Method for preparing novel heavy metal capture agent

A heavy metal scavenger, a new type of technology, used in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of less hydrolysis and deterioration, small temperature change range, and good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

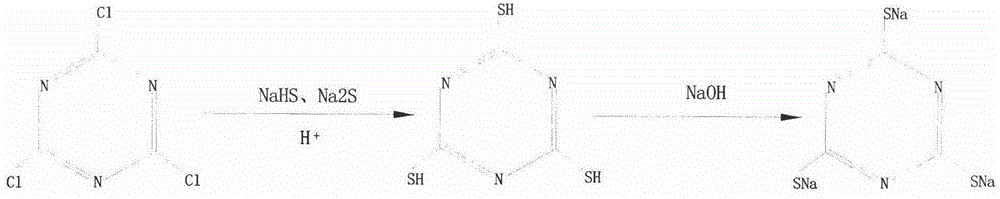

Method used

Image

Examples

Embodiment 1

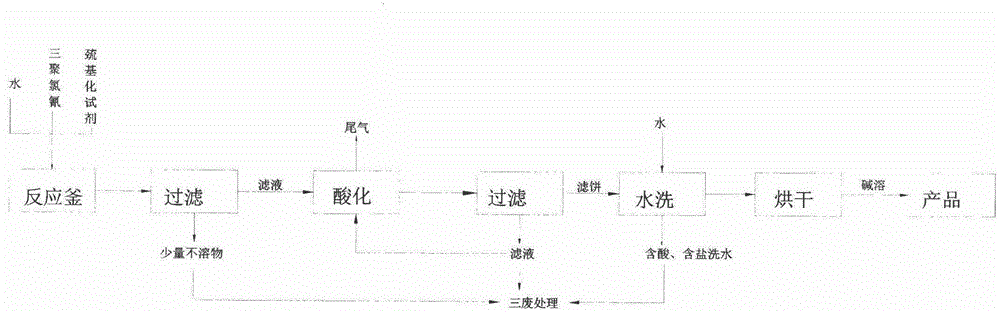

[0028] Mix 1000g pure water, 1g emulsifier, 200gNa 2 S (purity of 60%) was mixed, and the insolubles were filtered off to obtain Na 2 S liquid; dissolve 600g NaSH (purity of 70%) with 1000g pure water, filter out the insoluble matter, get NaSH liquid; 2 Add NaSH liquid dropwise to S, and at the same time, slowly add 500 g of cyanuric chloride (purity of 99.5%), stir, and control the temperature not to exceed 12 °C; after adding, stir for another half an hour, and heat the reactant to 70 °C Stir, keep the temperature for 3h; after the insulation, lower the mixture to room temperature, adjust the pH to 10 with NaOH, and separate the insolubles by filtration; add 15% HCl solution dropwise to the filtrate, add and stir for 2 hours, and adjust the pH to 2-3, divide the water to obtain the solid; wash the obtained solid with pure water until the effluent pH=7, and then dry the solid; weigh 100 g of the obtained solid and disperse it in 350 g of pure water, and then mix it fully wit...

Embodiment 2

[0032] Mix 900g pure water, 1.2g emulsifier, 180gNa 2 S (purity of 60%) was mixed, and the insolubles were filtered off to obtain Na 2 S liquid; dissolve 620g NaSH (purity of 70%) with 1100g pure water, filter off the insolubles, get NaSH liquid; 2 S was added dropwise with NaSH solution, and at the same time, 500 g of cyanuric chloride (purity of 99.5%) was slowly added, stirred, and the temperature was controlled not to exceed 12 °C; Stir, keep the temperature for 3h; after the insulation, lower the mixture to room temperature, adjust the pH to 10 with NaOH, and separate the insolubles by filtration; add 12% HCl solution dropwise to the filtrate, add and stir for 2 hours, and adjust the pH to 2-3, divide the water to obtain the solid; wash the obtained solid with pure water until the effluent pH=7, and then dry the solid; weigh 100 g of the obtained solid and disperse it in 350 g of pure water, and then mix it fully with 350 g of 30% NaOH solution by mass. , stir to dissol...

Embodiment 3

[0036] Mix 800g of pure water, 1.5g of emulsifier, and 160g of Na2S (purity of 60%), filter out insoluble matter to obtain Na2S solution; dissolve 640g of NaSH (purity of 70%) with 1200g of pure water, filter out insoluble matter to obtain NaSH liquid; to Na 2 Add NaSH liquid dropwise to S, and at the same time, slowly add 500 g of cyanuric chloride (purity of 99.5%), stir, and control the temperature not to exceed 12 °C; Stir and keep warm for 3 hours; after keeping warm, lower the mixture to room temperature, adjust the pH to 10 with NaOH, and separate the insolubles by filtration; add 10% HCl solution dropwise to the filtrate, and stir while adding for 2 hours to adjust the pH To 2-3, divide the water to obtain a solid; wash the obtained solid with pure water until the effluent pH=7, and then dry the solid; weigh 100 g of the obtained solid and disperse it in 350 g of pure water, and then mix it with 350 g of a 30% NaOH solution by mass, fully. Mix, stir to dissolve, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com