Patents

Literature

132results about How to "Production operation safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

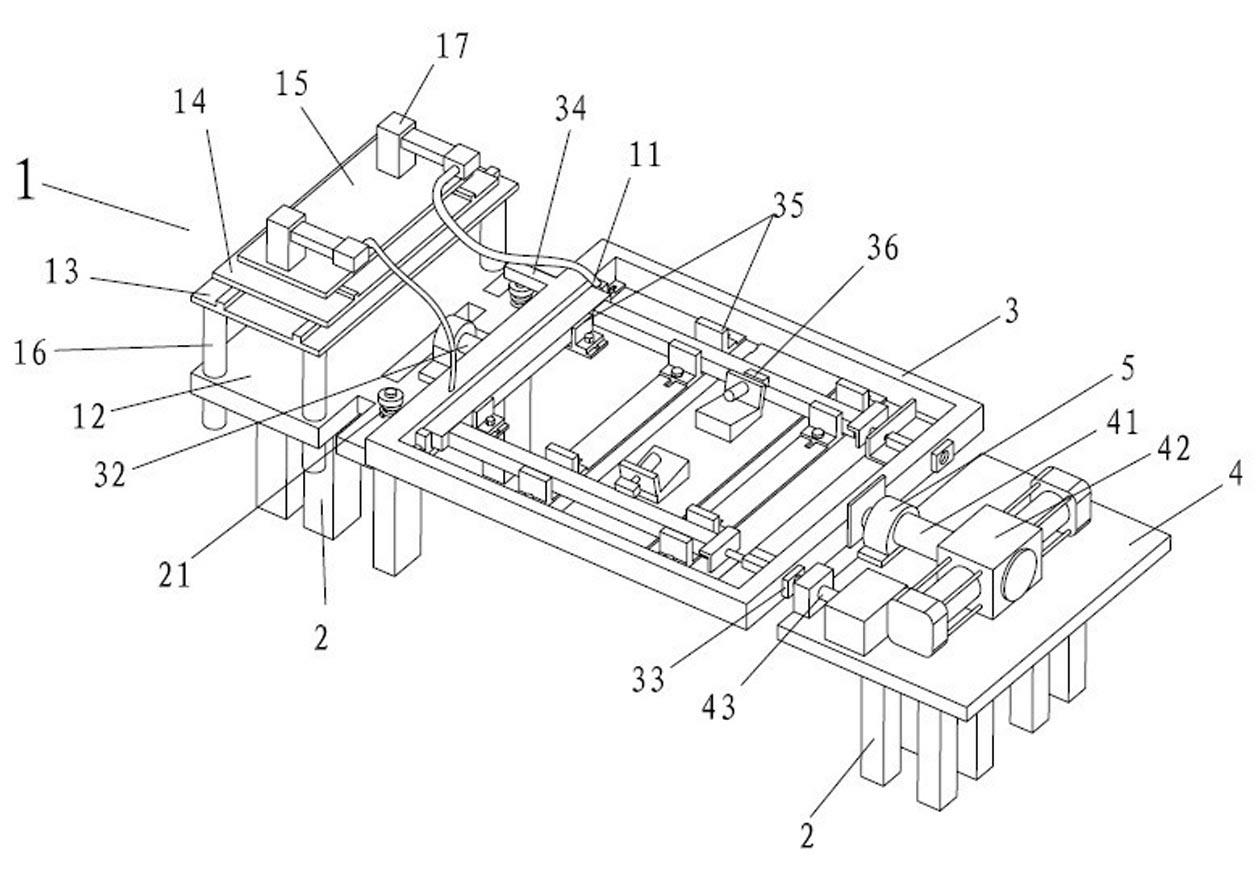

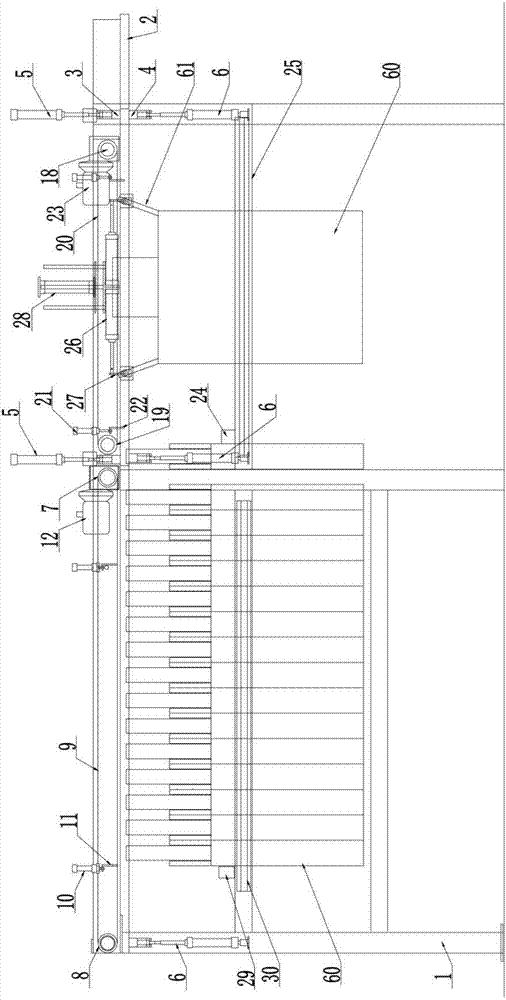

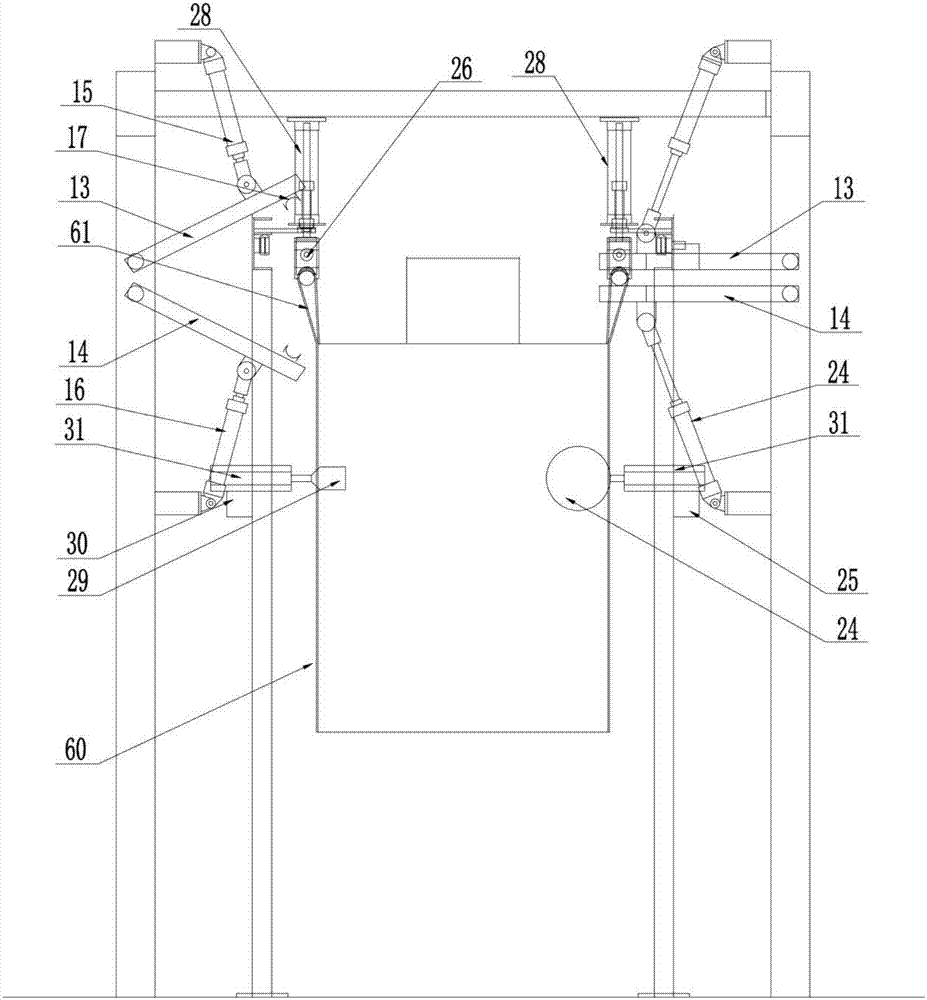

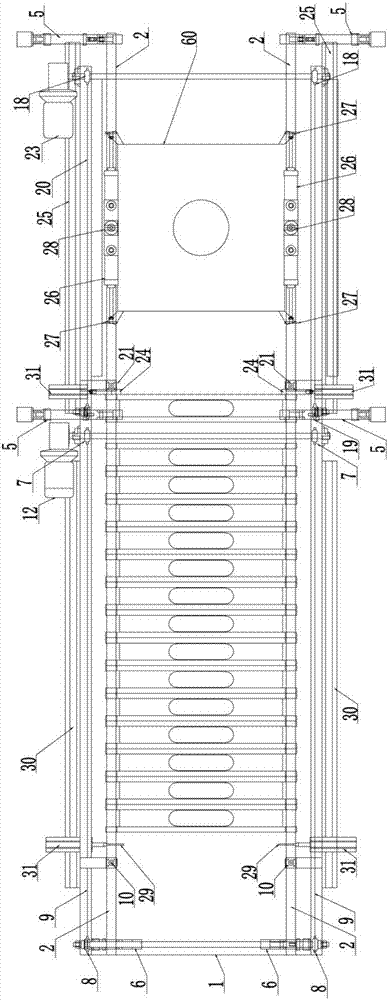

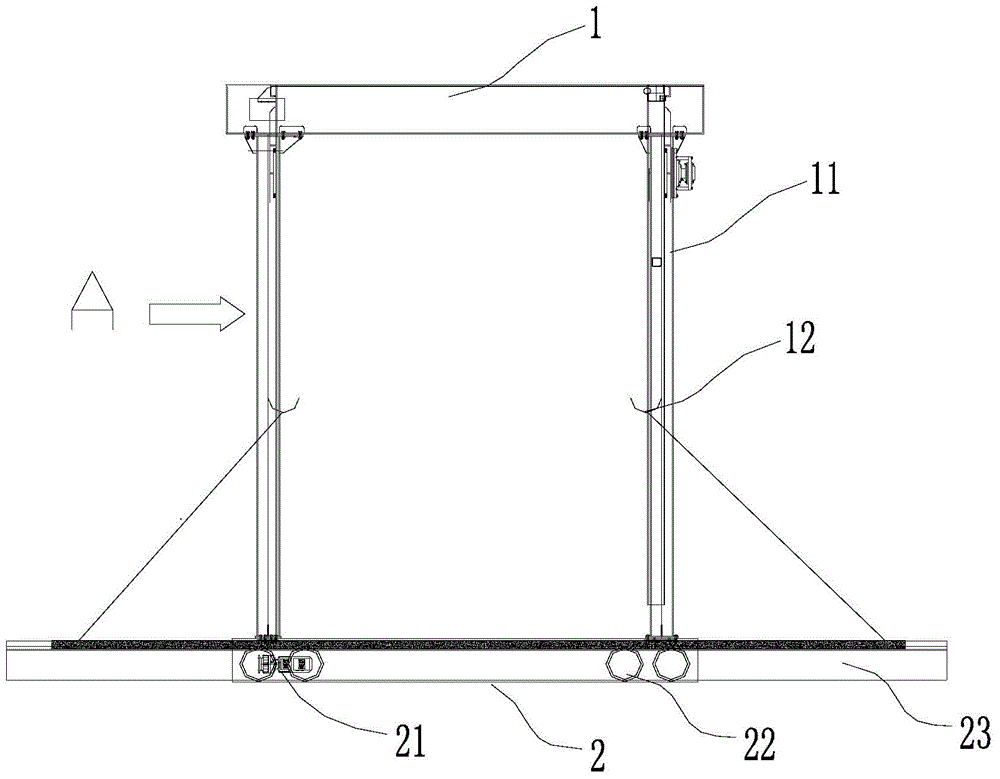

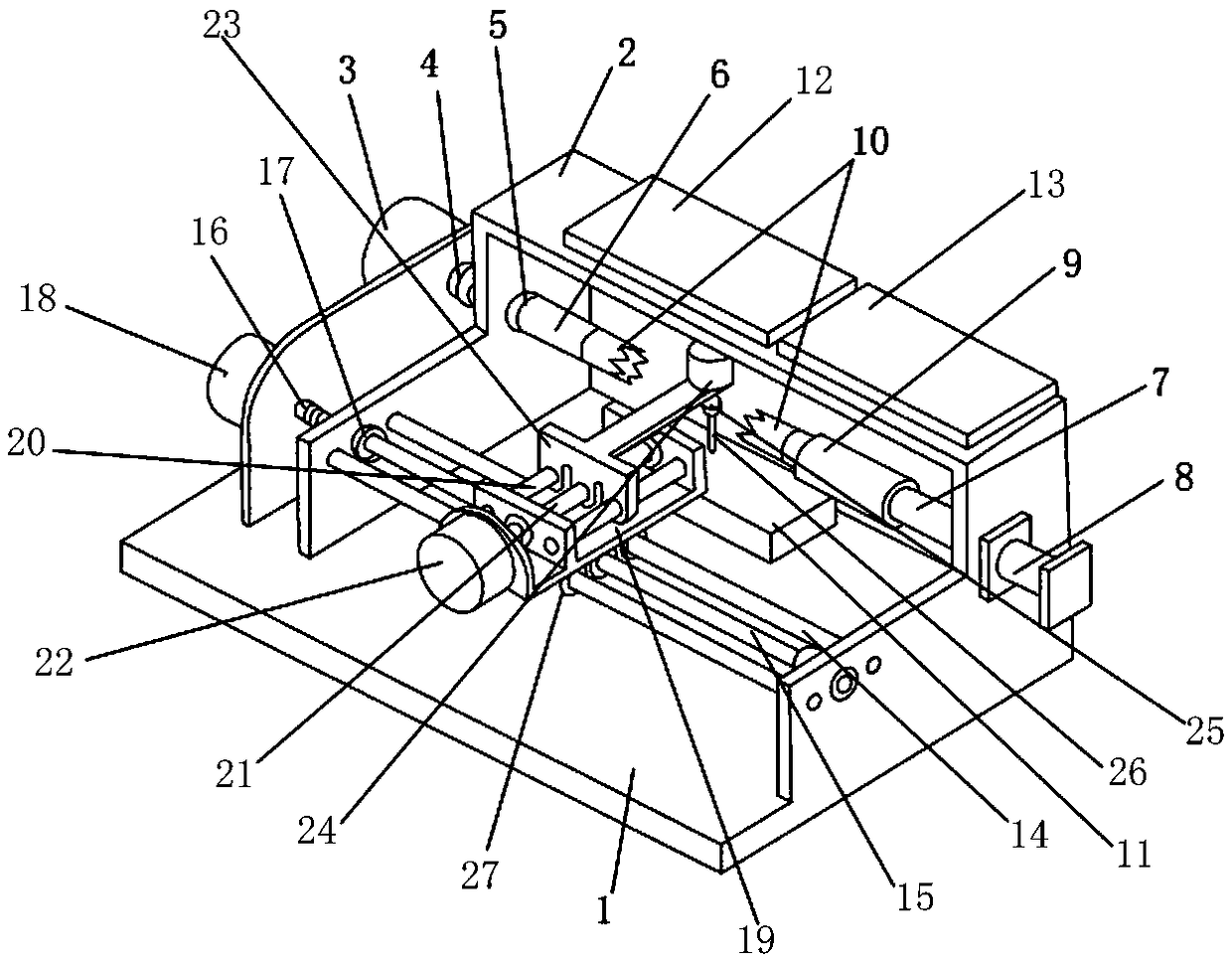

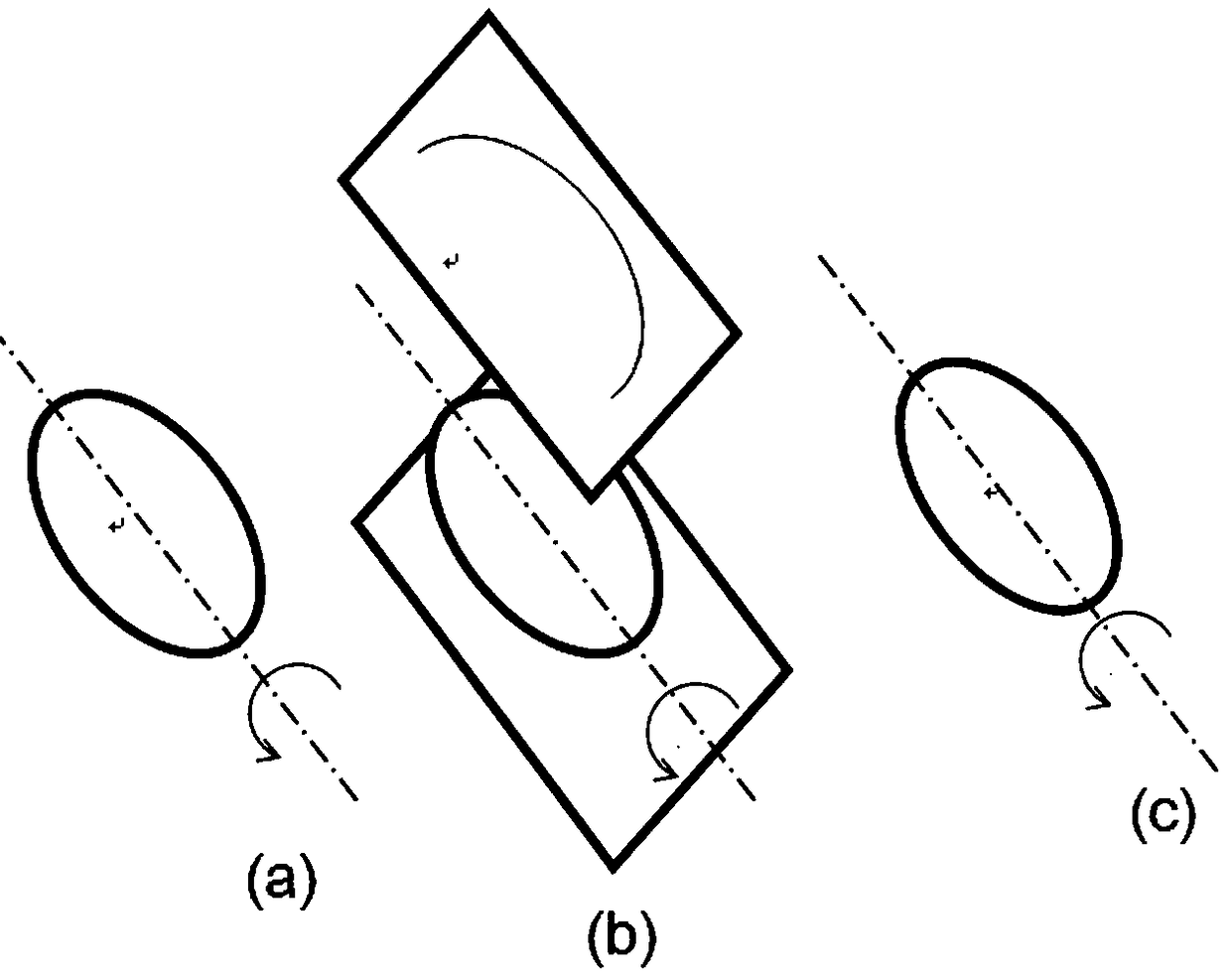

Welding device capable of being overturned automatically

InactiveCN102218632ASave human effortSave operating timeWelding/cutting auxillary devicesAuxillary welding devicesPositioning systemWelding

The invention relates to a mechanical welding apparatus, in particular to a welding device that is used for double face welding and can be overturned automatically. The welding device comprises a welding component, an automatic overturning component and a bracket; the welding component and the automatic overturning component are arranged on the bracket; the welding component comprises an automatic welding gun; the automatic overturning component comprises an overturning platform and a driving platform; a positioning system used for fixing an article to be welded is arranged on the overturning platform; rotating shafts are arranged at two ends of the overturning platform; a driving system connected with the rotating shafts is arranged on the driving platform; and the welding device also comprises a locking system used for fixing the overturning platform. The welding device has the advantages of greatly saving manpower, improving production efficiency, making products more uniform and attractive, and being produced and operated more safely.

Owner:浙江爱婴博士科技有限公司

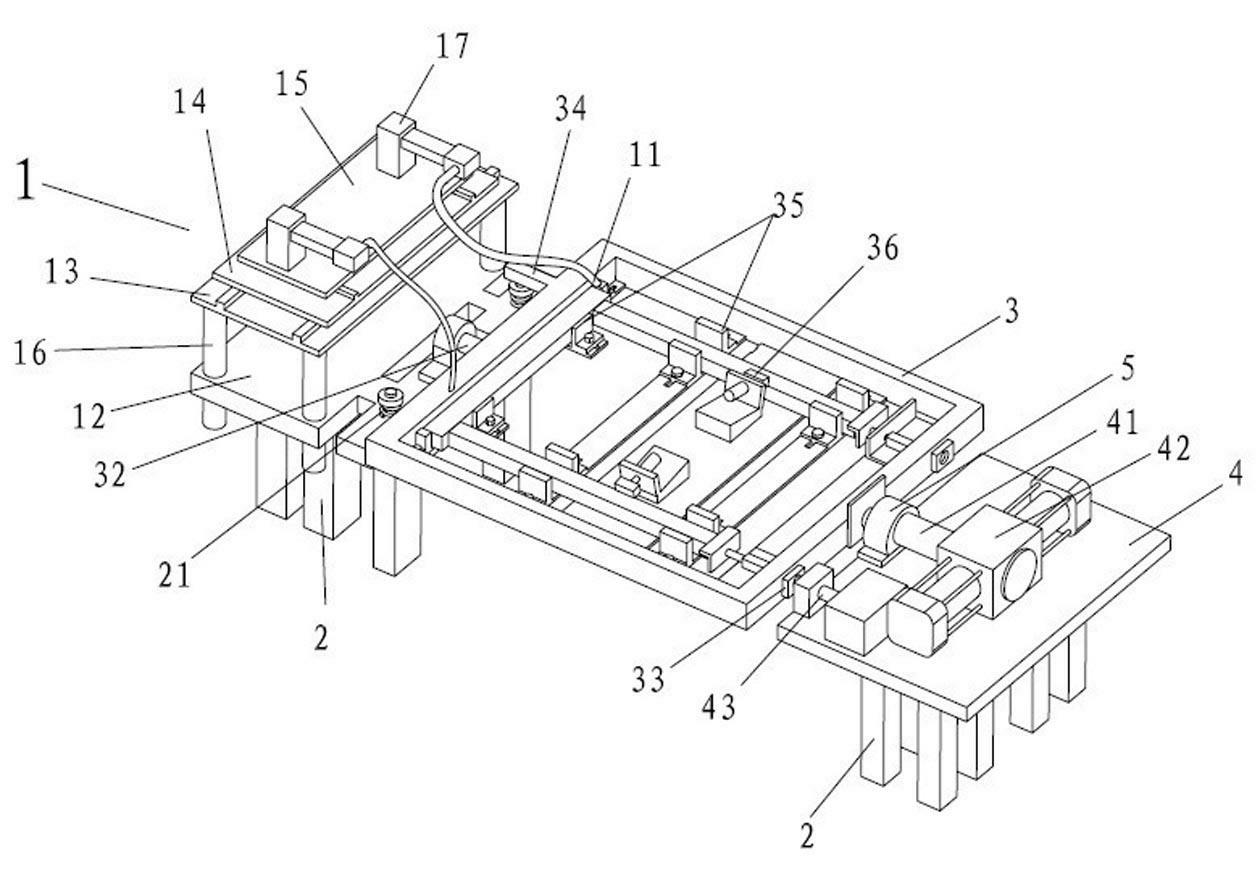

Water-emulsion-type high-efficiency terminator for polyvinyl chloride and preparation method thereof

InactiveCN102181000AStrong termination of polymerizationImprove thermal stabilityPolymer sciencePlasticizer

The invention relates to a water-emulsion-type high-efficiency terminator for polyvinyl chloride, which is prepared from the following raw materials in parts by mass: 10-16 parts of organic solvent or mixed solvent with a termination function, 15-22 parts of high-efficiency antiaging agent, 8-12 parts of plasticizer, 2-4 parts of thermal stabilizer, 2-5 parts of emulsifier and 0.2-1 part of emulsion stabilizer. The preparation method comprises the following steps: (1) organic phase dissolving and mixing; (2) water phase dissolving and mixing; (3) emulsifying by stirring; and (4) high-shear emulsifying. The terminator provided by the invention has a strong function on terminating polymerization, can enhance the thermal stability of resins, and can improve the whiteness and aging resistance of resins. Especially, the terminator provided by the invention is an environment-friendly terminator which is safe and convenient during production operation, and greatly enhances the use safety of the prepared polyvinyl chloride product. The terminator provided by the invention can be used in a food packaging material.

Owner:道尔达(西安)新材料有限公司

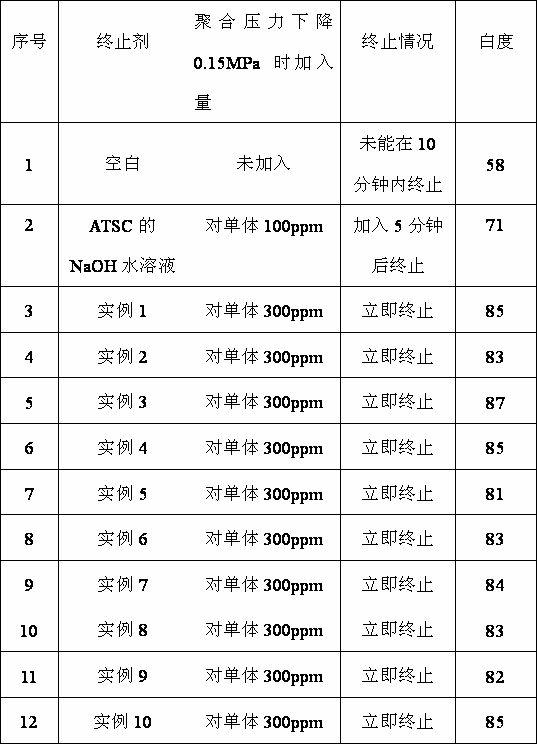

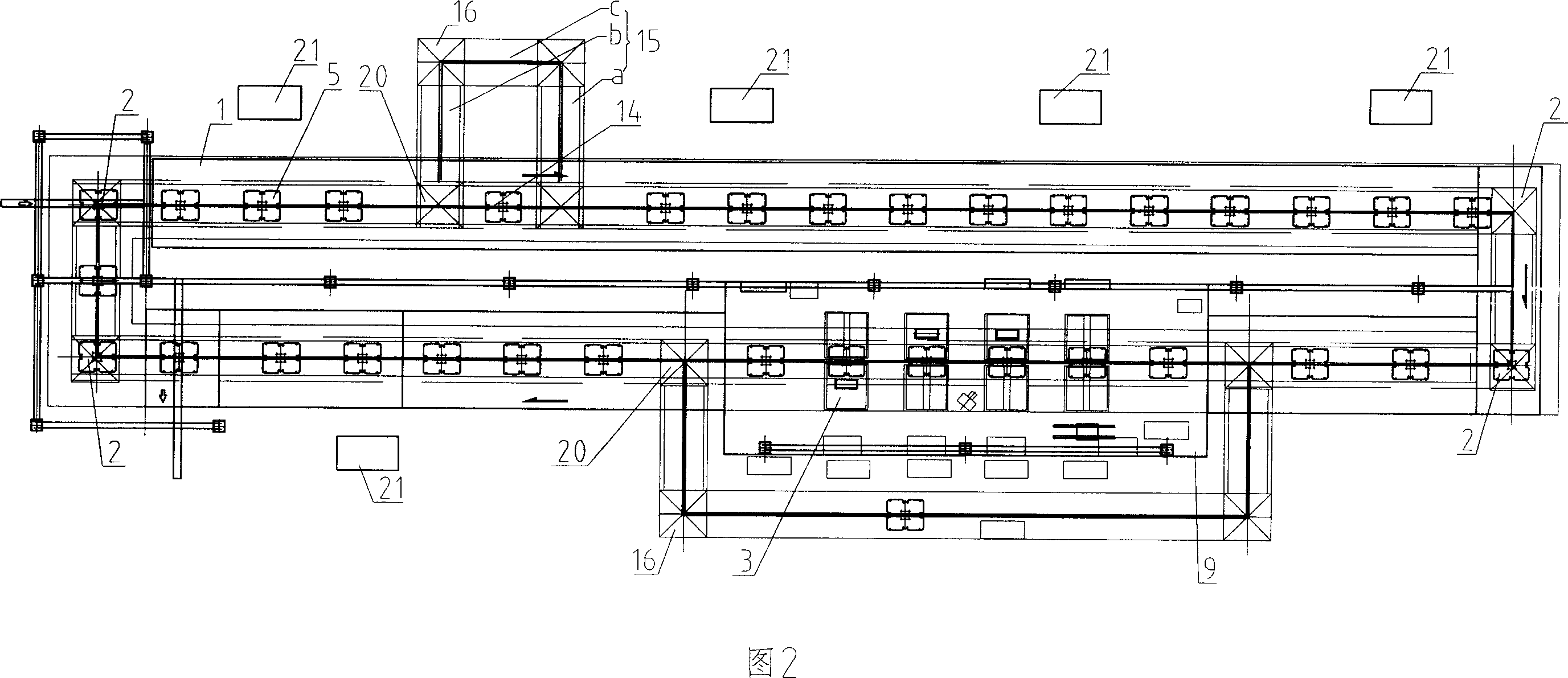

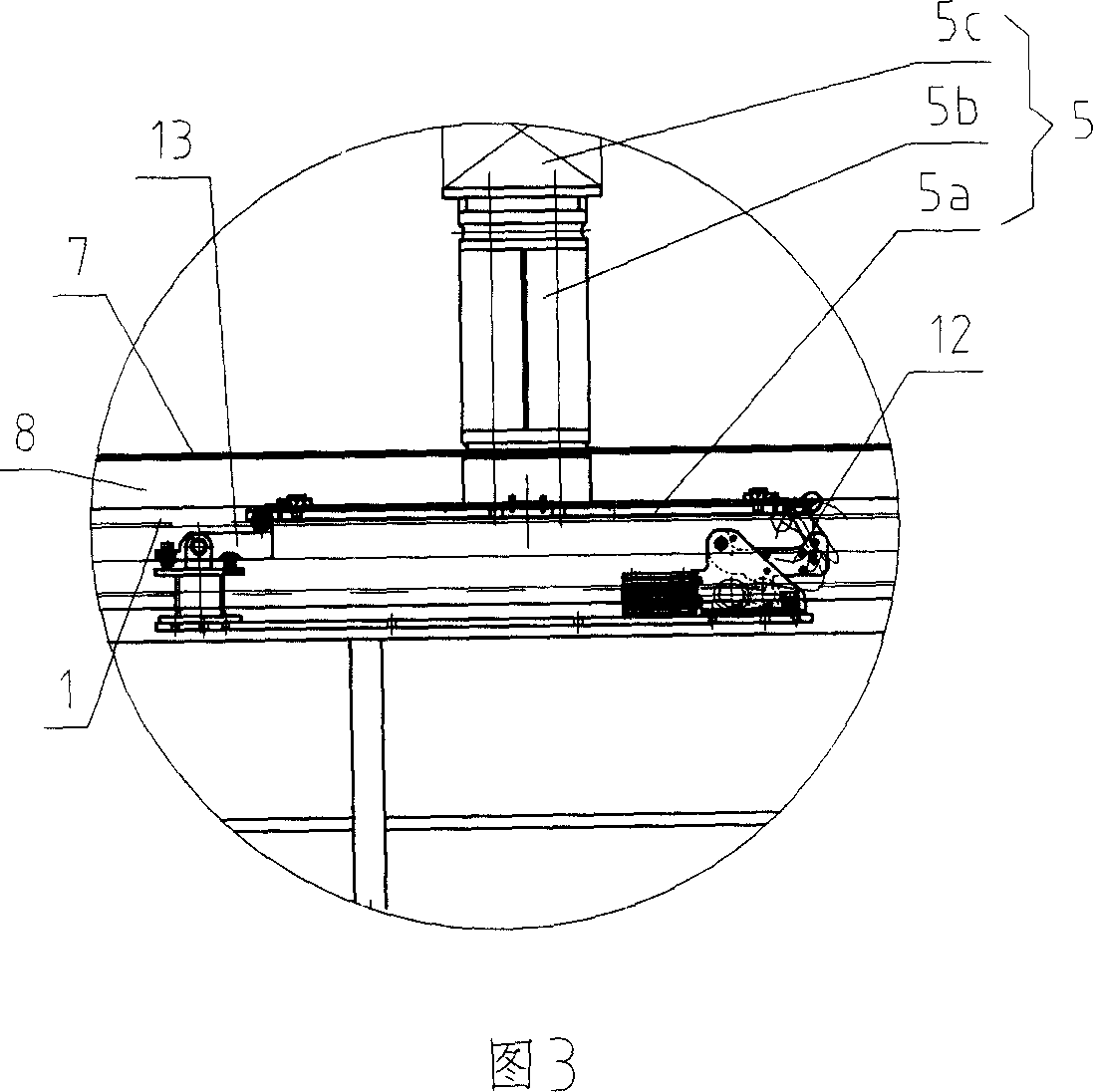

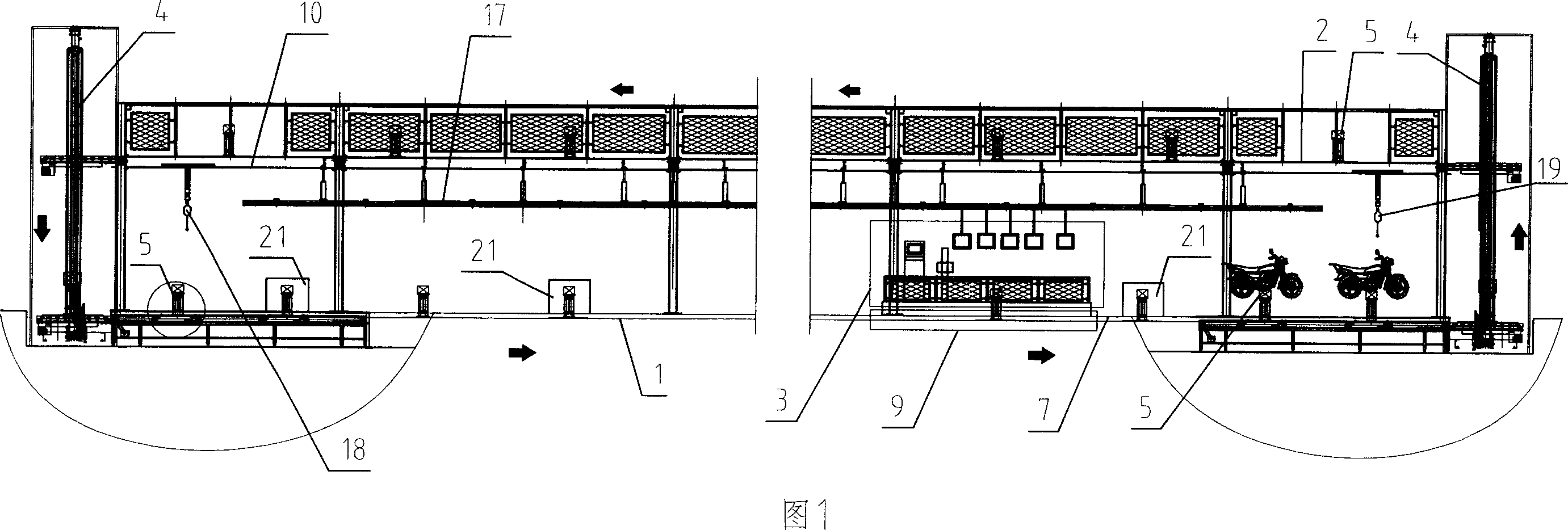

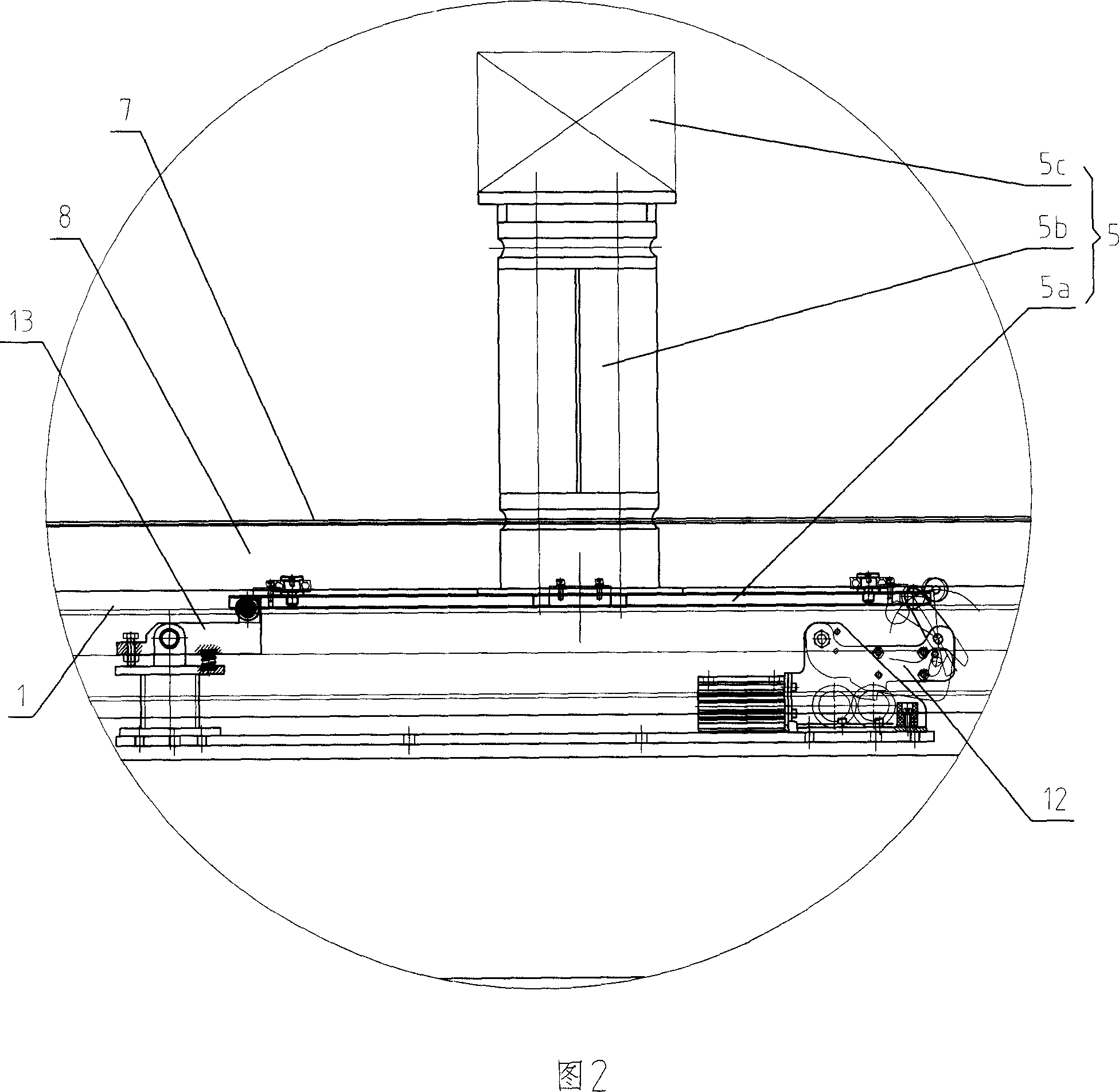

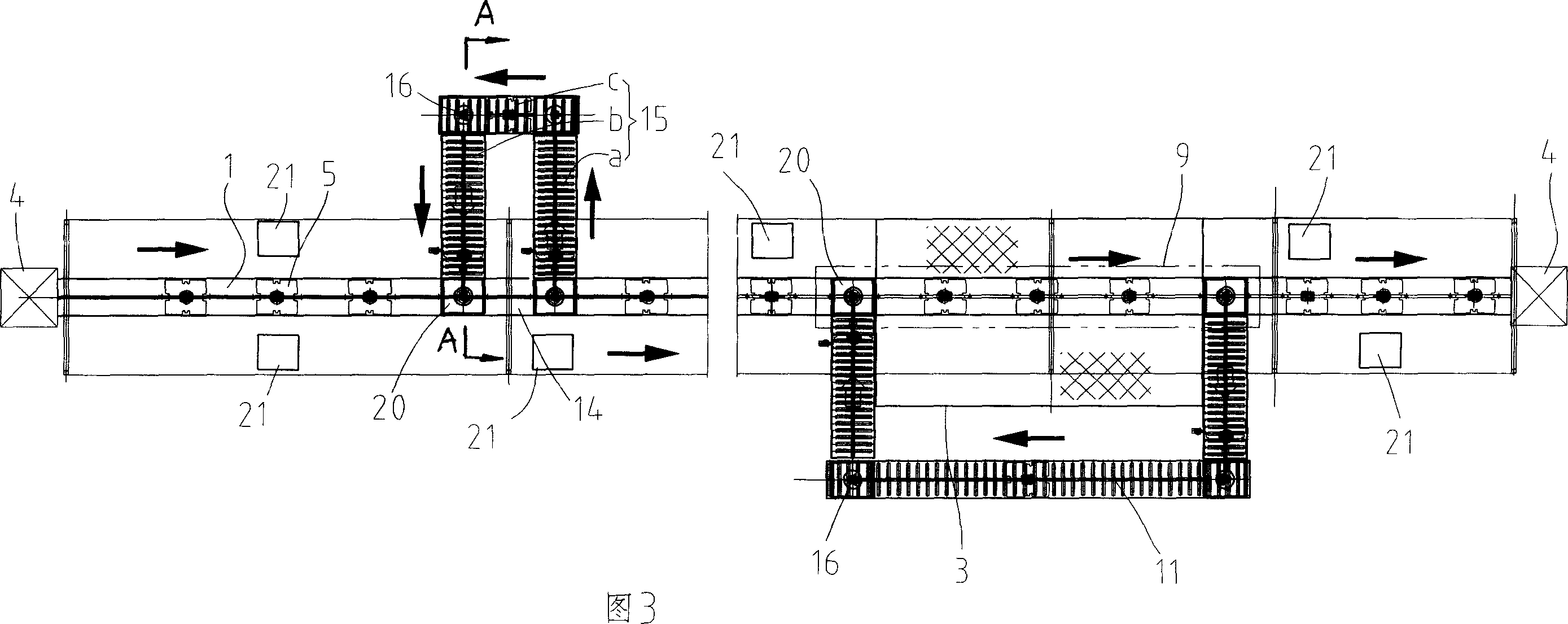

Integrative ground horizontal circular flexible production line for assembling and checking out motorcycle

ActiveCN101003292AFlexible and convenient operationReduce labor intensityVehiclesProduction lineRoller chain

A motorcycle assembling and testing integrated flexible production line circulating horizontally on the ground is composed of an endless master roller-chain conveyer line arranged horizontally underground, the assembling workstations at the side of said master conveyer, the flat base plates of assembling fixture on said roller-chain, performance test position, performance test system, and returning-repairing line.

Owner:ฉงชิ่ง จงเซิน มอเตอร์ไซเคิล อินดัสเทรียล แมนูแฟคเจอร์ โค แอลทีดี

Integrative aerial 3D circular flexible production line for assembling and checking out motorcycle

ActiveCN101003293AFlexible and convenient operationReduce labor intensityVehiclesProduction lineRoller chain

A motorcycle assembling and testing integrated flexible production line circulating over head is composed of an endless master roller-chain conveyer line arranged on the ground, a fixture returning back conveyer arranged over head, the assembling workstations at the side of said master conveyer, the flat base plates of assembling fixture on said roller-chain, performance test position, performance test system, and returning-repairing line.

Owner:ฉงชิ่ง จงเซิน มอเตอร์ไซเคิล อินดัสเทรียล แมนูแฟคเจอร์ โค แอลทีดี

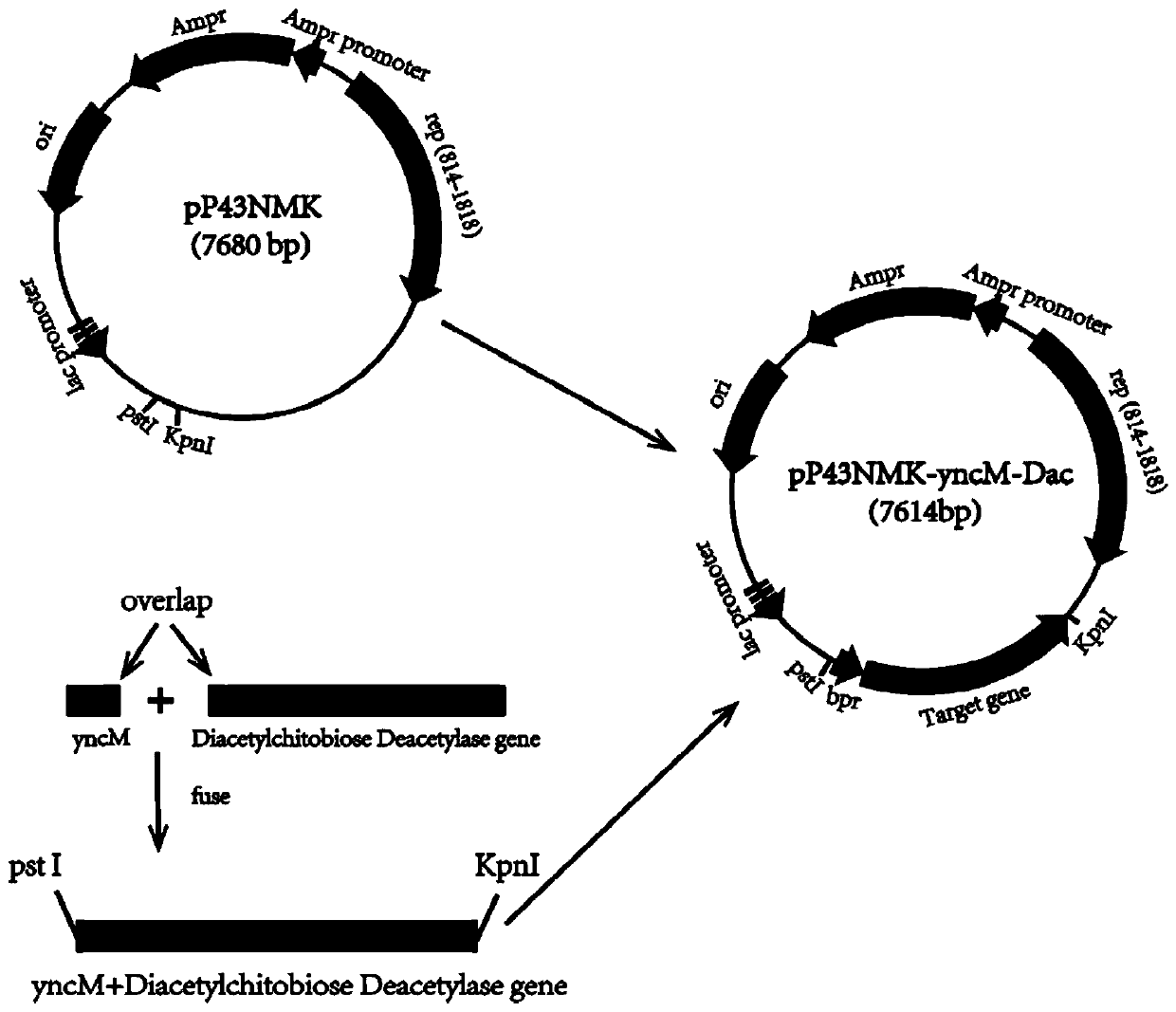

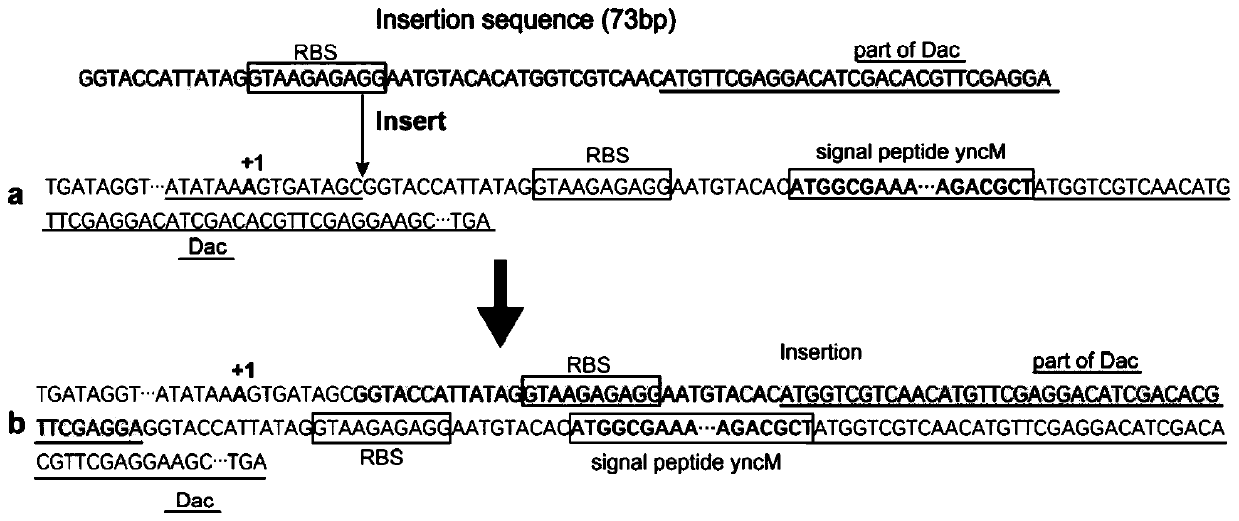

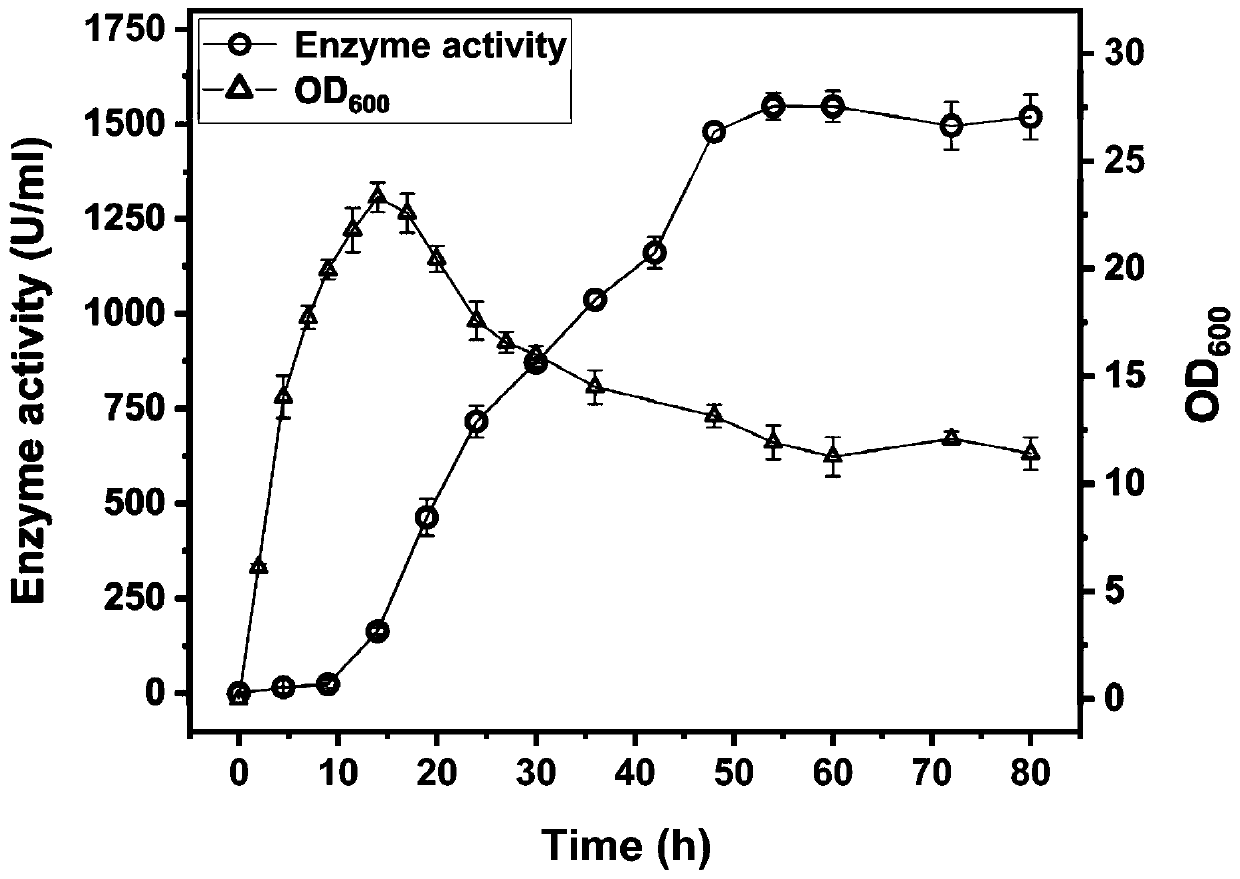

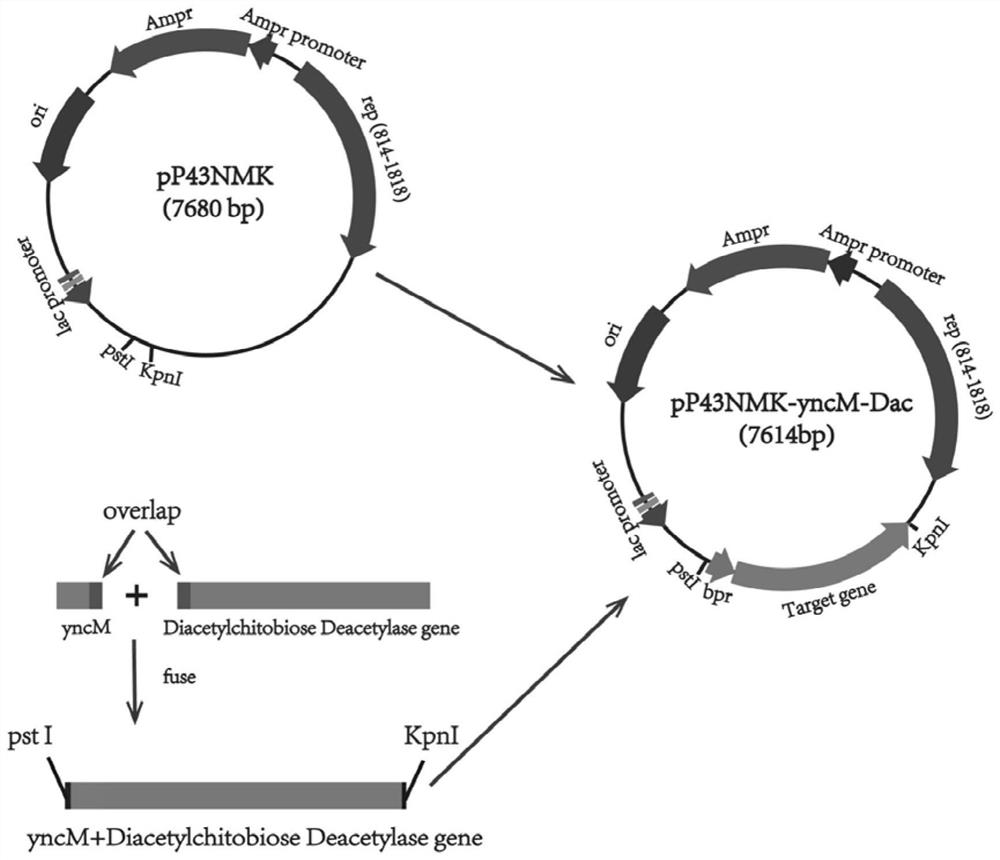

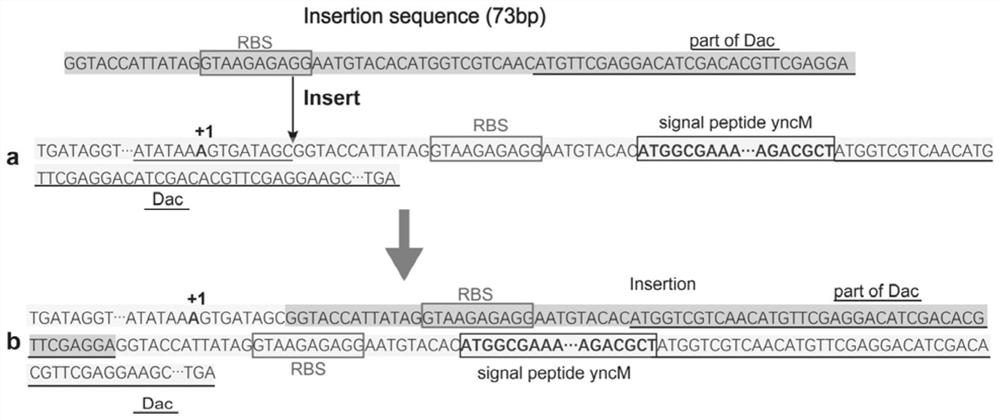

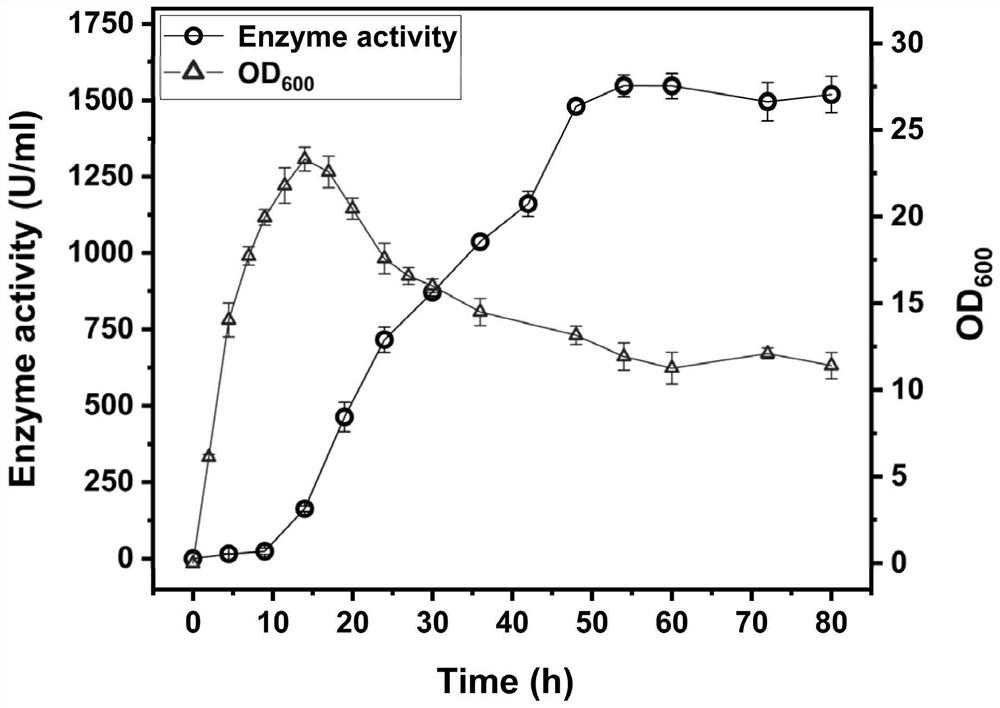

Construction and application of engineering bacteria secreting and expressing chitosan deacetylase

ActiveCN109777761AHigh expressionSimplify separation and purification stepsOrganic active ingredientsBacteriaHeterologousProtein target

The invention discloses a construction and application of an engineering bacteria secreting and expressing chitosan deacetylase, belonging to the technical field of fermentation engineering. The construction firstly constructs a recombinant Bacillus subtilis secreting and expressing chitosan deacetylase gene by a different source, and adds a signal peptide fragment yncM in the recombinant vector for a first time, wherein the signal peptide can secrete target protein chitosan deacetylase outside cells of the recombinant Bacillus subtilis, and obtain mutants in a non-translation region at 5' end, so that the expression of the target protein is significantly increased and steps of subsequent enzyme separation and purification are greatly simplified. The enzyme activity of obtained chitosan deacetylase is up to 1548.7 U / mL and the yield of chitosan deacetylase is up to 620 mg / L when fermentation medium is fermented and cultured for 50-60 hours. And meanwhile, the method has the advantages of low production cost, mild production conditions, simple purification process, safe operation and the like.

Owner:JIANGNAN UNIV +1

Automatic ton bag supplying device and automatic ton bag packaging system

The invention discloses an automatic ton bag supplying device and an automatic ton bag packaging system. The automatic ton bag supplying device comprises a bag supplying support, smooth shafts, a servo bag feeding mechanism, a hung bag conveying and locating mechanism, a servo traction mechanism and a hung bag fixing and locking mechanism. The automatic ton bag packaging system comprises the automatic ton bag supplying device, an automatic material feeding mechanism, an automatic sealing and filling mechanism, a packet receiving and vibrating conveyance mechanism and an automatic discharge conveying mechanism. The automatic sealing and filling mechanism is arranged above a filling area. The automatic material feeding mechanism is arranged above the automatic sealing and filling mechanism. The packet receiving and vibrating conveyance mechanism is arranged below the automatic sealing and filling mechanism. The automatic discharge conveying mechanism is arranged in front of the packet receiving and vibrating conveyance mechanism. By the adoption of the automatic ton bag supplying device and the automatic ton bag packaging system, automatic guiding in, opening, locating, filling, vibrating and discharging of ton bags are achieved, so that the supplying efficiency of the ton bags is improved, manual participation is not needed, the labor intensity of workers is lowered, the operation environment of the workers is improved, and safety accidents are prevented from happening.

Owner:烟台圣元自动化设备有限公司

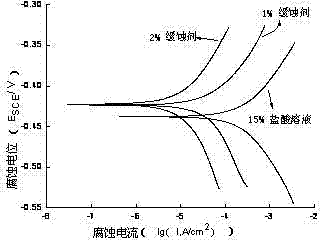

Preparation method and application of low toxicity acidizing corrosion inhibitor

InactiveCN103289663AEasy to degradeProduction operation safetyOrganic chemistryOrganic compound preparationAcid fracturingCarcinogen

The invention discloses a preparation method and application of a low toxicity acidizing corrosion inhibitor. The preparation method mainly includes two steps: 1. synthesizing a Mannich base quaternary ammonium salt; and 2. diluting the Mannich base quaternary ammonium salt to 15-20% (mass percentage) with a solvent. The corrosion inhibitor disclosed in the invention is a typical adsorption type corrosion inhibitor, can rapidly form a compact and firm hydrophobic protective membrane on the surface of a P110 steel test piece, thus effectively preventing an acid solution from corroding P110 steel. The corrosion inhibitor prepared in the invention belongs to a mixed corrosion inhibit inhibitor. The inhibitor employs cinnamic aldehyde with the advantages of the green, low toxicity, easy degradation and the like to replace the cancerogenic substance formaldehyde, is not added with iodide, alkynol or other synergists polluting the environment, has the advantages of simple synthesis process, small dosage, low toxicity, etc., and is suitable to oil and gas well acidizing, acid fracturing stimulation and other operations.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

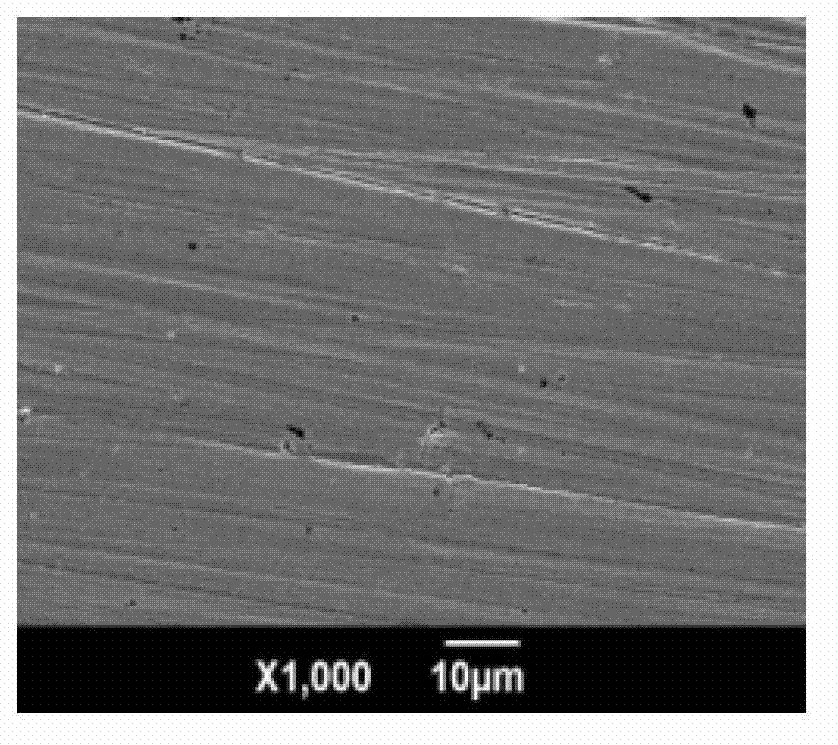

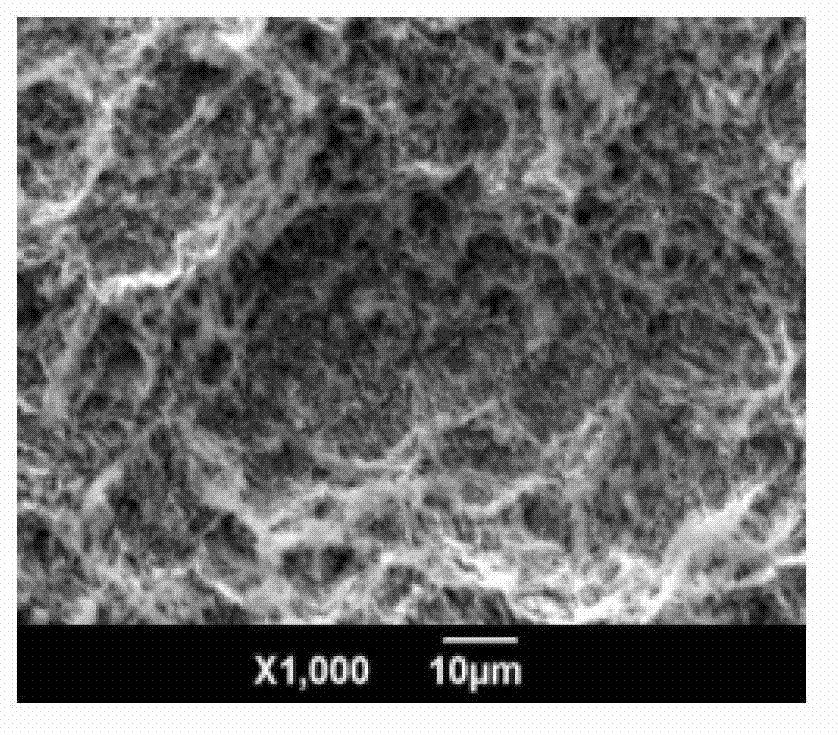

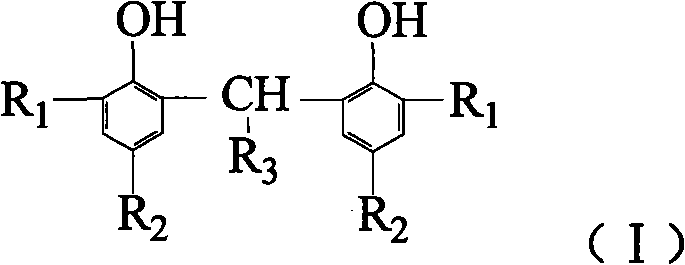

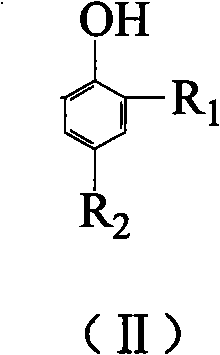

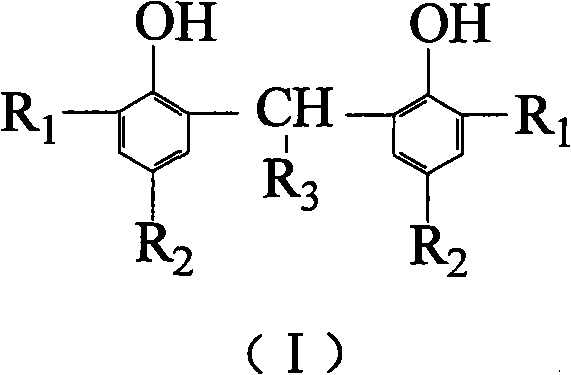

Method for preparing bisphenol compound antioxidant product by using organic acid catalyst

ActiveCN101704728AReduce consumptionControl and reduce emissionsOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a method for preparing a bisphenol compound antioxidant product by using an organic acid catalyst. A closed reactor is adopted, water is used as reaction solvent, a liquid organic acid catalyst is selected as a catalyst, and the bisphenol compound antioxidant product is generated through the condensation reaction of dialkyl phenol and aliphatic aldehyde. The liquid organicacid catalyst is one or a mixture of more of long-chain alkyl benzene sulfonic acid, long-chain dialkyl benzene sulfonic acid, long-chain alkyl diphenyl ether disulfonic acid and long-chain dialkyl diphenyl ether disulfonic acid and aliphatic hydrocarbon of C6 to C10 or aromatic hydrocarbon of C6 to C8 in a mass ratio of 1: 0.1-1.0. The dosage of the liquid organic acid catalyst is 7 to 30 percent by mass of dialkyl phenol; the mass ratio of the water to the dialkyl phenol is 2-5:1; and the molar ratio of the aliphatic aldehyde to the dialkyl phenol is 0.45-0.60: 1. The reaction pressure is 0to 0.1MPa, the reaction temperature is 60 to 95 DEG C, and the reaction time is 4 to 7 hours. The raw material variety used by the method is reduced, and the production efficiency is improved; and the method avoids using sulfuric acid and hydrochloric acid with stronger corrosion on the equipment.

Owner:溧阳常大技术转移中心有限公司

Reduction and carbonization method for titanium-containing raw material

The invention relates to a reduction carbonization method of the titanium-bearing material, which belongs to the metallurgy field. The invention solves the technology difficult problem that the bottom of a furnace rises and the generated foamed slag is excessive during the reduction carbonization process of the titanium-bearing material. The reduction carbonization method of the titanium-bearing material in the invention has various power distribution systems in the various implementation stages of material melting, reduction carbonization, and discharging; during the material melting stage, the transformer capacity is fully exerted, to ensure that the material is melted quickly; during the reduction carbonization stage, the electric furnace power is controlled to ensure that the depth of a steady foamed slag layer does not exceed 50 percent of the depth of a material melting tank; during the discharging stage, the electric furnace power is enhanced, to ensure that the melted and carbonized slag flow out of an electric furnace steadily, and the power cannot be shut off during the discharging. The reduction carbonization method of the titanium-bearing material of the invention can realize continuous production, the production operation is secure, the reduction carbonization power consumption and the production cost are reduced, the production efficiency is enhanced, and the invention has broad application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

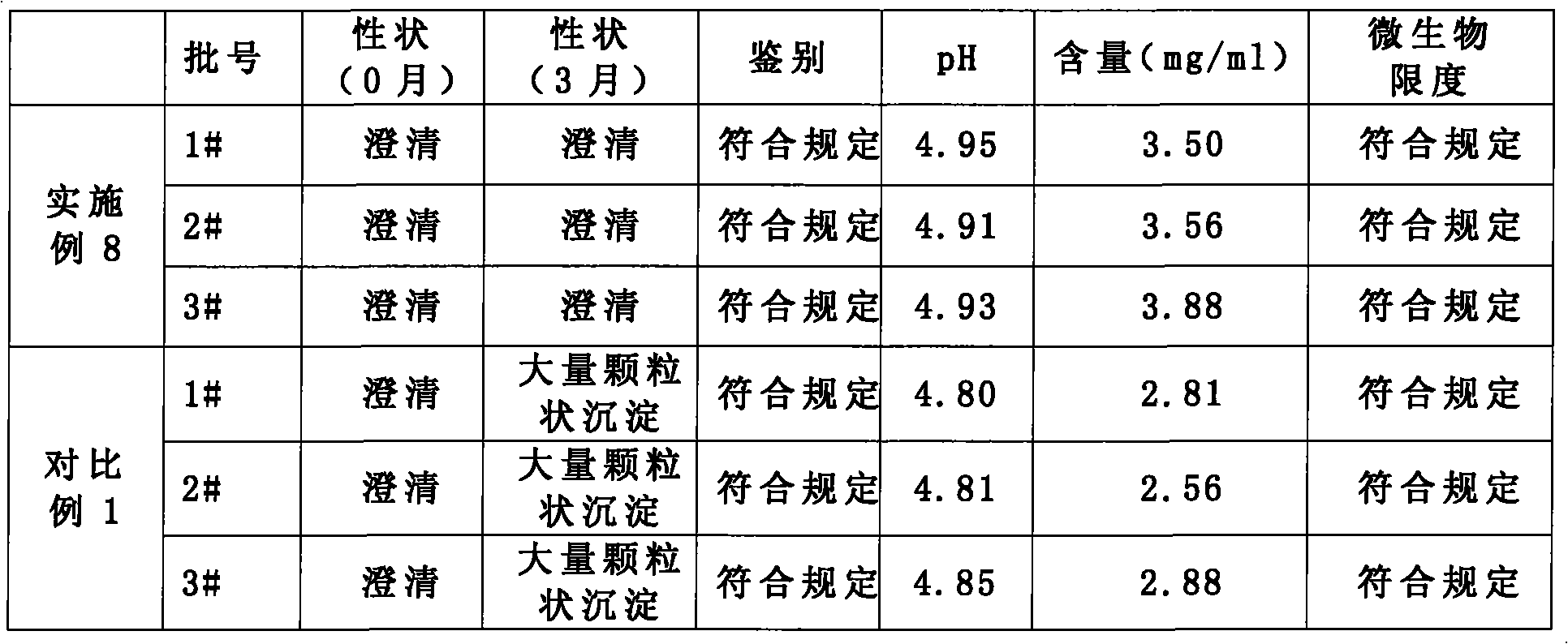

Process for preparing thermopsis lanceolate total alkaloids and several high-purity medicinal substances

InactiveCN102349940AReduce usageImprove stabilityNervous disorderAntimycoticsCountercurrent chromatographyAcid water

The invention relates to a process for preparing thermopsis lanceolate total alkaloids and several high-purity medicinal substances, and belongs to the technical field of the extraction of Chinese medicinal active ingredients. The medicinal substances comprise eulexine, thermopsine, sparteine and N-methyl eulexine. In the process, total alkaloids are prepared from thermopsis lanceolate serving as a raw material through acid water extraction, ionic resin adsorption and macroporous resin enrichment, and the total alkaloids are separated and purified by high-speed countercurrent chromatography and preparative liquid chromatography to obtain the high-purity eulexine, thermopsine, sparteine and N-methyl eulexine. The process has the advantages of simplicity, quickness, high repeatability, large preparation amount and the like, and industrialization is easy to realize.

Owner:NANJING ZELANG MEDICAL TECH

Four-function treating liquid for surface of iron or steel

InactiveCN101245458ANo pollutionProduction operation safetyMetallic material coating processesPolyvinyl alcoholPhosphoric acid

The invention relates to tetrafunctional surface treatment fluid for steel, the ingredients of which are: phosphoric acid: 60kg, polyvinyl alcohol: 0.2kg, zinc oxide: 2kg, zinc nitrate: 0.5kg, tartaric acid: 1.5kg, metal cleaner: 8611kg, ammonium molybdate: 0.36 kg and the rest of water. The product does not lead to environmental pollution and can guarantee the safety of production operation. Scientific material proportion ensures the product is limpid and has good stability. The invention has excellent derusting ability and can dispose of scale cinder attached on the surface of the steel, prevent an electrolyte from expansion and effectively control filiform corrosion under a film and corrosion in the breakage of a film coating. As for the usage method, dipping, spraying, brushing and wiping are all allowed. Simplification ensures that the operation process can be completed at one time.

Owner:天津新技术产业园区科茂化学试剂有限公司

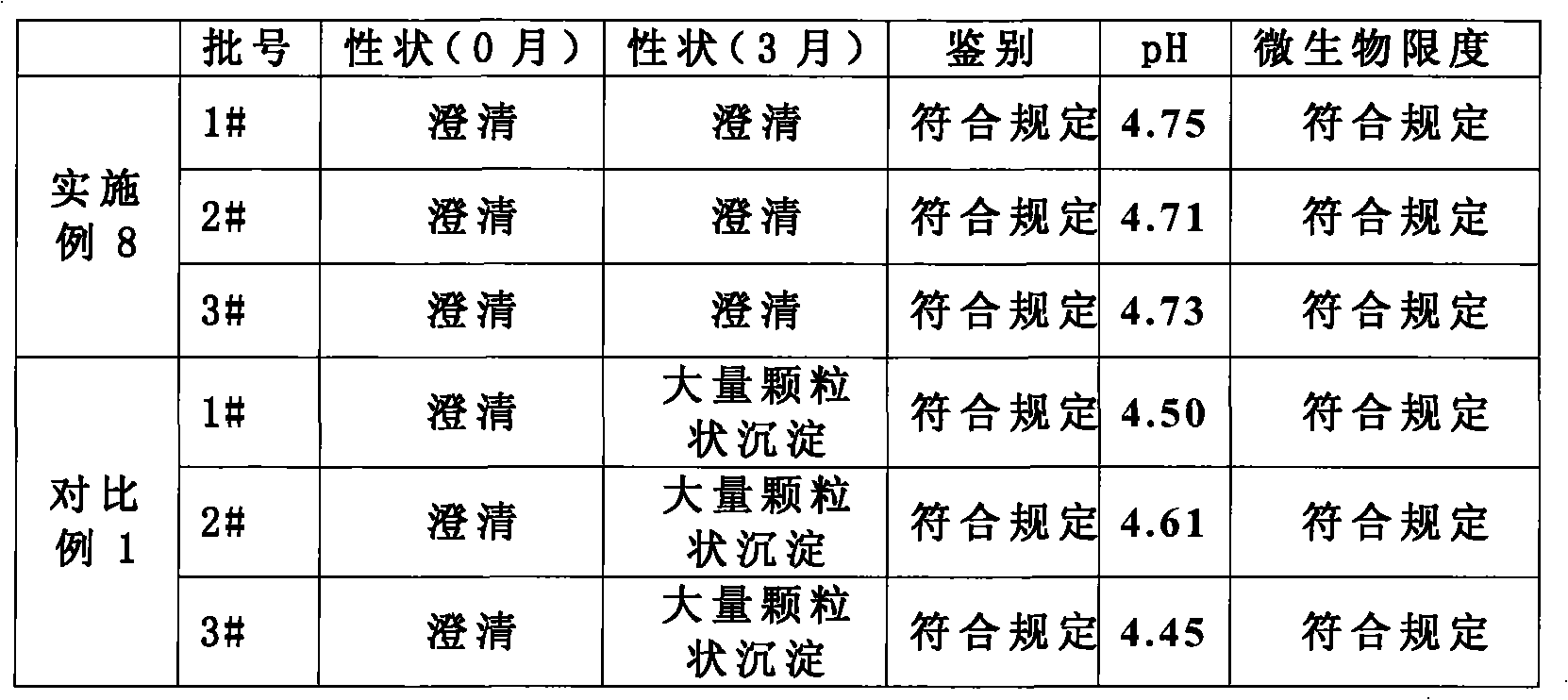

Technique for preparing oral liquid for cough and asthma of children

InactiveCN101406543AHigh clarityEfficient removalRespiratory disorderAluminium/calcium/magnesium active ingredientsCLARITYFiltration technique

The invention relates to a preparation technique for children cough oral liquid, which comprises the following steps in turn: (1) extracting primary liquid medicine; (2) purifying the primary liquid medicine to obtain clear solution, and further condensing the clear solution to obtain extractum; and (3) preparing the liquid medicine by the extractum, flavoring and water, and then obtaining the children cough oral liquid after filtering and condensing the liquid medicine in turn, in particular, in step (2), the purifying means filtering the primary liquid medicine through an ultramicro filter film; and in step (3), the filtering is also carried out by the ultramicro filter film. Through adopting the ultramicro filter film to effectively filter the primary extracted liquid medicine, the preparation technique achieves non-alcoholization production, simplifies processes, shortens production period, and reduces energy consumption and production cost; and at the same time, through adopting a filtering technique of a tubular ultrafilter film to carry out terminal filter for the prepared liquid medicine, the preparation technique ensures the content of effective components, improves clarity of the liquid medicine, improves quality of products, and ensures quality stability of the products.

Owner:苏州华辰净化股份有限公司

Weather resistant water-retaining agent and its prepn

The present invention is weather resistant water-retaining agent and its preparation. The weather resistant water-retaining agent has relatively high ultraviolet ray resistance and may be used widely in agriculture, forest, garden and other outdoor fields. The present invention features the neutralizing process with polymerization of acrylic acid; dissolving great amount of acrylamide into the neutralizing liquid to lower the temperature; composite reaction initializing system for reaction at different temperature conditions; greatly increased N, Ní»-methylene diacrylamide and acrylamide amount for raised weather resistance and lower production cost of the water-retaining agent; controlled reaction strength for high water absorbing capacity of the water-retaining agent, and disc polymerization with no need of nitrogen protection and short reaction time.

Owner:珠海得米新材料有限公司 +1

Metal bonding powder coating with mirror-like silver effect as well as preparation method and application thereof

PendingCN104877539AImprove corrosion resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesAntioxidantMelt extrusion

The invention belongs to the field of powder coating and particularly relates to a metal bonding powder coating with a mirror-like silver effect as well as a preparation method and application thereof. The powder coating is prepared by binding base powder and aluminum powder, wherein the base powder is prepared from the following raw materials in percentage by weight: 82 to 85 percent of polyester resin, 12.5 to 15 percent of curing agent, 0.8 to 1 part of leveling agent, 0.3 to 0.5 percent of benzoin, 0.8 to 1 percent of sensitizer and 0.3 to 0.5 percent of antioxidant. The preparation method of the metal bonding powder coating comprises the following steps of uniformly mixing raw materials, performing melt extrusion by an extruder, and performing tabletting, air cooling, grinding and sieving to obtain the base powder; binding the aluminum powder and the base powder. The powder coating disclosed by the invention has the characteristics of good corrosion resistance, good wear resistance, excellent decorating performance, good environment friendliness and no toxicity; the preparation method has the advantages of less investment, low cost, safe production and operation and in accordance with the requirements of large precise product manufacturers at home and abroad; a coating film of the coating has the advantages of high glossiness, high anti-pollution capacity, good greenness, good environmental protection and wide application field.

Owner:山东朗法博粉末涂装科技有限公司

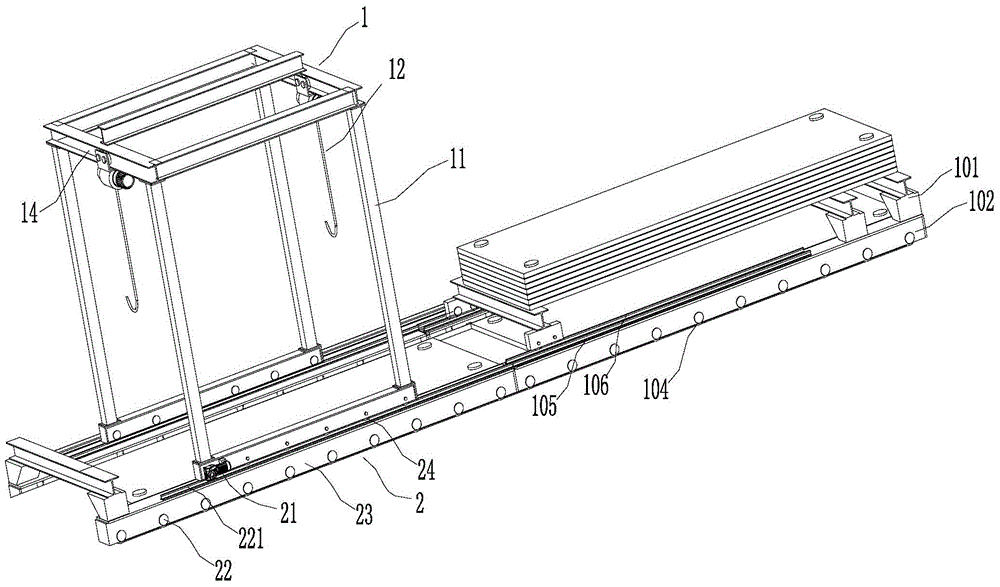

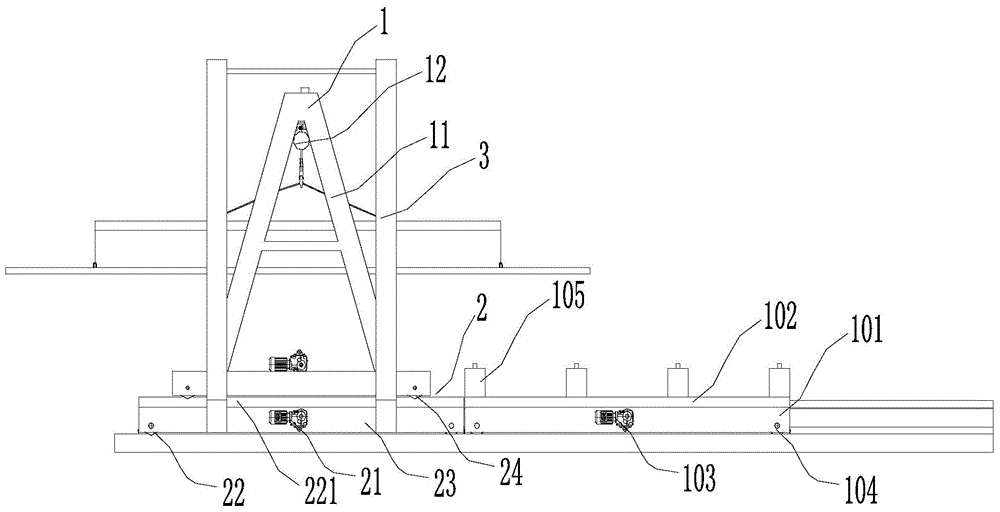

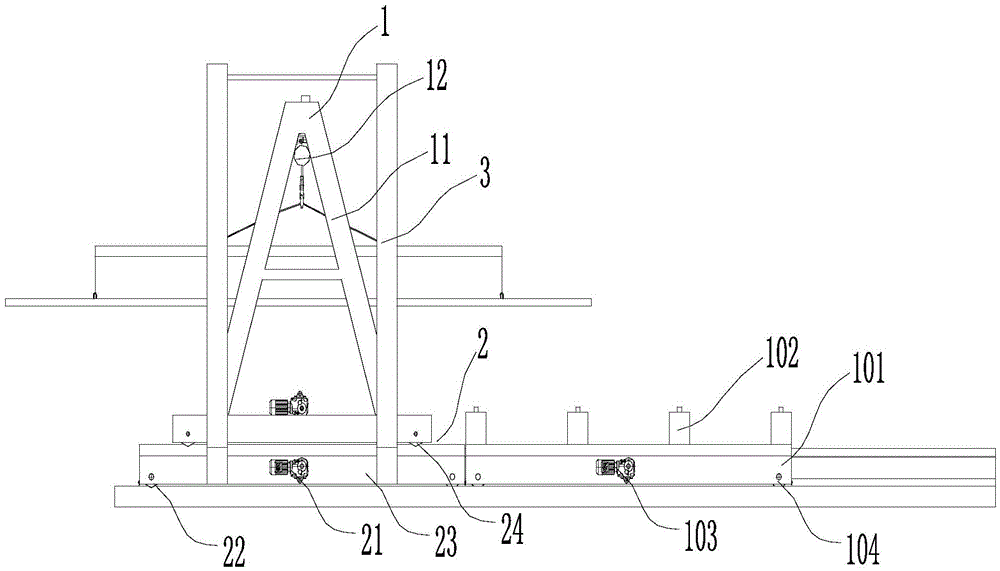

Prefabricated part production and transportation system

InactiveCN105668163ASmooth transitionProduction operation safetyMechanical conveyorsEngineeringProduction line

The invention proposes a prefabricated part production and transportation system. The system comprises at least one prefabricated part production and transportation line; the prefabricated part production and transportation line comprises a prefabricated part transportation car, a prefabricated part lifting car and a walking rail; the prefabricated part transportation car and the prefabricated part lifting car are operated on the walking rail; the prefabricated part lifting car includes a walking platform and a lifting device; the walking device is arranged at the bottom of the lifting device, and includes two longitudinal walking brackets, a second driving device and at least two sets of lifting walking wheels; the lifting walking wheels are arranged at the bottoms of the longitudinal walking brackets; the lifting device includes a lifting frame and a lifting hook component; the lifting hook component is arranged at the top of the lifting frame; and a lifting walking mechanism is arranged at the lower part of the lifting frame, and can move corresponding to the walking platform. The system shortens the lifting transfer time, and saves the field occupied area of the production line.

Owner:CHINA MINSHENG ZHUYOU

Stable everolimus tablet

ActiveCN104721158AEffective dissolutionSimple preparation processOrganic active ingredientsAntimycoticsEverolimusAdhesive

The invention provides a stable everolimus tablet containing one or several selected from everolimus, 2,6-tert-butyl-4-methylphenol, a filling agent, an adhesive, a disintegrating agent and a lubricating agent, wherein everolimus is micronized before being tabletted, and the micronized median particle diameter D50 does not exceed 100mu m. The everolimus tablet prepared by the invention has the advantages of relatively high dissolution rate, favorable stability, low production cost, stable and controllable process parameters and the like.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

Phenol analog derivative preparation method

ActiveCN101007752AReduce usageReduce dosageOrganic chemistryOrganic compound preparationAcetic acidOrganic solvent

The invention discloses a making method of phenol derivant, which comprises the following steps: (1) adopting acetophenone derivant as raw material and dilute sulfuric acid as catalyst; adding raw material, catalyst, glacial acetic acid and organic solvent into reacting container; (2) stirring; adding oxidizer into the system slowly; (3) insulating at 10-70 deg.c for 5-20h.

Owner:烟台九目化学股份有限公司

Preparation method for L-ornithine-alpha-ketoglutarate

InactiveCN102373245AHigh purityIncrease productionOn/in organic carrierFermentationTransformation efficiencyL-Ornithine

The present invention relates to a preparation method for L-ornithine-alpha-ketoglutarate. The L-ornithine-alpha-ketoglutarate is produced by arginase transformation. The preparation method comprises the following steps: (1) preparation of immobilized enzyme; (2) optimization of transformation conditions; (3) product extraction and refining process. Compared to the prior art, the preparation method of the present invention has the following advantages that: the preparation method of the present invention has characteristics of low production cost, mild production conditions, less impurities in the transformation system, simple process steps, safe production operation and high purity; qualified products meeting the light transmission requirements can be synthesized; each liter of the reaction solution contains 300-320 g of the L-ornithine-alpha-ketoglutarate, and the transformation efficiency of the alpha-ketoglutaric acid is more than 90%; the preparation method further has other advantages.

Owner:湖南天成生化科技有限公司

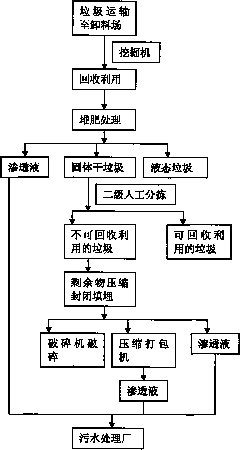

Garbage sorting compressing environmental processing technology

InactiveCN101823071AReduce investmentHazard reductionWaste processingSolid waste disposalSocial benefitsLitter

The invention provides a garbage sorting compressing environmental processing technology. Comprehensive sorting treatment is carried out on garbage, garbage is sequentially subject to four stages of recycling, composting, residue compression sealing landfill and penetrating liquid treatment, then a plurality of processes of sorting, bag-breaking screening, compression packaging and winding packaging are carried out on the garbage, density volume reduction is adopted to realize simplification of garbage treatment, the garbage is daily treated, storage capacity is effectively reduced, and the existing landfill time is prolonged for more than seven years. The invention has reasonable design, simple construction member, strong practicability and convenient and easy operation, no large-scale dump site is required to be established, the existing dump site landfill storage capacity can be directly utilized to carry out sorting, compression and sealing on garbage, funding is reduced, and the penetrating liquid produced by garbage is purified, harmfulness of various harmful substances can be reduced to minimum, no secondary pollution to the environment is produced, and the technology has obvious social benefit and economic benefit.

Owner:广东昕旺环保科技发展有限公司

Spinning and dyeing pretreatment auxiliary agent and preparation method and application thereof

The invention relates to a spinning and dyeing pretreatment auxiliary agent, which is prepared by adopting the following raw material components: 30 to 50 parts by weight of desizing agent, 5 to 20 parts by weight of alkali-resisting penetrant, and 4 to 10 parts by weight of complexing agent; the desizing agent is multi-alkyl amine salt; the alkali-resisting penetrant is an alkali-resisting nonionic surfactant; the complexing agent is hydroxy carboxylate. Further, the adopted raw material components also include 1 to 10 parts by weight of hydrogen peroxide stabilizer; the hydrogen peroxide stabilizer is organic phosphonate. The spinning and dyeing pretreatment auxiliary agent can be obtained through the preparation of successively mixing the raw material components, and the spinning and dyeing pretreatment auxiliary agent can be applied to a cold-batch method or open-width scouring-bleaching method spinning and dyeing pretreatment process. The spinning and dyeing pretreatment auxiliary agent can shorten the flow of the conventional spinning and dyeing pretreatment process, can reduce the energy consumption and material consumption in the pretreatment process, and can reduce the effluent volume; an obtained intermediate product of textile fabrics has good whiteness, capillary effect and desizing percentage.

Owner:青岛先达精细化工有限公司

Technique for preparing oral liquid for alleviating fever and detoxifcation

The invention relates to a technology for preparing heat clearing and detoxifying oral liquid, which comprises the following steps: (1) extracting original liquid medicine; (2) further concentrating clear liquid produced through purifying the original liquid medicine to produce heat clearing and detoxifying extract; and (3) preparing the heat clearing and detoxifying extract into liquid medicine with flavouring and water, and filtering and concentrating the liquid medicine to produce the heat clearing and detoxifying oral liquid. Particularly, in step (2), the purification means to filter the original liquid medicine through an ultramicro filter membrane; in step (3), the filter is ultrafiltration membrane filter. Pre-extracted liquid medicine is effectively filtered through the ultramicro filter membrane so as to achieve nonalcoholic production, simplify technology, shorten production period, reduce energy consumption and production cost; meanwhile, prepared liquid medicine is subjected to terminal filtration through organic tubular type ultrafiltration membrane filtering technology so as to ensure the content of effective compositions, improve clarity of the liquid medicine, improve product quality, and ensure quality stability of the product.

Owner:苏州华辰净化股份有限公司

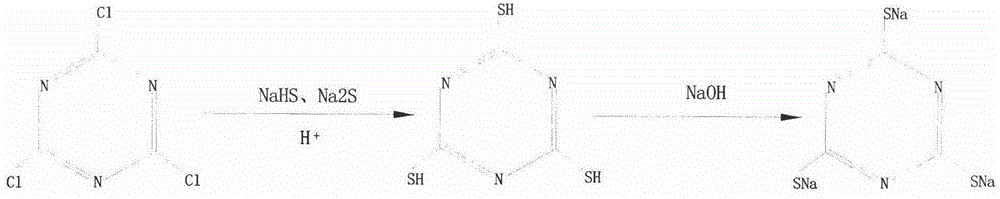

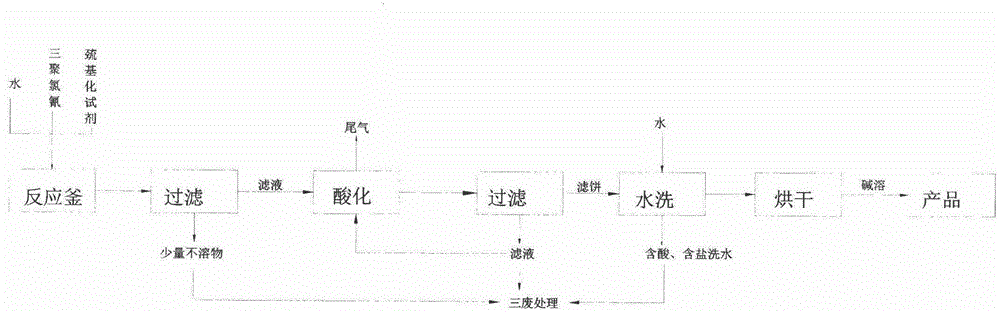

Method for preparing novel heavy metal capture agent

InactiveCN104529920ALess hydrolytic deteriorationTake advantage ofOrganic chemistryWater/sewage treatmentOrganic solventOrganic reaction

The invention discloses a method for preparing a novel heavy metal capture agent. The method includes the following steps that I, cyanuric chloride reacts on a sulfhydrylization reagent in water solutions at the temperature of 10 DEG C-70 DEG C, and the reaction time is 1-8 h; II, the PH is adjusted to be 10, and undissolved substances are filtered out; III, hydrochloric acid is added into a product in the step II for acidification, and then a large amount of sediments are obtained; IV, the sediments obtained in the step III are separated and are cleaned by water until the cleaned water is neutral, and the obtained sediment solids are dried; V, the sediments obtained in the step IV are dispersed in water and then are mixed with sodium hydroxide liquid, and therefore the novel heavy metal capture agent is obtained. According to the method, flammable and combustible organic solvents are not used, so production operation is safe; the concept of environment protection is penetrated in the method, unlike a traditional organic reaction which needs an additionally arranged solvent recovery device, the method is relatively lower in cost, and a good reaction effect can be obtained just through selection of pure water.

Owner:苏州国昆裕重金属处理技术有限公司

Solid-state heavy metal waste water treatment agent and application method thereof

ActiveCN104828925AReduce usageExcellent application effectOther chemical processesWater/sewage treatment by sorptionSodium BentoniteSesquioxide

The invention relates to a solid-state heavy metal waste water treatment agent and an application method thereof. The solid-state heavy metal waste water treatment agent comprises, by weight percentage, 35-65% of calcium bentonite, 5-15% of calcium oxide, 5-10% of magnesium oxide, 1-15% of iron sesquioxide, 2-10% of sodium carbonate and 2-15% of calcium hypochlorite. The application method includes: adding the solid-state heavy metal waste water treatment agent into waste water containing heavy metal ions, and continuously stirring for 5-60 minutes; then performing liquid-solid separation, and discharging water with the heavy metal being removed. By the method capable of treating the waste water, containing the heavy metal, of electroplating and etching liquid, the heavy metal content in the discharged water can reach below 0.5-1ppm, and the heavy metal removing rate in low- and medium-concentration waste water can reach more than 90-99%.

Owner:ZHEJIANG ZHENGJIE ENVIRONMENTAL SCI & TECH CO LTD

Preparation method of aluminum alloy surface film

ActiveCN110042381AImprove corrosion resistanceStop or delay erosionLiquid/solution decomposition chemical coatingCeriumSilicon dioxide

The invention relates to a preparation method of an aluminum alloy surface film, and belongs to the technical field of surface films. The aluminum alloy surface film is prepared by adding cerium, corrosion of the external corrosion atmosphere to the surface of a matrix material and permeation of corrosion liquid to a conversion film are effectively blocked or delayed, an aluminum alloy matrix is protected against corrosion, and the corrosion resistance of aluminum alloy is improved. As a silicon dioxide ceramic film is prepared on the surface of the aluminum alloy, the corrosion resistance ofthe aluminum alloy is improved, the chemical properties of silicon dioxide are stable, and the etching-resistant capacity is high; and sol-gel method equipment adopted for preparing the silicon dioxide ceramic film is simple, the sintering temperature is low, large workpieces can be coated, good repeatability is achieved, the grain diameter of coating components is controllable, dispersion of themolecular level among the components can be achieved, the surface of the aluminum alloy can be effectively coated with the silicon dioxide ceramic film, the aluminum alloy matrix can be effectively protected against corrosion, and therefore the use time of the aluminum alloy is prolonged.

Owner:瑞上兴通信信号器材连云港有限公司

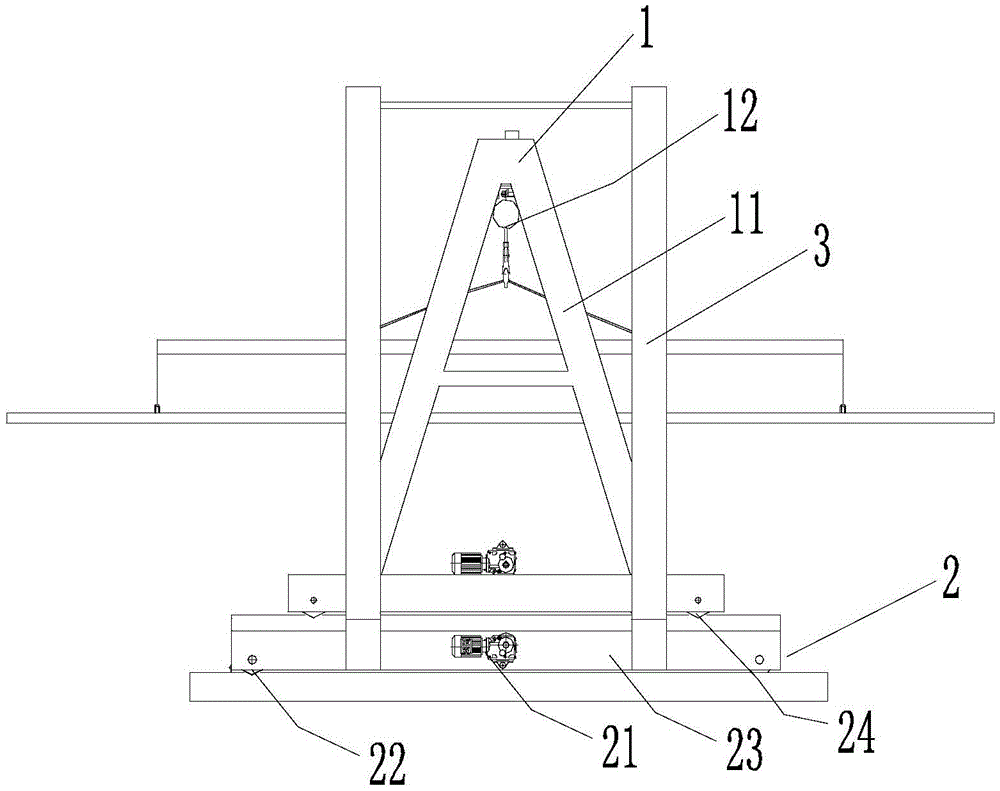

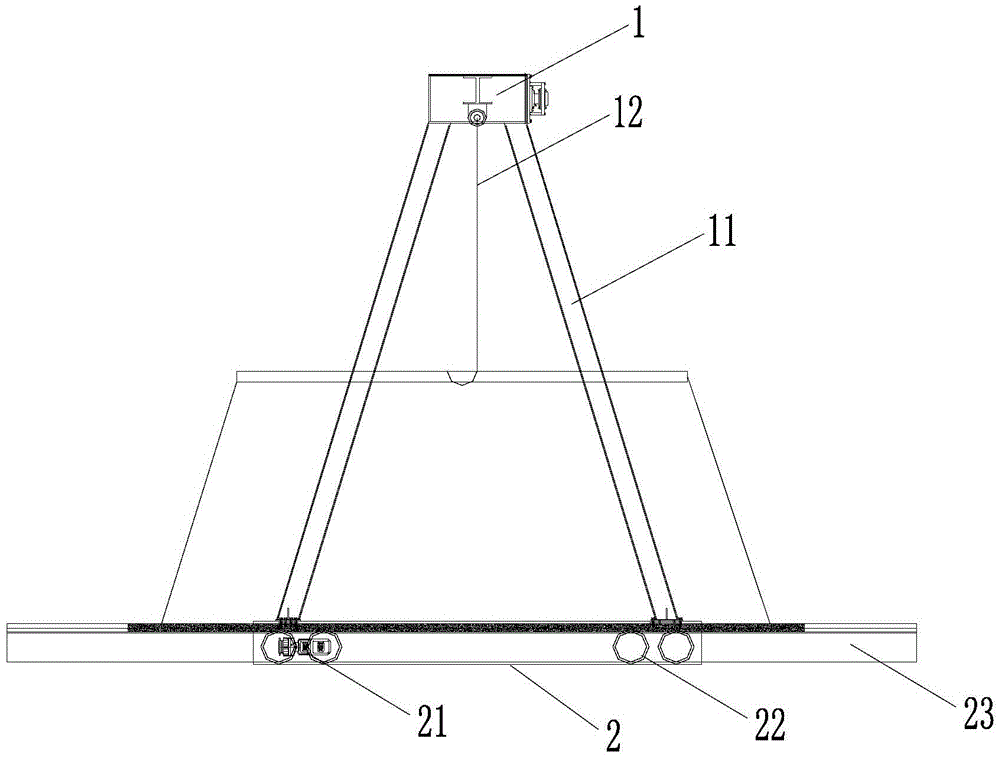

Fabricated part production and transport system

InactiveCN105480662ASmooth transitionProduction operation safetyMechanical conveyorsProduction lineTransport system

The invention provides a fabricated part production and transport system which comprises one or more fabricated part production and transport lines, each fabricated part production and transport line comprises a fabricated part transport cart, a transport rail, a fabricated part hoisting cart and a hoisting rail, the corresponding fabricated part transport cart and the corresponding fabricated part hoisting cart operate on the transport rail and the hoisting rail respectively, the width of the corresponding hoisting rail is larger than that of the corresponding transport rail, and the corresponding transport rail is arranged on the inner side of the corresponding hoisting rail; the corresponding fabricated part hoisting cart comprises a walking platform and a hoisting device, and the corresponding walking platform is arranged at the bottom of the hoisting device; the corresponding walking platform comprises two longitudinal walking supports, a second drive device and two or more groups of hoisting and walking wheels, the corresponding second drive device drives one or more of the hoisting and walking wheels to move on the hoisting rail, and the hoisting and walking wheels are arranged at the bottom of the longitudinal walking supports. In this way, hoisting and transferring time is reduced, and the occupied area of a production line site is saved.

Owner:CHINA MINSHENG ZHUYOU

Material peeling device with visual identification system and peeling method

PendingCN108876801AIncrease the yield of pulpProduction operation safetyImage enhancementImage analysisEngineeringLight source

The invention provides a material peeling device with a visual identification system and a material peeling method. The material peeling device comprise a supporting structure, a material fixing system, a cutter feeding and rotating system and the visual identification system; wherein the material fixing system comprises a first motor, a driving shaft and a telescopic screw rod. One end of the telescopic screw rod is driven by an air cylinder, the other end of the telescopic screw rod is connected with a rotating rod in a sleeved mode, and clamping pieces are fixedly arranged at the ends of the driving shaft and the rotating rod; and the cutter feeding and rotating system comprises a cutter feeding system and a cutter rotating system. The visual identification system comprises a light source system, a contour line sensing system and a control system. According to the device and method, the peeling thickness is constant and adjustable, and full-automatic peeling of roots, stems and fruits, particularly materials with hard skin such as gold-jujube persimmons is realized. The pulp yield is remarkably improved, and the production operation is safe and environment-friendly. The device is simple in structure, high in stability and high in reliability, and can be applied to occasions with different production batch requirements of families and enterprises.

Owner:丽水市莲都区山水果树研究所 +1

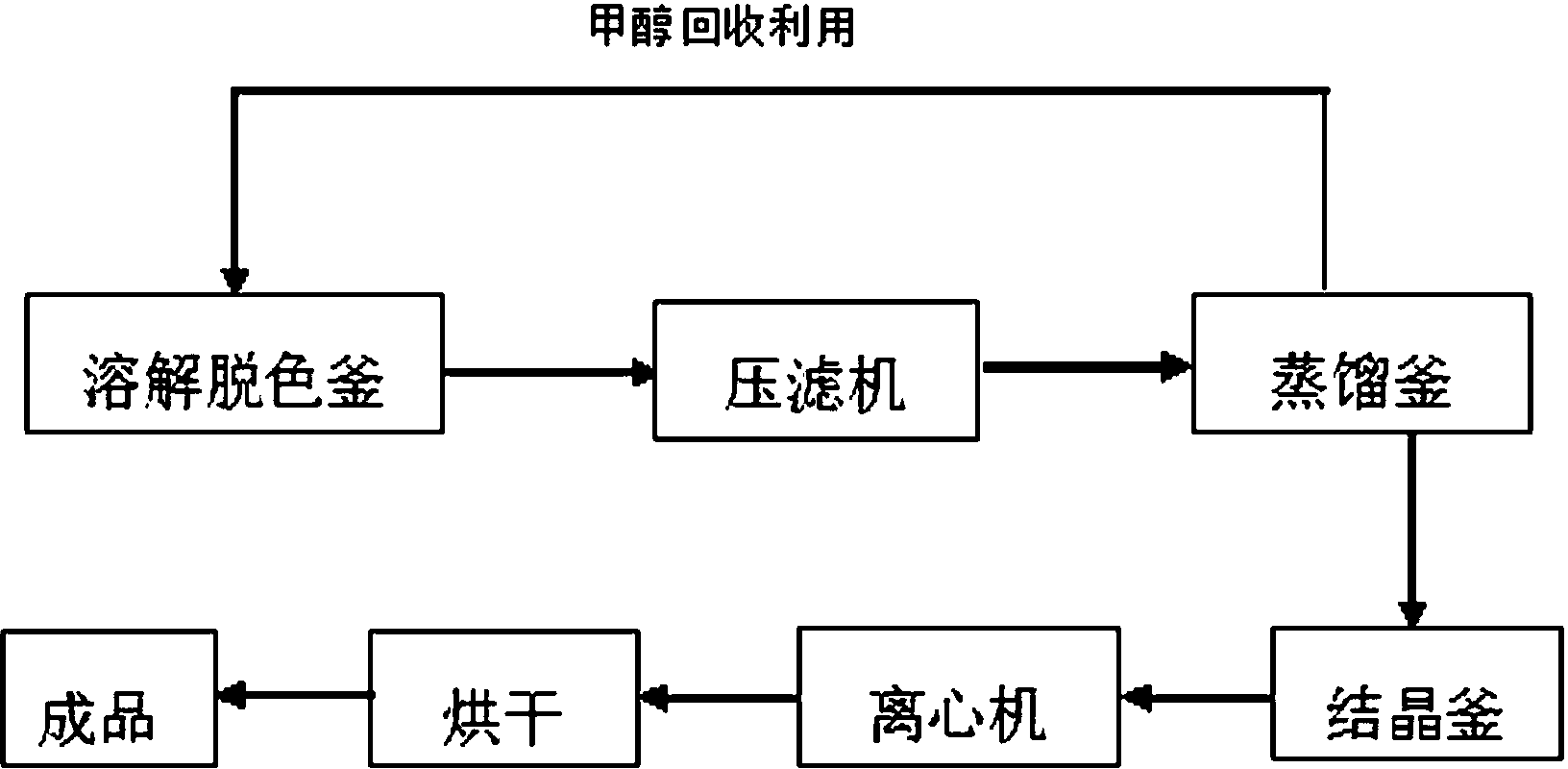

Decolorization method of pyridinium finished product

ActiveCN104341337AProduction operation safetyImprove working environmentOrganic chemistryActivated carbonPyridinium

The invention relates to a decolorization method of a pyridinium finished product, which comprises the following steps: 1) adding a pyridinium finished product to be decolorized and methanol into a reaction kettle in a weight ratio of 1:1.5, heating to 50 DEG C, stirring for half an hour until all the material is completely dissolved, adding activated carbon which accounts for 1 wt% of the pyridinium finished product, and continuing stirring for half an hour to perform decolorization; 2) after the decolorization, completely extruding out the activated carbon by using a press filter, sending the filtrate into a distillation kettle, and distilling to recover the methanol; and 3) after drying off the methanol by distillation, adding ethanol to recrystallize, centrifugating to obtain the finished product, and drying to obtain the high-quality product. When being used for decolorizing the pyridinium, the method is safer in the production operation process, obviously improves the working environment, can recover the methanol, and thus, has lower consumption of methanol.

Owner:ANHUI JINGHE IND

Construction and application of an engineered bacterium that secretes and expresses chitobiose deacetylase

ActiveCN109777761BHigh expressionSimplify separation and purification stepsOrganic active ingredientsBacteriaHeterologousProtein target

The invention discloses the construction and application of an engineering bacterium that secretes and expresses chitobiose deacetylase, and belongs to the technical field of fermentation engineering. The present invention first constructs a recombinant Bacillus subtilis strain heterologously secreting and expressing the chitobiose deacetylase gene, and adds a signal peptide fragment yncM to the recombinant vector for the first time, and the signal peptide can convert the target protein chitobiose deacetylase It is secreted outside the cells of the recombinant Bacillus subtilis and obtains a mutant of the 5' untranslated region, which significantly increases the expression of the target protein and greatly simplifies the steps of subsequent enzyme separation and purification. The obtained chitobiose deacetylase has the highest enzyme activity of 1548.7U / mL when fermented and cultivated in the fermentation medium for 50-60 hours, and the highest chitobiose deacetylase yield is about 620mg / L. At the same time, the method has the advantages of low production cost, mild production conditions, simple purification process steps, safe production operation and the like.

Owner:JIANGNAN UNIV +1

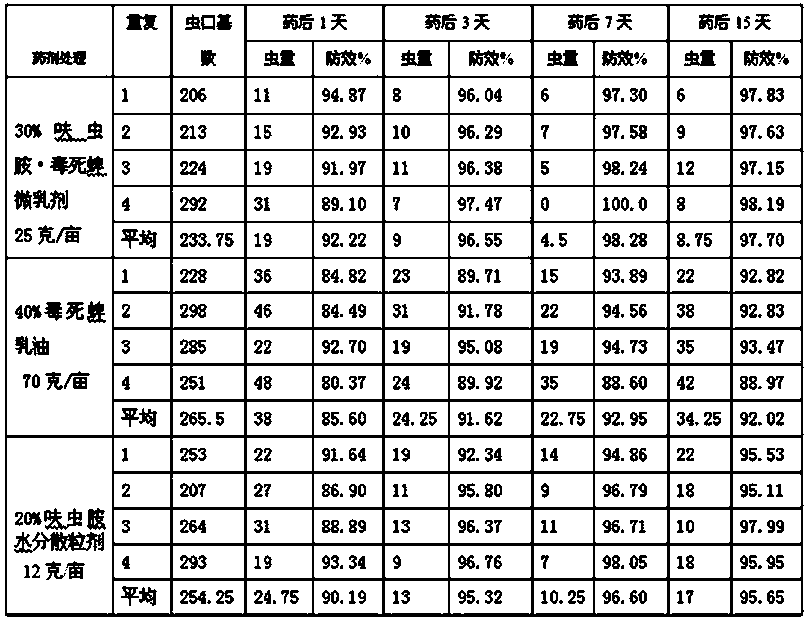

Dinotefuran-containing pesticide

InactiveCN103444772AHigh activityExpand insecticidal spectrumBiocideAnimal repellantsChlorpyrifosInsect pest

The invention relates to a dinotefuran-containing pesticide belonging to the field of agricultural insecticides. The dinotefuran-containing pesticide comprises effective ingredients of dinotefuran and chlorpyrifos with the weight ratio of (1:50)-(50:1), wherein the total weight of the dinotefuran and the chlorpyrifos accounts for 1-50 percent of the pesticide. The dinotefuran-containing pesticide is capable of controlling multiple kinds of insect pests, and has a remarkable synergism; an insecticidal spectrum is enlarged, the pesticide dosage is reduced, the residual quantity of the pesticide on crops is lowered, and the environmental pollution is lightened. The dinotefuran-containing pesticide has relatively high activity on rice planthoppers, rice leaf folders and striped rice borers, is safe to people and livestock, and is good in environment consistency; the pests hard generate pesticide resistance.

Owner:陆学云

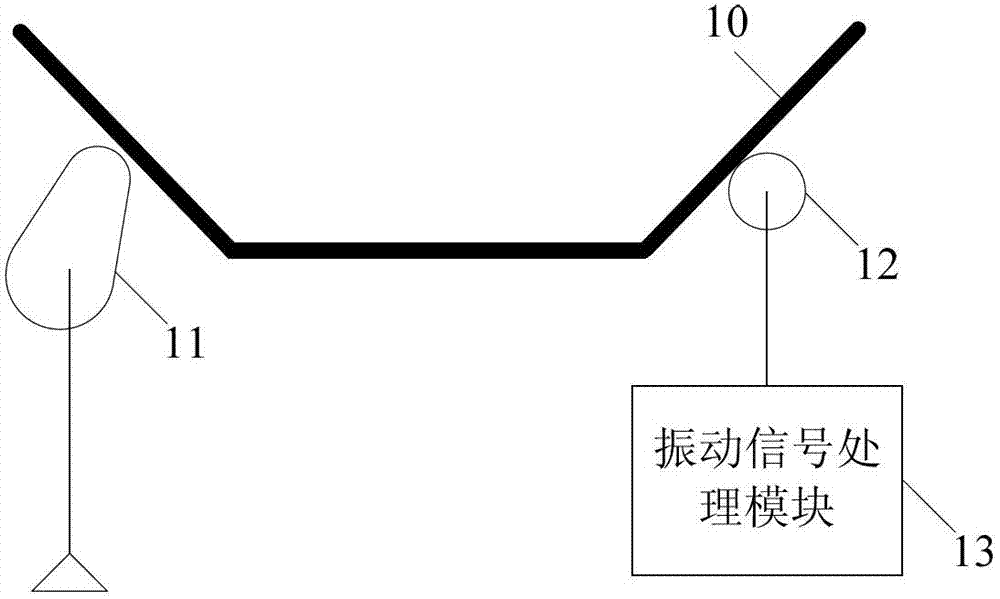

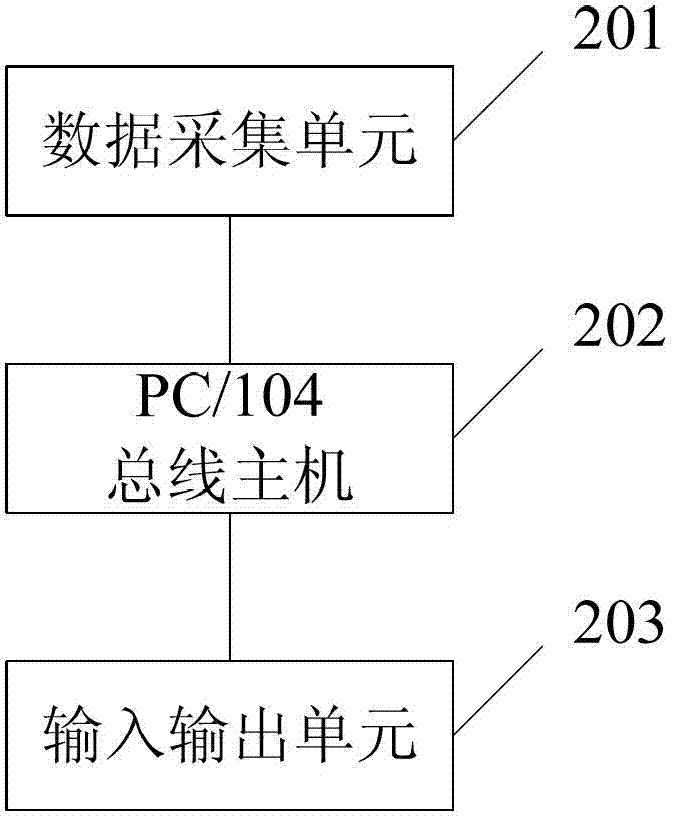

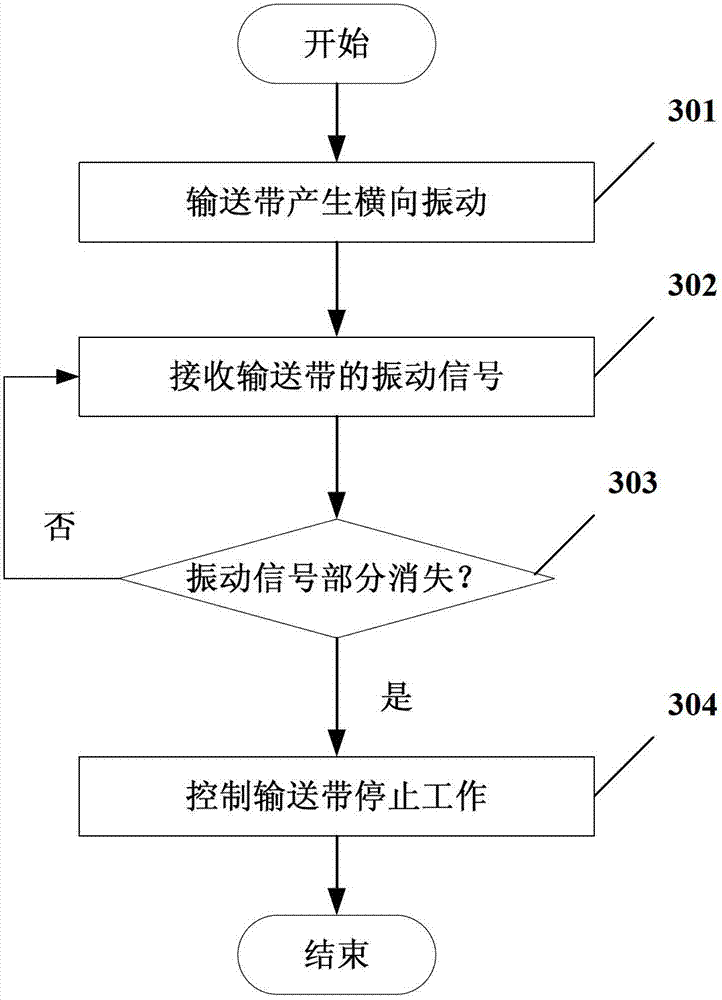

Device and method for monitoring longitudinal tear of conveying belt

InactiveCN103112704AAvoid damageProduction operation safetyControl devices for conveyorsTransverse vibrationVibration source

The invention discloses a device and a method for monitoring longitudinal tear of a conveying belt. The device comprises a vibration source, a vibration signal receiving module and a vibration signal processing module. The vibration source is used for allowing the conveying belt to generate transverse vibration. The vibration signal receiving module is used for receiving vibration signals generated by the conveying belt under the action of the vibration source and transmitting the vibration signals to the vibration signal processing module. The vibration signal processing module is used for judging whether longitudinal tear occurs or not according to the vibration signals and controlling the conveying belt to stop when longitudinal tear occurs. By the device, the convey belt can be stopped timely when longitudinal tear of the conveying belt occurs, and accordingly safe production is guaranteed, safety accidents caused by longitudinal tear of the conveying belt can be avoided, and damage to conveying devices can be avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com