End capping method of perfluoropolyether

A perfluoropolyether, end group technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high energy consumption, unsuitable for industrial production, low reaction efficiency, etc., to simplify the operation process, The effect of saving the cost of raw materials and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

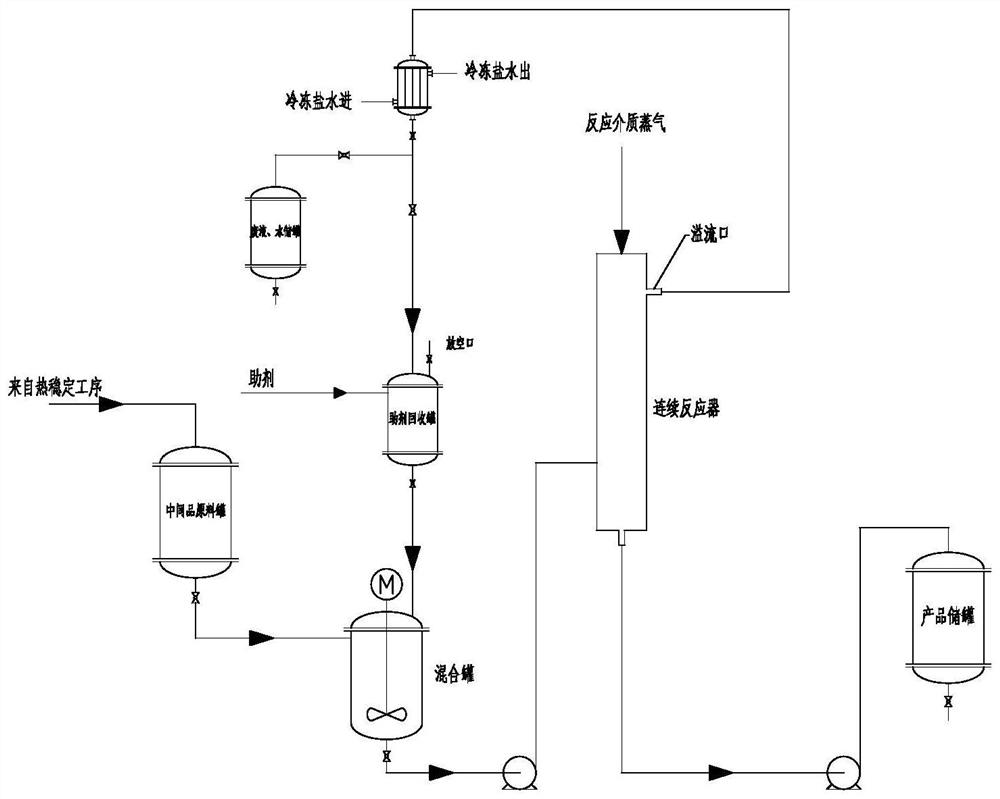

[0069] According to this embodiment figure 1 The process flow shown is carried out.

[0070] The perfluoropolyether (molecular general formula: CF 3 O(CF(CF 3 ) CF 2 O) m CF 2 COF, m=8-13, average molecular weight is 2174) into the raw material tank, and triethylamine into the auxiliary agent tank. Add 6522g of perfluoropolyether acid fluoride and triethylamine into the mixing tank at a molar ratio of 1:1 for mixing, and then pump them into a 15L plug-flow reactor.

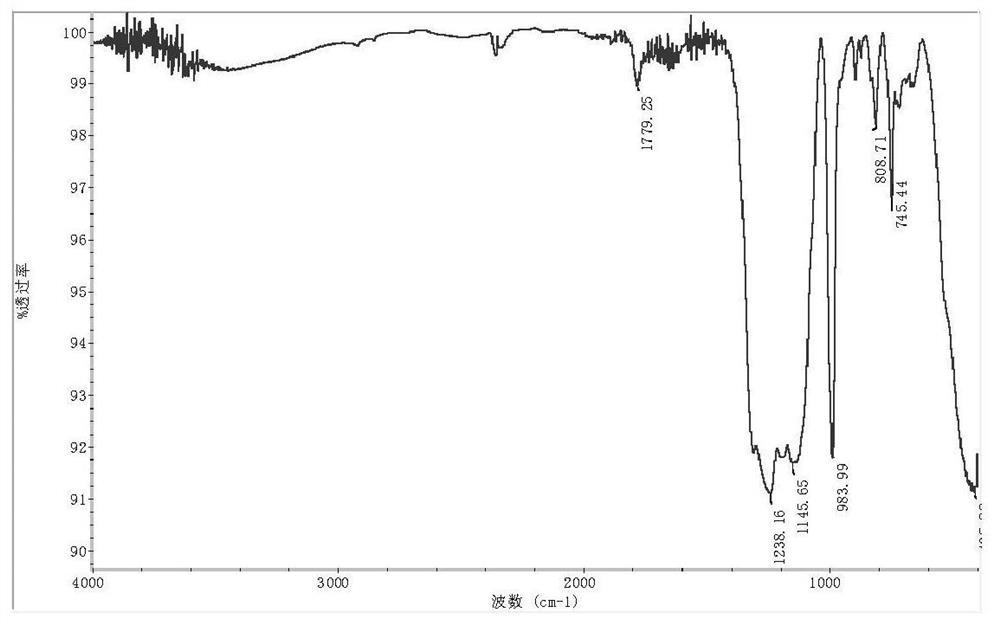

[0071] The 300°C superheated steam enters the reactor from the bottom coil pipe, and the molar ratio of steam to perfluoropolyetheryl fluoride is 6:1. The temperature in the reactor is controlled by controlling the flow of water vapor. The temperature in the reactor is 192±3°C, the maximum pressure is 2.8MPa, and the residence time of the material in the reactor is 20h. After the reaction finished, the reaction crude product was discharged from the outlet of the reactor as 6274g colorless transparent liquid...

Embodiment 2

[0074] According to this embodiment figure 1 The process flow shown is carried out.

[0075] The perfluoropolyether (molecular general formula: CF 3 O(CF 2 CF 2 O) m (CF 2 O) n COF, m=6-20, n=8-15, average molecular weight of 1955) is added to the raw material tank, and ethylenediamine is added to the auxiliary agent tank. Add 5000g of perfluoropolyether acid fluoride and ethylenediamine into the mixing tank at a molar ratio of 1:1.2 for mixing, and then pump them into a 15L plug-flow reactor.

[0076] The 280°C superheated steam enters the reactor from the bottom coil pipe, and the molar ratio of steam to perfluoropolyetheryl fluoride is 6:1. The temperature inside the reactor is controlled to be 180±3°C, the maximum pressure is 2.5MPa, and the residence time of the material in the reactor is 17h. After the reaction finished, the reaction crude product was discharged from the outlet of the reactor as 4733g colorless transparent liquid.

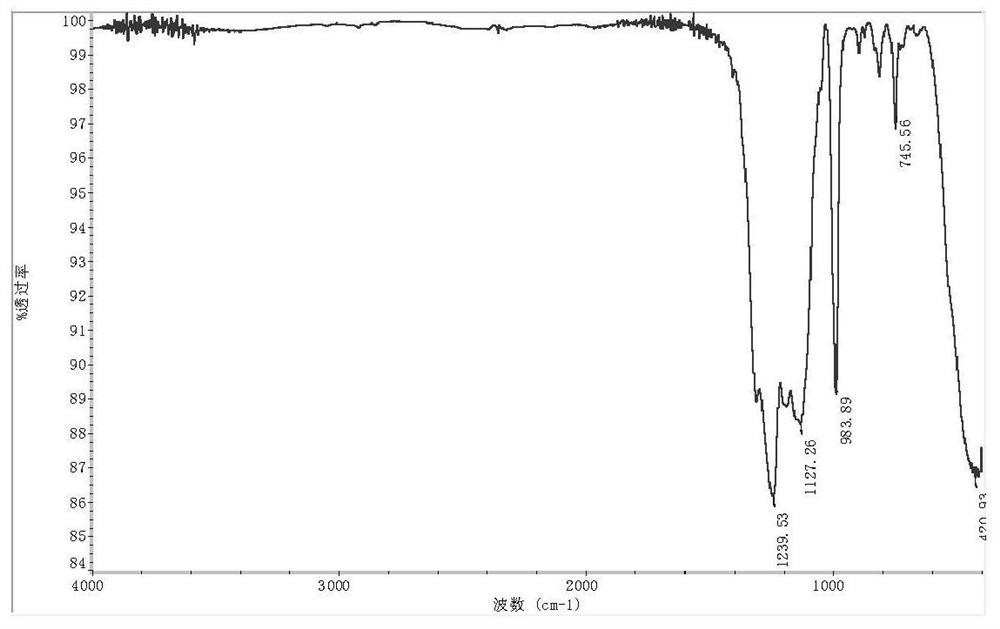

[0077] Infrared analysis was ...

Embodiment 3

[0079] According to this embodiment figure 1 The process flow shown is carried out.

[0080] The perfluoropolyether (molecular general formula is: (CF) containing acyl fluoride group 3 O(CF(CF 3 ) CF 2 O) m (CF 2 O) p (CF(CF 3 )O) n CF 2 COF, m=5-8, p=5-10, n=5-10, average molecular weight is 2060) is added to the raw material tank, and triethylamine is added to the auxiliary agent tank. Add 6180g of perfluoropolyether acid fluoride and triethylamine into the mixing tank at a molar ratio of 1:1.2 for mixing, and then pump them into a 15L plug-flow reactor.

[0081] The superheated mixed steam of 300°C water and methanol enters the reactor from the bottom coil, the amount of methanol added to the superheated mixed steam is 20wt%, and the molar ratio of steam to perfluoropolyetheryl fluoride is 6:1. The temperature inside the reactor is controlled to be 198±2°C, the maximum pressure is 5MPa, and the residence time of the material in the reactor is 20h. After the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com