Water-emulsion-type high-efficiency terminator for polyvinyl chloride and preparation method thereof

A polyvinyl chloride and water-emulsion type technology, which is applied in the field of water-emulsion type high-efficiency terminator in the polyvinyl chloride polymerization process and its preparation, can solve the problems of affecting the safety of use, damage to users, injury to environmental operators, etc. Improved safety, improved thermal stability, and strong termination of polymerization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

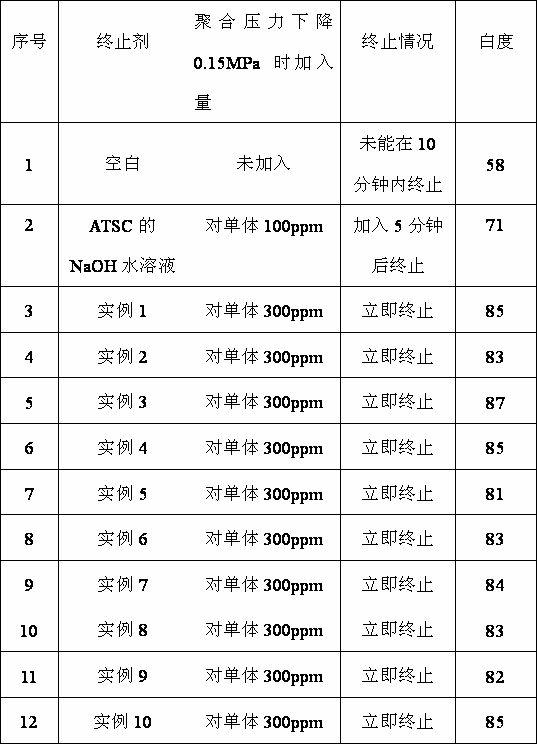

Examples

Embodiment 1

[0025] 1. Take raw materials according to the following formula: 13kg of organic solvent with terminating effect, 18kg of high-efficiency anti-aging agent, 10kg of plasticizer, 3kg of heat stabilizer, 3kg of emulsifier, and 0.6kg of emulsion stabilizer; Wherein, the organic solvent with terminating effect is a-methylstyrene; the high-efficiency anti-aging agent is bis(2,4-di-tert-butylphenyl) pentaerythritol bis-diphosphite; Plasticizer is dioctyl phthalate; Described thermal stabilizer is dioctyltin maleate; Described emulsion stabilizer is polyvinyl alcohol 1788; Described emulsifier is sodium lauryl sulfate and NPE-10 combination, wherein the dosage of sodium lauryl sulfate is 0.3kg, and the dosage of NPE-10 is 2.7kg.

[0026] The high-efficiency anti-aging agent described in this embodiment can also be N,N-diethylhydroxylamine or β(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate or 2,4 ,6-tri-tert-butylphenol or tris(2·4-di-tert-butylphenyl)phosphite or 2,6-di-ter...

Embodiment 2

[0033] The raw materials are weighed according to the following formula: 16kg of organic solvent with terminating effect, 15kg of high-efficiency anti-aging agent, 12kg of plasticizer, 4kg of heat stabilizer, 2kg of emulsifier, and 0.2kg of emulsion stabilizer; The organic solvent with termination effect is a-methylstyrene; the high-efficiency anti-aging agent is N,N-diethylhydroxylamine and bis(2,4-di-tert-butylphenyl)pentaerythritol bis-di Phosphite, wherein N,N-diethylhydroxylamine 7kg, two (2,4-di-tert-butylphenyl) pentaerythritol bis-diphosphite 8kg; the plasticizer is epoxy soybean oil; the The thermal stabilizer is calcium benzoate; the emulsion stabilizer is polyvinyl alcohol 1788; the emulsifier is a combination of emulsifier MOA-4 and MOA-9, wherein MOA-4 accounts for 0.5kg, and MOA-9 accounts for 1.5kg kg.

[0034] The preparation method is basically the same as in Example 1, except that the mass of water is 50.8 kg during the dissolution and mixing of the water ph...

Embodiment 3

[0036]Take raw materials by following formula: take the organic solvent that has termination function as 10kg, efficient anti-aging agent as 22kg, plasticizer as 8kg, thermal stabilizer as 2kg, emulsifier as 5kg, emulsion stabilizer as 1kg; Wherein, all The organic solvent with terminating effect is a-methylstyrene; the high-efficiency anti-aging agent is N,N-diethylhydroxylamine, bis(2,4-di-tert-butylphenyl)pentaerythritol bis-diethylene Phosphate and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, of which N,N-diethylhydroxylamine accounted for 7kg, bis(2,4-di-tert-butyl phenyl) pentaerythritol bis-diphosphite accounts for 7kg, and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester accounts for 8kg; the plasticizer is trioctyl phosphate ester; the heat stabilizer is zinc abietate; the emulsion stabilizer is polyvinyl alcohol 1788; the emulsifier is sorbitan monostearate, polyoxyethylene sorbitan monostearate Fatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com