Integrative ground horizontal circular flexible production line for assembling and checking out motorcycle

A flexible production line and motorcycle technology, applied in the fields of motor vehicles, transportation and packaging, can solve the problems of inconvenient and timely detection and control of assembly quality, unsuitable for multi-variety and small batch production, affecting the work efficiency of production lines, etc. The effect of layout and logistics optimization, flexible and convenient operation, and convenient production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

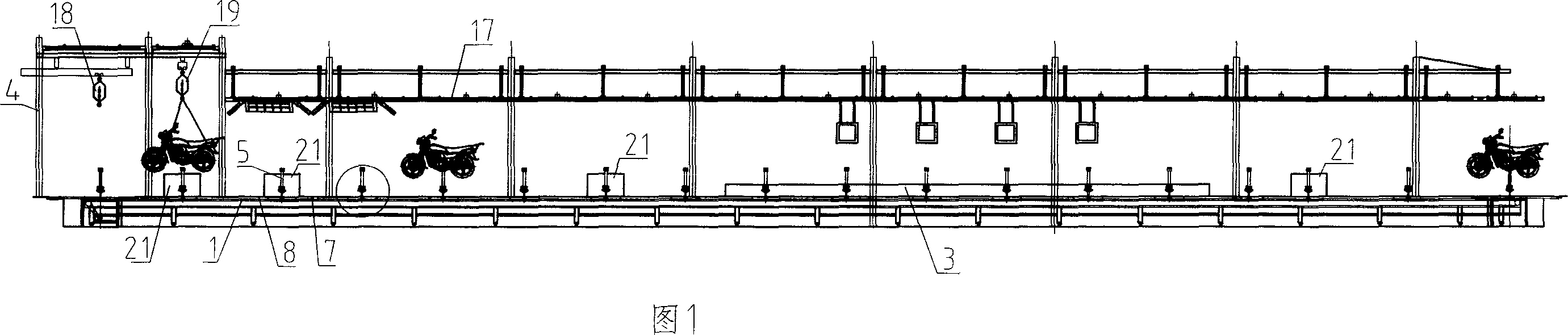

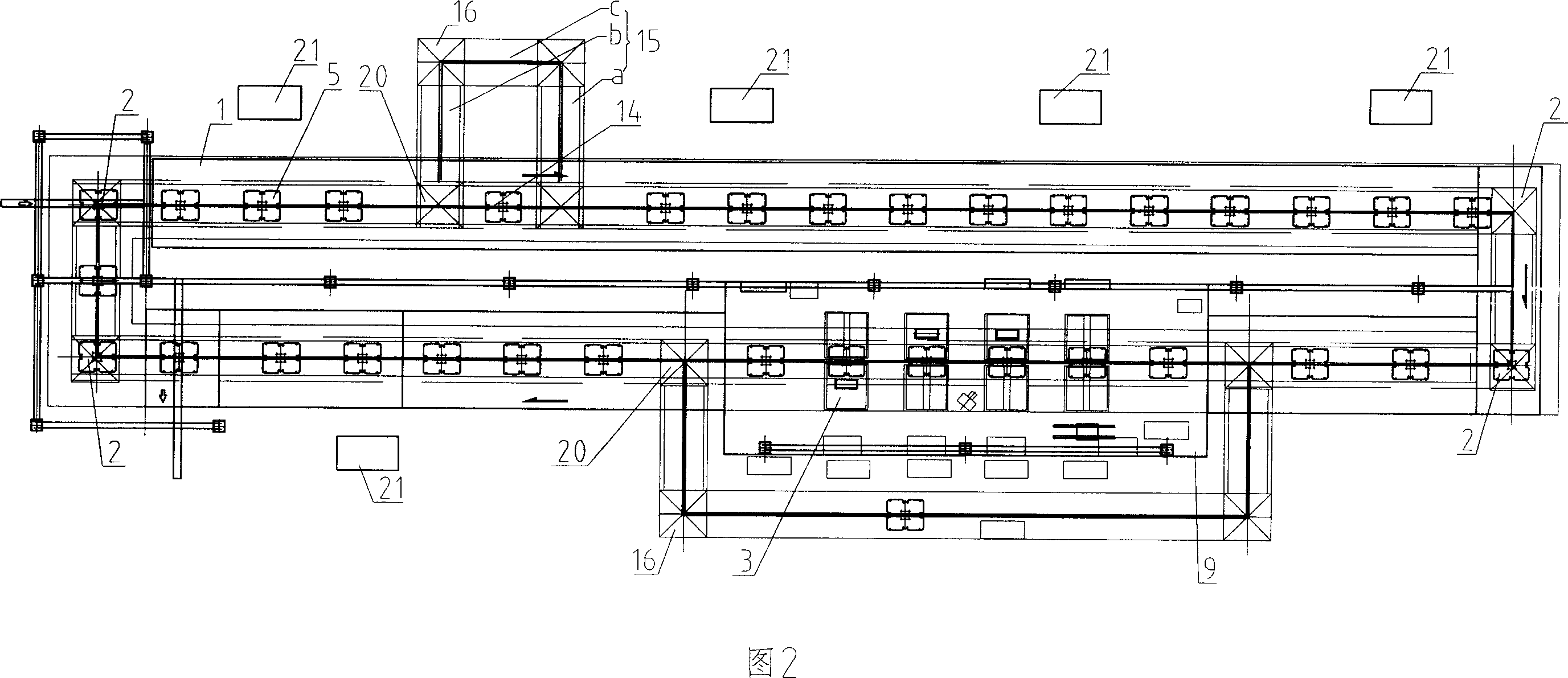

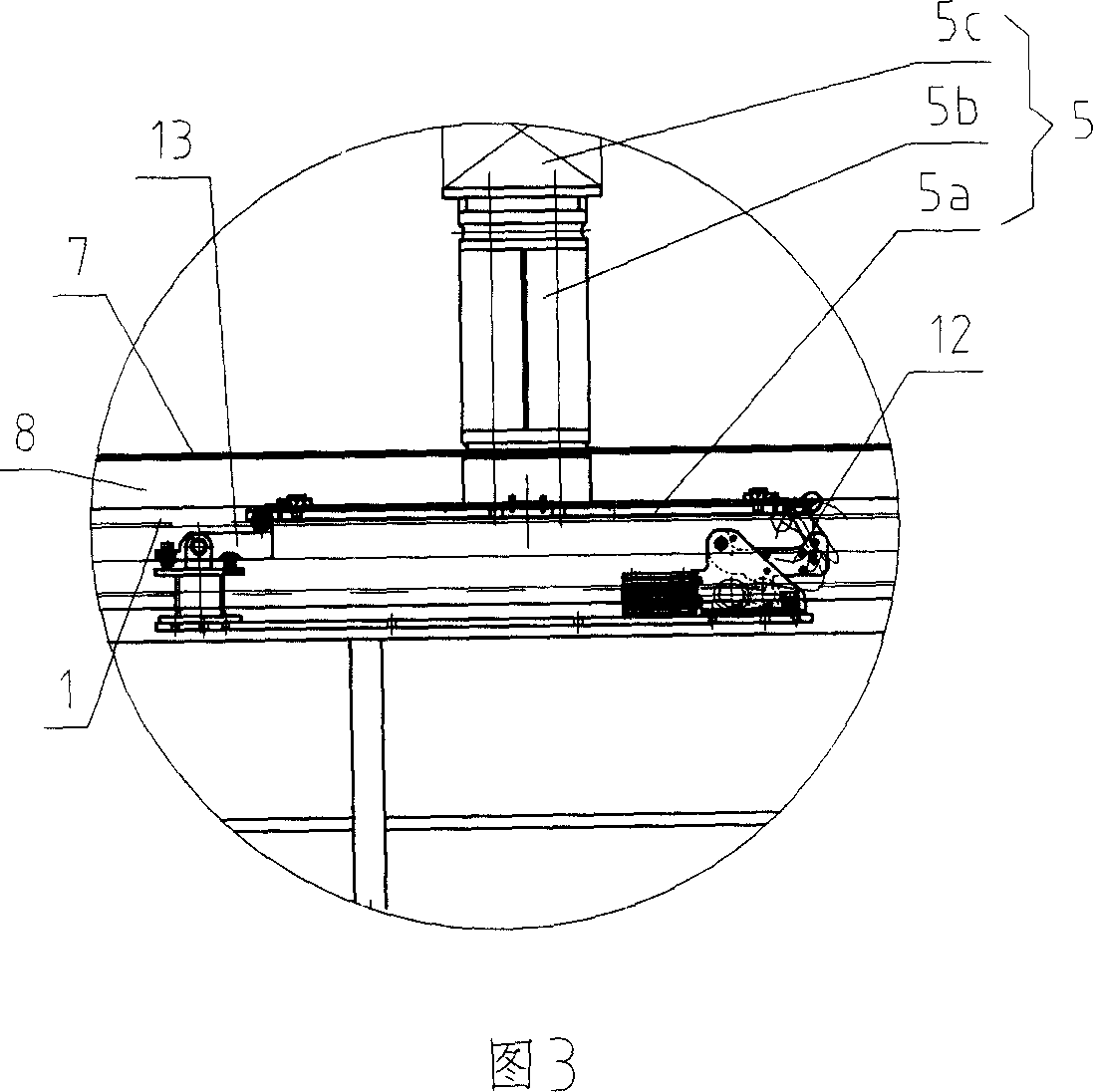

[0022] Referring to Fig. 1 and Fig. 2, the motorcycle assembly and testing integrated ground horizontal circulation flexible production line includes a main line 1, a performance testing system 3 and a part assembly workbench 21. The main line 1 is a roller chain conveyor line and is arranged under the ground 7. The entire main line 1 is distributed in a rectangular closed circuit along the horizontal direction. The main line 1 is not exposed on the ground, which makes the production operation more convenient and safe. The rectangular closed layout makes the main line 1 The length of the assembly workshop is greatly shortened, the assembly area and temporary material storage space are more compact, and the site is enlarged. The partial assembly workbench 21 is arranged at the position corresponding to the corresponding station next to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com