Processing device of thin-diameter thin-wall metal elbow

A processing device and thin-walled technology, which is applied in the field of processing devices for small-diameter and thin-walled metal elbows, can solve the problems affecting product safety, reliability, appearance quality, poor dimensional accuracy, and local wall thickness thinning. The effect of high practical value, low cost and complete specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

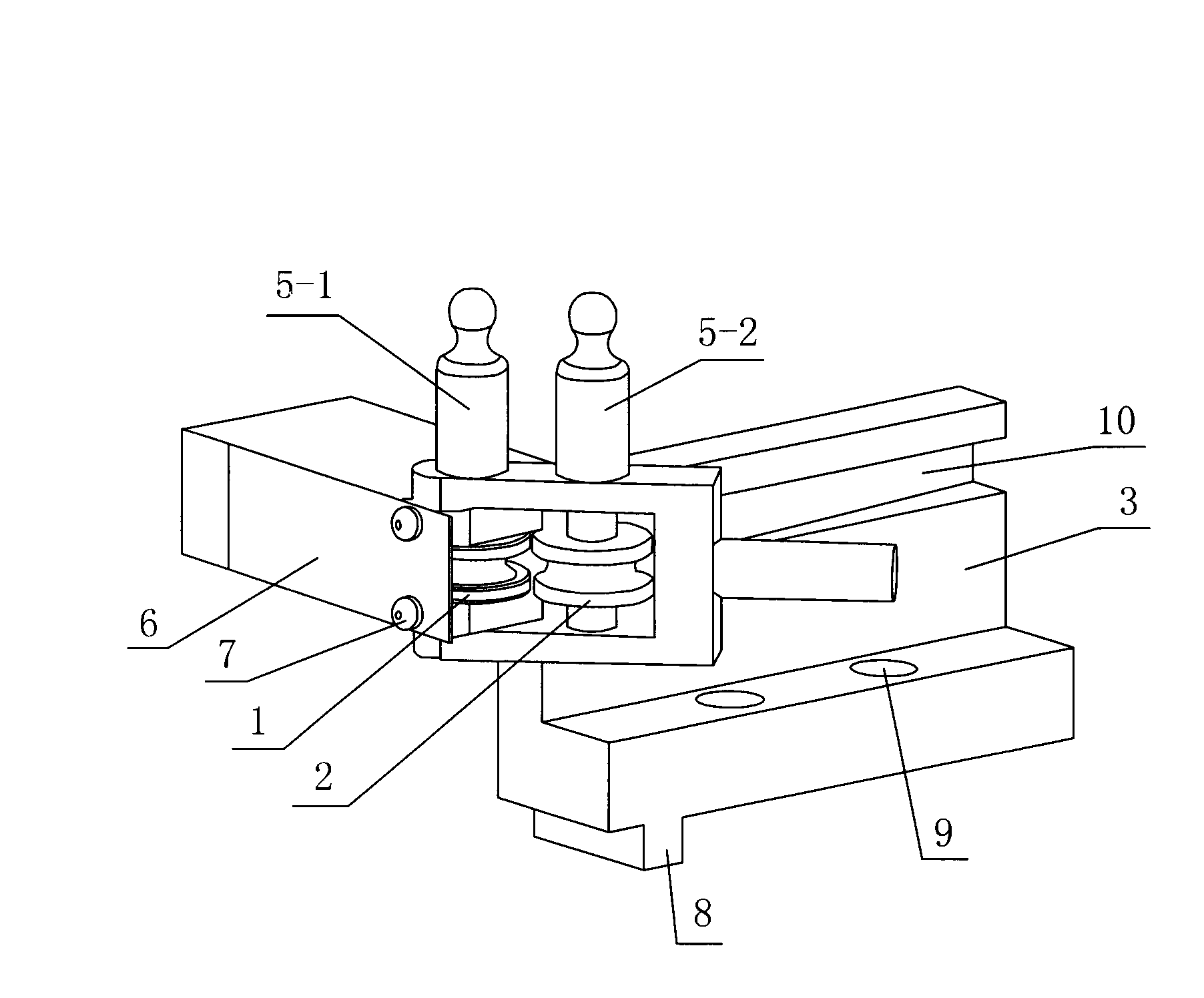

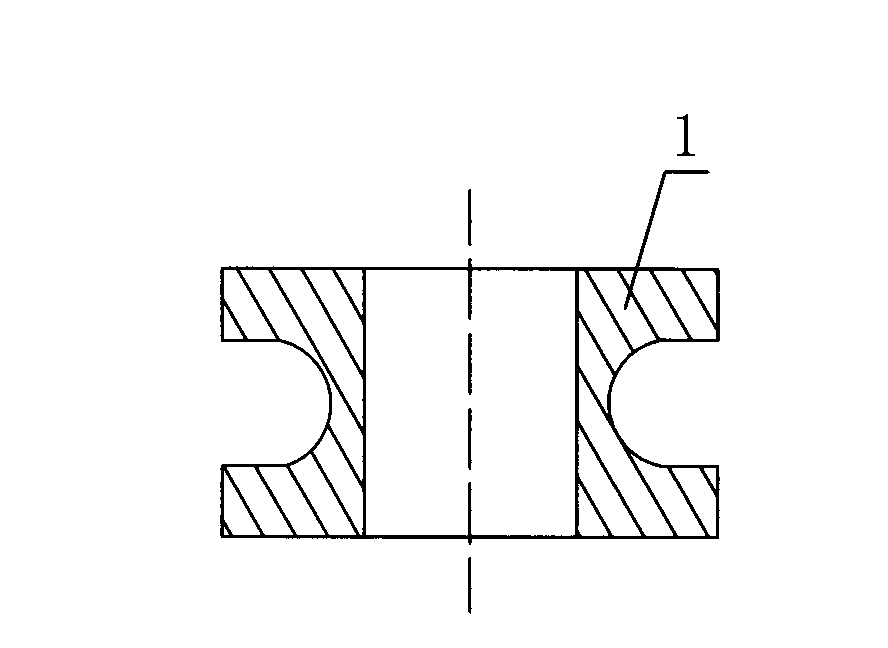

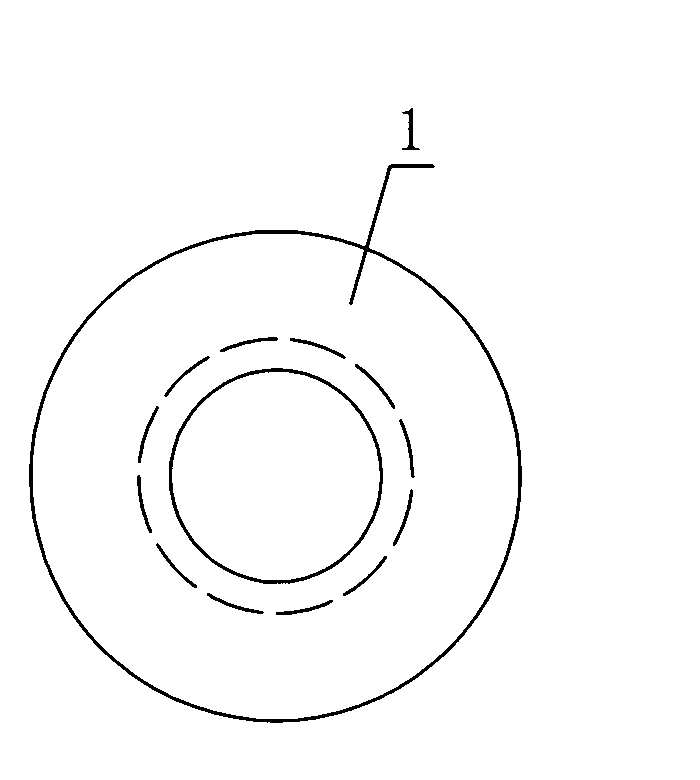

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a base 3 fixedly installed on the workbench, a guide wheel-1 that is movably installed on the base 3 and can rotate around its central axis, is installed on the base 3 through a movable connector and can move around the The handle 4 that the connector rotates left and right, the guide wheel 2 installed in the slot in the middle of the handle 4, and the baffle 6 that is fixed on the base 3 and ensures that the bent pipe does not move radially during the bending process, said Both the first guide wheel 1 and the second guide wheel 2 are provided with forming circular arc grooves with the same diameter as the bent pipe material along the circumferential direction, and the forming circular arc grooves provided by the two are located on the same horizontal line. The rear end of the blocking piece 6 is fixed on the outer side of the joint between the upper and lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com