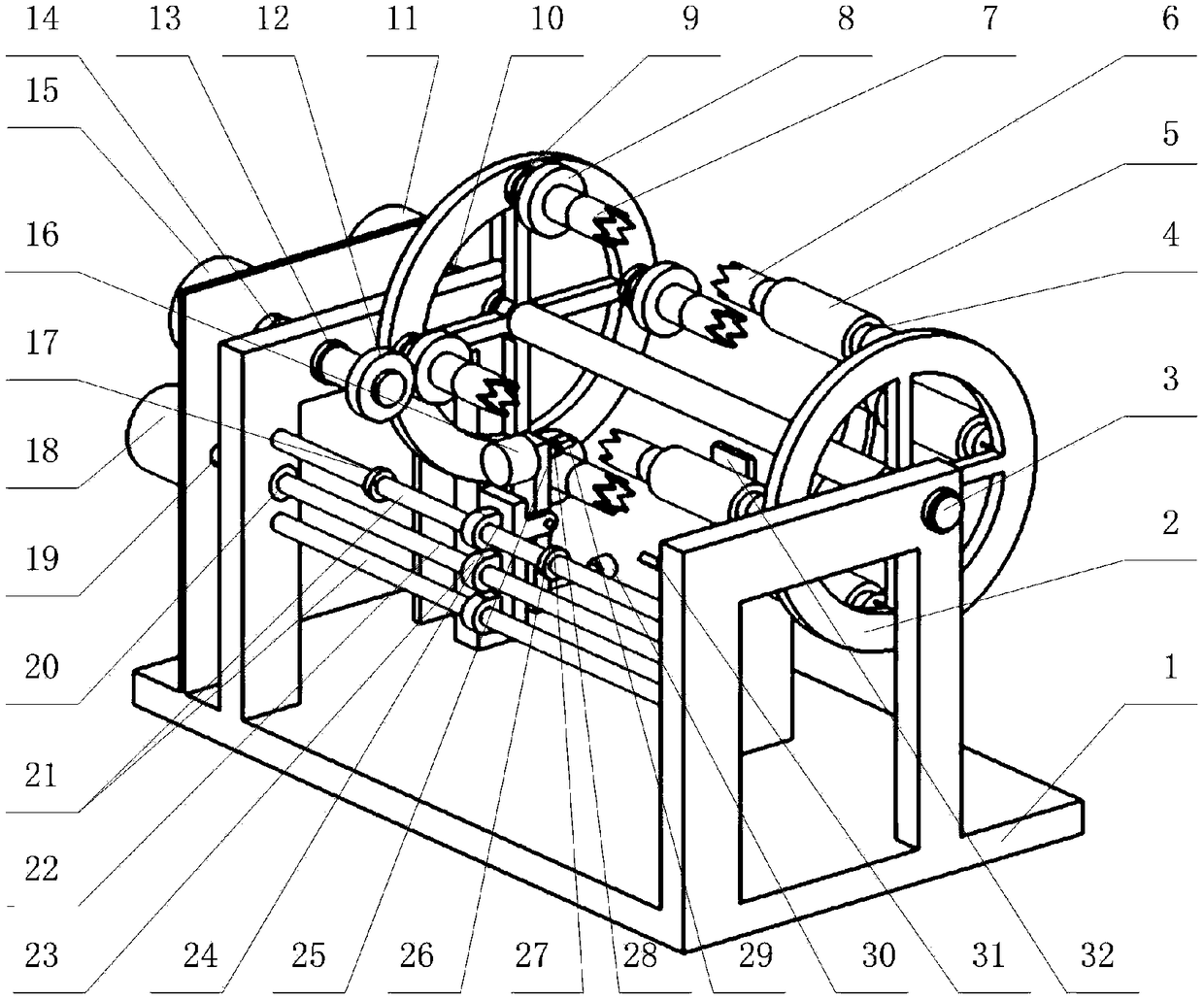

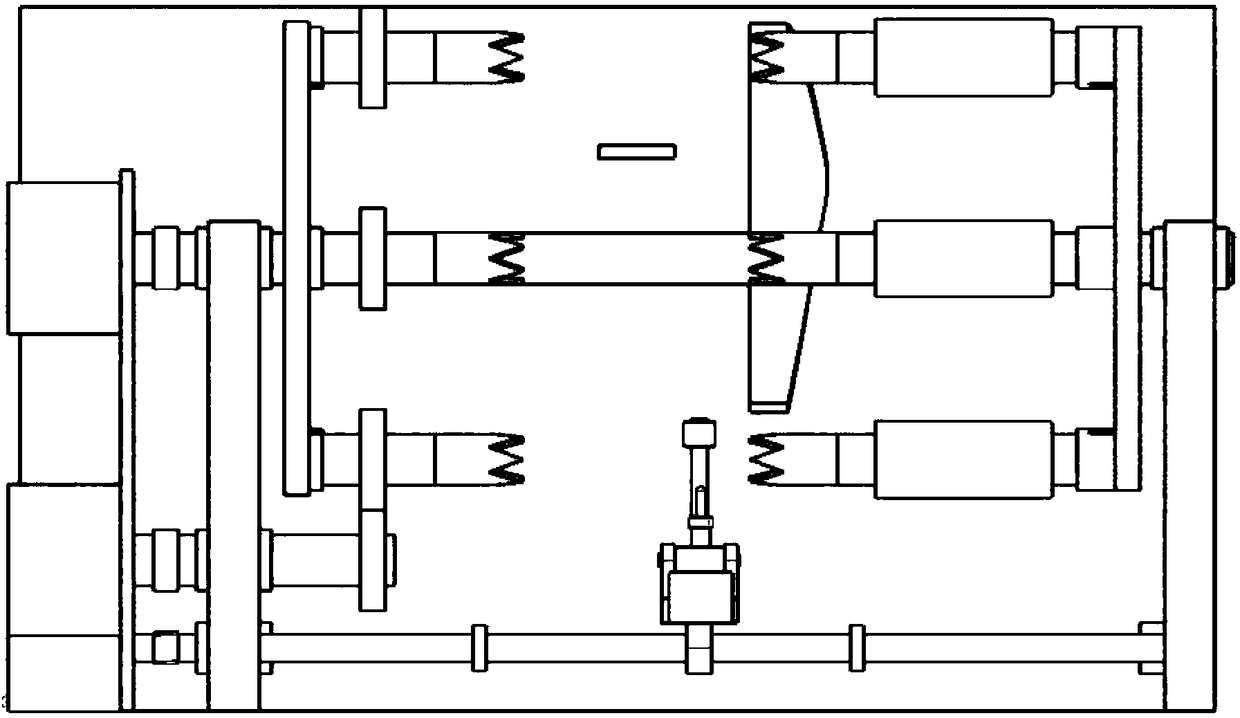

[0040] refer to Figure 1-Figure 3 , the present embodiment is an automatic peeling machine, which includes a bed, a loading and unloading device, a main rotary device, a feed mechanism, and a cutter device; the loading and unloading device, the main rotary device, the feed device, and the cutter device are installed on the bed.

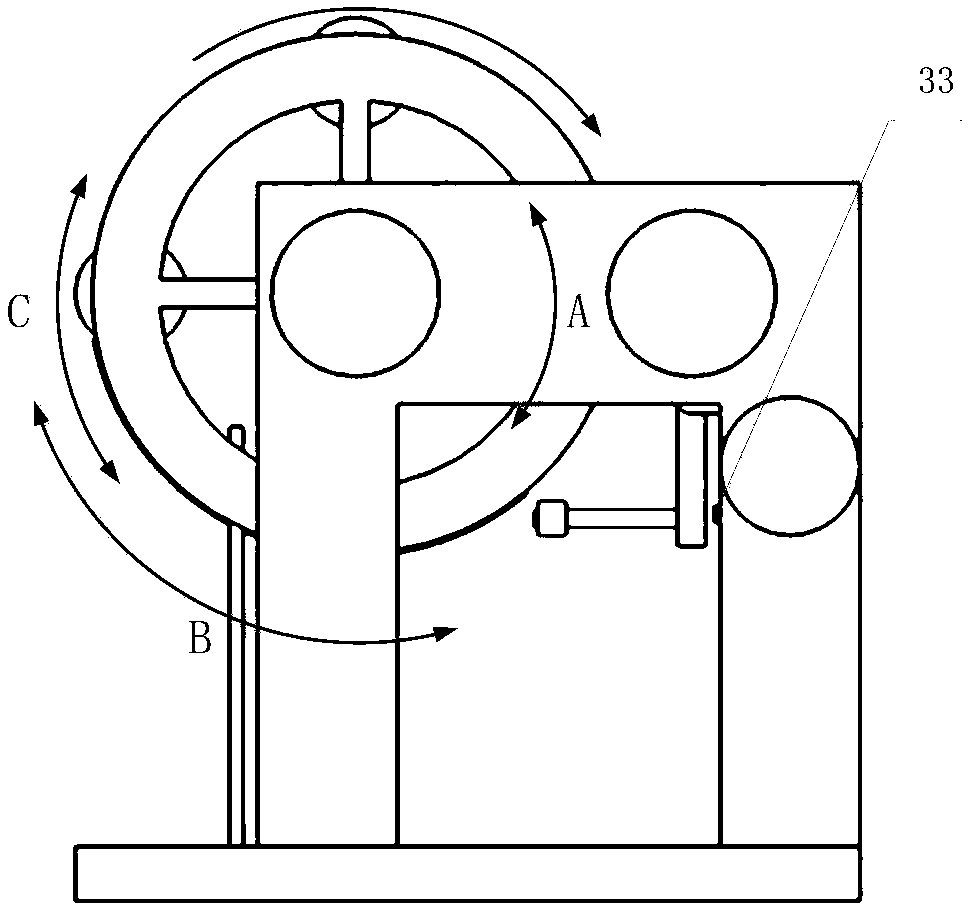

[0041] The automatic peeling machine is divided into functional areas, including feeding area C, unloading area B, and peeling area A. The feeding area C is used to complete material clamping, the peeling area B is used for peeling, and the unloading area A is used to realize the material collection after peeling. Driven by the loading and unloading device, the materials pass through the feeding area C, the unloading area B, and the peeling area A in sequence.

[0042] The loading and unloading device includes a motor a11, a loading and unloading bracket 2, a clamping mechanism, a slide plate 31 for removing the clamping force, and a blanking baffl...

Embodiment 2

[0050] refer to Figure 1-Figure 3 , the present embodiment provides a method of using an automatic peeling machine for peeling the material golden jujube persimmon, including the following steps:

[0051] 1. Select the plum blossom top model, adjust the position, and set parameters: according to the average size of the golden jujube persimmon, choose a plum blossom top with a suitable diameter, adjust the axial elastic expansion and rotation of the plum blossom top, the blanking baffle, the limit switch, and the limit screw Set the position of the motor of the main rotary mechanism, the motor of the feeding mechanism, and the motor of the tool device.

[0052] 2. Loading: In the feeding area C, the material is placed between the top 7 and the plum blossom top 6, and is clamped under the action of the axial elastic force of the axial elastic expansion and rotation of the plum blossom top;

[0053] 3. Transportation: After the feeding device touches the limit switch, the loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com