Preparation method and application of low toxicity acidizing corrosion inhibitor

A technology of acidifying corrosion inhibitor and solvent, which is applied in the preparation of organic compounds, chemical instruments and methods, earth drilling and mining, etc. It can solve the problems of large environmental pollution, easy delamination, poor dissolution and dispersion performance, etc., and reduce the corrosion rate , Anti-corrosion, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

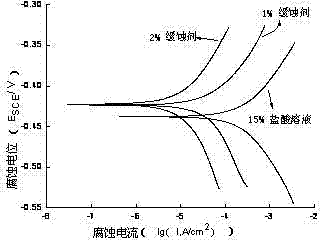

Embodiment 1

[0024] Mix 12.56g of N-methylcyclohexylamine, 26.44g of cinnamaldehyde and 5.46g of isopropanol into a three-necked flask, then slowly add 15.62g of acetophenone dropwise, stir evenly, and adjust the pH to 4 with hydrochloric acid. React at ~95°C for 7 hours, and the Mannich base can be obtained after the system is cooled. Take out 15g of the Mannich base and put it into a three-necked flask, slowly add 18g of benzyl bromide dropwise, react at 84-93°C for 3h, and cool down to room temperature to obtain the Mannich base quaternary ammonium salt. Take out 15g of Mannich base quaternary ammonium salt and 85g of methanol and stir evenly to obtain the corrosion inhibitor of the present invention, which is designated as corrosion inhibitor sample A. Wherein the Mannich base quaternary ammonium salt molecular formula is:

[0025]

Embodiment 2

[0027] Mix 11.42g of N-methylcyclohexylamine, 26.44g of cinnamaldehyde and 4.99g of isopropanol into a three-necked flask, then slowly add 12.02g of acetophenone dropwise, stir evenly, and adjust the pH to 4 with hydrochloric acid. React at ~98°C for 5 hours, and the Mannich base can be obtained after the system is cooled. Take out 15g of the Mannich base and put it into a three-necked flask, slowly add 15g of benzyl chloride dropwise, react at 86-95°C for 2h, and cool down to room temperature to obtain the Mannich base quaternary ammonium salt. Take out 17g of Mannich base quaternary ammonium salt and 83g of absolute ethanol and stir evenly to obtain the corrosion inhibitor of the present invention, which is designated as corrosion inhibitor sample B. Wherein the Mannich base quaternary ammonium salt molecular formula is:

[0028]

Embodiment 3

[0030] Mix 14.85g of N-methylcyclohexylamine, 26.44g of cinnamaldehyde and 5.45g of isopropanol into a three-necked flask, then slowly add 13.22g of acetophenone dropwise, stir evenly, and adjust the pH to 4 with hydrochloric acid. React at ~100°C for 6 hours, and the Mannich base can be obtained after the system is cooled. Take out 15g of the Mannich base and put it into a three-necked flask, slowly add 19.5g of benzyl chloride dropwise, react at 83~89°C for 4h, and cool down to room temperature to obtain the Mannich base quaternary ammonium salt. Take out 20g of Mannich base quaternary ammonium salt, 70g of methanol and 10g of dimethylformamide and stir evenly to obtain the corrosion inhibitor of the present invention, which is designated as corrosion inhibitor sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com