Decolorization method of pyridinium finished product

A technology for finished salt products and pyridine, applied in the field of decolorization of pyridine salt products, can solve the problems of poor operating environment, high risk and high consumption of finished products, and achieve the effects of improved working environment, safe production and operation process and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

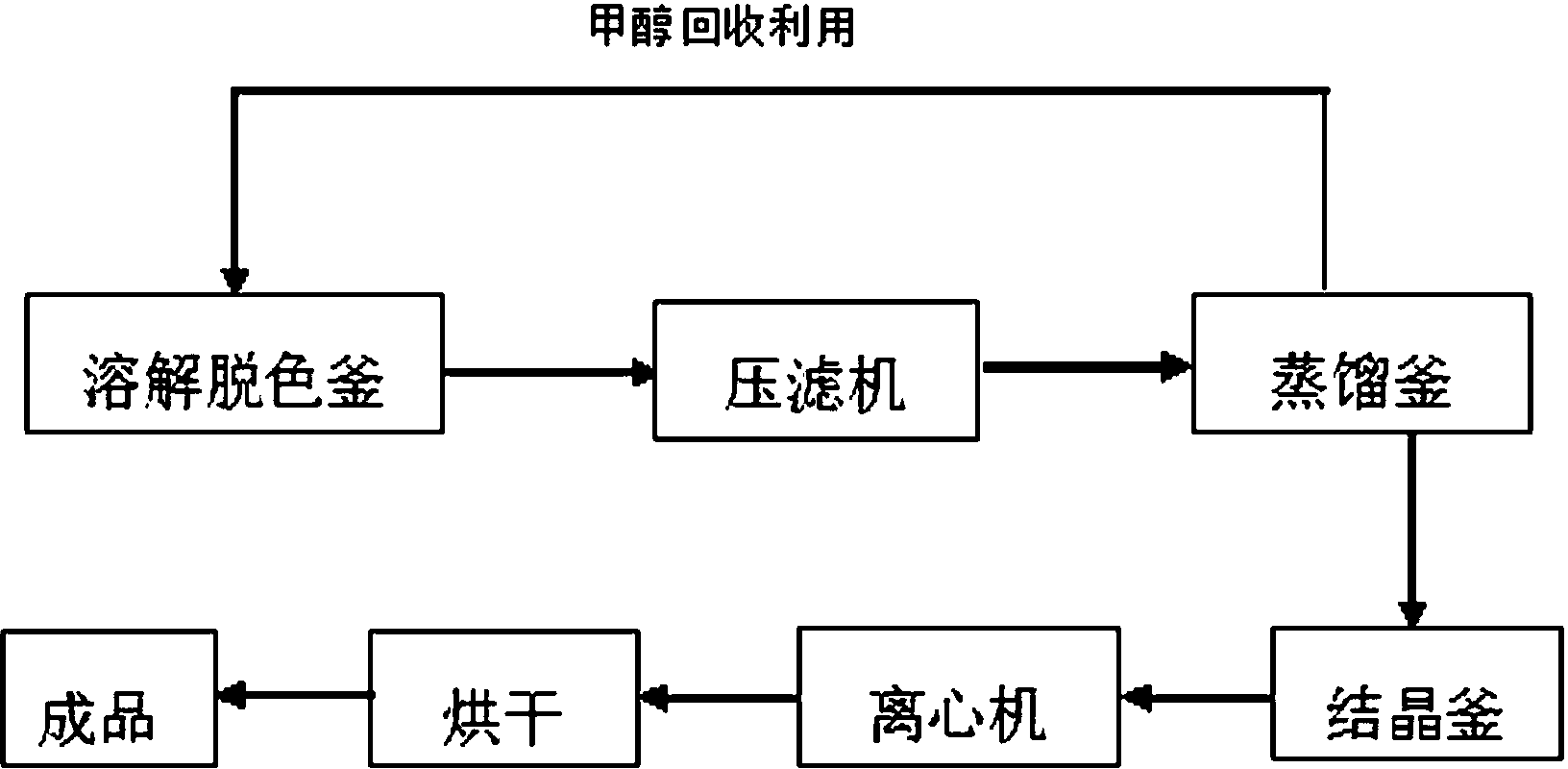

Image

Examples

Embodiment Construction

[0012] Put 500kg of finished pyridinium salt and 750kg of methanol into a 5000L jacketed glass-lined reactor, raise the temperature to 50°C and stir for 0.5 hours, then add 5kg of activated carbon, continue stirring for 0.5 hours, press out the activated carbon with a filter press, and The filtrate is sent to the distillation kettle, and the methanol is recovered by distillation at 0.09MPa and 35°C. After the methanol is evaporated to dryness, add 600kg of absolute ethanol, heat up to 50°C and keep it for 2 hours, then move to the crystallization kettle to cool down and crystallize, and then use a centrifuge to shake the material , After getting the wet product, dry it to get about 450kg of finished product with a content of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com