Patents

Literature

117results about How to "Simplify separation and purification steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of agarose immune magnetic microspheres and applications thereof

ActiveCN103212377ASeparation does not affectEliminate the pre-filtering stepOther chemical processesImmunoglobulins against cell receptors/antigens/surface-determinantsMicrosphereGenetic engineering

The invention discloses a preparation method of agarose immune magnetic microspheres and applications thereof, and relates to a preparation method of microspheres and applications thereof, which solves the technical problems that an existing purified monoclonal antibody is complex in process, is low in yield, and is high in cost, and coupling agents are hypertoxic. The preparation method comprises the following steps of: 1. preparing a ferric oleate precurser; 2. preparing a magnetic fluid; 3. preparing an oil phase and a water phase; 4. preparing agarose magnetic microspheres; 5. preparing activated and crosslinked agarose magnetic microspheres; 6. preparing agarose magnetic microspheres joined with spacer arms; and 7. preparing agarose immune magnetic microspheres. The agarose immune magnetic microspheres provided by the invention are used for purifying genetic engineering recombination trastuzumab monoclonal antibodies. The agarose immune magnetic microspheres prepared by the invention are used for the field of separating and purifying the monoclonal antibodies.

Owner:HARBIN YICAI NEW MATERIAL

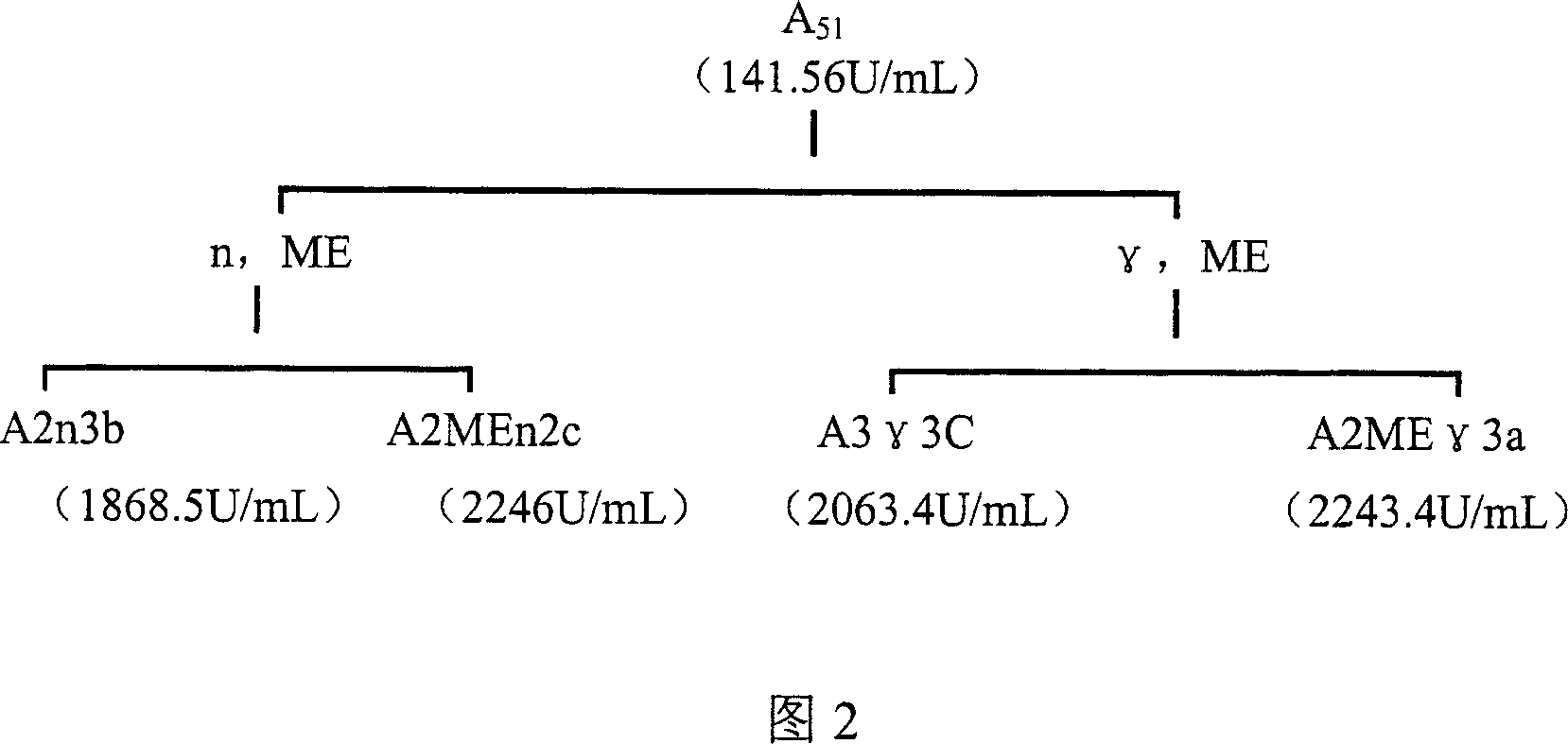

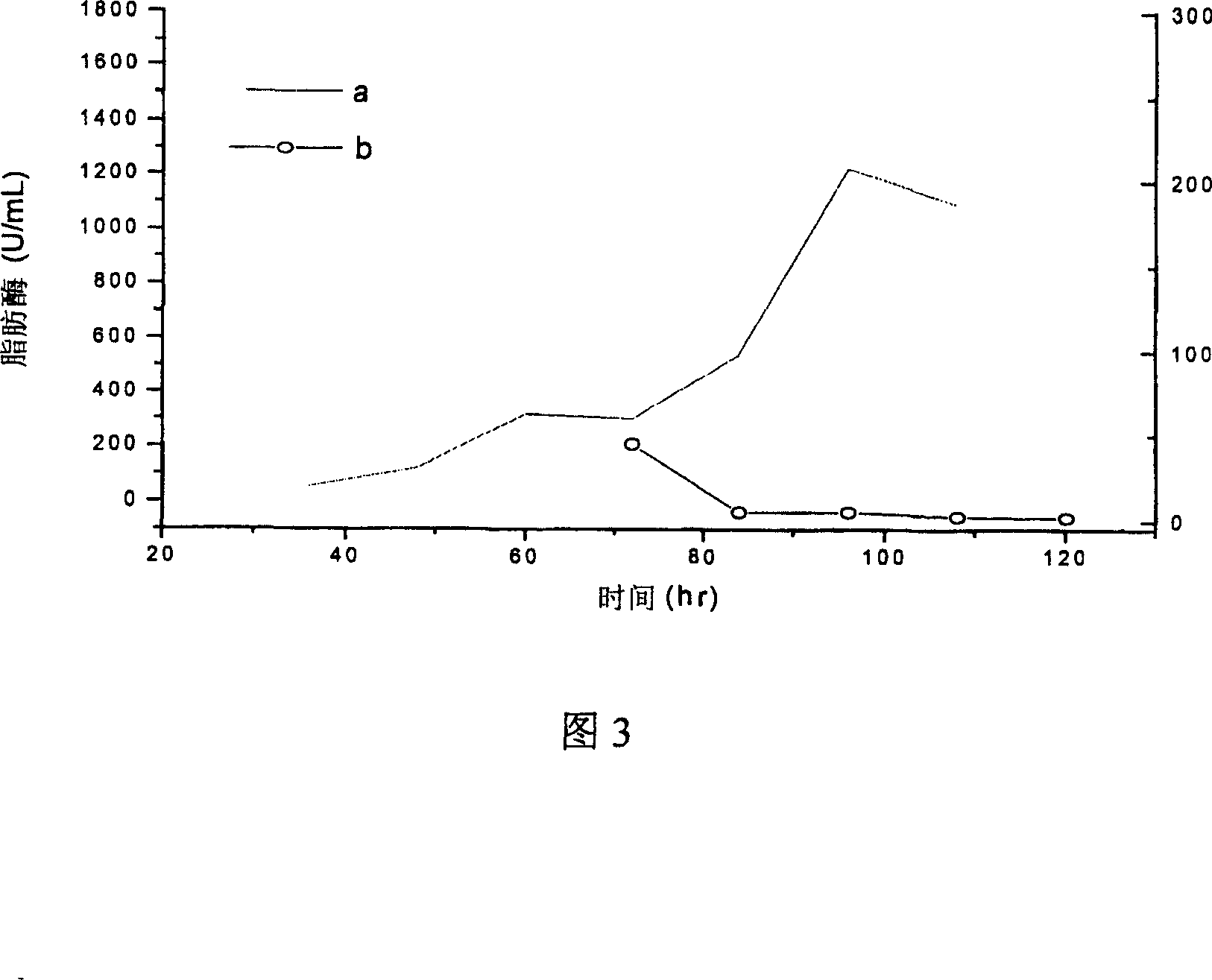

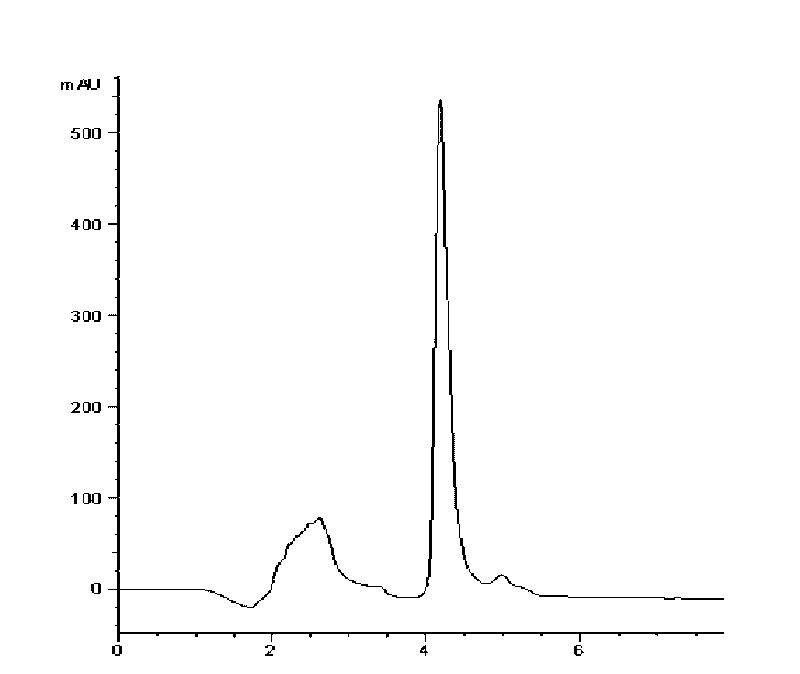

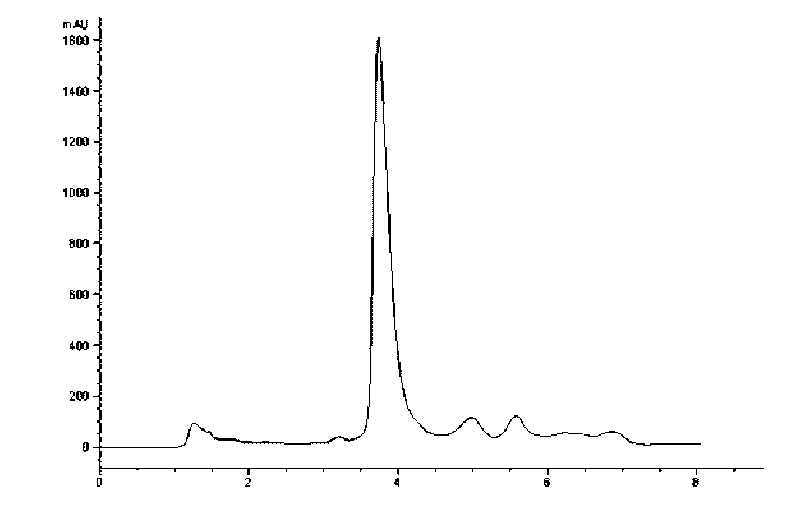

Lipase, its gene, yalulipolytic geast for producing said enzyme and its application

ActiveCN1948470AWide substrate adaptabilityImprove stabilityImmobilised enzymesFungiConservative mutationAmino acid

This invention relates to a preparation of a kind of lipase and the method of using the lipase to compound ester. Exactly is that amino acid sequence is SEQ ID NO:1 or its lipase of conservative mutation sequence, it also relates to the gene coding this lipase, Yarrowia lipolytica generating this lipase.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting purified dendrobine from dendrobium stem

The invention mainly relates to a method for extracting purified dendrobine from dendrobium stem. The method comprises the following steps of: firstly, extracting with acid alcohol, enriching and purifying extract by cation exchange resin, stripping with an organic solvent, and separating and preparing by HPLC (High Performance Liquid Chromatography). The stable extract with the dendrobine content not less than 90% is prepared by the method, the extract is furthered prepared by the HPLC, and the dendrobine with the purity not less than 95% is obtained. Compared with the traditional process, the invention has the advantages of high selectivity, moderate reaction condition, simple process, short production period, and high dendrobine yield and purity. By utilizing the HPLC to separate and prepare, the dendrobine loss can be reduced, the relevant matters with similar structure can be obtained, the practical value is high, and a new path by utilizing the dendrobium stem plants is provided.

Owner:ZUNYI MEDICAL UNIVERSITY

Process for continuously extracting cordyceps militaris essential oil, cordycepin, cordycepic acid and cordyceps militaris polysaccharide from cordyceps militaris

ActiveCN101580755ASimplify the separation and purification stepsReduce usageAntibacterial agentsAntipyreticCordycepsKetone

The invention discloses a process for continuously extracting cordyceps militaris essential oil, cordycepin, cordycepic acid and cordyceps militaris polysaccharide from cordyceps militaris. Cordyceps militaris mycelium powder screened by a 40 to 60 mesh sieve is added into a supercritical CO2 fluid extraction apparatus; the step of extraction is carried out for 1 to 3 hours under the conditions that the pressure is 15 to 25 MPa, the temperature is 35 to 40 DEG C and the flow rate is 50 to 150 L / min CO2, and the cordyceps militaris essential oil is separated out from a separation kettle; ester or ketone organic entrainer of which the mass is 1 to 3 times that of the cordyceps militaris mycelium powder is used for continuous extraction for 1 to 3 hours so as to separate out the cordycepin; and distilled water of which the mass is 1 to 3 times that of the cordyceps militaris mycelium powder is used as an entrainer for extraction for 1 to 3 hours, and the first grade separate mode is adopted for separating out an aqueous solution containing the cordycepic acid and the cordyceps militaris polysaccharide. The process reduces the usage of organic solvent, increases the production efficiency and reduces the production cost. The extraction yield of the obtained cordyceps militaris essential oil is nearly 6.5 percent, the extraction yield of the cordycepin is nearly 0.049 percent, the purity of the cordycepin is nearly 45 percent, and the extraction yield of the cordycepic acid is nearly 2 percent.

Owner:HUNAN AGRICULTURAL UNIV

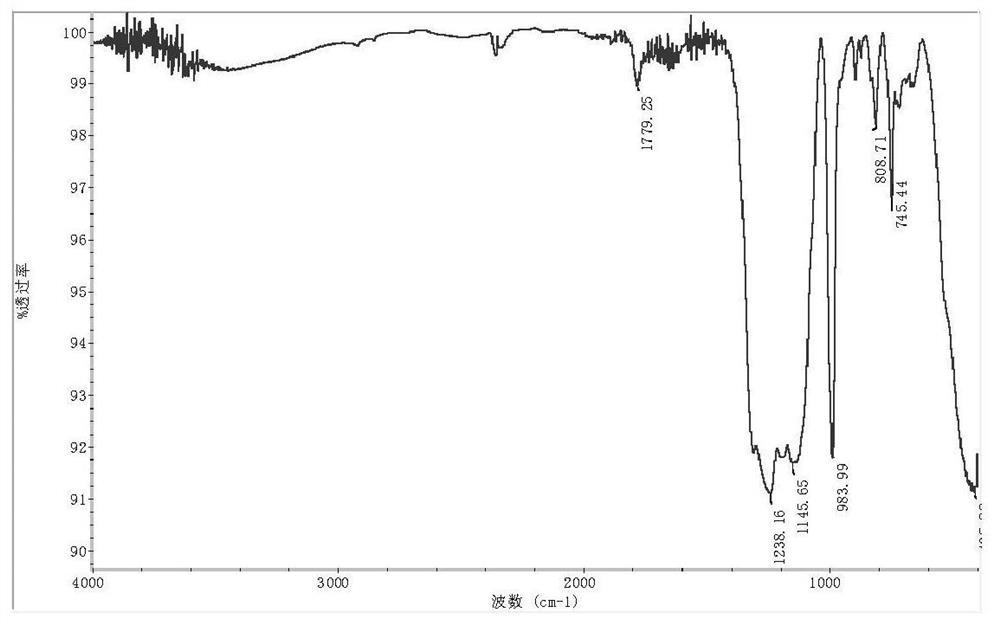

Perfluoropolyether group-containing silane compound, preparation method thereof, surface treatment agent and article

ActiveCN109071793AImprove hydrophobicityGood oleophobic effectAntifouling/underwater paintsPaints with biocidesSurface finishingWear resistant

The invention relates to a perfluoropolyether group-containing silane compound represented by a formula (1): Rf-X1-X2-NQkT2-k(1), and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound shown in the description, and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound represented by a formula (3) shown in the description, and a preparation method therefor. The perfluoropolyether group-containing silane compound can be used for a surface treatment agent so that the glassand other base materials processed by the surface treatment agent are excellent in anti-pollution, anti-fingerprint, scrape-resistant and wear-resistant performances, and the preparation methods for the compounds are simple in process, and are easy to operate and implement.

Owner:GUANGZHOU UR MATERIALS TECH CO LTD

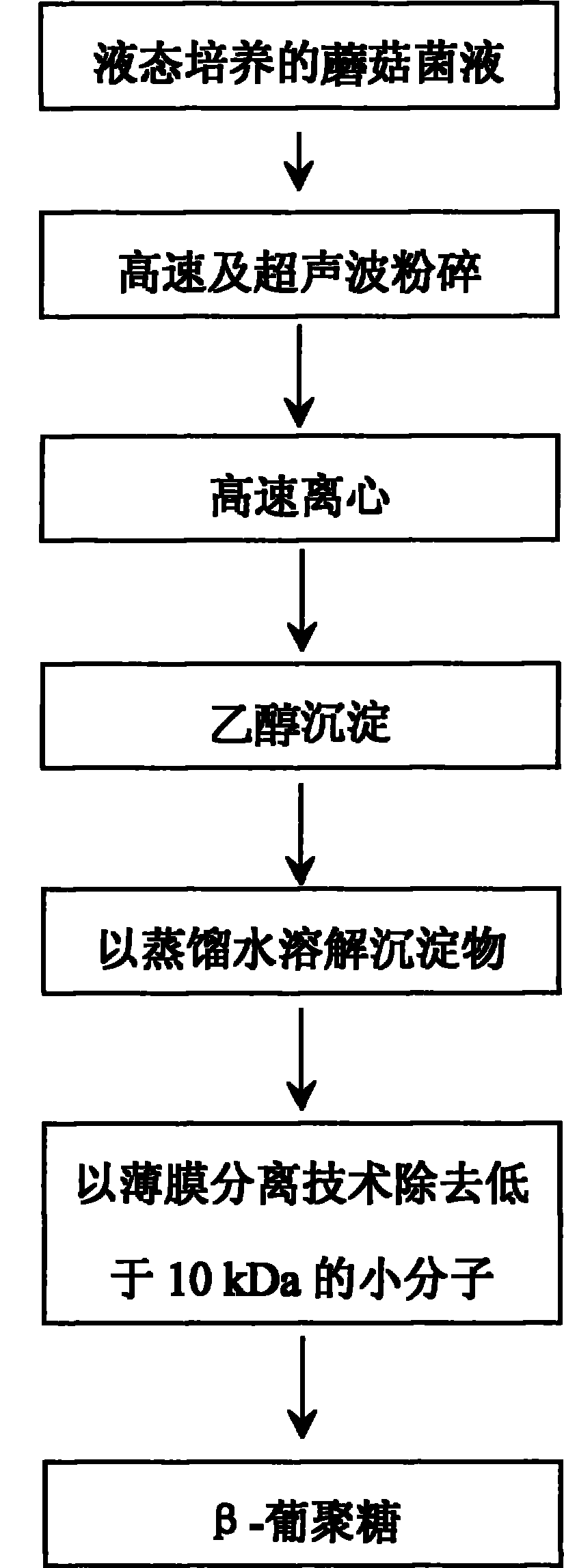

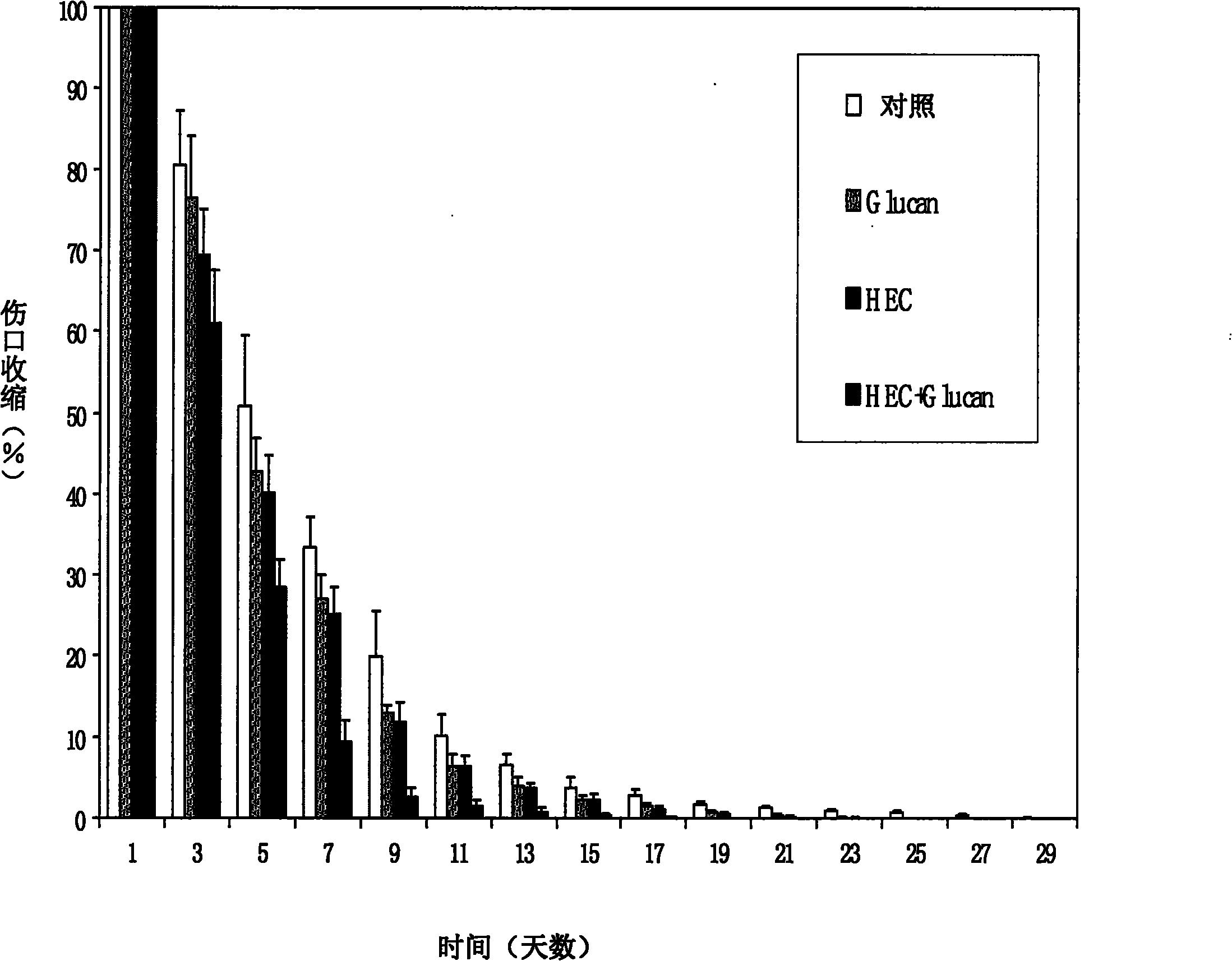

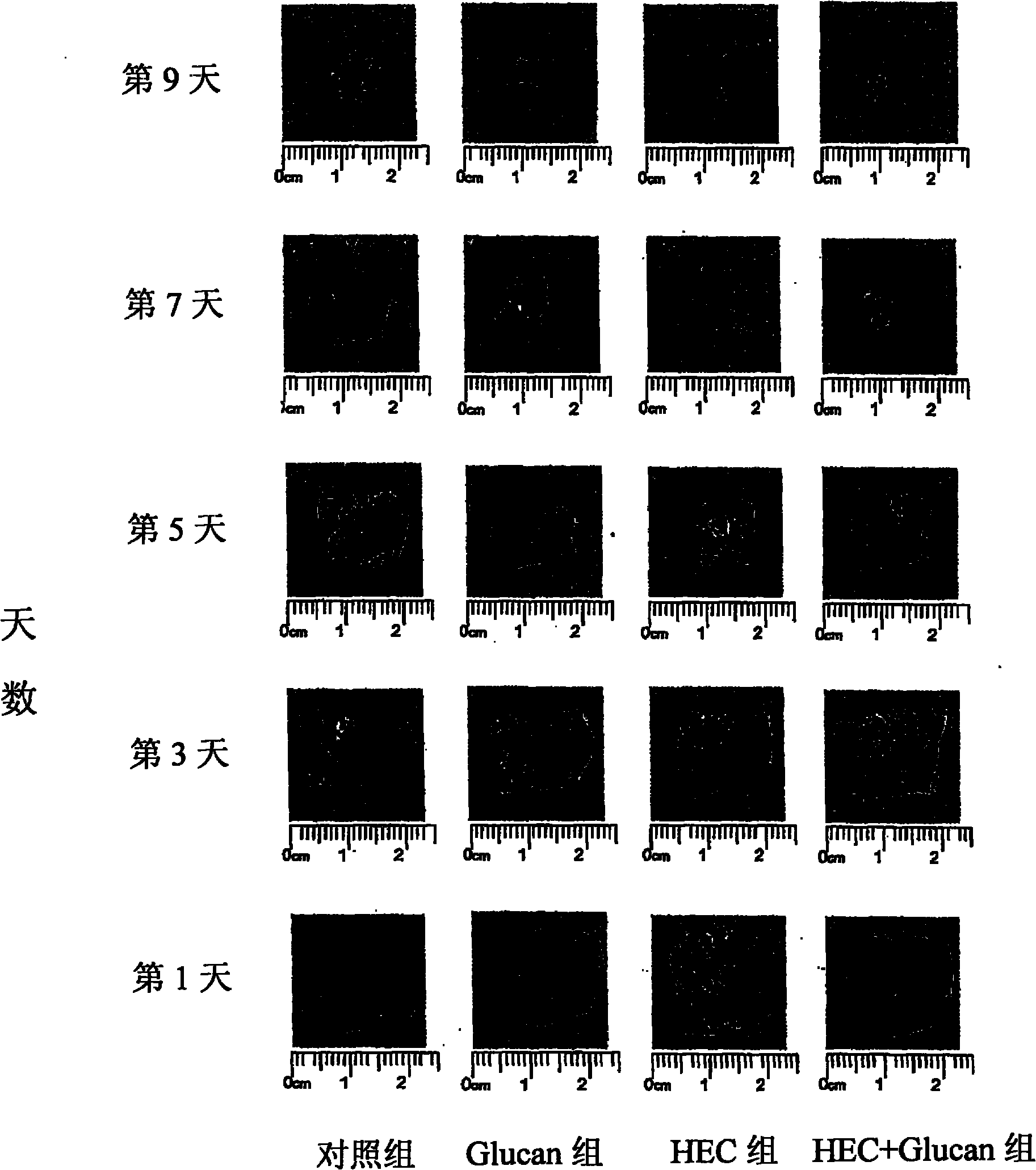

Combination containing mushroom polysaccharide and preparation method thereof

InactiveCN101766656APromote wound healingImprove immune activityOrganic active ingredientsFungiBearded toothLentinula

The invention provides a combination containing mushroom polysaccharide and a preparation method thereof. The combination contains mushroom polysaccharide and a carrier, wherein the mushroom is selected from Schizophyllumcommune, Agarics blaze, Cordyceps sinensis, Ganoderma lucidum, Coriolus versicolor, Anthodiacamphorate, Phellinus linteus, Pleurotuscitrinopileatus, Lentinula edodes, Agrocybe aegerita, Hericium erinaceus, Pleurotus eryngiig, Sparrasis crispa, Auricularia auricular, Flammulinavelutipes or a combination thereof.

Owner:陈秀男

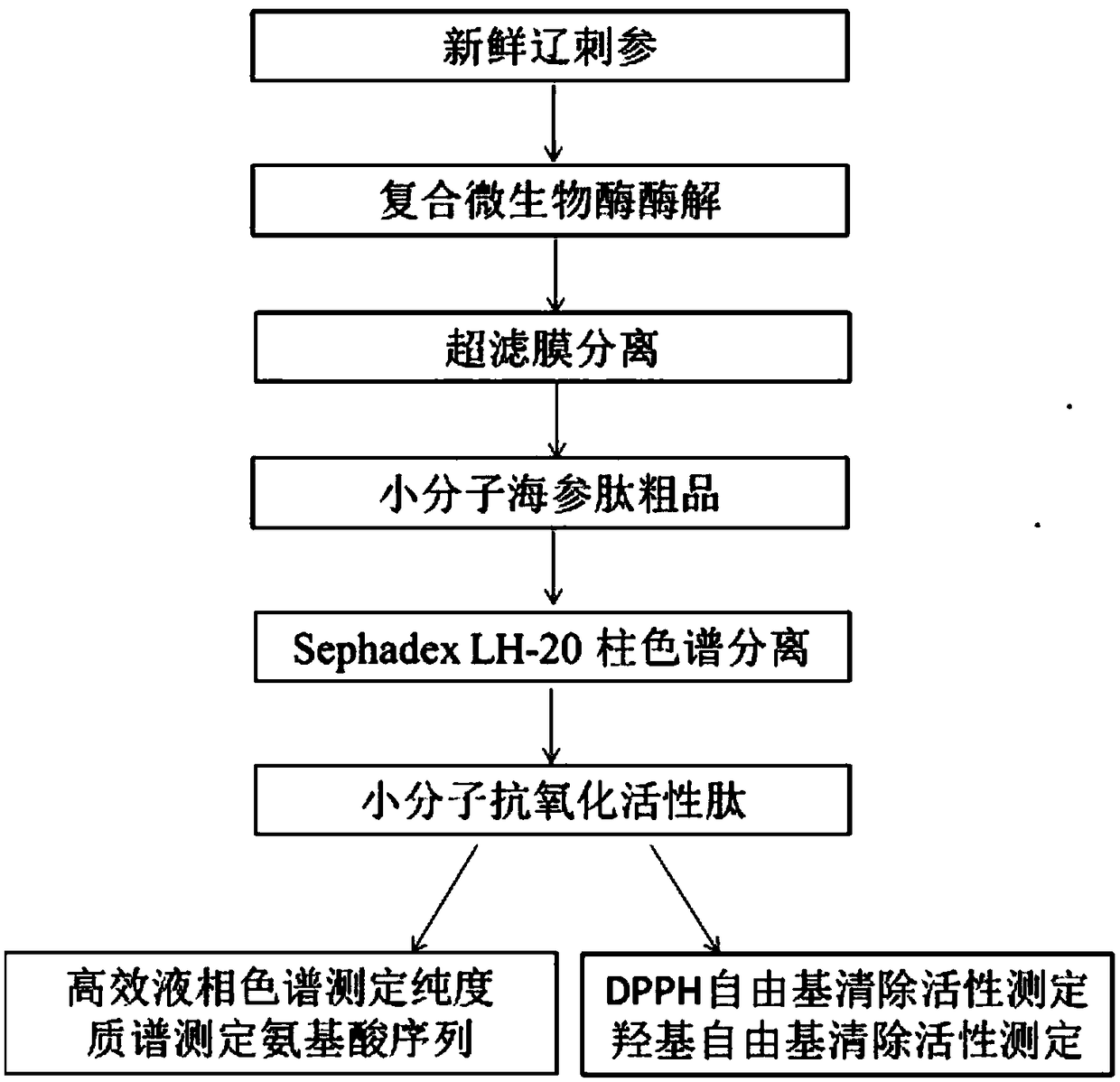

Anti-oxidation and DPP-IV inhibition active peptide derived from apostichopus japonicus

ActiveCN109400678AHigh puritySmall molecular weightPeptide preparation methodsFermentationDiseaseSeparation technology

The invention belongs to the field of marine organism small-molecular active peptides, and particularly relates to an anti-oxidation and DPP-IV inhibition active peptide derived from apostichopus japonicus by enzymolysis. The amino acid sequence of the anti-oxidation and DPP-IV inhibition active peptide is Ser-Arg-Pro-Gln-Tyr-Pro-Gln-Tyr-Pro-Ser. The anti-oxidation and DPP-IV inhibition active peptide is prepared by the following steps: adding water into fresh apostichopus japonicus for homogenizing, and placing the homogenate in an enzymolysis tank; performing enzymolysis with compound protease to obtain enzymatic hydrolysate; treating the enzymatic hydrolysate with a membrane separation technology to obtain a small-molecular active peptide crude product; separating the crude product through Sephadex LH-20 to obtain a small-molecular active peptide. The purity of the small-molecular active peptide as measured by adopting RP-HPLC (Reversed-Phase High Performance Liquid Chromatography)is greater than 95 percent, and the amino acid composition of the active peptide is measured by high performance liquid chromatography / mass spectrometry, so that the amino acid sequence of the small-molecular peptide is determined finally. The active small-molecular peptide derived from the apostichopus japonicus has the advantages of small molecular weight, simple separating-purifying steps, easiness in preparation, high purity and higher oxidization resistance and DPP-IV inhibition activity, has the characteristics of naturalness, safety and high efficiency, can be applied to the preventionand treatment of relevant diseases such as diabetes mellitus as an antioxidant as well as a DPP-IV inhibitor, and has a wide application prospect in the fields of foods, health care products and medicines.

Owner:DALIAN SHENLAN PEPTIDE TECH R & D CO LTD

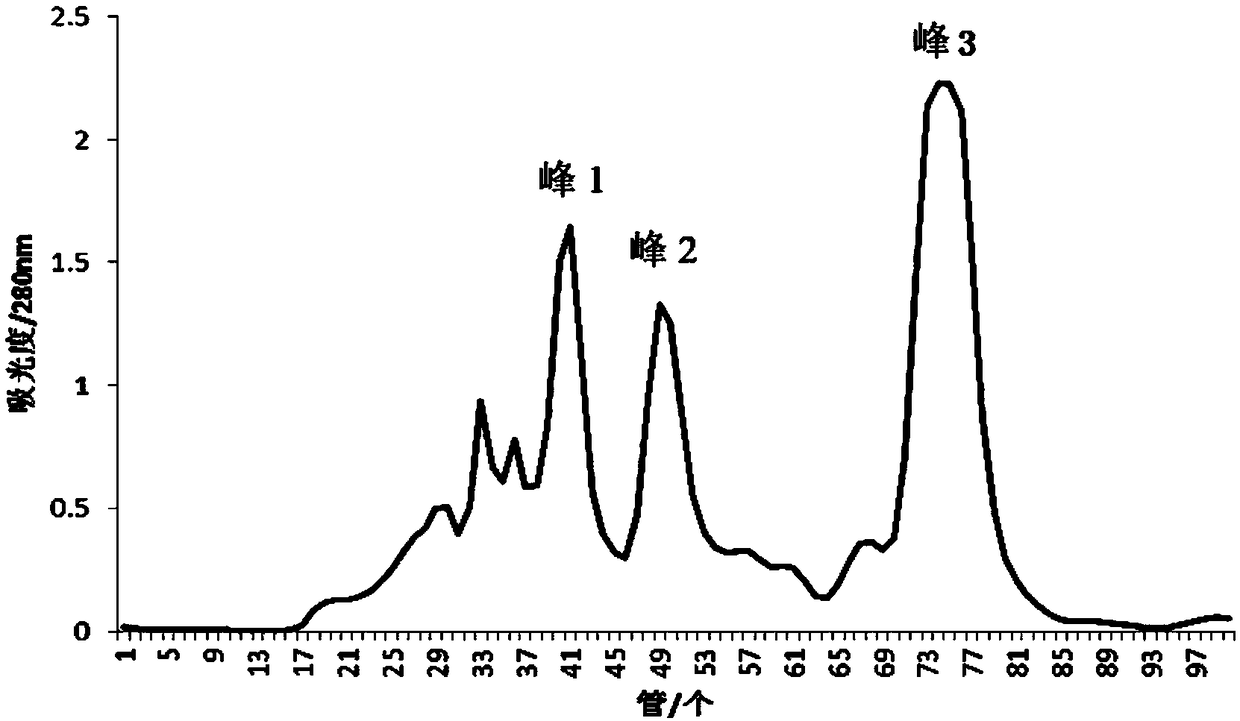

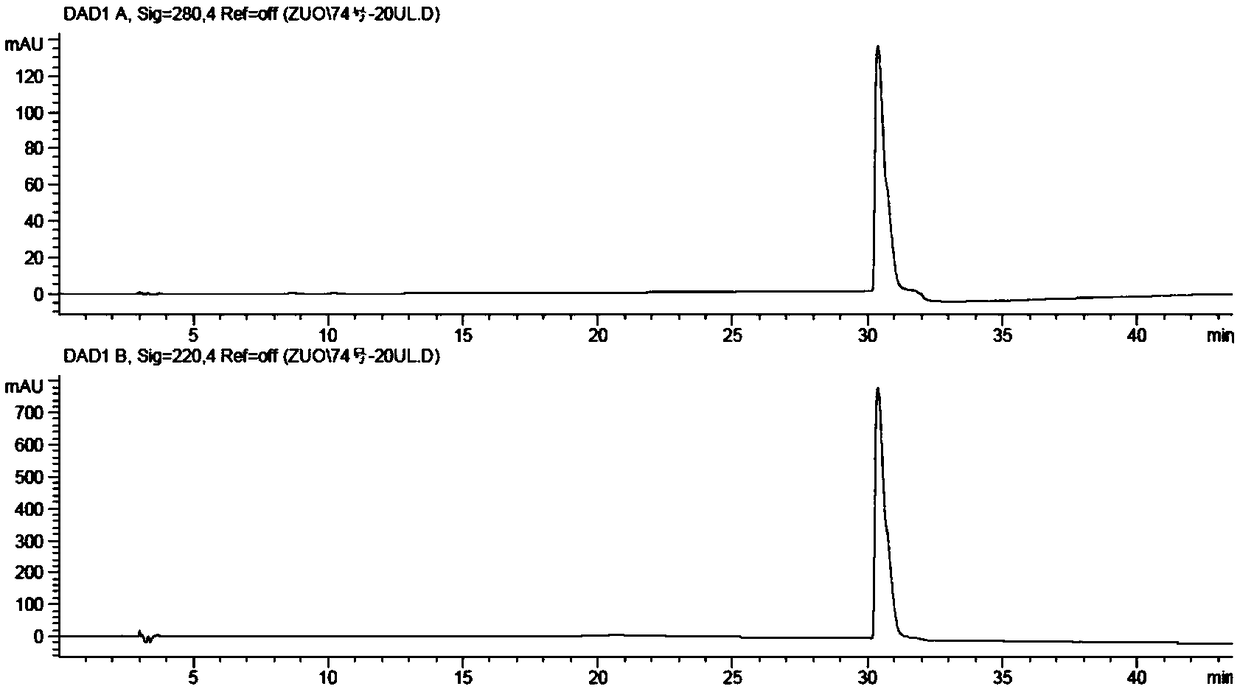

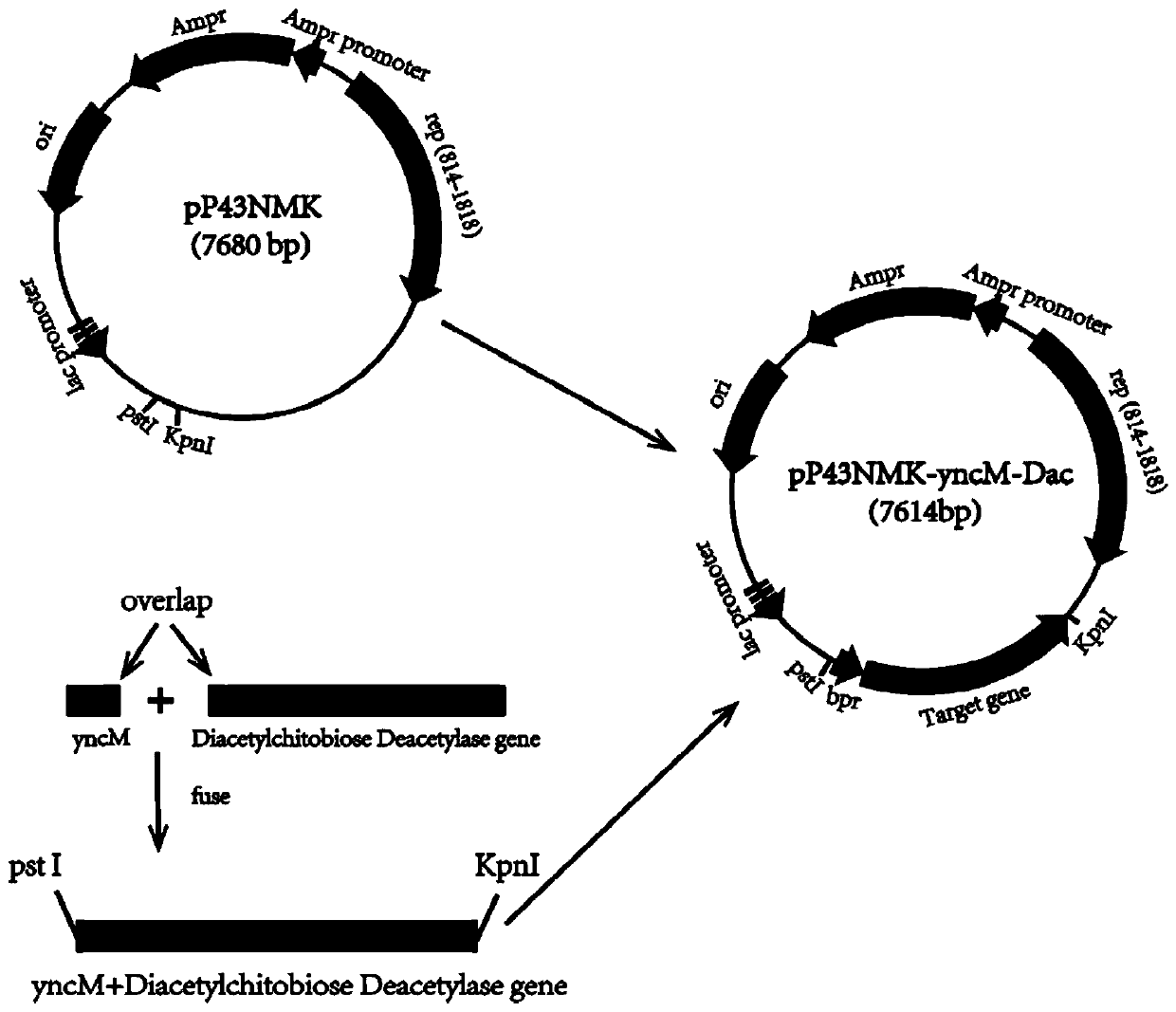

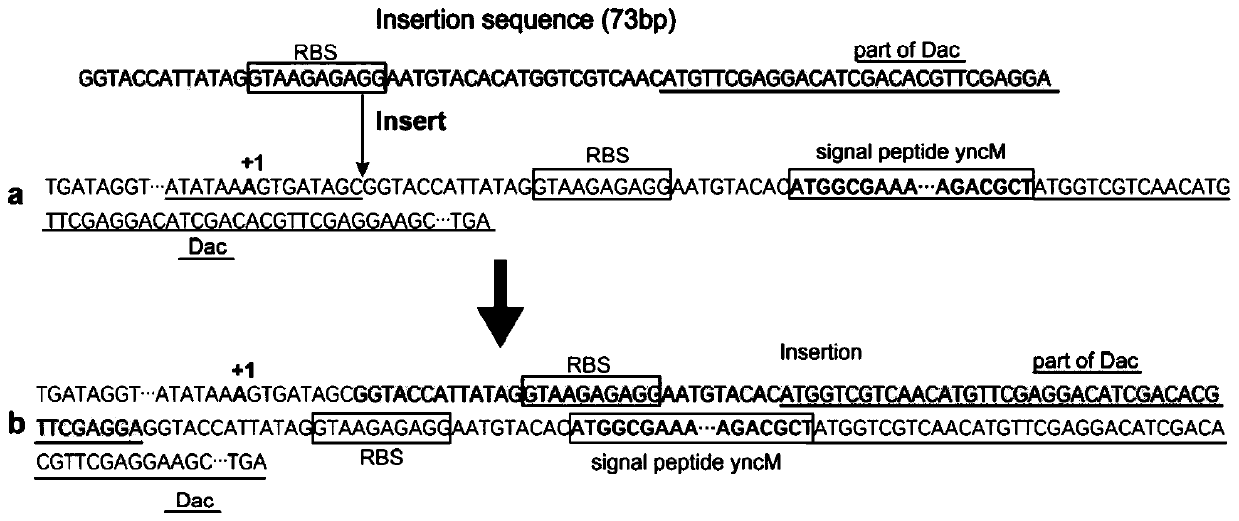

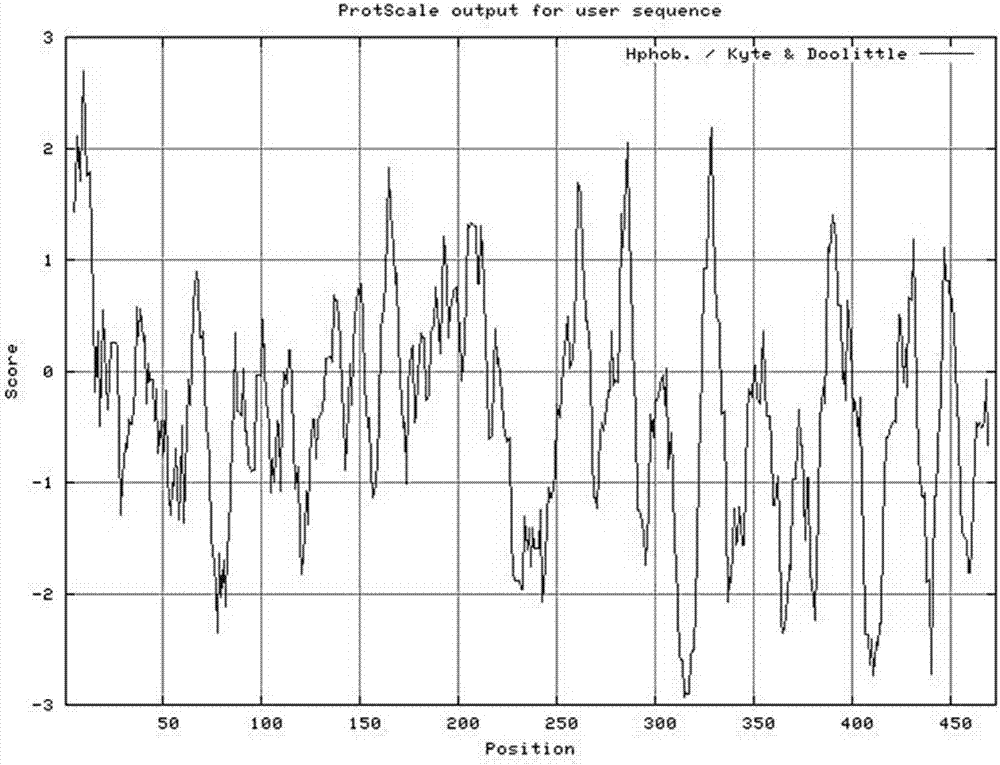

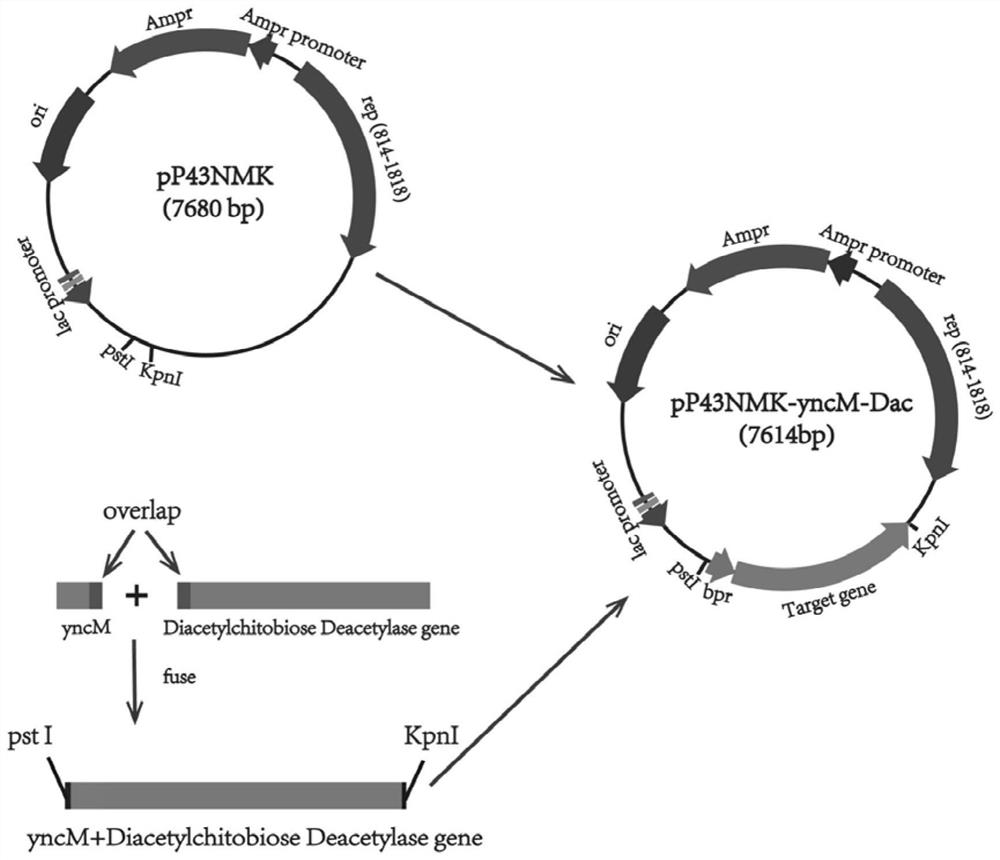

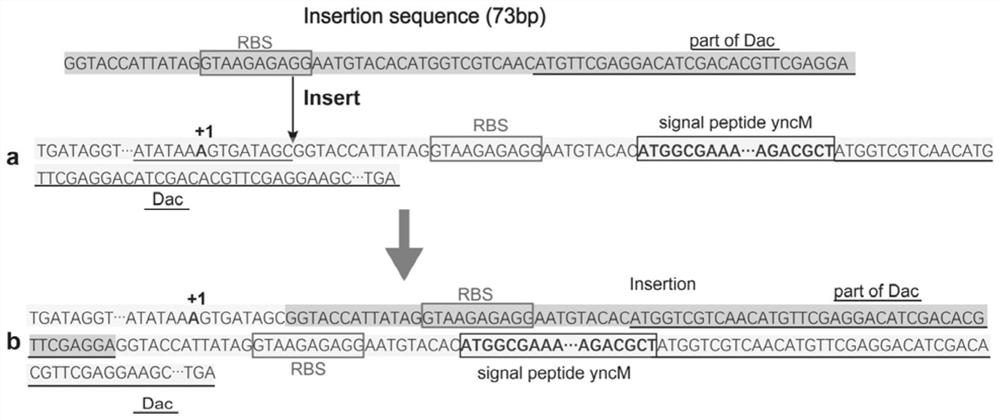

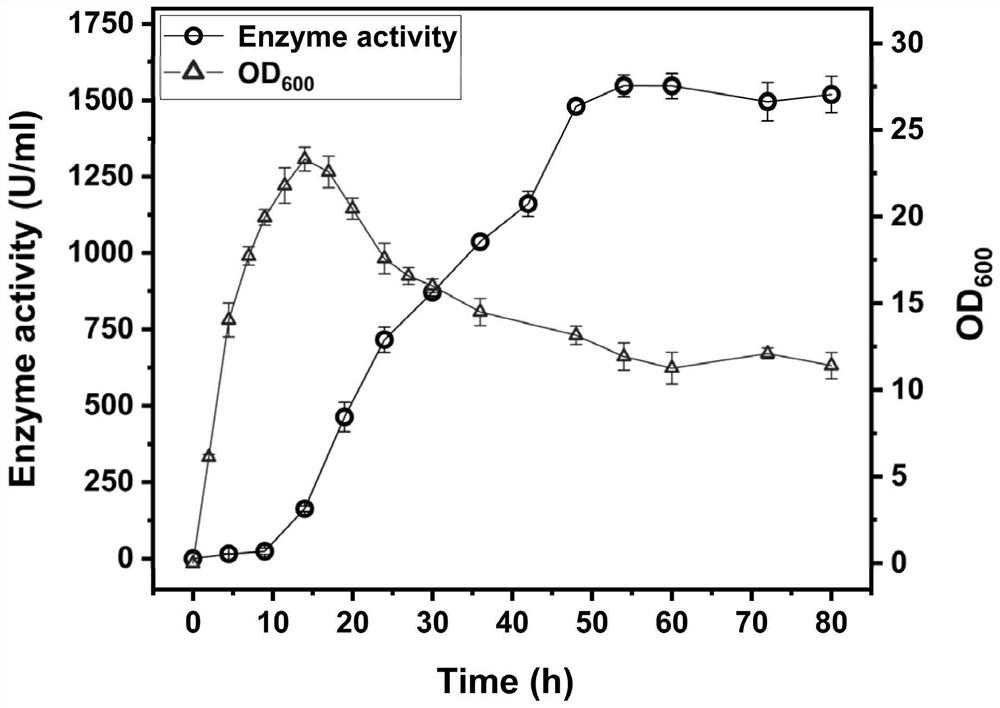

Construction and application of engineering bacteria secreting and expressing chitosan deacetylase

ActiveCN109777761AHigh expressionSimplify separation and purification stepsOrganic active ingredientsBacteriaHeterologousProtein target

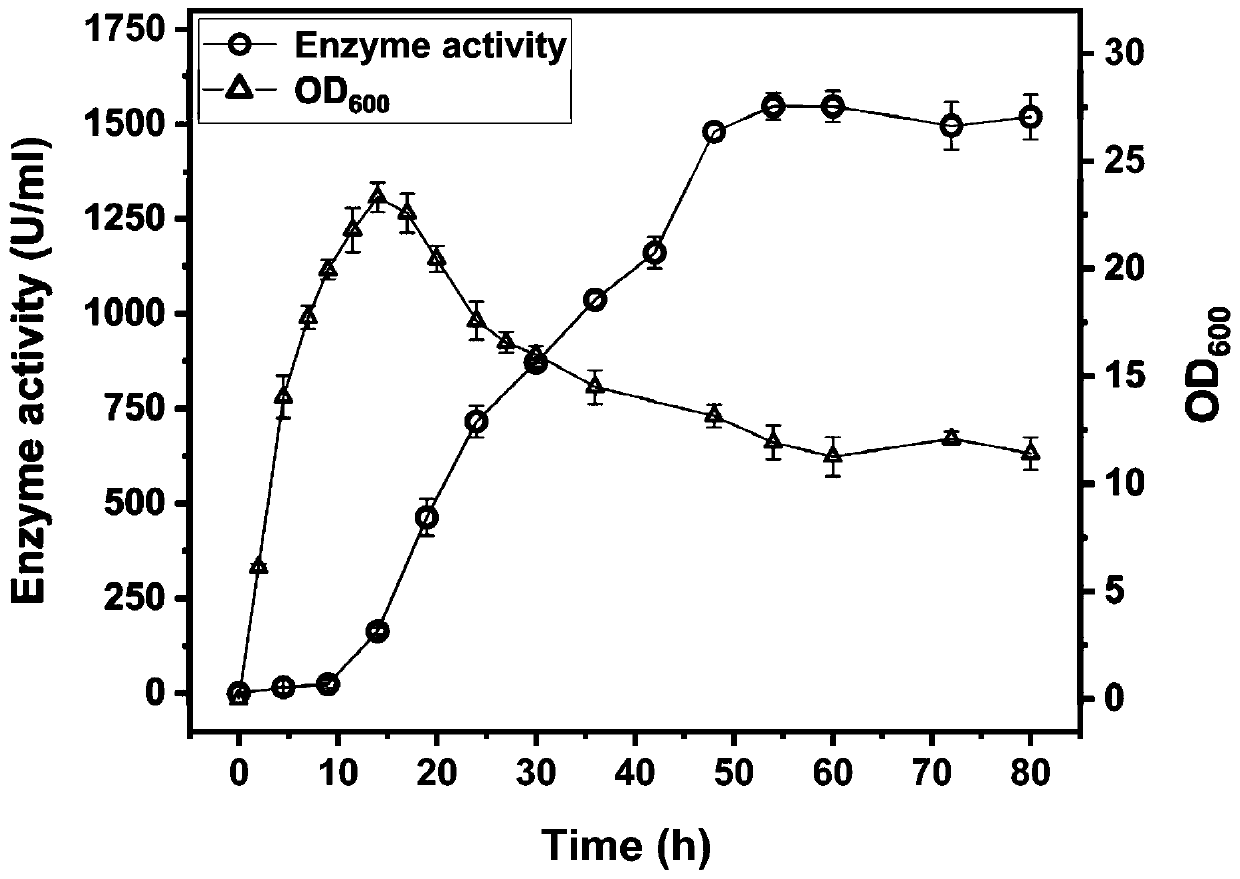

The invention discloses a construction and application of an engineering bacteria secreting and expressing chitosan deacetylase, belonging to the technical field of fermentation engineering. The construction firstly constructs a recombinant Bacillus subtilis secreting and expressing chitosan deacetylase gene by a different source, and adds a signal peptide fragment yncM in the recombinant vector for a first time, wherein the signal peptide can secrete target protein chitosan deacetylase outside cells of the recombinant Bacillus subtilis, and obtain mutants in a non-translation region at 5' end, so that the expression of the target protein is significantly increased and steps of subsequent enzyme separation and purification are greatly simplified. The enzyme activity of obtained chitosan deacetylase is up to 1548.7 U / mL and the yield of chitosan deacetylase is up to 620 mg / L when fermentation medium is fermented and cultured for 50-60 hours. And meanwhile, the method has the advantages of low production cost, mild production conditions, simple purification process, safe operation and the like.

Owner:JIANGNAN UNIV +1

Preparation method of standard radix pseudostellariae cyclopeptide B

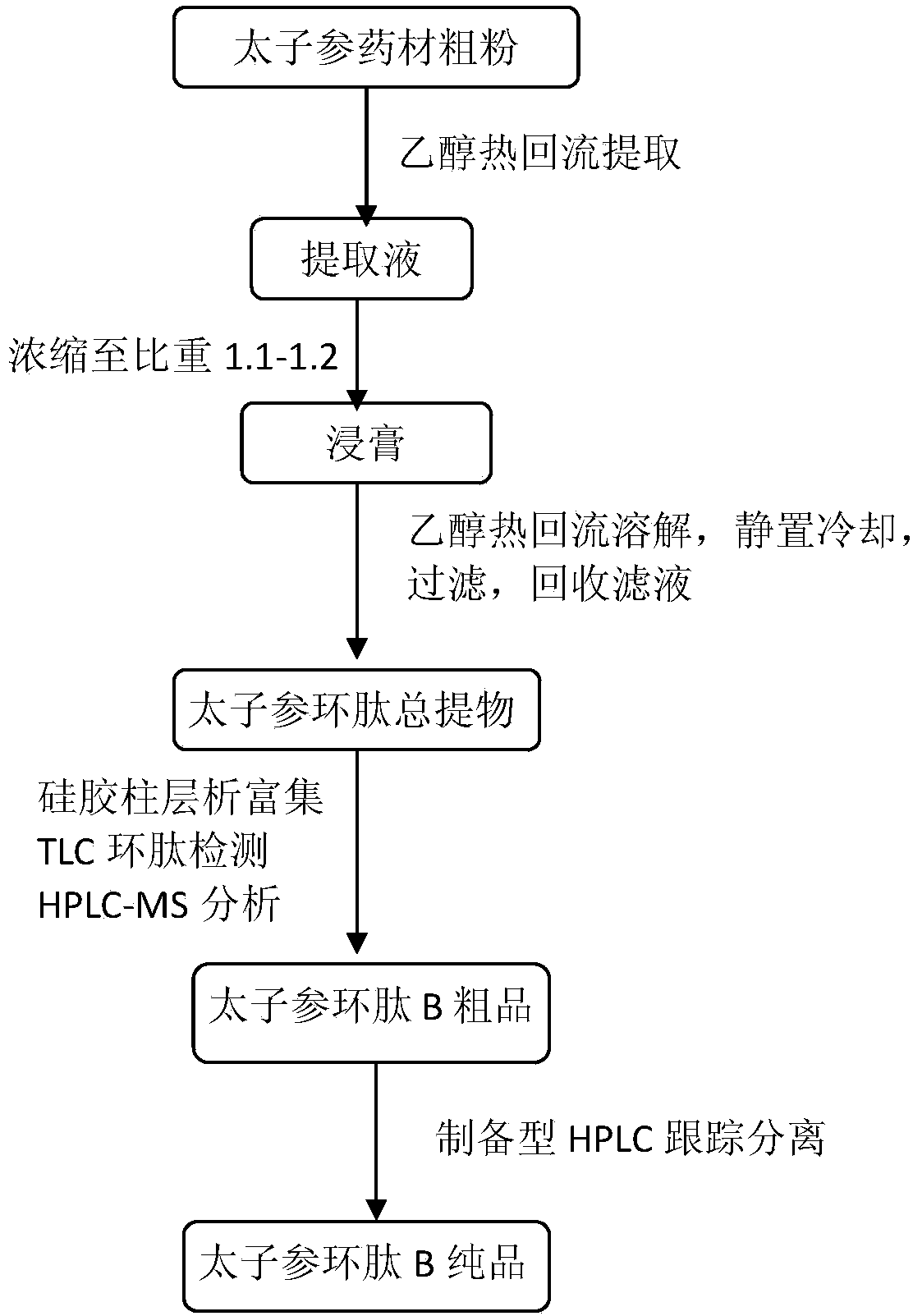

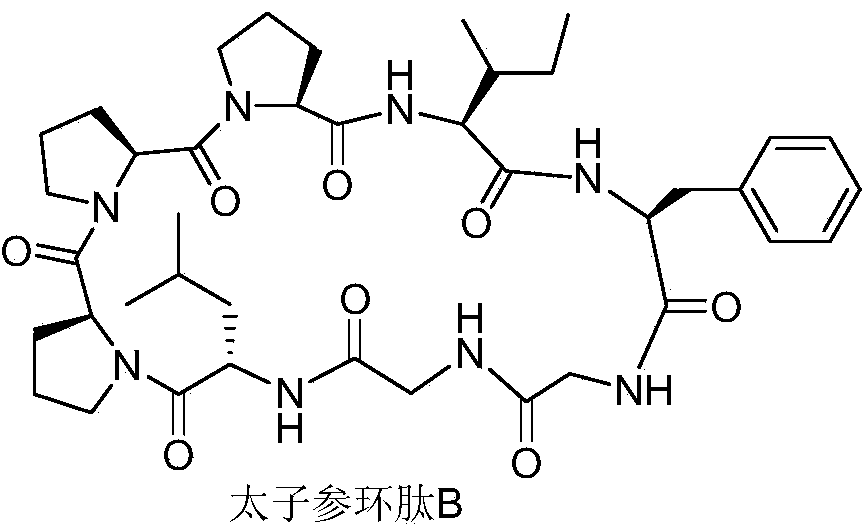

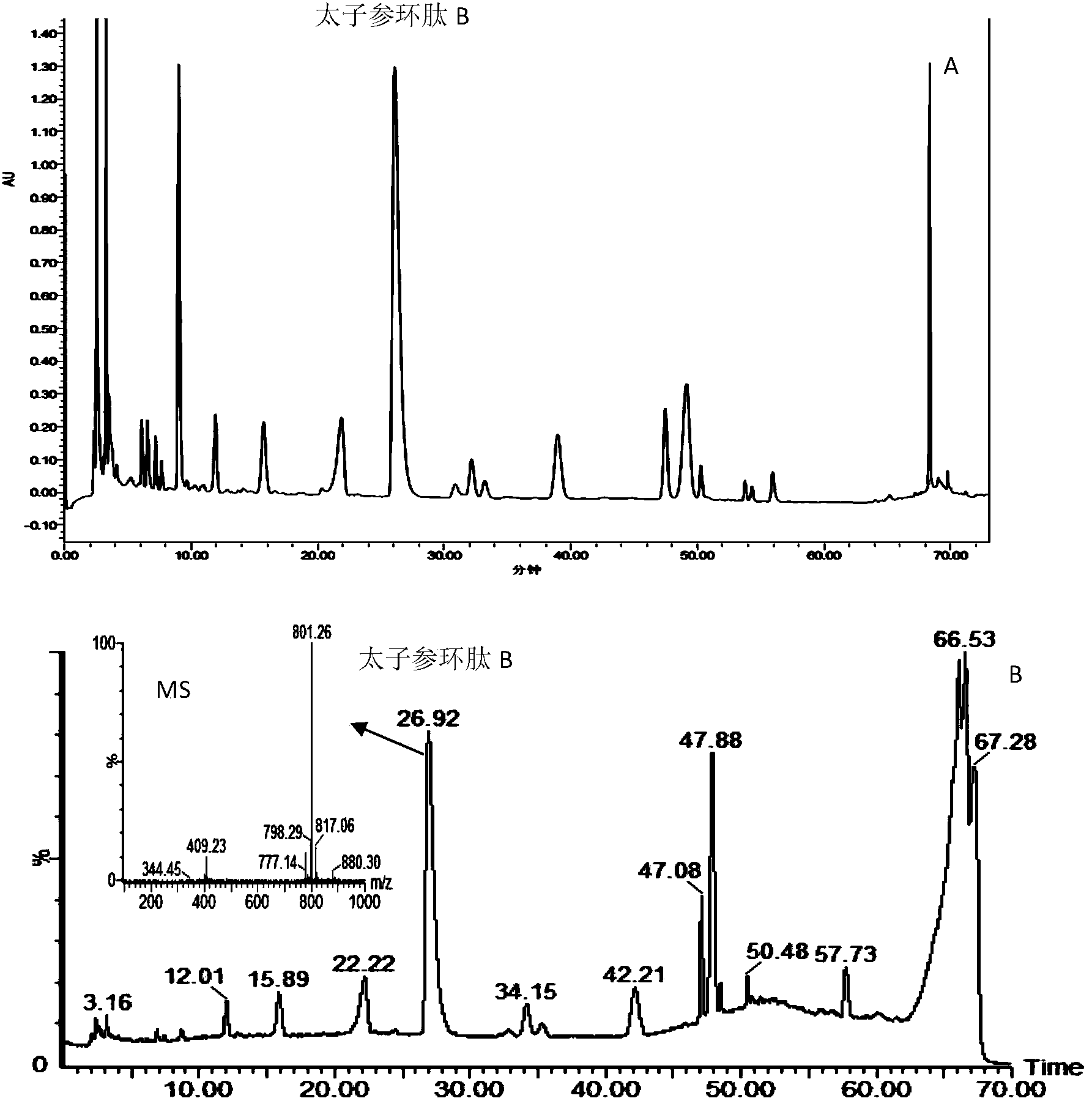

InactiveCN103923191AReduce dissolutionPromote dissolutionPeptide preparation methodsMedicinal herbsReflux extraction

The invention provides a preparation method of a standard radix pseudostellariae cyclopeptide B. The preparation method comprises the steps of extracting and separating standard radix pseudostellariae cyclopeptide B from traditional Chinese medicine radix pseudostellariae, and purifying standard radix pseudostellariae cyclopeptide B; smashing the dry medicinal material of radix pseudostellariae, and then, carrying out heat reflux extraction on the dry medicinal material of radix pseudostellariae by using industrial ethanol to obtain an extract; pretreating the extract by using ethanol; enriching radix pseudostellariae cyclopeptide B through a silica gel column chromatography, wherein a chloroform and methanol system is used as an eluting solvent; finally, preparing radix pseudostellariae cyclopeptide B with the purity of more than 98% by using a preparative high performance liquid chromatography. The method provided by the invention can be used for rapidly separating radix pseudostellariae cyclopeptide B and is low in sample loss, relatively low in cost, convenient to operate, good in controllability and repeatability and suitable for industrial production; in addition, the solvent can be repeatedly recycled.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

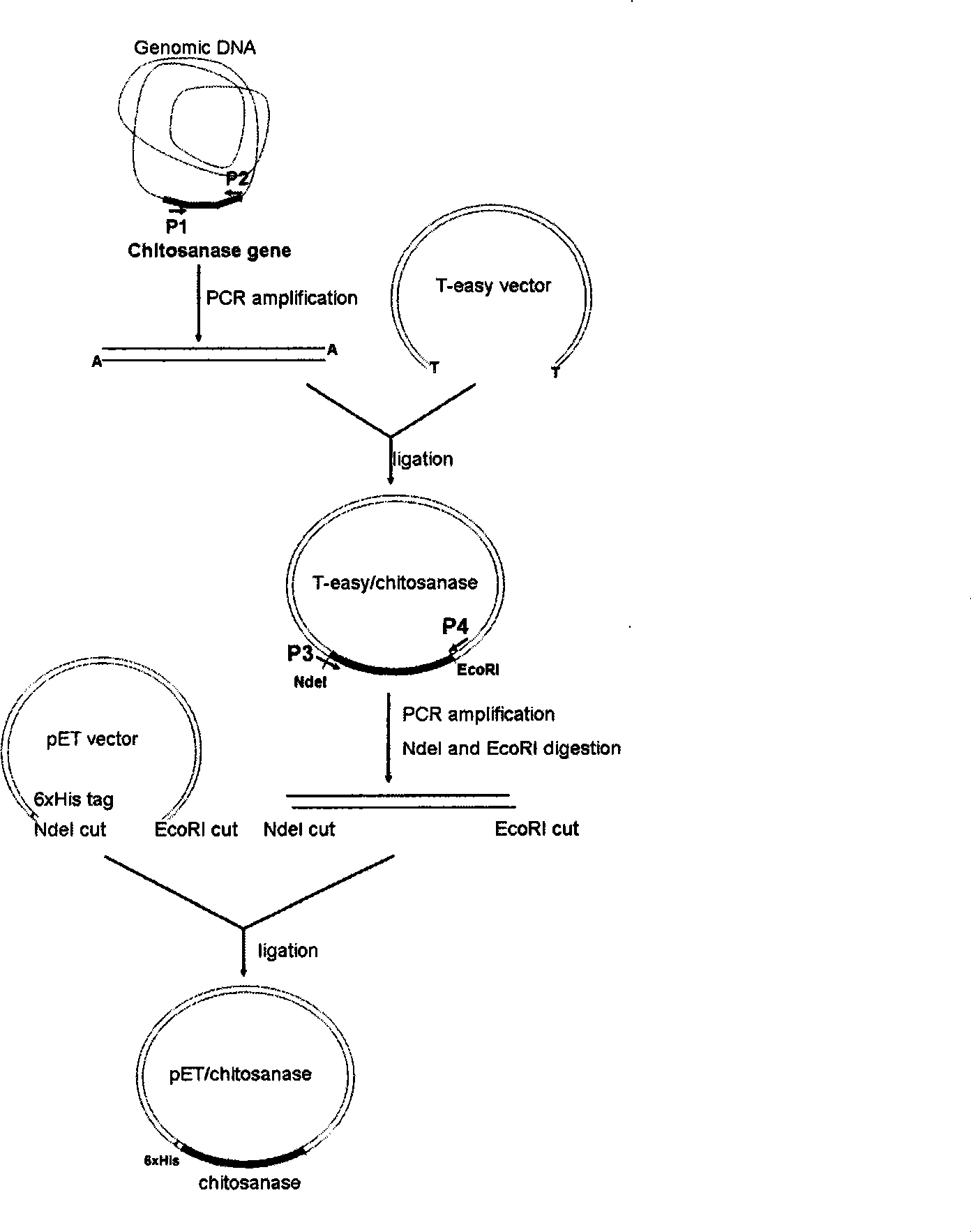

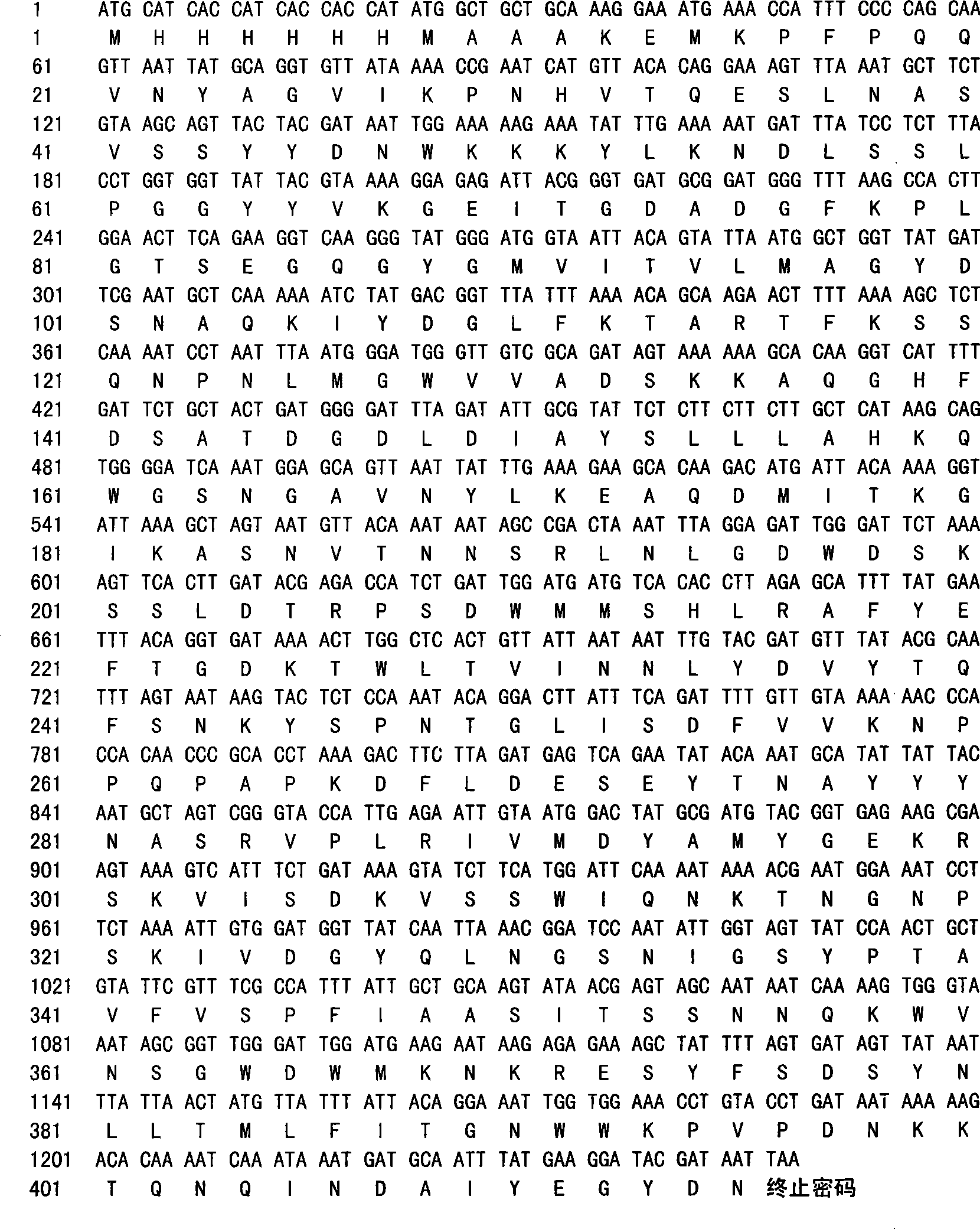

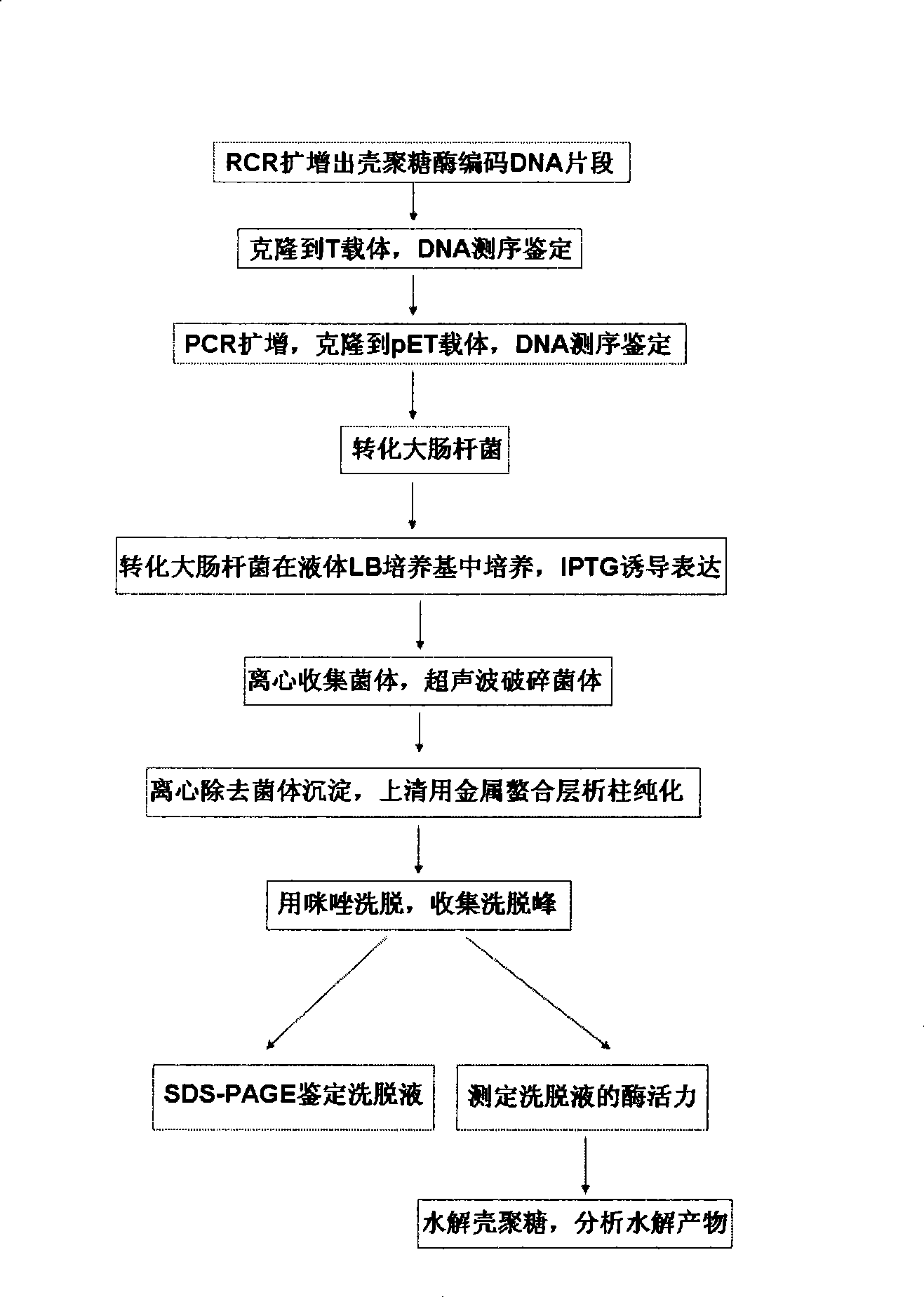

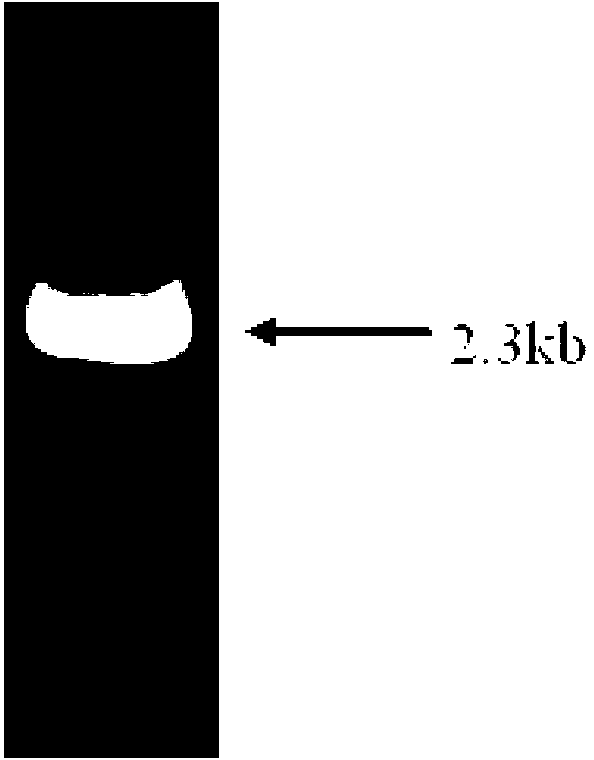

High efficiency recombinant expressed chitoanase

ActiveCN101397552ASimplify separation and purification stepsReduce manufacturing costBacteriaMicroorganism based processesGenetic engineeringGene

The invention relates to novel recombinant chitosanase and the applications thereof, as well as a method for preparing the recombinant chitosanase and the nucleic acid, vectors, host cells and the like used in the method. The recombinant chitosanase is shorter than full-length chitosanase, can be high effectively expressed through genetic engineering method with the expression amount higher than 500mg / L and carry out separation and purification by utilizing simplified purification technology; and the specific activity of the enzyme thereof can reach 700U / mg, thus having low production cost and being suitable for popularization in practical use.

Owner:ZHEJIANG FENGAN BIOPHARM

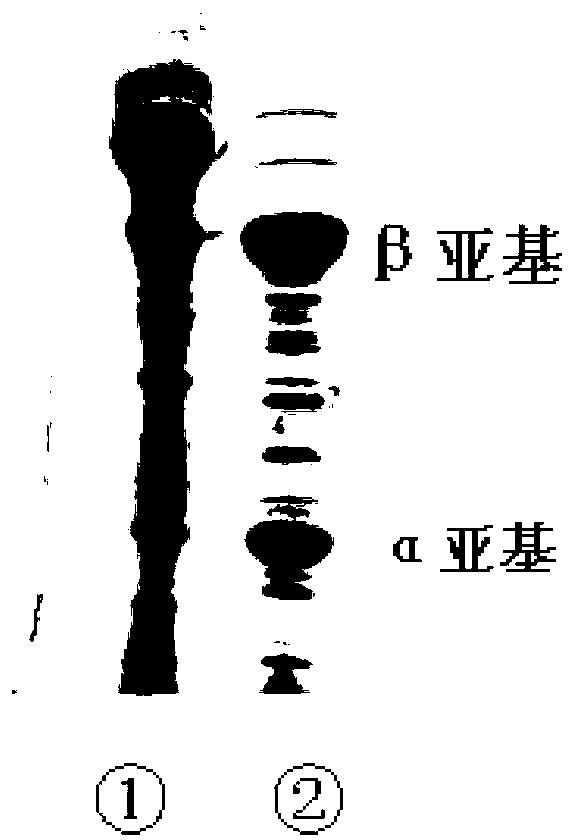

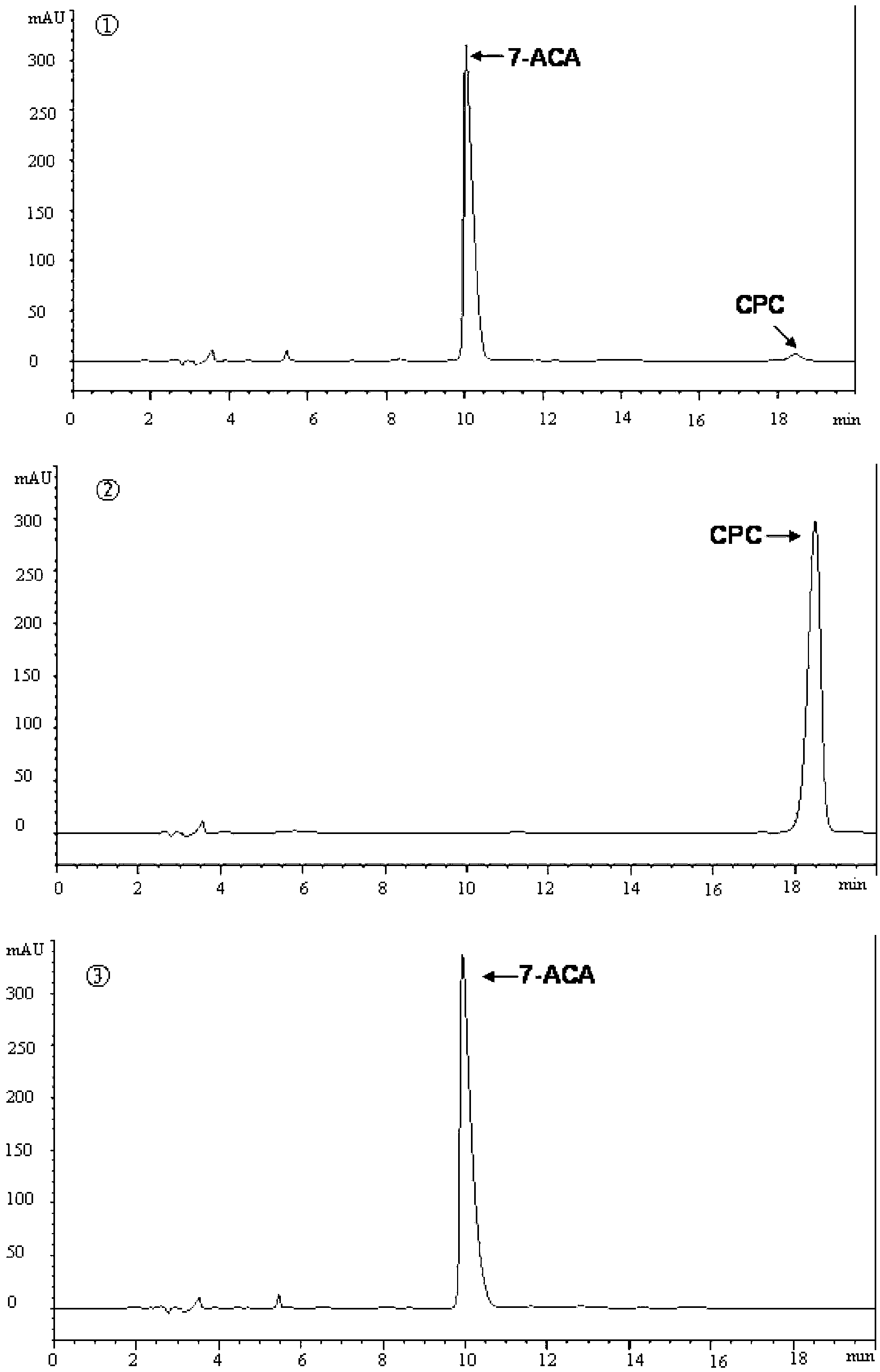

Cephalosporin C acylase mutant as well as coding gene and application thereof

The invention relates to a cephalosporin C acylase mutant as well as a coding gene and the application thereof. An amino acid sequence is shown as SEQ ID NO. 4; or after one or more amino acids are replaced, deleted or added, the sequence forms an amino acid sequence having an equivalent function and derived from the SEQ ID NO.4. The cephalosporin C acylase mutant provided by the invention has the advantages as follows: in the enzymatic reaction process of converting CPC into 7-ACA by using the mutant, the conversion rate reaches 99% and the yield reaches 96%.

Owner:ANHUI BBCA GENETIC ENG TECH CO LTD

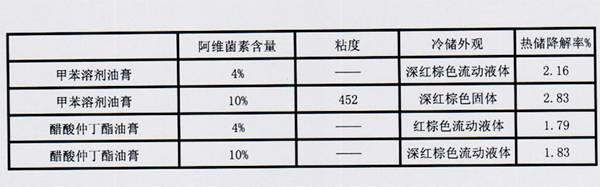

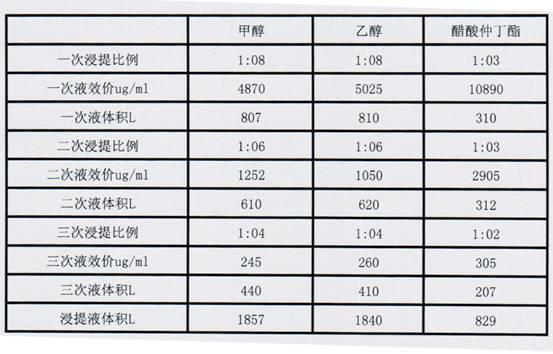

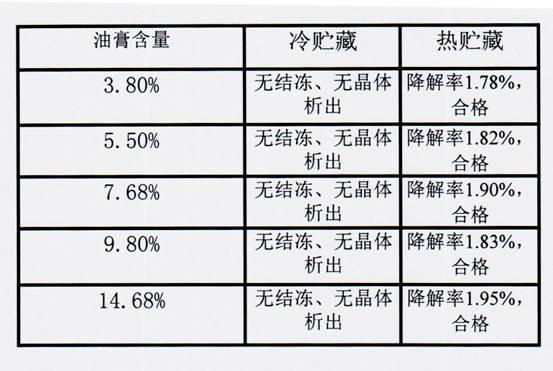

Environmentally-friendly abamectin ointment production process

InactiveCN102217591AHigh purityShorten the separation and purification processBiocideArthropodicidesAbamectinSolvent

The invention relates to an environmentally-friendly abamectin ointment production process. The environmentally-friendly abamectin ointment production process comprises the following steps of: A, fermenting abamectin; B, filtering and drying a fermentation solution; C, extracting with secbutyl acetate, washing and filtering; D, concentrating the extract into paste to obtain an environmentally-friendly abamectin ointment product; and E, continuously extracting, dissolving and repeatedly crystallizing the concentrate to obtain a fine abamectin powder product. The environmentally-friendly nontoxic secbutyl acetate solvent is used for substituting a toxic toluene solvent to produce the abamectin ointment product, so that secondary pollution of the toxic solvent to a farmland is reduced, the harm of the toxic solvent to a user is reduced, and precious petroleum resources are saved.

Owner:张福志

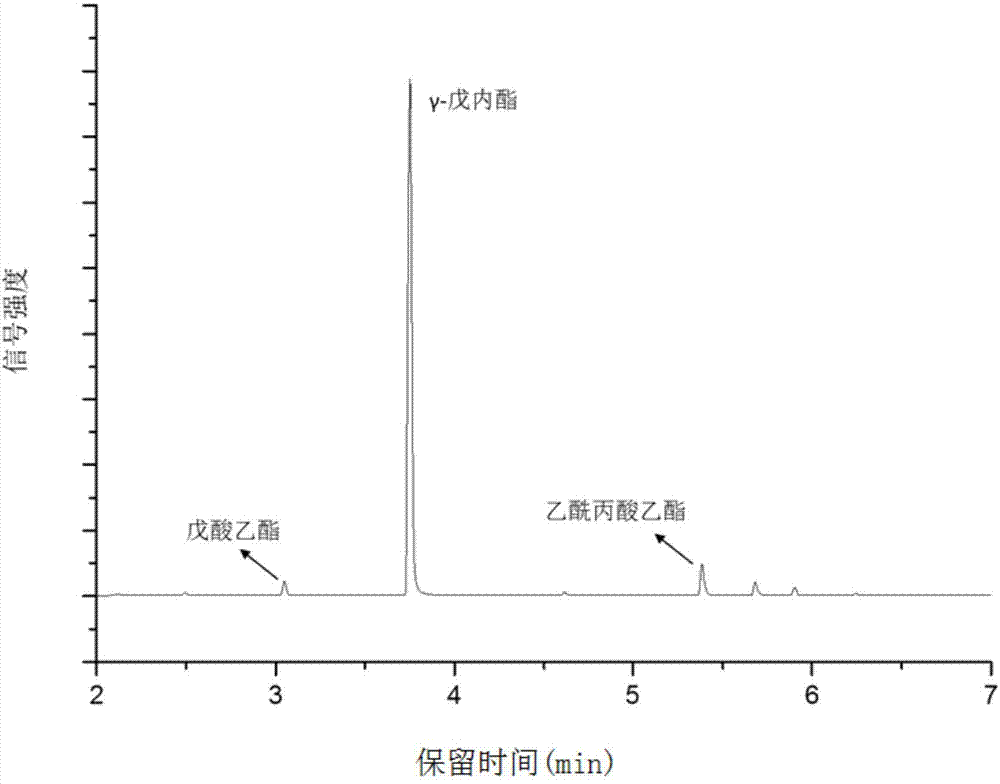

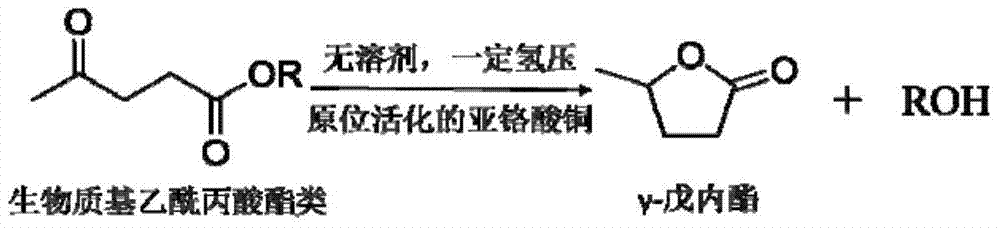

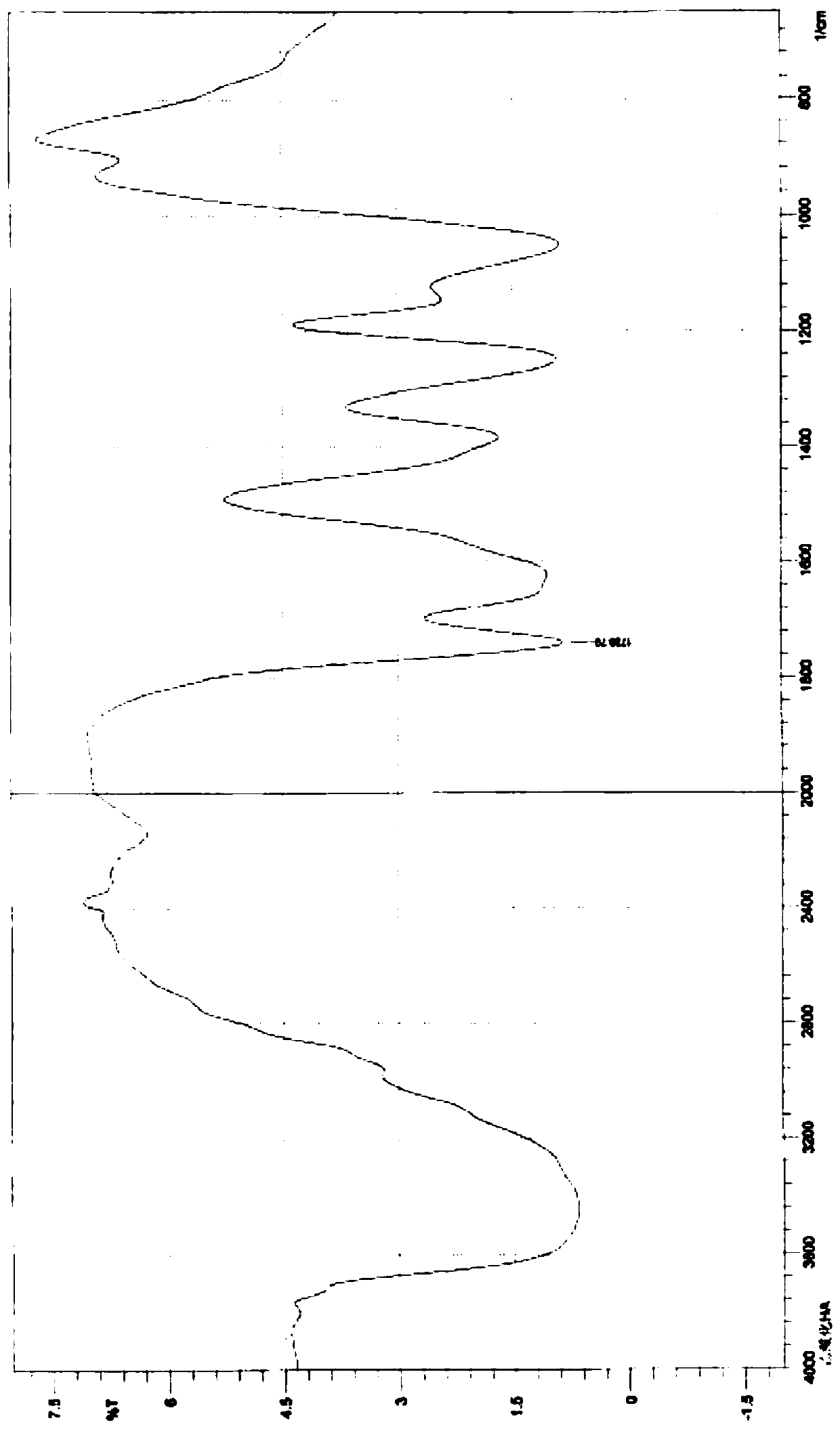

Method for preparing gamma-valerolactone by levulinic acid ester without solvents

InactiveCN104844542AImprove reaction efficiencySimplify separation and purification stepsOrganic chemistryPropanoic acidAlcohol

The invention discloses a method for preparing gamma-valerolactone by levulinic acid ester without solvents, and relates to gamma-valerolactone. A copper chromite catalyst is added into the levulinic acid ester and reacts in hydrogen atmosphere to obtain solid-liquid mixture, pressure is reduced, suction filtration is performed to obtain binary liquid mixture containing gamma-valerolactone and corresponding alcohols, and the alcohols are recovered by distillation to obtain the gamma-valerolactone. Cheap and easily separated copper chromite serving as the catalyst is added into the levulinic acid ester from biomass, and the gamma-valerolactone is prepared at one step in a solvent-free system. The copper chromite catalyst is activated in situ in the system, so that a traditional catalyst pre-hydrogenation step is omitted. The method is simple and efficient, and an effective way is provided for large-scale preparation of biomass-based gamma-valerolactone.

Owner:XIAMEN UNIV

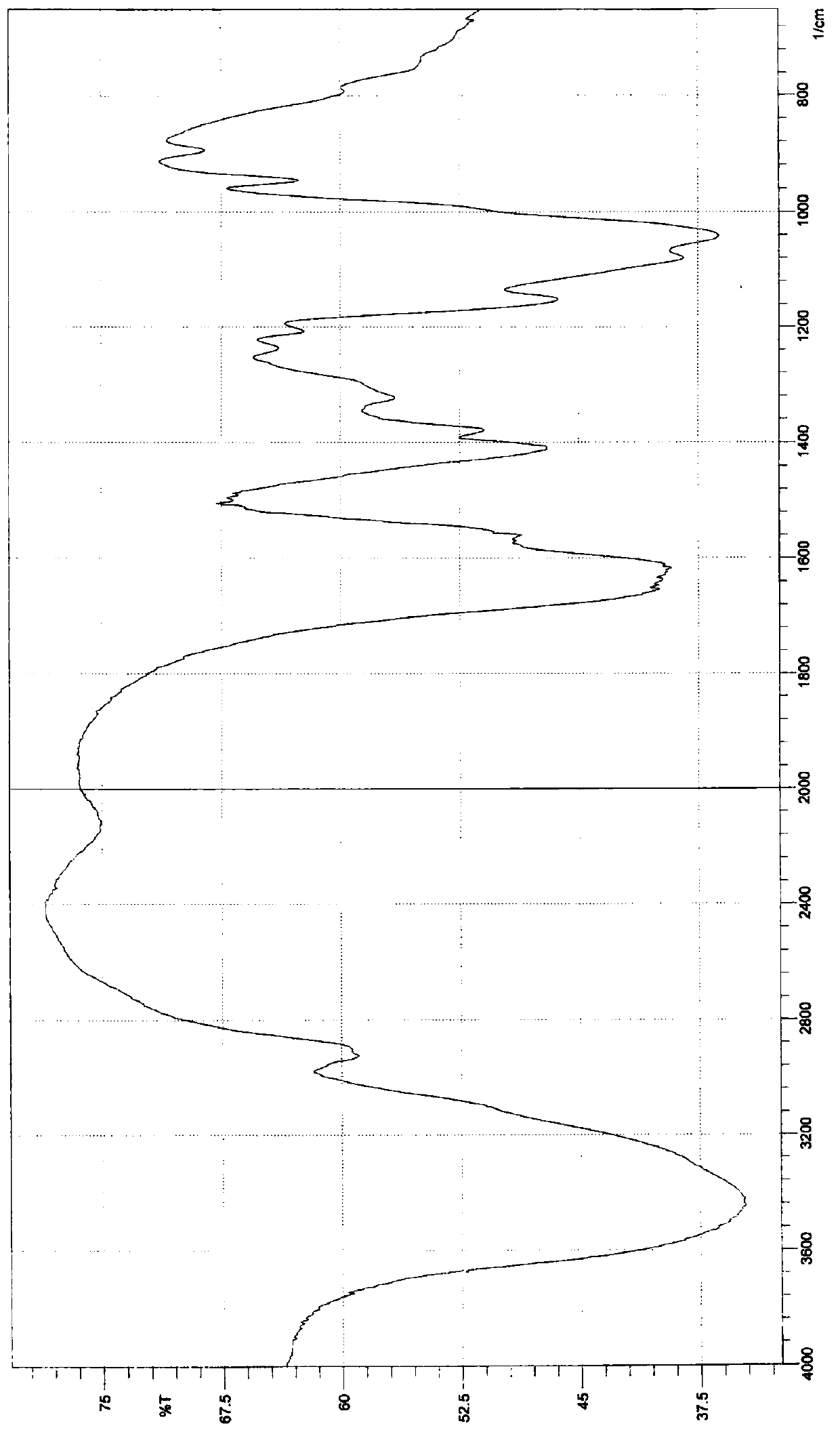

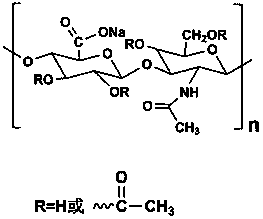

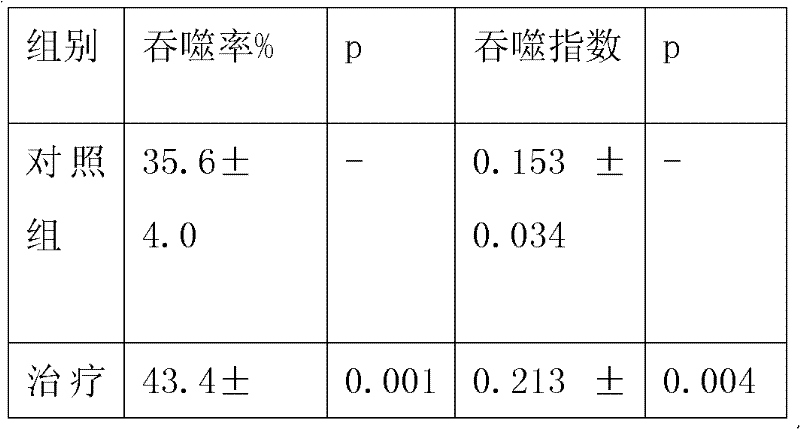

Preparation method of acetylated sodium hyaluronate

PendingCN110724171AMild responseSimple stepsEsterified saccharide compoundsSugar derivativesAcetyl chlorideOrganic solvent

The invention provides a preparation method of acetylated sodium hyaluronate. In a protective gas, hyaluronate and acetylchloride react in an organic solvent, and a product is separated and purified and then reacts with alkali for salification so as to obtain the product. The preparation method of the invention has the following advantages: a corrosive catalyst such as s concentrated sulfuric acidor a pyridine catalyst that is difficult to purify is not required; the reaction is mild and the steps are simple; and the separation and purification step is simple.

Owner:SHANDONG TOPSCI BIO TECH

Pine needle tea bag and preparation method thereof

The invention discloses a pine needle tea bag and a preparation method thereof. The pine needle tea bag is prepared from the following raw materials in part by weight: 30 to 90 parts of fine pine needle powder, 10 to 30 parts of pine needle extract, or 30 to 60 parts of fine pine needle powder, 10 to 30 parts of pine needle extract, 5 to 15 parts of fine ginseng powder and 15 to 30 parts of fine kudzuvine root powder, or 30 to 60 parts of fine pine needle powder, 10 to 30 parts of pine needle extract, 10 to 30 parts of fine ganoderma lucidum powder and 10 to 30 parts of fine kudzuvine root powder. The produced pine needle tea has naturally green color, thick fragrance and pure mouthfeel; the components of the beverage are easily absorbed by the human body; and the beverage is a health-care beverage which is suitable for both the old and the young.

Owner:ANHUI GAOSHAN PHARMA

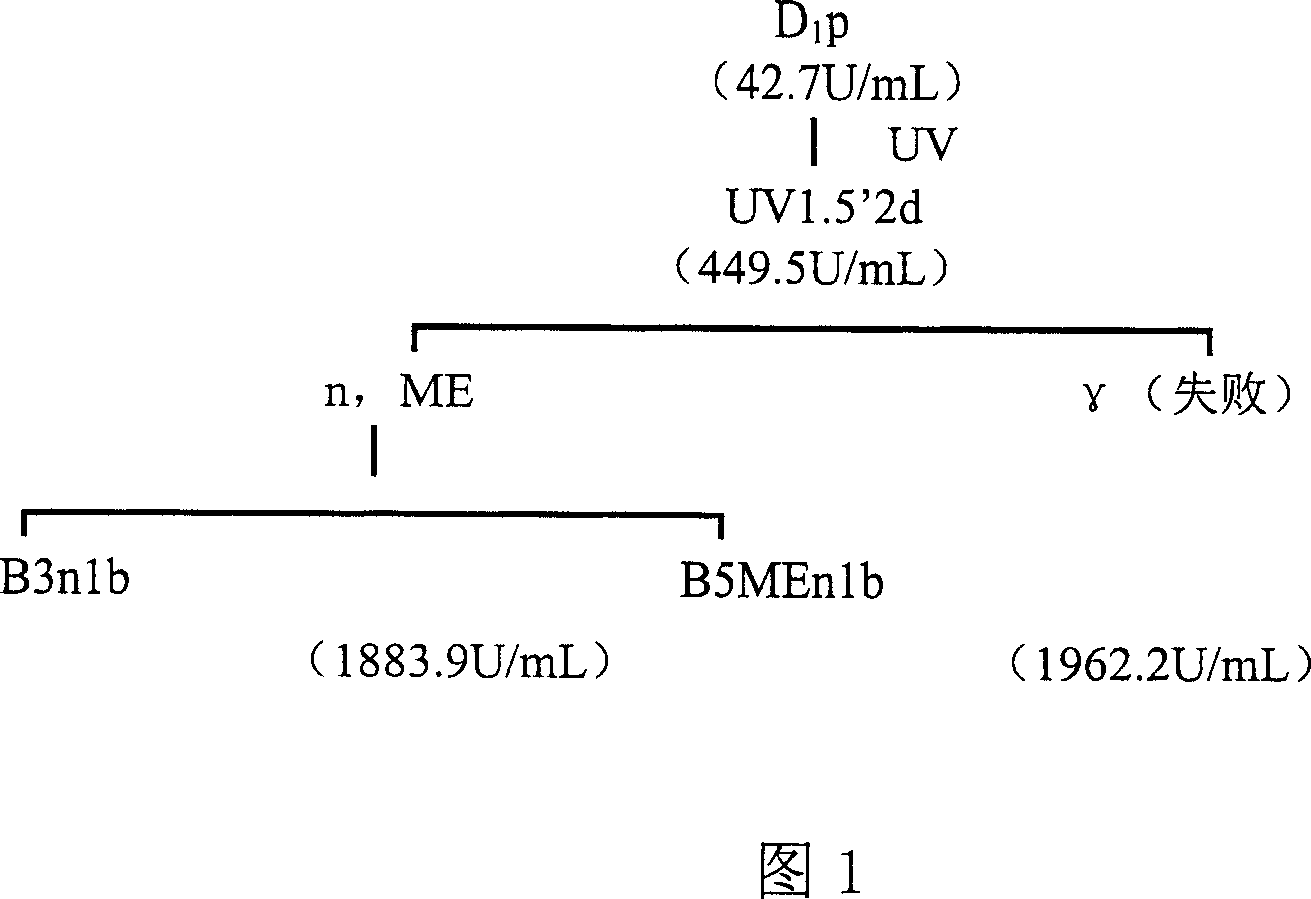

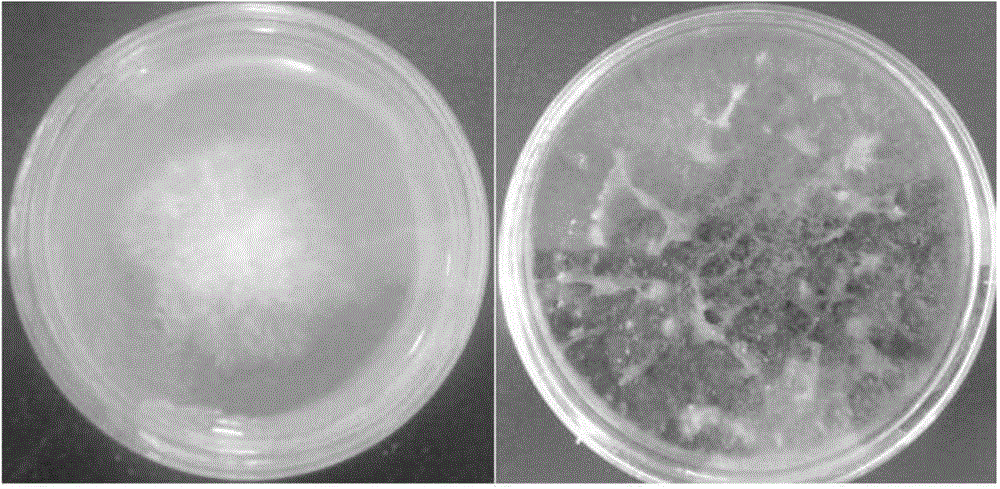

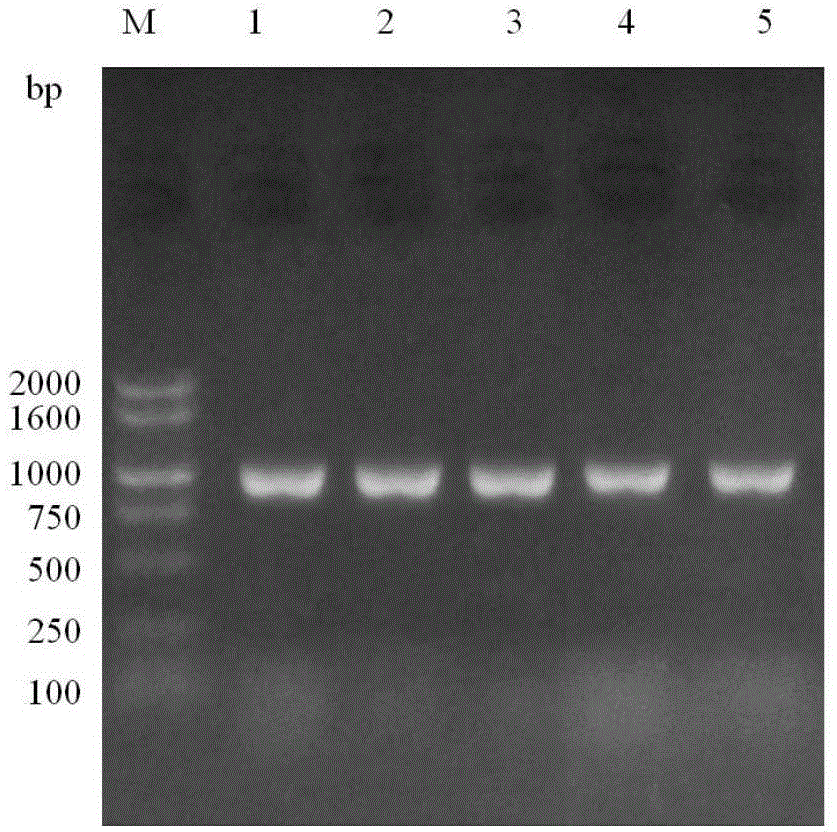

Endophytic fungus strain having high paclitaxel yield and method for producing paclitaxel by endophytic fungus strain

ActiveCN103911293AWon't breakReduce manufacturing costFungiOrganic chemistryBiotechnologyEndophytic fungus

The invention discloses an endophytic fungus strain, which is capable of producing paclitaxel and is separated from young stems of taxus chinensis. The endophytic fungus strain is named as Botryosphaeria dothidea J11, is preserved in the China center for type culture collection and has an accession number of CCTCC NO: M2013591. The invention also relates to a method for producing paclitaxel by the preserved endophytic fungus strain. The method comprises the following steps of culturing the preserved endophytic fungus strain by a culture medium so that paclitaxel is produced and gathered in strain hyphae, recovering the paclitaxel in the cells and carrying out purification. The endophytic fungus strain provides a novel strain for microbial fermentation production of paclitaxel. Through the endophytic fungus strain, a paclitaxel fermentation production period is short and a cost is low. A HPLC analysis detection result shows that through the shake flask fermentation of the endophytic fungus strain, a paclitaxel yield has 617.6 microgrammes per liter. The endophytic fungus strain has a potential for use in industrial production.

Owner:HUIZHOU UNIV

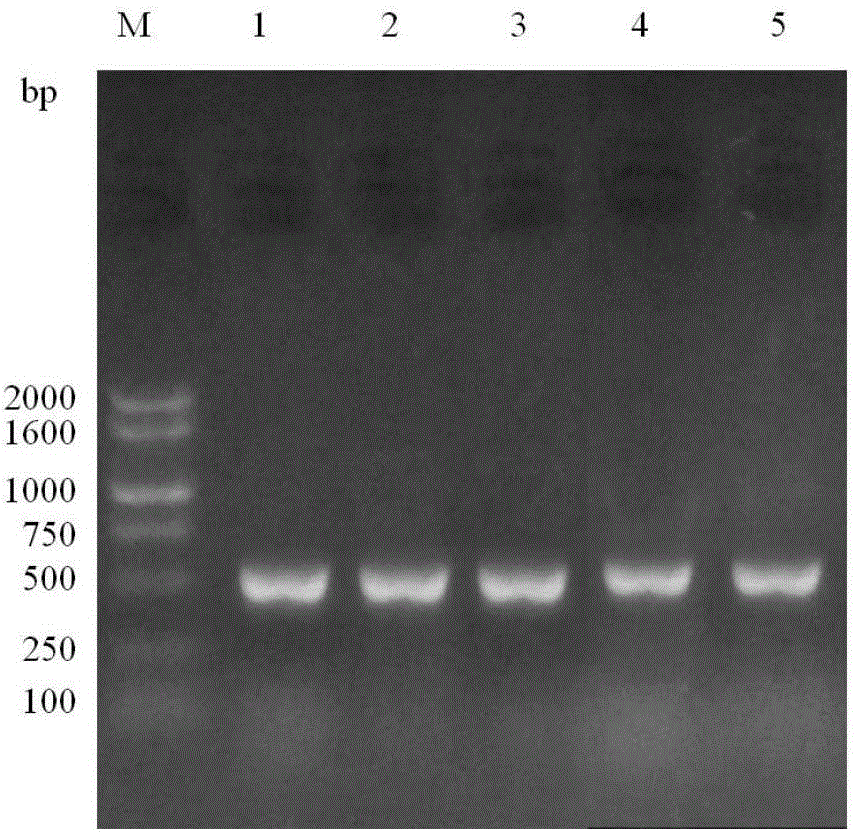

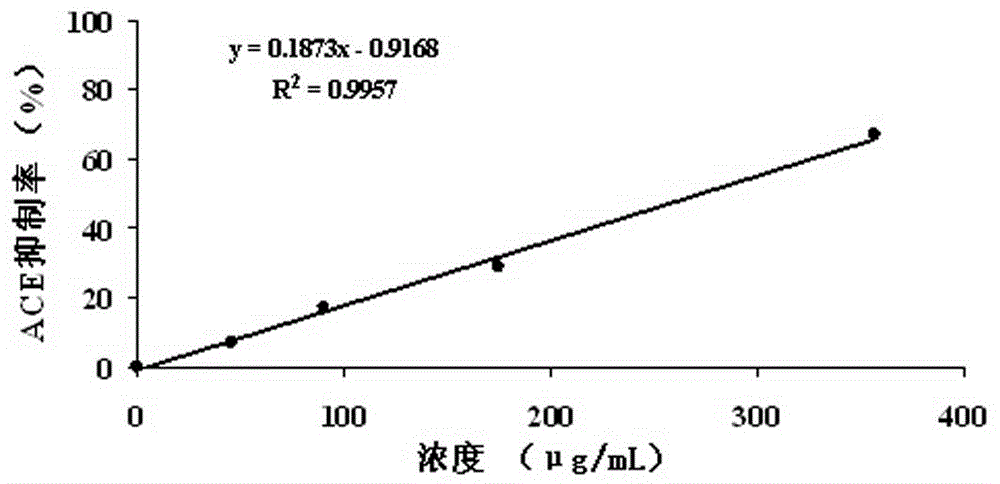

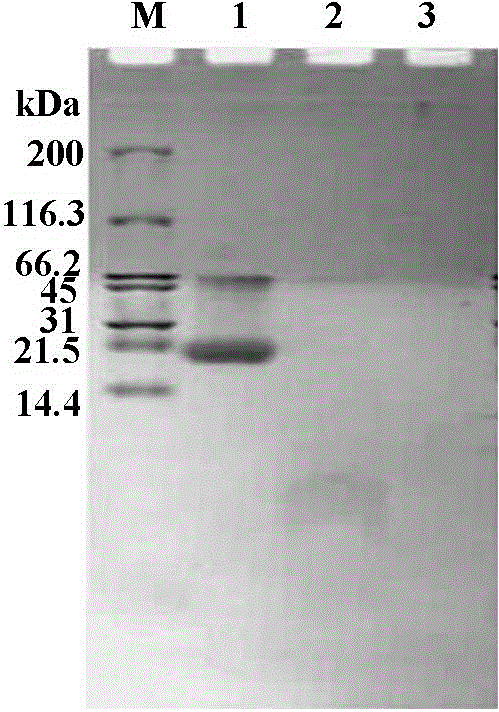

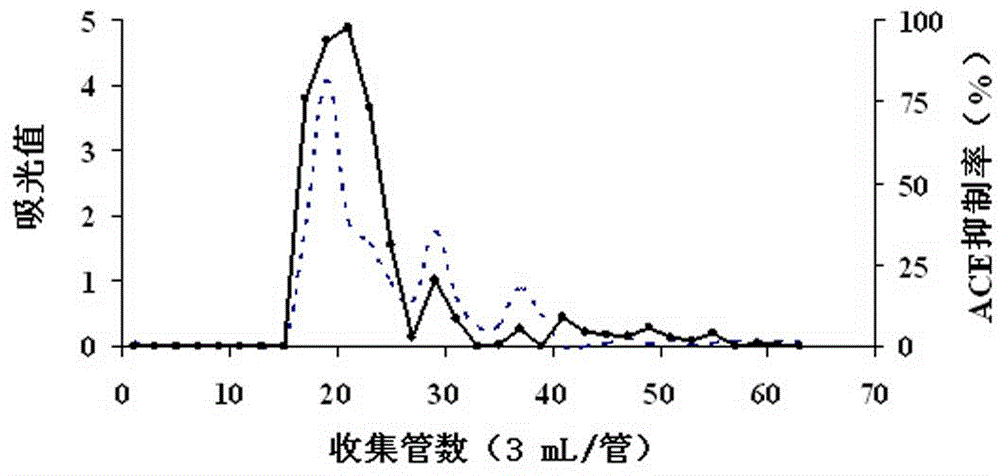

Preparation method for phycoerythrin ACE inhibitory peptide

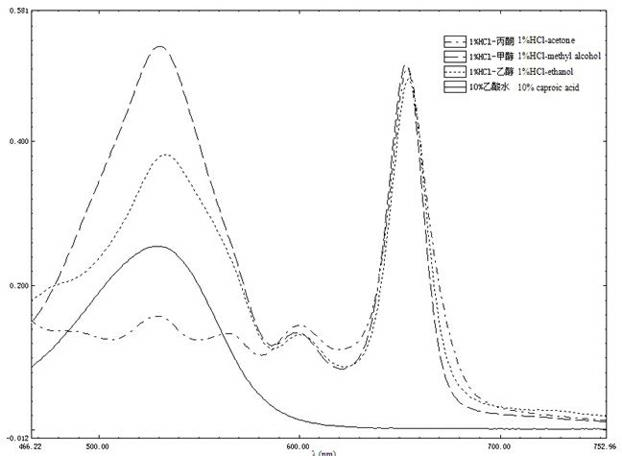

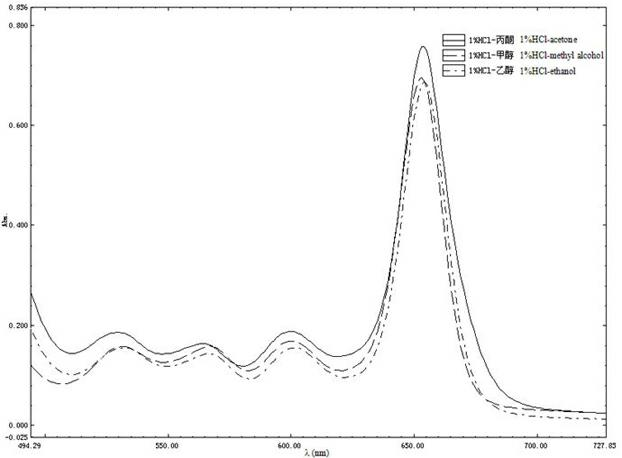

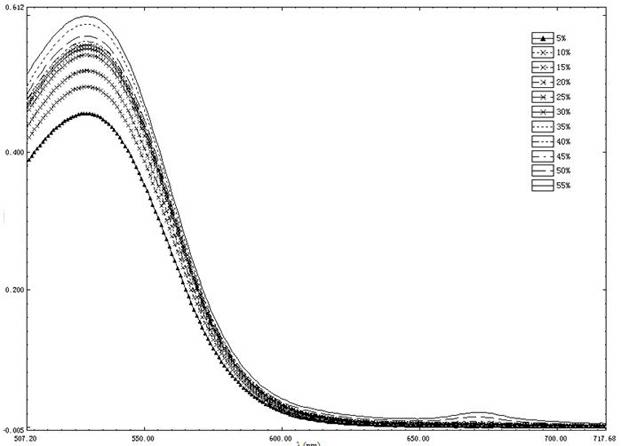

ActiveCN104131055AOptimizing Chromatographic ConditionsEffective and feasible technical parametersPeptide preparation methodsAlgae/lichens peptidesMolecular biologyPepsin

Owner:JIMEI UNIV

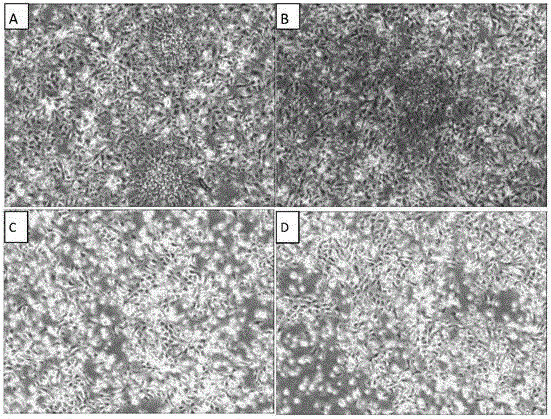

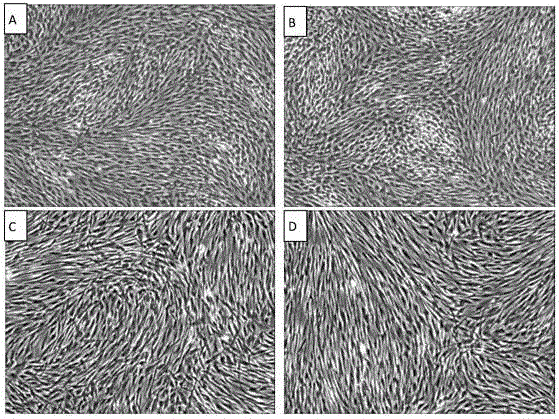

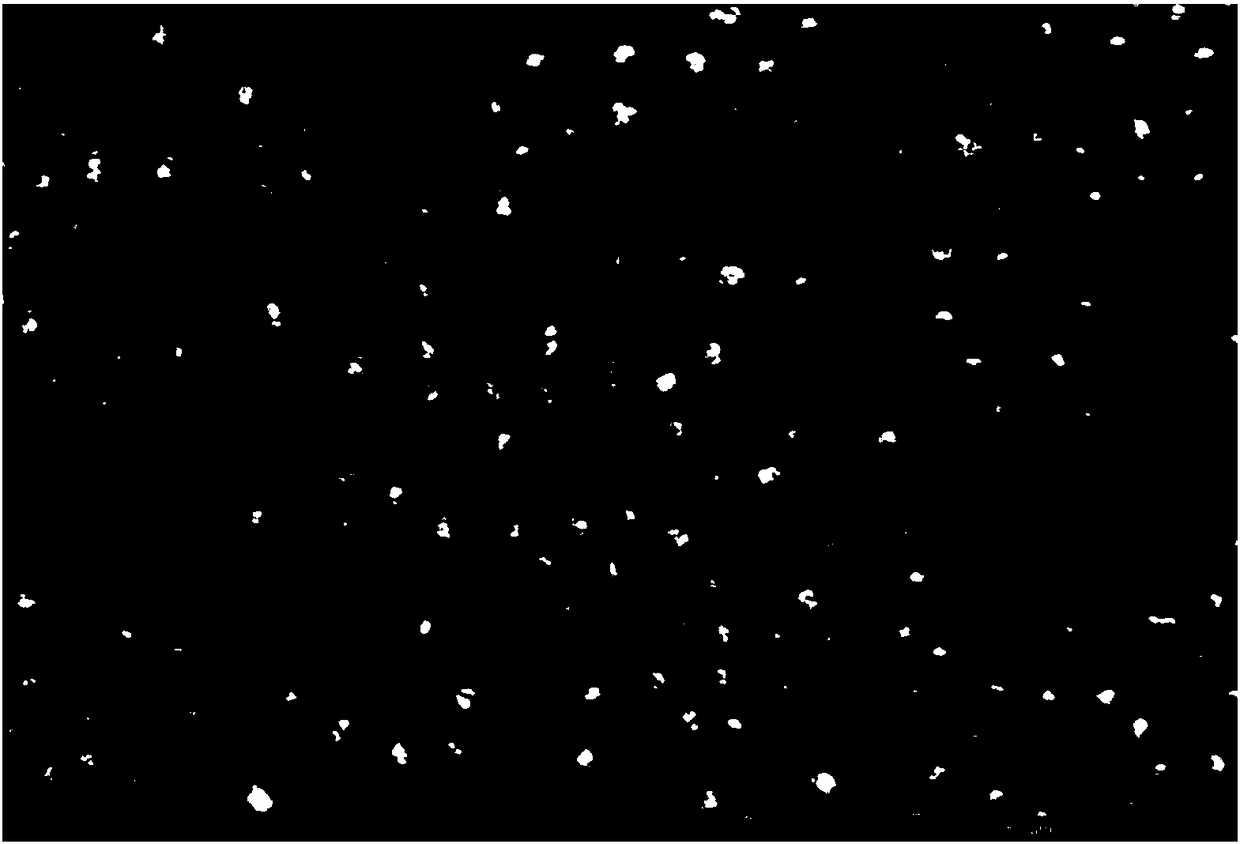

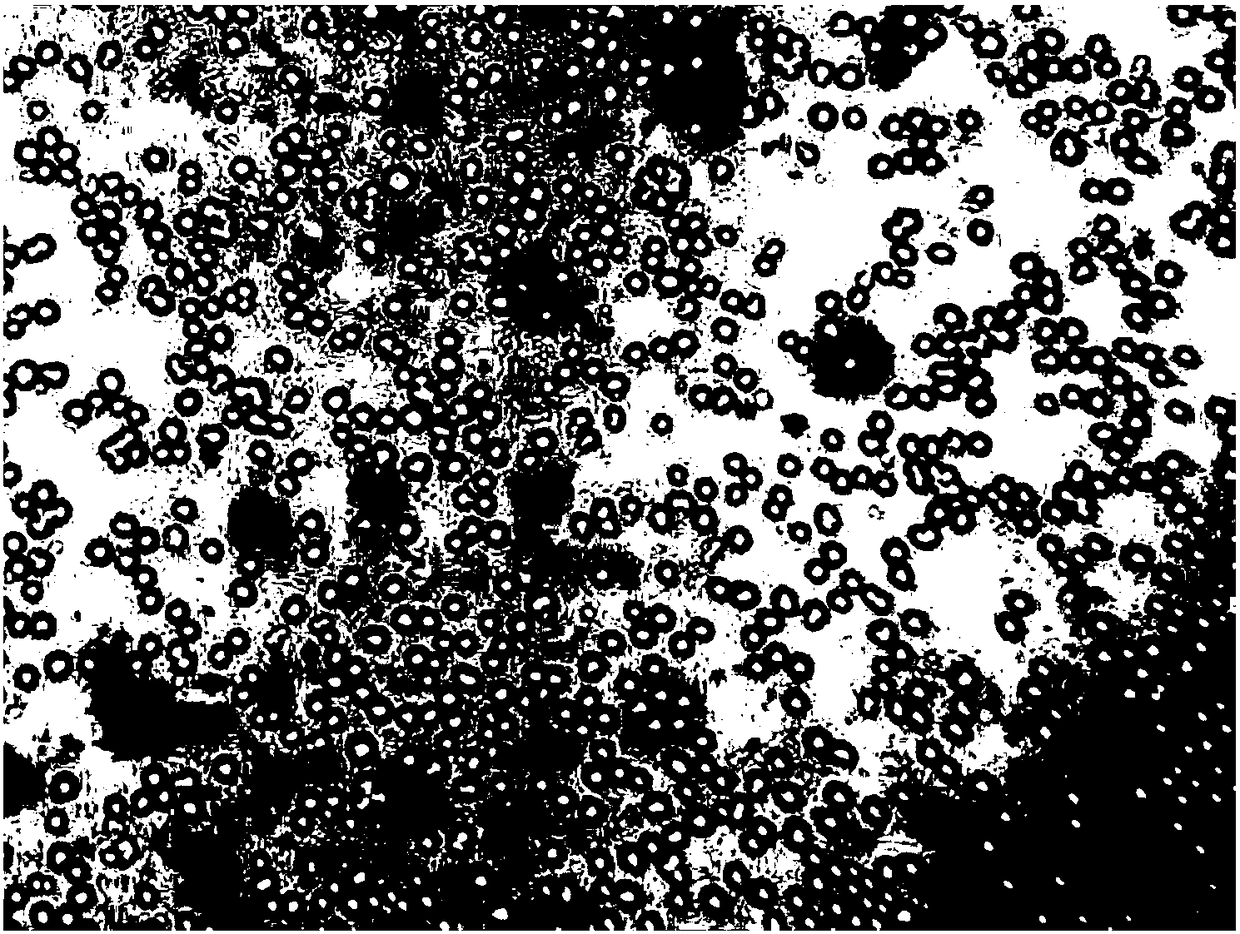

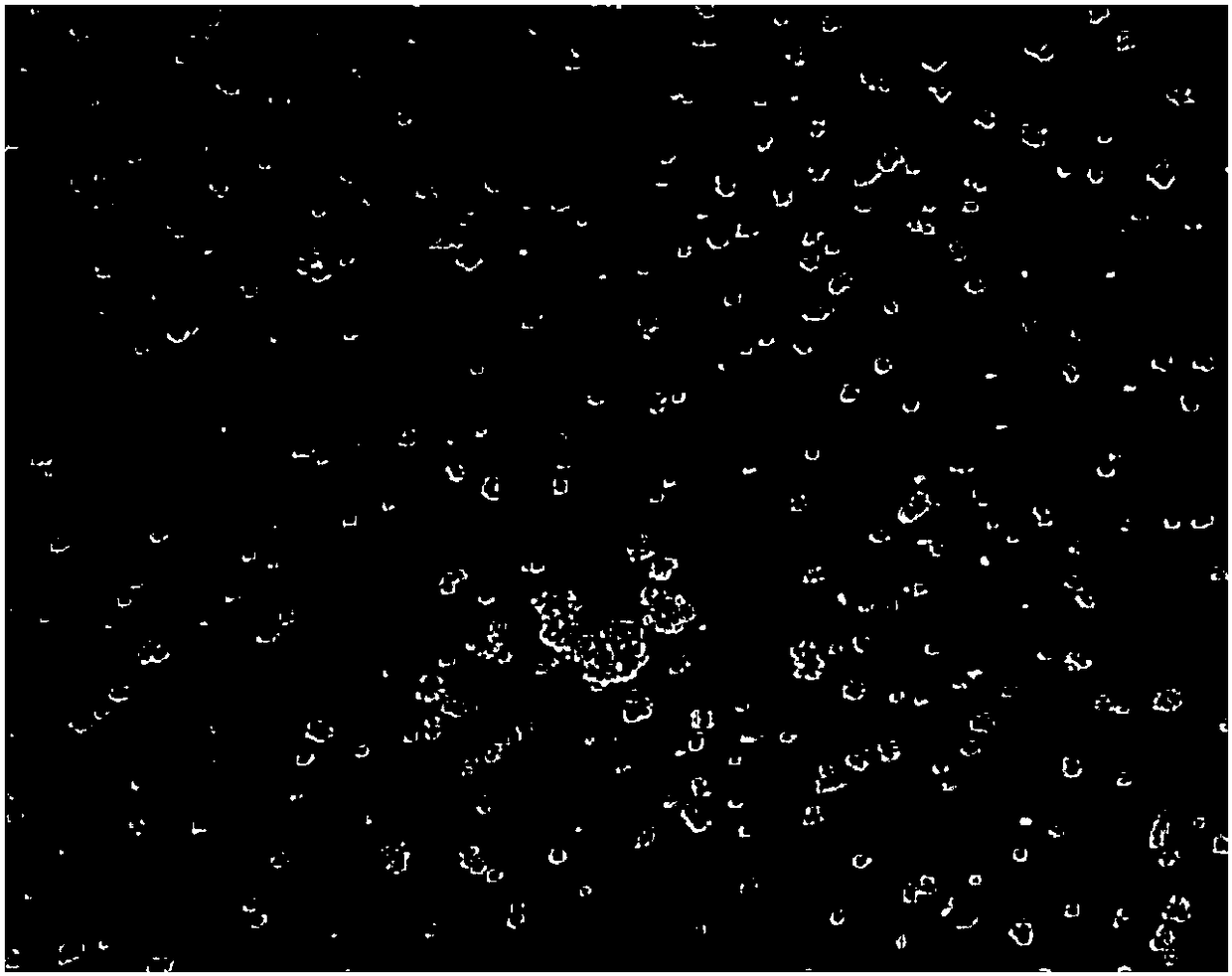

Multifunctional serum-free cell culture medium and application thereof

InactiveCN105861421APromote growthConsistent performanceCulture processEpidermal cells/skin cellsCell culture mediaBiochemistry

The invention provides a multifunctional serum-free cell culture medium and application thereof. A method for preparing the multifunctional serum-free cell culture medium includes mixing DMEM (dulbecco modified eagle medium) high-glucose culture media and F12 nutrient culture media with one another; adding B27 additives, PC-1 additives, gene recombination human epidermal growth factors and myllicin double-antibodies into the DMEM high-glucose culture media and the F12 nutrient culture media. The multifunctional serum-free cell culture medium and the application have the advantages that the multifunctional serum-free cell culture medium contains simple components, and repeated passage requirements can be met; more importantly, the multifunctional serum-free culture medium not only can be used for quickly amplifying and cultivating primary hypodermal fibroblasts and passage hypodermal fibroblasts in an in-vitro manner, but also can be used for cultivating primary epidermal cells.

Owner:JINAN PANSHENG BIOTECH

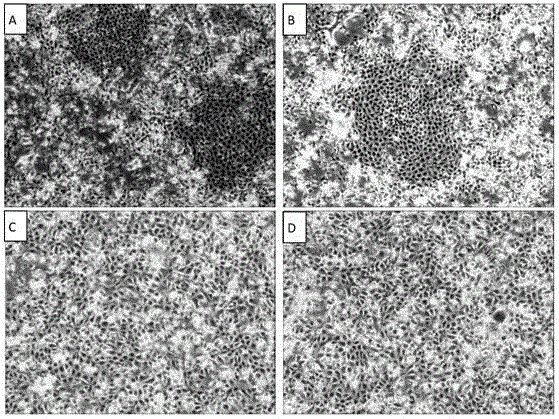

ST culture medium and application thereof

InactiveCN108795841AEliminate security concernsAchieve high density cultureCulture processArtificial cell constructsSerum freeHigh density

The invention belongs to the technical field of biology, and particularly relates to a ST culture medium and application thereof. The ST culture medium does not contain serum, fully-suspended serum-free culture of ST cells can be realized by adopting the ST culture medium, and high-density culture can be realized without using a microcarrier. The serum is not needed in the process of suspended culture of the ST cells, and the culture medium does not contain animal-derived components, so that batch-to-batch difference and the safety problem caused by the animal-derived components like the serumare eliminated, production cost is lowered, and the downstream separation and purification step is simplified. In addition, components in the culture medium are determined, so that repeatability andstability from supply of the culture medium to cell culture to product production.

Owner:SHANGHAI OPM BIOSCI CO LTD

Escherichia coli recombinant strain for heterologous expression of nitrile hydratase and application thereof

InactiveCN109251881ASimplify separation and purification stepsIncrease productivityBacteriaMicroorganism based processesEscherichia coliHeterologous

The invention discloses an escherichia coli recombinant strain for heterologous expression of nitrile hydratase and application thereof, and belongs to the field of bioengineering. The escherichia coli recombinant strain with high nitrile hydrase activity is obtained by constructing recombinant escherichia coli. The recombinant escherichia coli is subjected to high-density fermentation. Nicotinamide or acrylamide is adopted as a substrate to conduct whole-cell catalytic reaction to prepare nicotinamide or acrylonitrile. Compared with a chemical production method, the method is high in catalytic efficiency, and yield of the nicotinamide or acrylamide is over 95%.

Owner:JIANGNAN UNIV

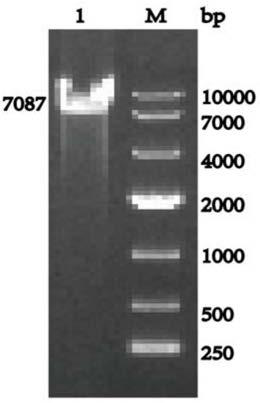

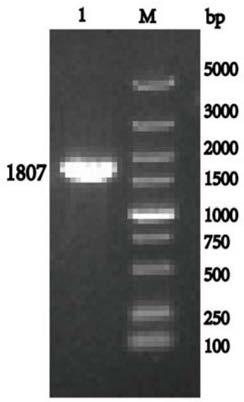

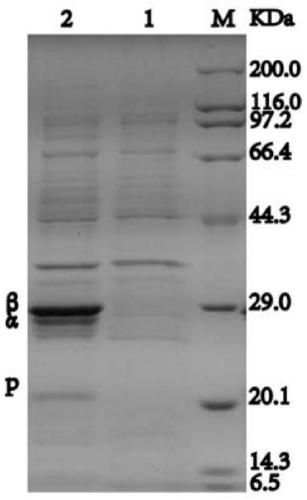

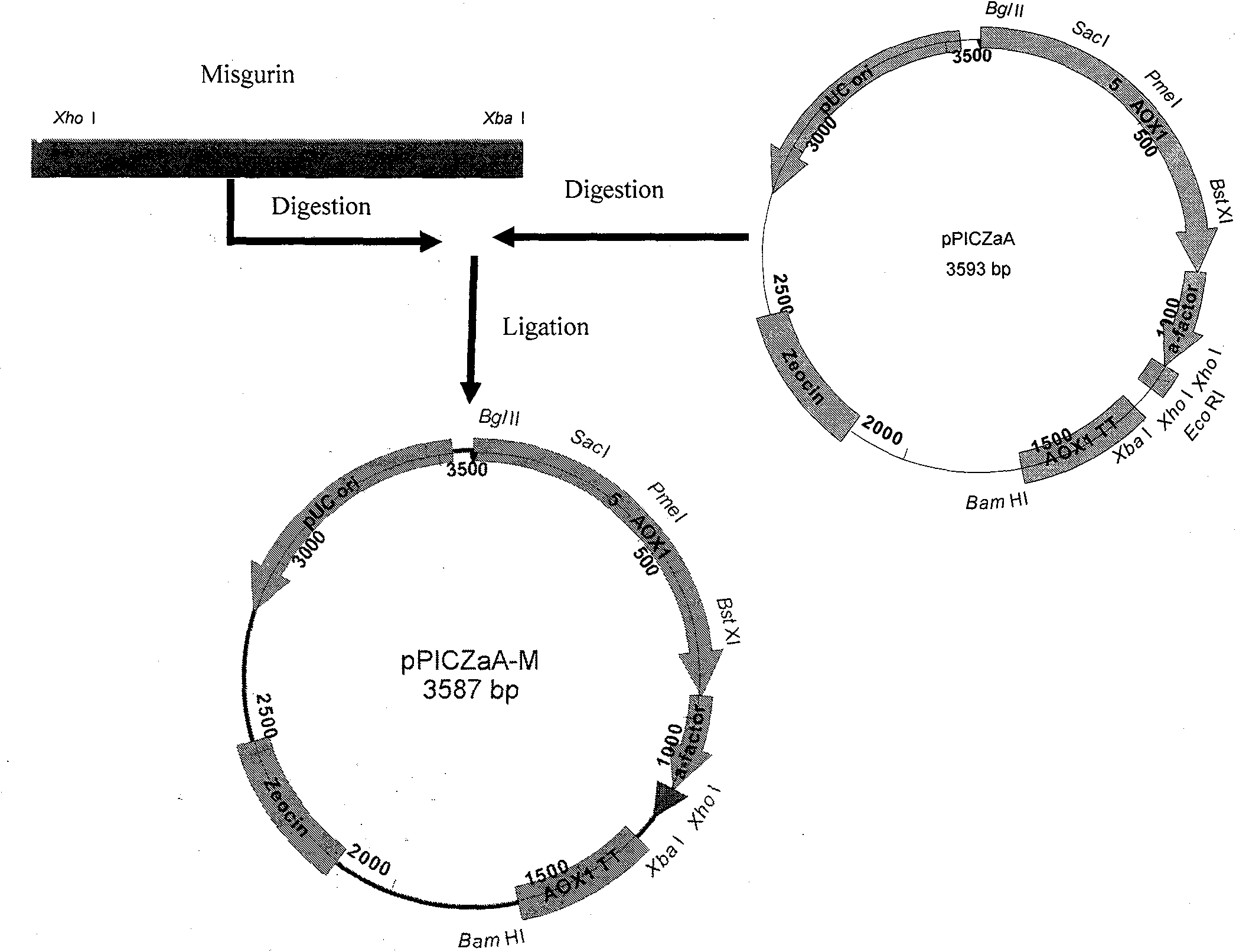

Preparation method and application of novel antimicrobial peptide Misgurin mutant

InactiveCN102080079AHigh antibacterial activityEasy to identifyAntibacterial agentsPeptide/protein ingredientsBiotechnologyESCHERICHIA COLI ANTIGEN

The invention belongs to the technical field of biology and relates to a preparation method and application of a novel antimicrobial peptide Misgurin mutant. The technical scheme is as follows: introducing glutamine at the C tail end of the amino acid sequence of natural Misgurin so as to design a novel Misgurin mutant; selecting Pichia yeast biased codons so as to artificially synthesize a complete gene of the novel Misgurin mutant; constructing a Pichia yeast secretion type expression vector pPICZaA-M; transforming a host cell SMD1168 by a vector electroporation method; selecting to obtain high-efficiency expression strains; and under proper culture conditions, ensuring 100 microgram of recombinant novel Misgurin mutant is contained in per milliliter of expression supernatant. The obtained product has a good nematocidal activity on staphylococcus aureus, pig salmonella and pig pathogenic Escherichia coli K88, K99 and 987P, and has an obvious effect on prevention and treatment of clinical bacterial diseases.

Owner:上海市农业科学院畜牧兽医研究所

Preparation method of squalene synthetase inhibitor CJ-13982

InactiveCN102517350AEasy to prepareMild culture conditionsMicroorganism based processesFermentationNigrospora oryzaeBiology

The invention discloses a preparation method of a squalene synthetase inhibitor CJ-13982. The compound CJ-13982 is separated and prepared from a fermentation culture of nigrospora oryzae A8 which has a collection number of CCTCC NO. M 2011412. The invention provides a method for preparing the compound CJ-13982 with the squalene synthetase inhibiting effect from the fermentation culture of a plant endophytic fungi nigrospora oryzae A8. The method is advantaged in mild culturing condition, simple and feasible culturing medium preparation, simple separation and purification steps, and high yield. With the method, large-scale production can be realized in a manual controlling condition. With the method, a problem of raw material required by compound CJ-13982 researches or applications can easily be solved, and a novel approach is provided for the preparation of the compound CJ-13982.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Method for separating and purifying various components from cefaclor enzymatic reaction solution

InactiveCN103193800AAvoid wastingReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationChemistryCationic exchange

The invention relates to a method for separating and purifying various components from a cefaclor enzymatic reaction solution, and the method comprises the following steps of: (1) recovering an unreacted mother nucleus 7-ACCA from the cefaclor enzymatic reaction solution by adopting an acid precipitation method; (2) separating and purifying cefaclor by adopting macroporous adsorption resin; and (3) separating and purifying D-phenylglycine by adopting cation exchange resin. The method disclosed by the invention can be used for separating and purifying the unreacted mother nucleus 7-ACCA, the product cefaclor and the by-product D-phenylglycine from the reaction solution used for enzymatically synthesizing the cefaclor, sufficiently utilizes the raw materials and reduces the production cost; and products obtained by adopting the method disclosed by the invention are high in yield purity and suitable for popularization and usage.

Owner:CHENGDU UNIV

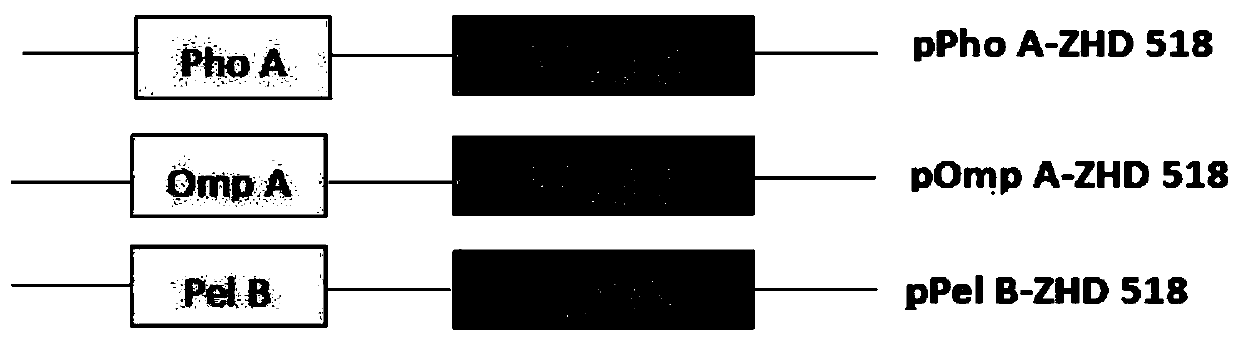

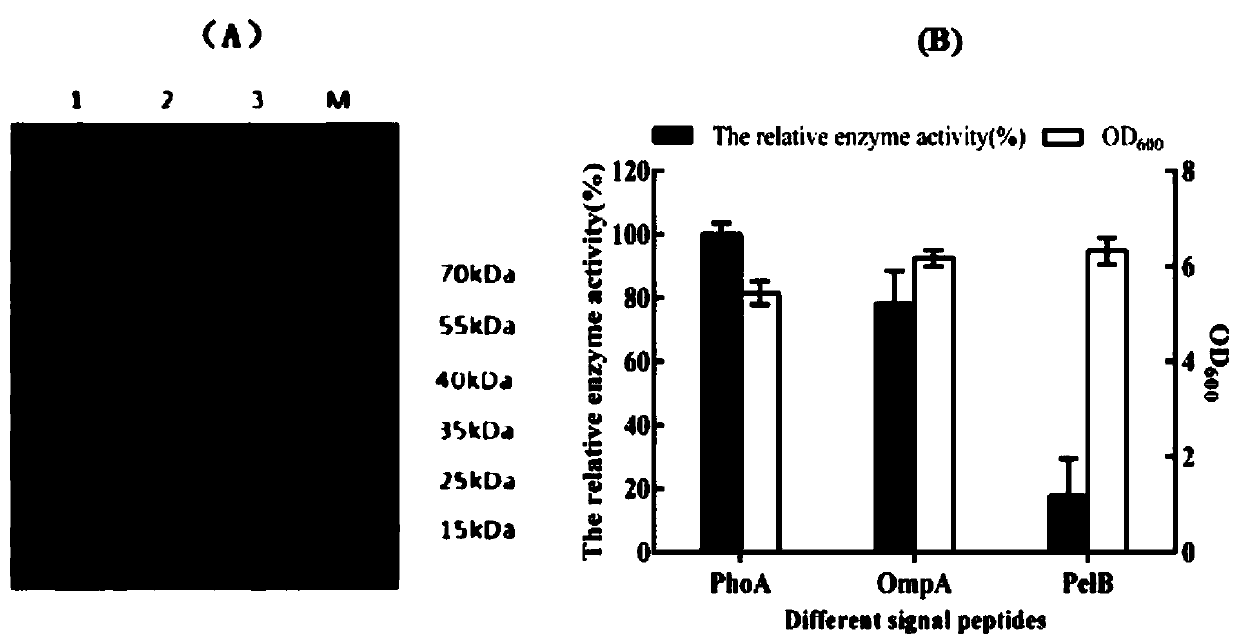

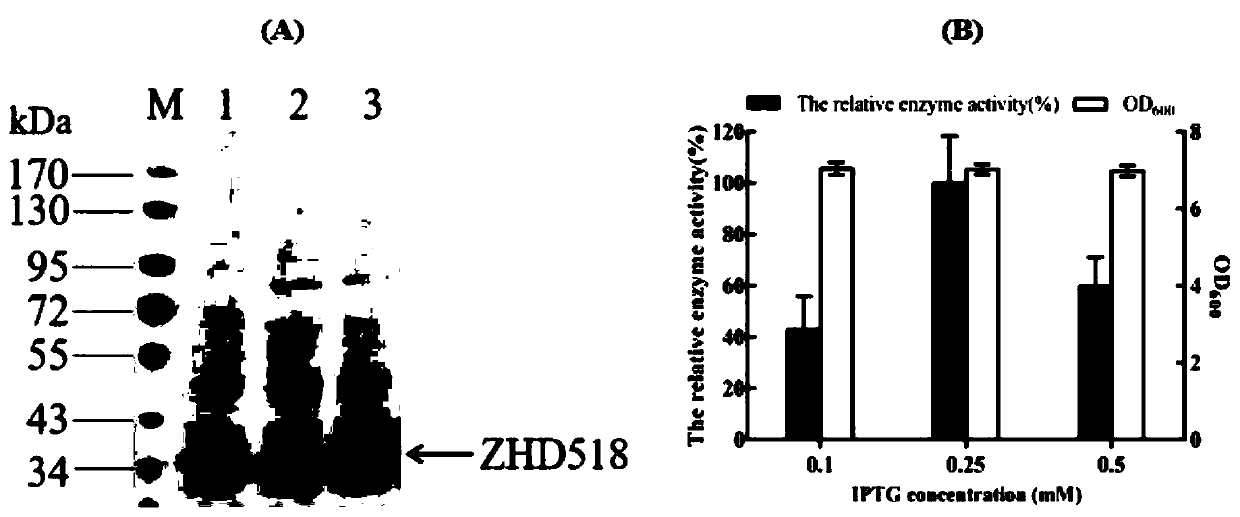

Method for promoting secretory expression of corn gibberelenone degrading enzyme ZHD 518 protein as well as application

ActiveCN110616230ASimplify the steps of protein separation and purificationReduce wastePolypeptide with localisation/targeting motifHydrolasesPeptideSignal peptide

The invention belongs to the technical field of molecular biology and provides a method for promoting secretory expression of corn gibberelenone degrading enzyme ZHD 518 protein by fusion signal peptide as well as increasing secretory expression quantity by optimizing induction and secretion conditions; secondly, a method for promoting the secretory expression of the ZHD 518 protein is obtained bycombining a fusion expression strategy with the own characteristics of ZHD 518 protein, so that the protein is secreted outside the cell, the subsequent enzyme separation and purification step is simplified and the aim of rapidly obtaining target protein is fulfilled.

Owner:HUBEI UNIV

Method for extracting anthocyanin from purple cabbage leaves

InactiveCN102167691AMild experimental conditionsSave time on extraction timeOrganic chemistryNatural dyesChlorophyllinBotany

The invention discloses a method for extracting anthocyanin from purple cabbage leaves. The method comprises the following steps of: performing freeze drying on purple cabbage leaves serving as a raw material, and crushing; and leaching twice by taking acetic acid with the volume fraction of 35 percent as an extracting agent at the temperature of 25 DEG C to fully extract anthocyanin. The method provided by the invention is easy, convenient and practical, and the test condition is nontoxic and mild and has low energy consumption; the extraction time is short; the concentration of anthocyanin serving as an extracting solution is high; and the characteristic of high chlorophyll content of the purple cabbage is fully considered in the extracting agent screening process, so that the interference of chlorophyll separation on anthocyanin is effectively avoided and the characteristic peak of the chlorophyll is not found during spectrum scanning. The solvent for extracting anthocyanin from purple cabbage leaves is safe and nontoxic, so that the environmental protection and the popularization of pigments in the field of foods are facilitated.

Owner:NORTHWEST A & F UNIV

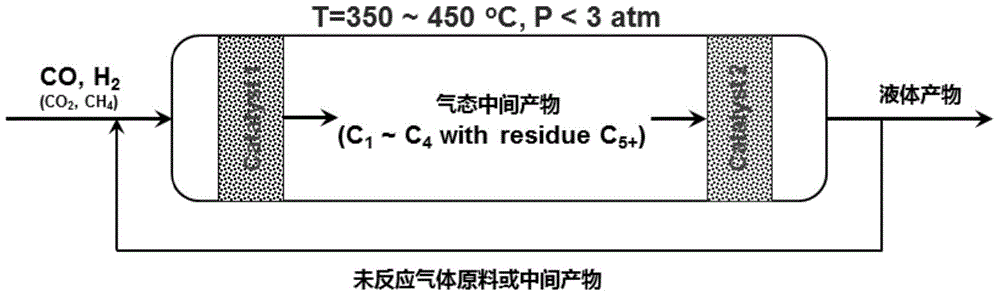

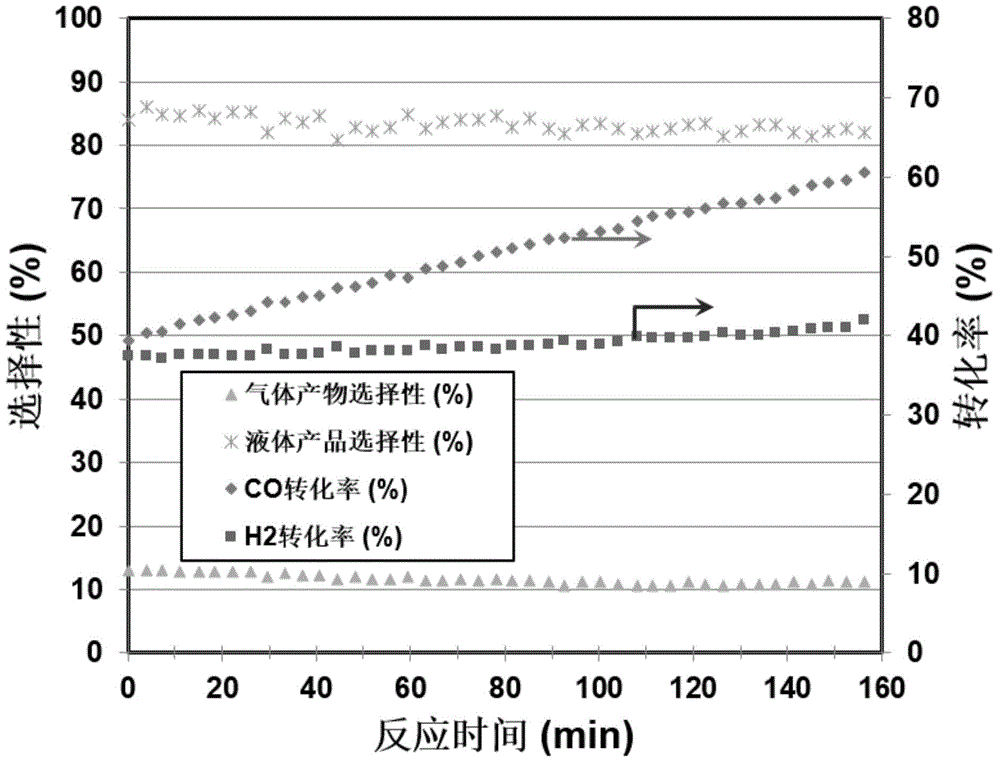

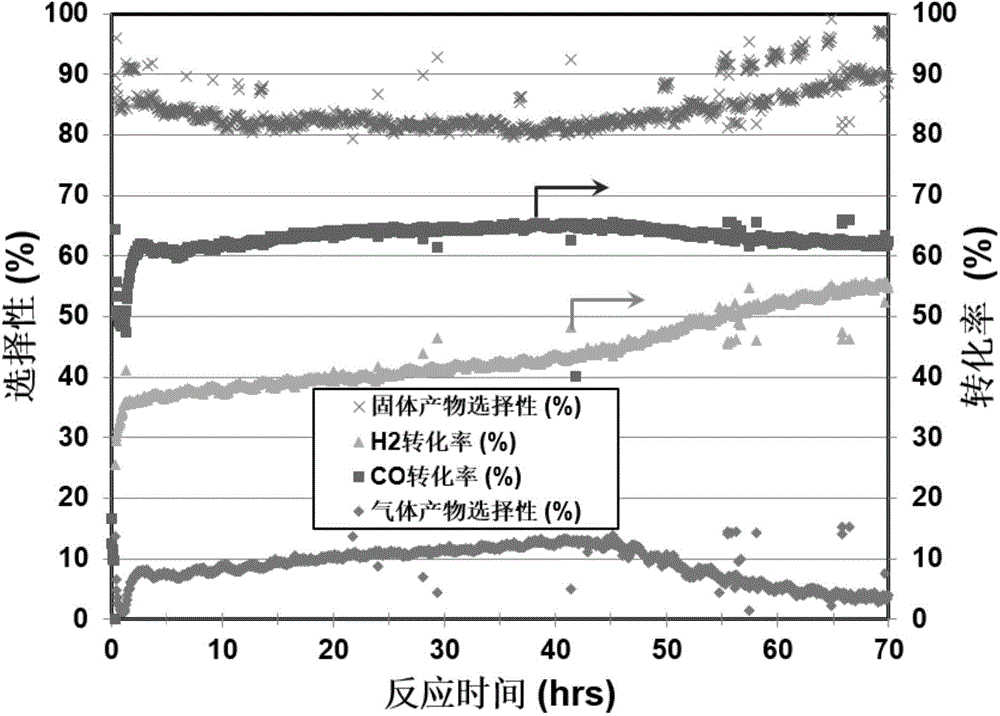

Synthesis gas liquification catalyst and catalyzing method thereof, beds and preparation method

ActiveCN104096571AReduce input requirementsLow reaction pressureMolecular sieve catalystsLiquid hydrocarbon mixture productionSyngasAdditive ingredient

The invention relates to a synthesis gas liquification catalyst and a catalyzing method thereof, beds and a preparation method. The liquification catalyst comprises a primary catalyst and a secondary catalyst, wherein the primary catalyst adopts a fischer-tropsch catalyst obtained after component adjustment, and the secondary catalyst adopts a novel catalyst developed through synergistic effect of hydrocarbon. The catalyzing method of the synthesis gas liquification catalyst comprises steps as follows: firstly, synthesis gas reacts with the primary catalyst to be converted into a product with a main ingredient of saturated or unsaturated C1-C4 hydrocarbon and then reacts with the secondary catalyst to generate liquid hydrocarbon. The beds used for synthesizing the liquification catalyst comprise a first bed and a second bed, the first bed is loaded with the primary catalyst, and the second bed is loaded with a secondary catalyst. The preparation method comprises steps as follows: after the primary catalyst and the secondary catalyst are prepared respectively, the primary catalyst and the secondary catalyst are adjacently placed or physically mixed at the mass ratio of (0.1-10):1 to obtain the synthesis gas liquification catalyst. With the adoption of the catalyst, synthesis gas can be liquified under the reaction condition of ambient pressure.

Owner:广西华大骄阳能源环保科技有限公司

Humanized anti-CD20 monoclonal antibody with high affinity

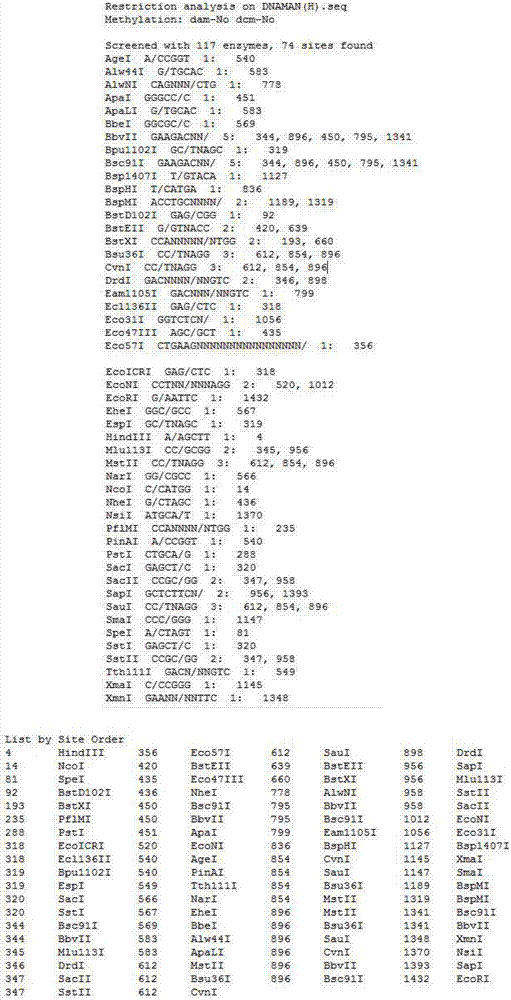

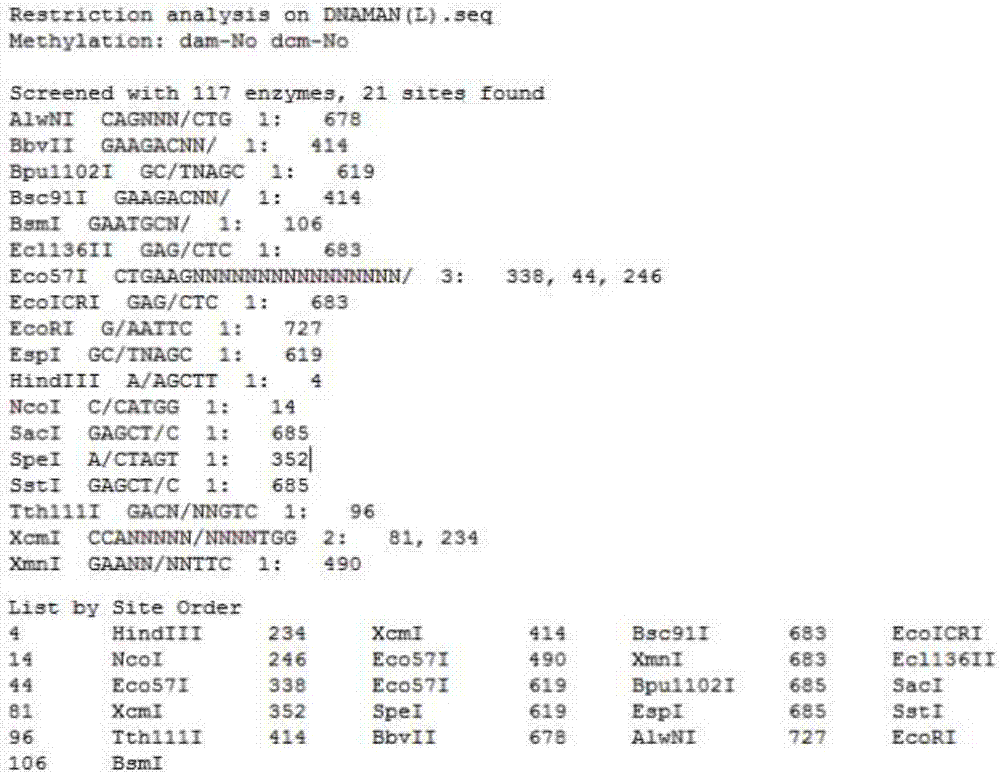

InactiveCN107033244AWeak affinityLow immunogenicityImmunoglobulins against cell receptors/antigens/surface-determinantsNucleic acid vectorCD20Genetic engineering

The invention relates to the technical field of genetic engineering and discloses a humanized anti-CD20 monoclonal antibody with high affinity. The antibody comprises optimized CD20H and CD20L nucleotide sequences, wherein CD20H is obtained by connecting a CD20 heavy chain variable region with a constant region Fc sequence, and CD20L is obtained by connecting a CD20 light chain variable region with a constant region Fc sequence; the CD20H and CD20L nucleotide sequences are optimized by virtue of a CHO cell preference codon, an eukaryotic expression original Kozak sequence, a signal peptide sequence and an initiation codon ATG are added at the tail end of N, a Hind III restriction enzyme cutting site is added at a 5' terminal, and an EcoRI site is added at a 3' terminal, so that the optimized CD20H and CD20L nucleotide sequences are obtained. According to the invention, by virtue of a large number of experiments, the humanized anti-CD20 monoclonal antibody with high affinity is finally determined, and the antibody has low immunogenicity and high affinity at the same time.

Owner:LIAOCHENG UNIV

Separation and purification method for cell culture mixture

InactiveCN102191226AHigh purityStrong targetingImmunoglobulins against animals/humansMicroorganism based processesPurification methodsPore diameter

The invention discloses a separation and purification method for a cell culture mixture, comprising the step of: filtering the cell culture mixture by a filter, wherein the filter is provided with at least two layers of filtering membranes, the nominal pore diameter of each layer of filtering membrane is gradually reduced in the direction of flow of the filtrate, i.e. the nominal pore diameter of the first layer of filtering membrane is about 2-10mu m, and the nominal pore diameter of the final layer of filtering membrane is about 0.1-0.2mu m. The separation and purification method for a cell culture mixture disclosed by the invention has the advantages of strong pertinence, large treatment capacity, simple separation and purification step, stable product quality, low cost and the like.

Owner:BEIJING SKYWING TECH CO LTD

Construction and application of an engineered bacterium that secretes and expresses chitobiose deacetylase

ActiveCN109777761BHigh expressionSimplify separation and purification stepsOrganic active ingredientsBacteriaHeterologousProtein target

The invention discloses the construction and application of an engineering bacterium that secretes and expresses chitobiose deacetylase, and belongs to the technical field of fermentation engineering. The present invention first constructs a recombinant Bacillus subtilis strain heterologously secreting and expressing the chitobiose deacetylase gene, and adds a signal peptide fragment yncM to the recombinant vector for the first time, and the signal peptide can convert the target protein chitobiose deacetylase It is secreted outside the cells of the recombinant Bacillus subtilis and obtains a mutant of the 5' untranslated region, which significantly increases the expression of the target protein and greatly simplifies the steps of subsequent enzyme separation and purification. The obtained chitobiose deacetylase has the highest enzyme activity of 1548.7U / mL when fermented and cultivated in the fermentation medium for 50-60 hours, and the highest chitobiose deacetylase yield is about 620mg / L. At the same time, the method has the advantages of low production cost, mild production conditions, simple purification process steps, safe production operation and the like.

Owner:JIANGNAN UNIV +1

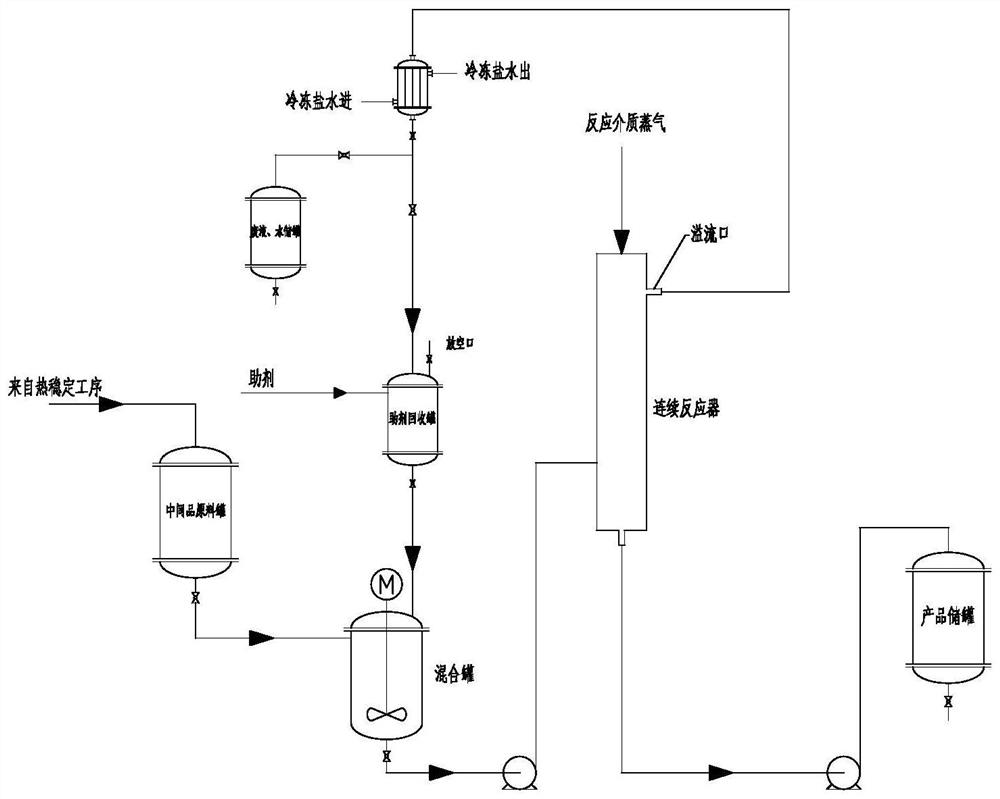

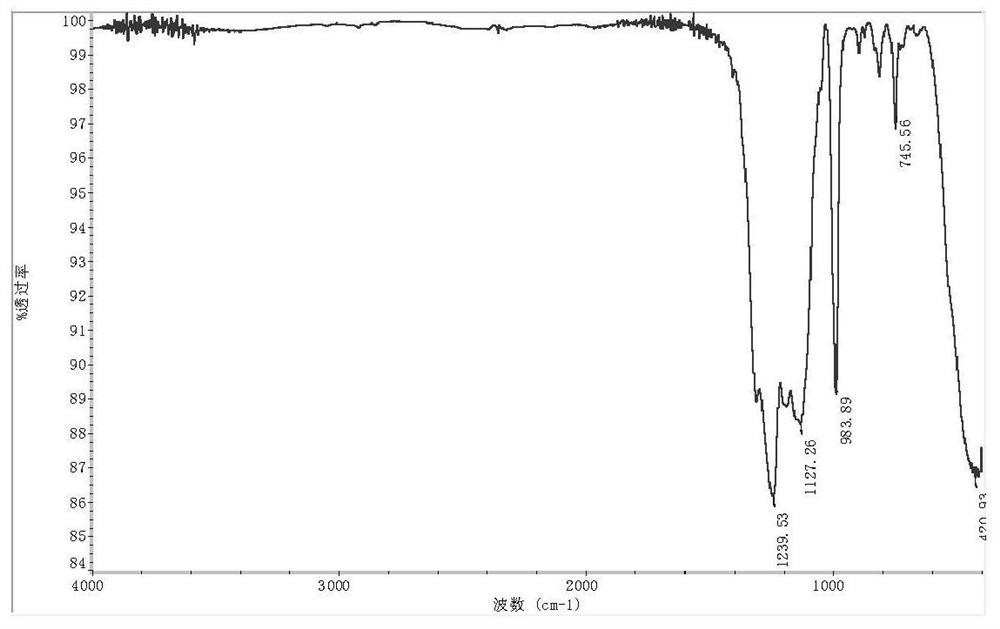

End capping method of perfluoropolyether

ActiveCN113150262AImprove conversion rateImprove efficiencyOrganic chemistryOrganic compound preparationChemical industryEndcapping

The invention discloses an end capping method of perfluoropolyether, and relates to the technical field of fluorine chemical industry. The end capping method comprises the following steps: carrying out end capping reaction on a perfluoropolyether raw material with an unsaturated group as an end group in the presence of an auxiliary agent and reaction medium steam to obtain saturated perfluoropolyether, the auxiliary agent is an organic amine compound or a mixture of the organic amine compound and inorganic base. The method solves the problems that an existing blocking method is low in reaction efficiency, high in energy consumption and not suitable for industrial production, the yield and production efficiency of saturated perfluoropolyether are improved, energy consumption is reduced, and the method is suitable for industrial production.

Owner:JUHUA GROUP TECH CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com