Patents

Literature

96results about How to "High continuous production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

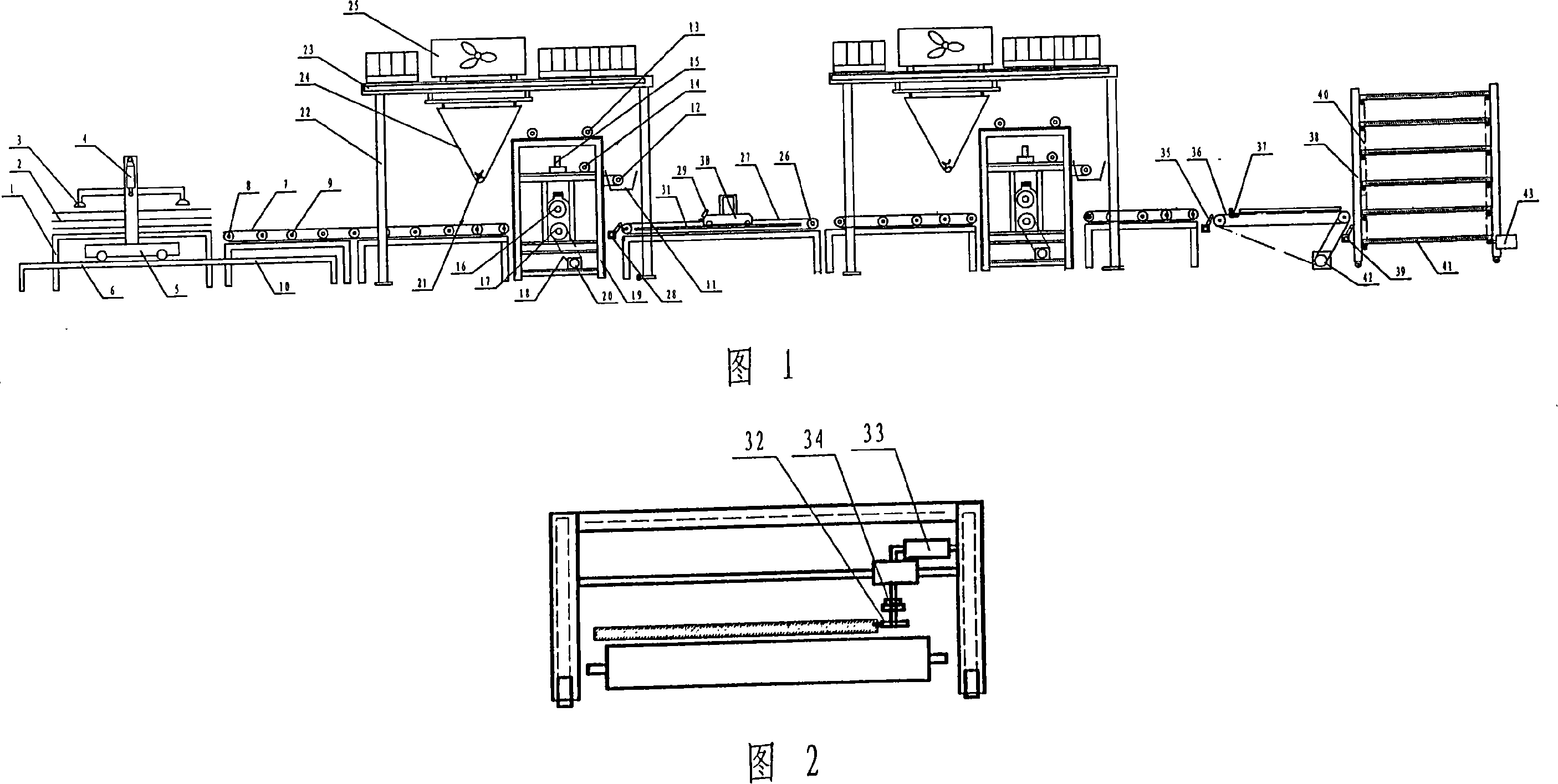

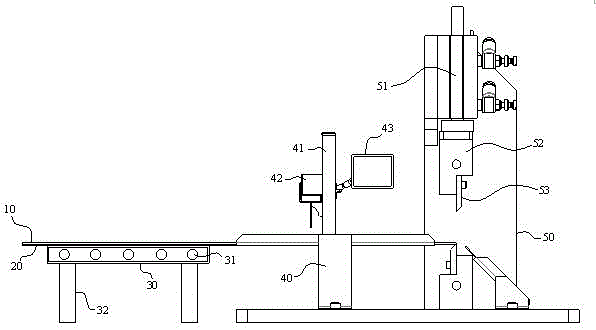

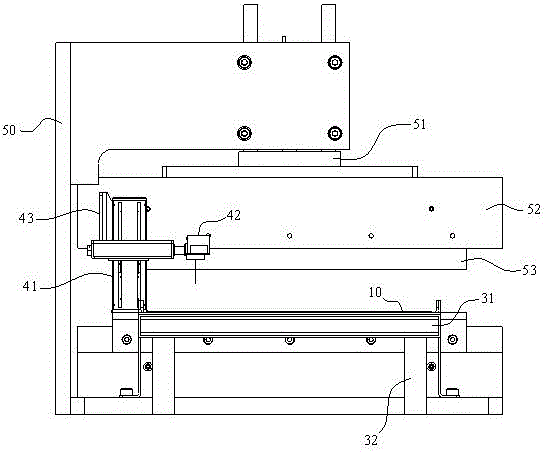

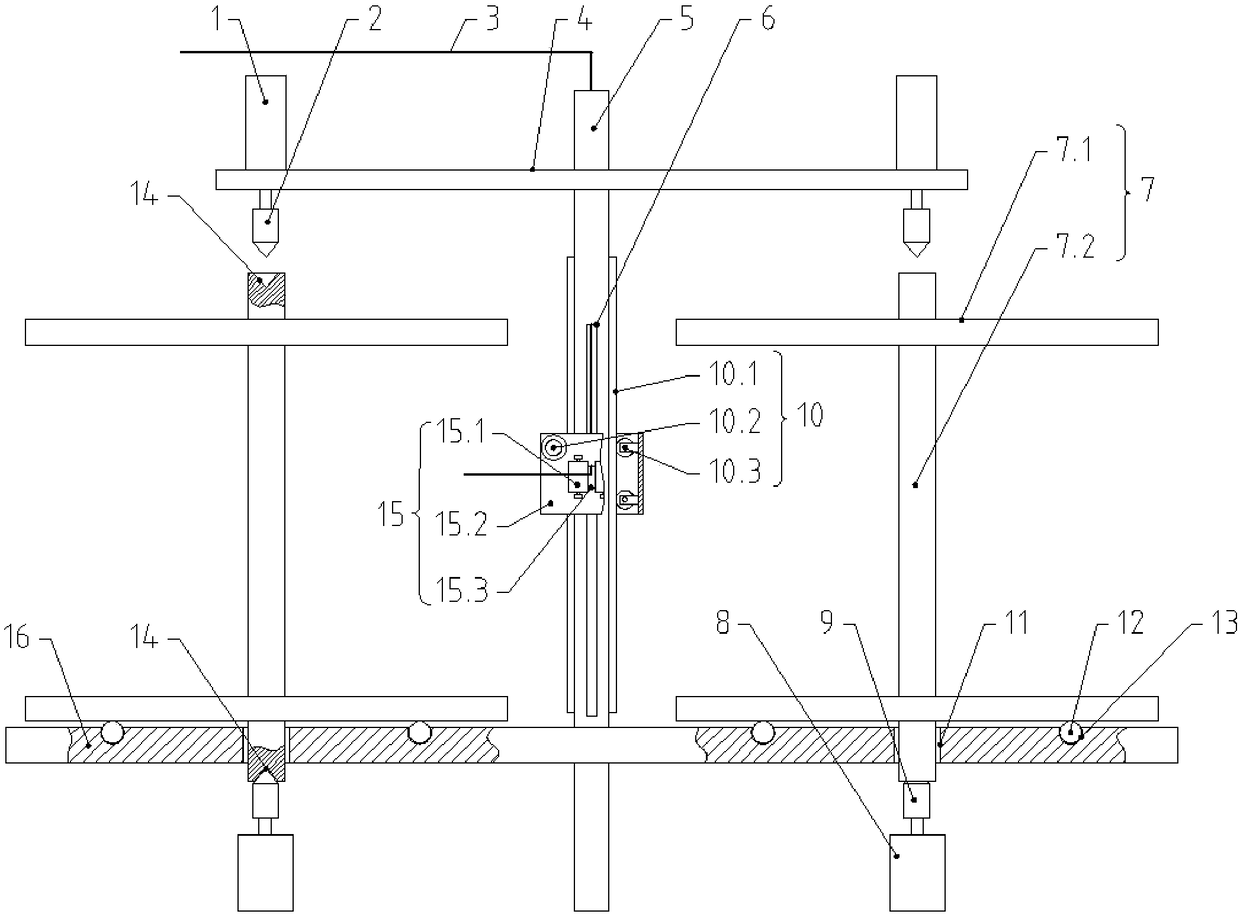

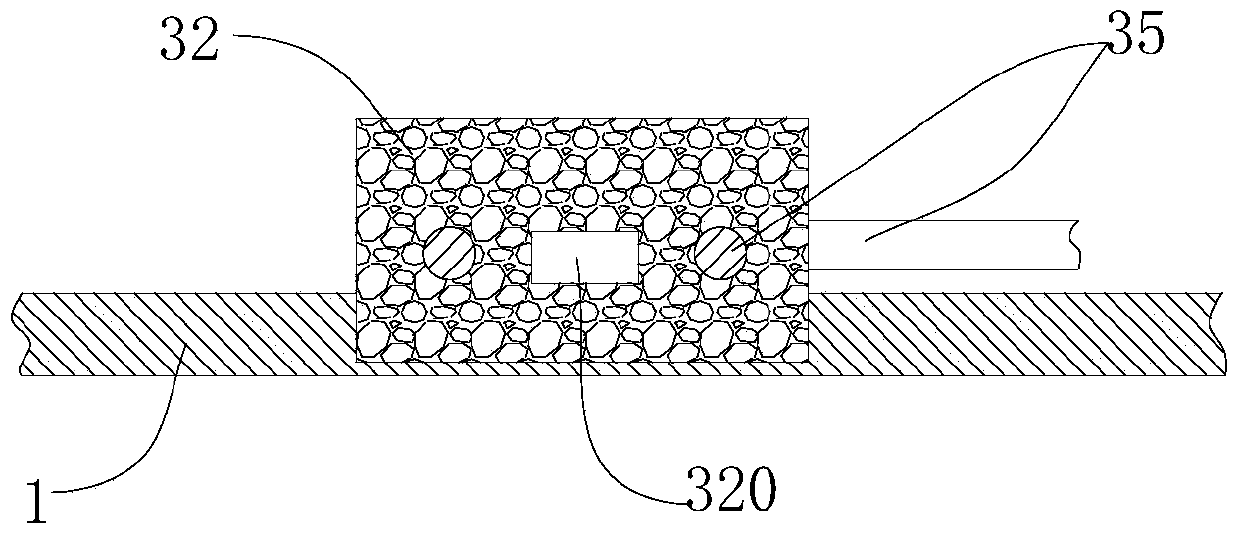

Compound thermal insulation wall plate and external wall heat-insulation board producing line

InactiveCN101138866AIncrease productivityEasy to operateDischarging arrangementCeramic shaping plantsProduction lineThermal insulation

The present invention discloses a production line of a composite heat proof wall plate and an external heat proof plate of an external wall. The production line includes an automatic mounting moulding board mechanism, cloth-net roll mechanisms, a reseau cloth automatic cutting mechanism and an automatic plate-sending, shelf-installing and shelf-sending mechanism which are orderly linked by a belt feeding production chain. Mixing and material-dropping mechanisms are arranged above a section of belt feeding production chain between the automatic mounting moulding board mechanism and a first group of cloth-net roll mechanism and between a forward group of cloth-net roll mechanism and a next group of cloth-net roll mechanism. At least two groups of matched mixing and material-dropping mechanisms and the cloth-net roll mechanisms are arranged. The production line can produce the composite heat proof wall plate and at the same time can also produce the external heat proof plate of an external wall and has the characteristics of high production efficiency, simple and convenient operation and high quality of processing.

Owner:泰安鲍文特科技有限公司

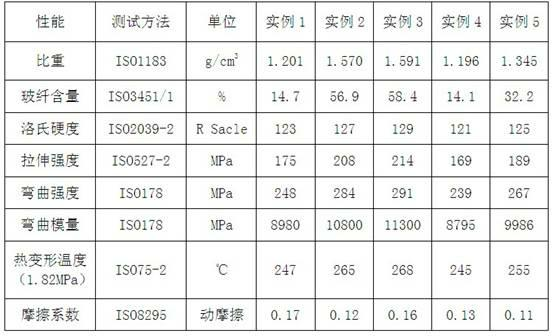

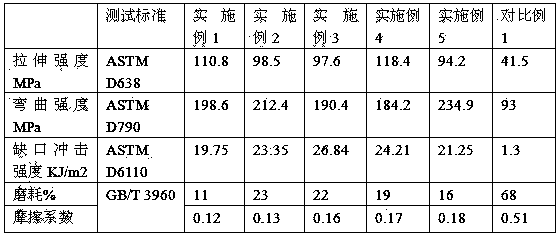

Reinforced wear-resistance nylon 66 composite for textile apparatuses and preparation method thereof

The invention provides a reinforced wear-resistance nylon 66 composite for textile apparatuses and a preparation method thereof. The composite material is prepared by mixing components including 100 parts of nylon 66, 1 to 15 parts of flexibilizer, 1 to 10 parts of anti-wear agent, 0.5 to 3 parts of processing assistant, 15 to 100 parts of glass fibers and the like and by processing the mixture and glass fibers by a twin-screw melt blending extrusion process. The composite of the invention has high anti-wear performance and high mechanical performance and is widely used in production of weaving spindles. In the invention, the composite is prepared by twin-screw extrusion, the method is simple in process and can perform continuous high-efficiency production, and the product quality is stable.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Hollow fiber compound nanofiltration membrane and preparation method thereof

InactiveCN104607056AHigh removal rateImprove removal effectSemi-permeable membranesPolyetherimidePolyvinyl alcohol

The invention relates to a hollow fiber compound nanofiltration membrane. The nanofiltration membrane takes a porous supporting layer as an inner layer and a separating function layer as an outer layer. A casting membrane solution of the porous supporting layer contains an inner layer macromolecular polymer which is selected from one or more of polysulfone, polyether sulfone, polyvinylidene fluoride, polyvinyl chloride and polyacrylonitrile; a casting membrane solution of the separating function layer contains an outer layer macromolecular polymer which is selected from one or more of polyetherimide, polyether-ether-ketone, sulfonated polyether-ether-ketone, polymethyl methacrylate and polyvinyl alcohol; a preparation method comprises the following steps: synchronously extruding and molding the inner layer casting membrane solution and the outer layer casting membrane solution; solidifying to obtain a membrane filament in a nascent state; and carrying out an oxidizing agent aqueous solution to obtain the hollow fiber compound nanofiltration membrane. The invention further provides the preparation method of the nanofiltration membrane correspondingly. According to the hollow fiber compound nanofiltration membrane provided by the invention, the flux of the nanofiltration membrane is remarkably improved, and moreover, the nanofiltration membrane further has the certain desalinization rate.

Owner:HUNAN OVAY TECH CO LTD

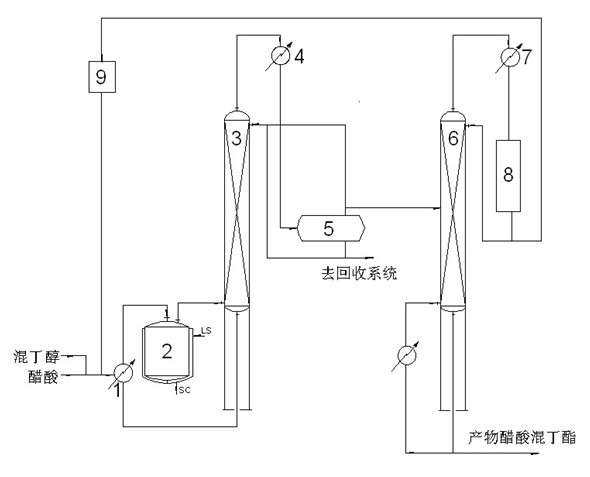

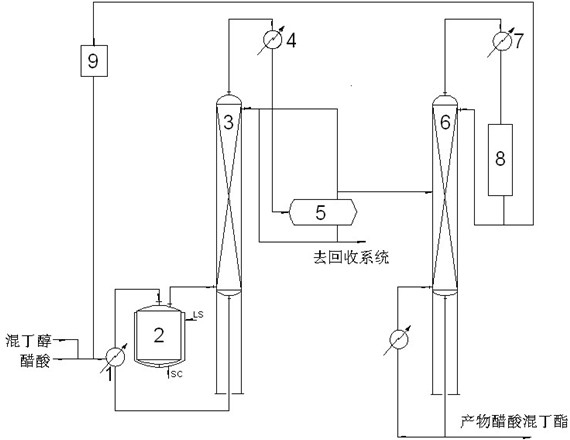

Method for preparing acetic acid mixed butyl ester by continuous reaction and rectification

InactiveCN102690197AEliminate dehydration processLow investment costOrganic compound preparationCarboxylic acid esters preparationAcetic acidPtru catalyst

The invention relates to a method for preparing acetic acid mixed butyl ester by continuous reaction and rectification. The method includes: acetic acid and mixed butanol are mixed and preheated according to molar ratio of 1:1, and temperatures of the mixed and preheated acetic acid and mixed butanol are increased after entering an esterification reactor and are reacted under catalysis of acid catalyst, a reaction product is performed initial gross separation in an esterification column in azeotrope form after being heated, a part of aqueous phase is performed reflux to the esterification column after a distillate at the top of the esterification column is performed condensation and phase separation, another part of the aqueous phase is discharged to a recovery column, a part of oil phase is performed reflux, and another part of the oil phase enters a rectification column as rough product to be further refined; and the rough product enters the rectification column from the middle of the same after being heated, a part of water and light components are removed by a membrane separator after a distillate at the top of the rectification column is condensed, a large part of the material reflows to the rectification column, a small part of the material is extracted to be reacted in the esterification reactor, and high-purity acetic acid mixed butyl ester is obtained at the bottom of the rectification column. Continuous production is achieved, and processes of neutralization, sedimentation and dehydration are omitted.

Owner:谦信化工集团有限公司

Thermoplastic polyurethane/fiber composite soft cloth and preparation method thereof

InactiveCN104015444ASmoothSmooth surfaceLamination ancillary operationsSynthetic resin layered productsTextileFiber

The invention relates to a piece of thermoplastic polyurethane / fiber composite soft cloth. An intermediate layer is a piece of continuous fiber cloth, an upper surface layer and a lower surface layer are respectively a thermoplastic polyurethane resin layer, and the intermediate layer is connected with the upper surface layer and the lower surface layer through a hot laminating way. The composite soft cloth adopts TPU and fiber fabrics of different types and colors as raw materials, and TPU is bonded with the fabrics in a hot laminating manner, so that the pollution is avoided, the process is simple, the cost is low, the appearance effect is excellent, and the thermoplastic polyurethane / fiber composite soft cloth can be applied to top-grade appearance parts such as cases and vamps.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

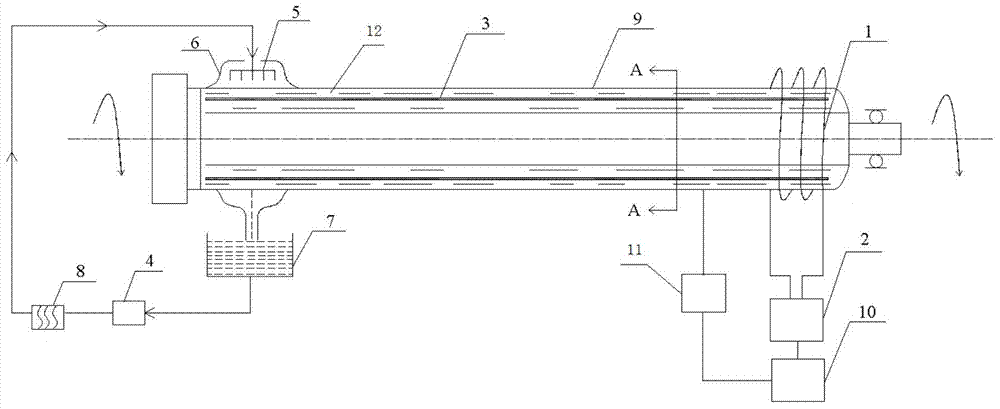

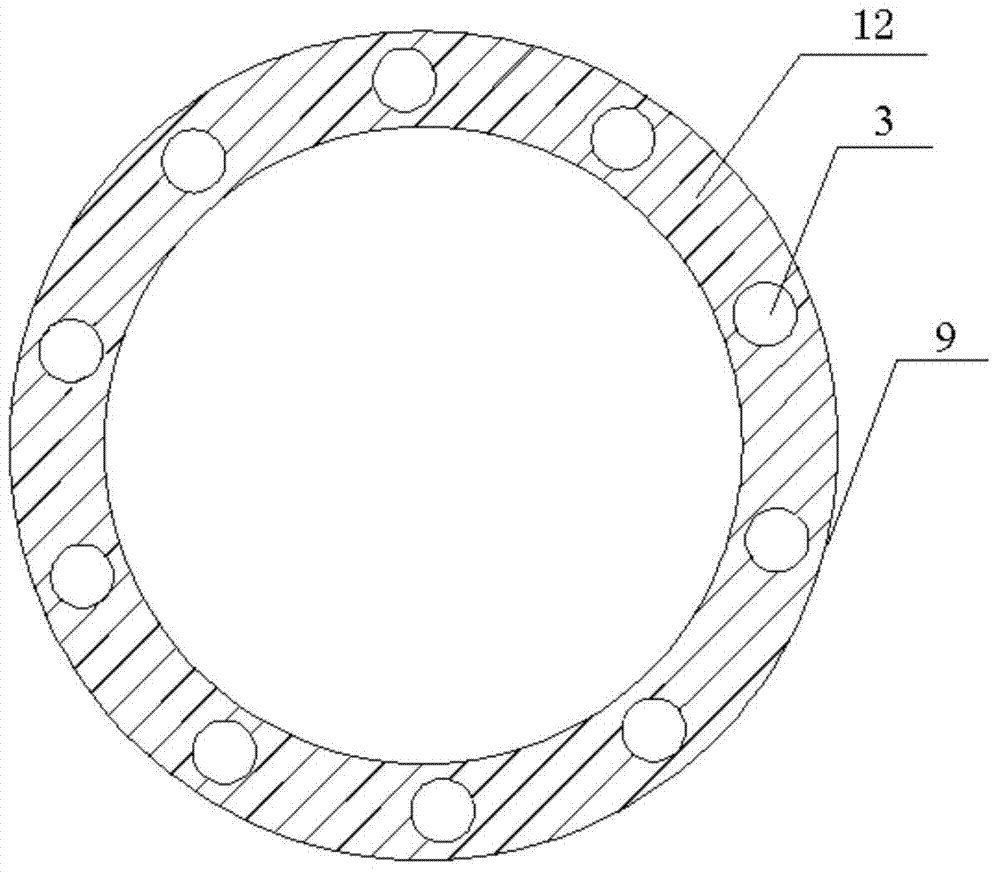

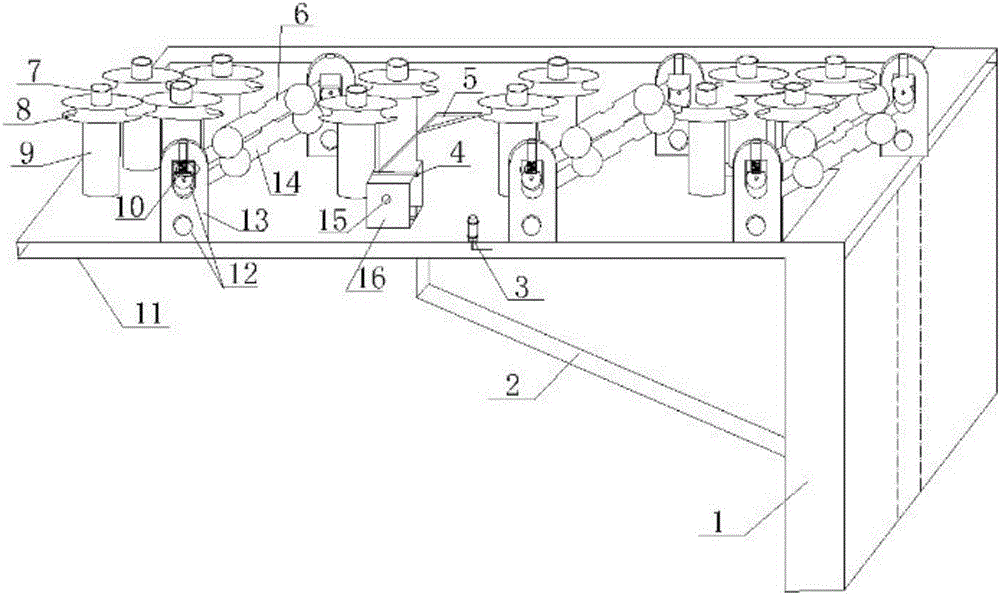

Electromagnetic heating curing and forming device and method for preparing filament wound composite material pipe body by using electromagnetic heating curing and forming device

ActiveCN104260328AHigh temperature control accuracyImprove heating efficiencyTubular articlesWinding machineHeat conducting

The invention provides an electromagnetic heating curing and forming device and a method for preparing a filament wound composite material pipe body by using the electromagnetic heating curing and forming device, and relates to a heating and curing device and a method for preparing the composite material pipe body by using the heating and curing device. The invention aims to solve the problems of an existing heating and curing device for preparing the composite material pipe body that a heat source of an inner heating and curing core die cannot be obtained easily, the heating efficiency is low, and the heating precision and the heating uniformity are poor. The device comprises an electromagnetic heating coil, an electromagnetic heating power supply, a temperature sensor, heat pipes, a heat conducting medium, a sprayer, a cooling liquid protection cover, a cooling liquid tank, a water pump, a heat radiator and a core die, wherein an interlayer is formed between the outer wall of an inner pipe and the inner wall of an outer wall of the core die; a heat pipe array is distributed in the heat conducting medium in the interlayer; and the electromagnetic heating coil is uniformly arranged outside the tail end of the core die. The method comprises the following steps: the core die is fixed on a main shaft of a winding machine; and the core die is heated and cured simultaneously when being wound, and then heated, cured, and the processed core die is cooled. The electromagnetic heating curing and forming device can be obtained.

Owner:鑫捷瑞泰安复合材料科技有限公司

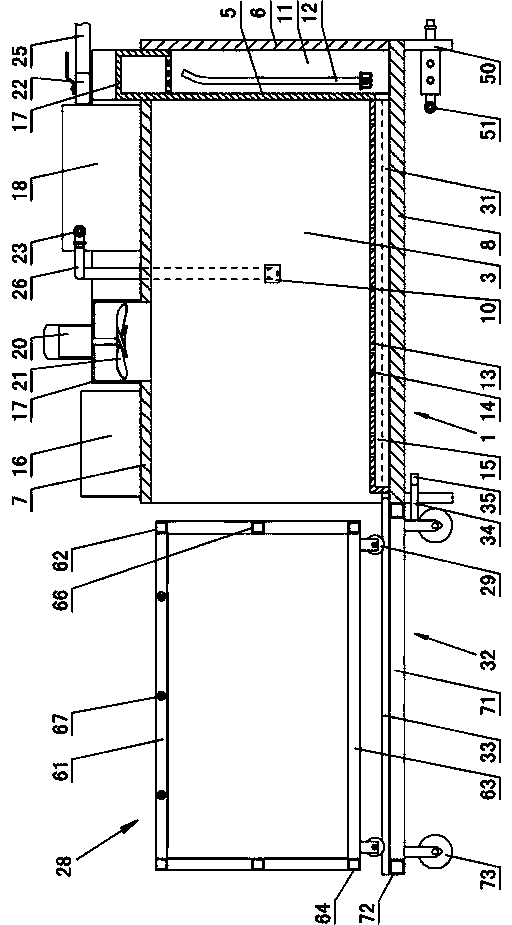

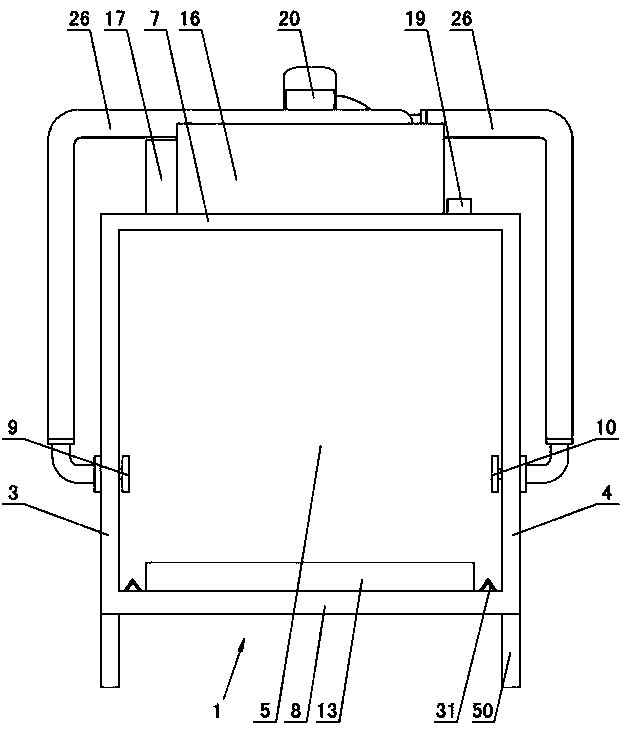

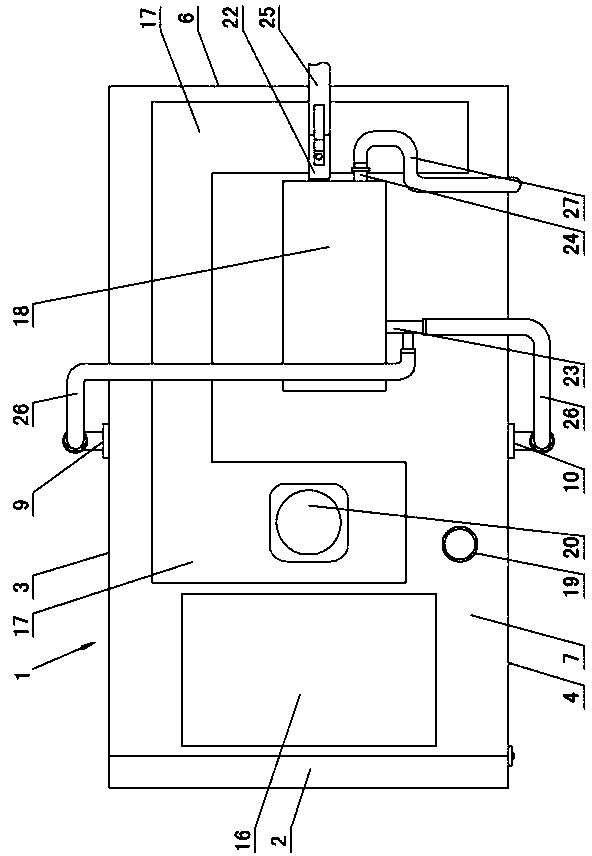

Electrothermal steam drying and setting machine

InactiveCN103469513AReduce volumeImprove drying efficiencyDrying solid materials with heatDrying gas arrangementsInlet channelSpray nozzle

The invention relates to an electrothermal steam drying and setting machine. The electrothermal steam drying and setting machine is characterized by comprising an oven, a movable clothes hanging framework and a bottom trolley, wherein water joints are arranged on bottom feet of the oven, a left gas spray nozzle and a right gas spray nozzle are mounted on a left box plate and a right box plate, an electric heating pipe is mounted between a partition plate and a rear box plate, air suction holes are formed in an air suction plate arranged on a box bottom plate, the hollow end in the middle of the air suction plate is communicated with a mounting chamber, a circuit control box, a gas inlet channel, a gas storage tank and an exhaust pipe are arranged on a box top plate, one end of the gas inlet channel is communicated with the oven, a fan is arranged in the gas inlet channel and driven by a motor, the other end of the gas inlet channel is communicated with the mounting chamber, the movable clothes hanging framework comprises upper cross bars, upper longitudinal bars, lower cross bars, lower longitudinal bars, vertical bars and middle crosspieces, clothes hanging bars are arranged between the upper cross bars, rolling wheels are mounted below the lower cross bars and the lower longitudinal bars, guide slots are formed in the rolling wheels, sliding rails are mounted on the two sides of the air suction plate, the bottom trolley forms a square bottom frame through cross bottom bars and longitudinal bottom bars, wheels are mounted below the bottom trolley, guide rails are mounted on the cross bottom bars, positioning insert plates are arranged on the two sides of the cross bottom bars, and inner oblique insert plates are formed at the front parts of the positioning insert plates for being in contact with the inner side of the bottom feet.

Owner:浙江省黄岩服装机械厂

Epoxy resin adhesive for potting PVDF hollow fiber membrane and preparation method of epoxy resin adhesive

InactiveCN104371626AImprove mechanical propertiesImprove aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHydrophobic silicaSilicon oxide

The invention provides an epoxy resin adhesive for potting a PVDF hollow fiber membrane. The epoxy resin adhesive comprises a component A and a component B at a mass ratio of 100 to (15-35), wherein the component A comprises 50-70 parts of epoxy resin, 5-15 parts of a toughening agent and 1-5 parts of a defoaming agent, the component B comprise an amine curing agent, the epoxy resin comprises bisphenol A diglycidyl ether; the toughening agent is a low-molecular polyurethane or polyol glycidyl ether; and the defoaming agent is one or more selected from organic phosphonic acid, polysiloxane, fatty alcohol, fatty acid ester and hydrophobic silicon oxide. The epoxy resin adhesive provided by the invention has the advantages of excellent mechanical property, aging resistance, heat resistance, corrosion resistance, good flexibility and the like, especially, the flexibility is enhanced and the problems of breakage and soaking of a membrane fiber during the potting of the epoxy resin adhesive are solved.

Owner:HUNAN OVAY TECH CO LTD

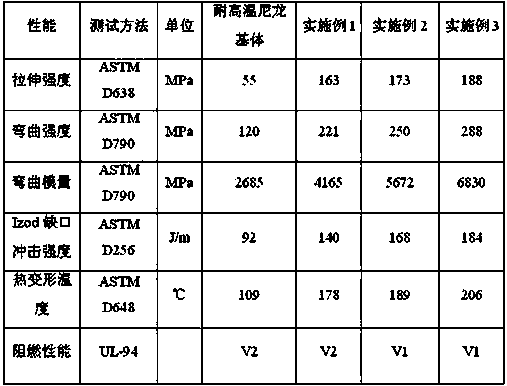

Aramid fiber-reinforced high-temperature-resistant nylon composite material and preparation method thereof

InactiveCN103627164AImprove flame retardant performanceImprove heat resistanceNylon materialProcedure Agents

The invention discloses an aramid fiber-reinforced high-temperature-resistant nylon composite material and a preparation method thereof. The composite material is prepared from an aramid fiber, high-temperature-resistant nylon, a compatilizer, processing aids and the like through mixing and then melt blending and extrusion by a screw. The composite material prepared in the invention has excellent heat resistance, mechanical properties and flame retardation and is extensively used in fields like electric products, automobiles and the war industry. The composite material is prepared through extrusion by the screw; the preparation method has the advantages of simple process, high continuous production efficiency and stable product quality.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

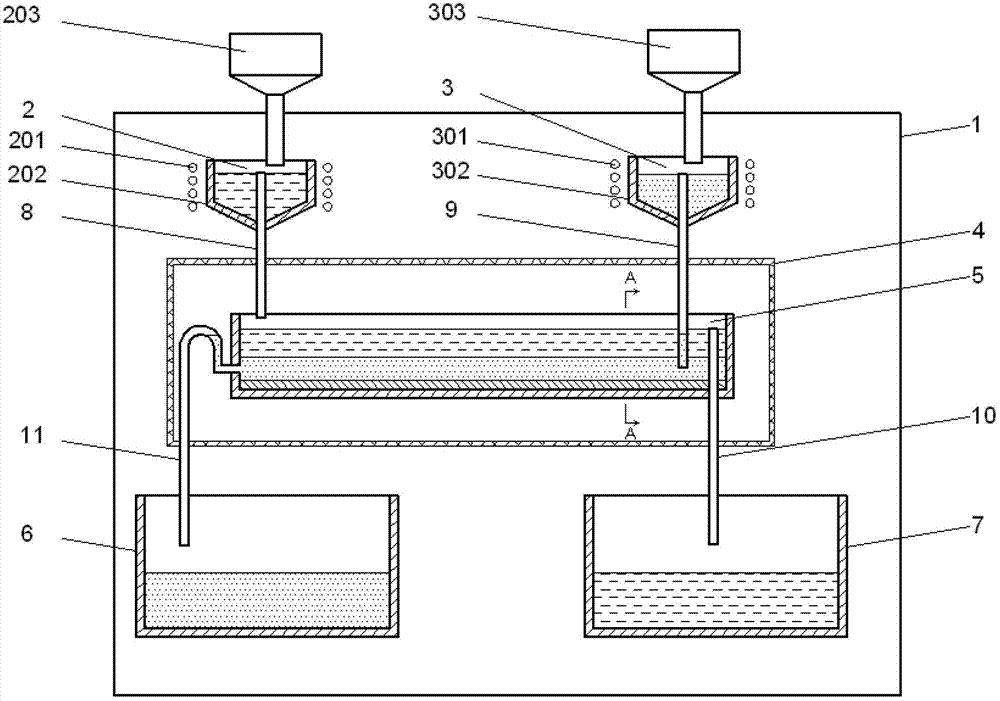

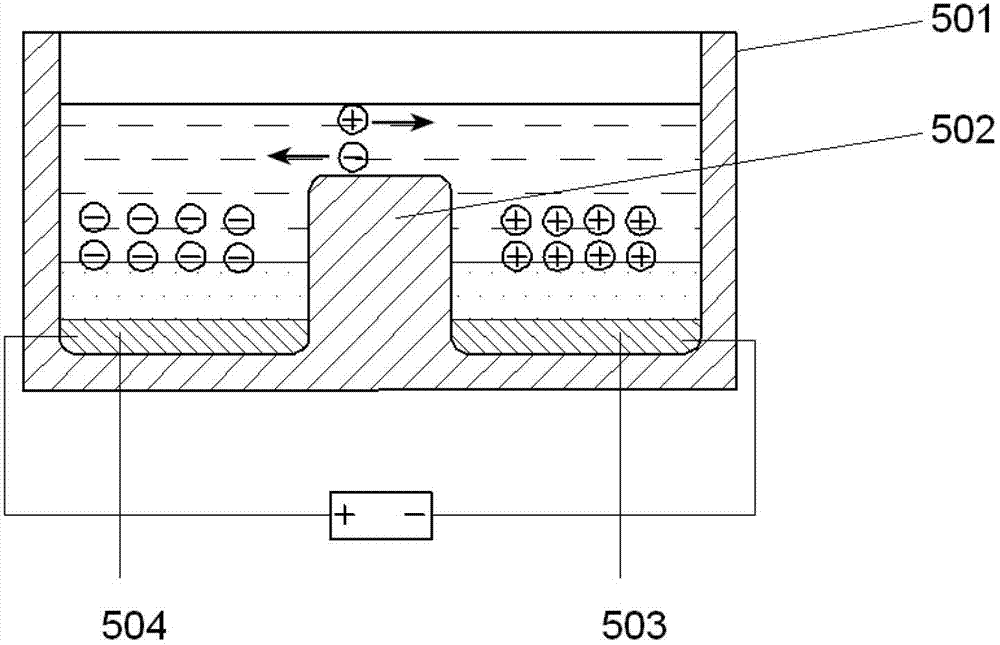

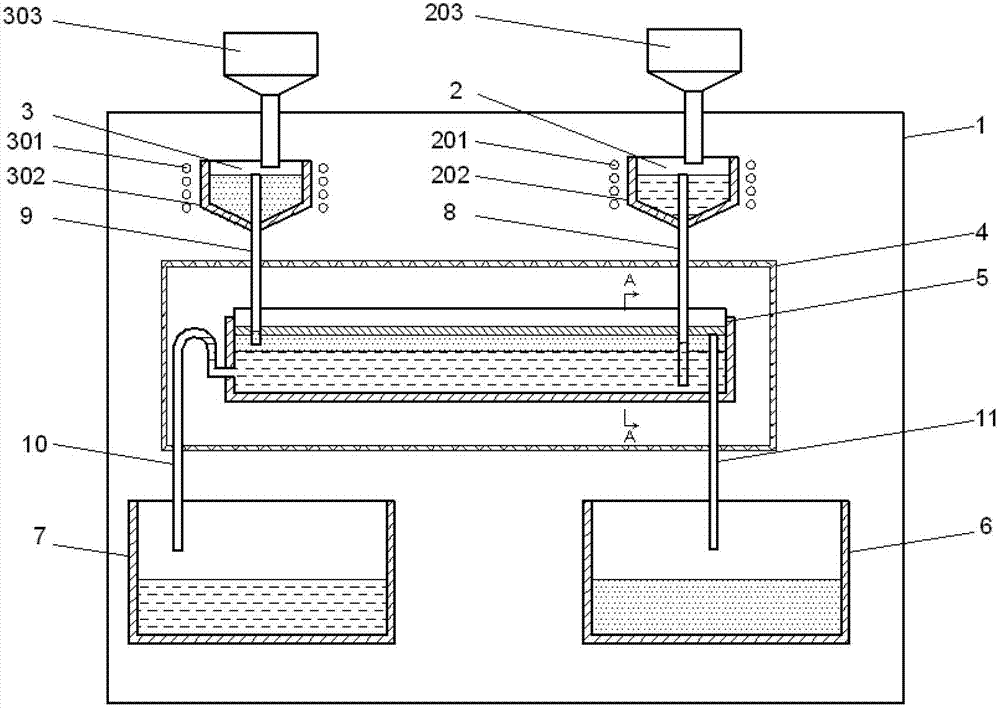

System and method for purifying polysilicon through continuous slagging under electric field

The present invention discloses a system and a method for preparing high purity polysilicon through continuous slagging under an electric field effect. The system comprises: a silicon material melting device arranged in a closed chamber, a slagging agent melting device, an electrical migration device arranged in a thermal insulation chamber, a slag liquid collection tank, and a silicon liquid collection tank. According to the method, a direct current electric field perpendicular to a silicon liquid flowing direction is applied on a slowly-flowing melting silicon liquid, a layer of the slagging agent is arranged between the electrode and the silicon liquid, the silicone liquid flows while impurities migrate to the electrode direction with the electric field effect, and the impurities contact the slagging agent, and then is subjected to a reaction to be absorbed. With the method of the present invention, the use amount of the slagging agent can be reduced, the purification effect can be increased, the purity requirement on the slagging agent can be reduced, and continuous production of the high purity silicon can be achieved. In addition, the method of the present invention has advantages of good purification effect, high production efficiency, small use amount of the slagging agent, and the like.

Owner:上海太阳能电池研究与发展中心

Wear-resistant nylon composite material and preparation method therefor

The invention discloses a wear-resistant nylon composite material. The wear-resistant nylon composite material is prepared from the following ingredients in parts by weight: 65-95 parts of high-temperature resistant nylon, 1-15 parts of pretreated molybdenum disulfide, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricant. The invention also discloses a preparation method for the wear-resistant nylon composite material. According to the wear-resistant nylon composite material and the preparation method therefor, the pretreated molybdenum disulfide is added as a wear resistance modifier, and proper processing aids are added, so that the wear resistance and heat resistance of high-temperature nylon are improved, the use value is higher, the field of employment is widened, and the wear-resistant nylon composite material can be extensively applied to the fields of electronic electrical appliances, automobiles, war industry and the like; the composite material disclosed by the invention is simple in extruded preparation process, high in continuous production efficiency and stable in product quality; and the high-temperature nylon and the pretreated molybdenum disulfide are pre-mixed firstly, so that the dispersity of the pretreated molybdenum disulfide in the composite material is greatly improved, and the wear resistance of the composite material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

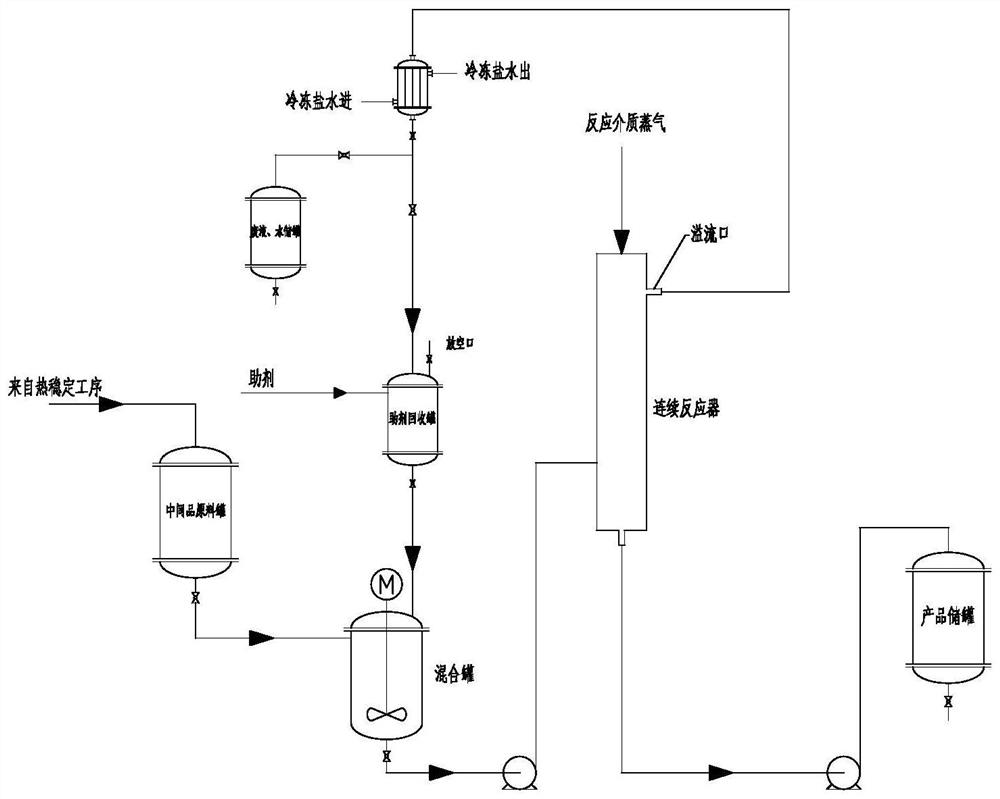

Method for producing hexamethyldisiloxane by utilization of organosilicon azeotrope

The invention discloses a method for producing hexamethyldisiloxane by the utilization of organosilicon azeotrope, comprising the following steps: (1) carrying out heating distillation on the organosilicon azeotrope, and removing fractions with boiling point being lower than 40 DEG C to obtain an intermediate mixture; (2) mixing the intermediate mixture and ethanol to carry out an intermittence esterification reaction, carrying out heating distillation on the reaction solution, and collecting fractions with the boiling point being lower than 80 DEG C to obtain a trimethylchlorosilane crude product; and (3) hydrolyzing the trimethylchlorosilane crude product, and separating from the hydrolysate so as to obtain hexamethyldisiloxane. According to the method provided by the invention, price of the raw materials is cheap, supply is sufficient, condition during the reaction process is mild, the technology is stable, continuous production efficiency is high, there is no by-product, and it is not necessary to use other poisonous and harmful organic solvents. Purity of the obtained hexamethyldisiloxane finished product is more than 99%, and the content of chloride ions is less than 100ppm.

Owner:HOSHINE SILICON IND CO LTD

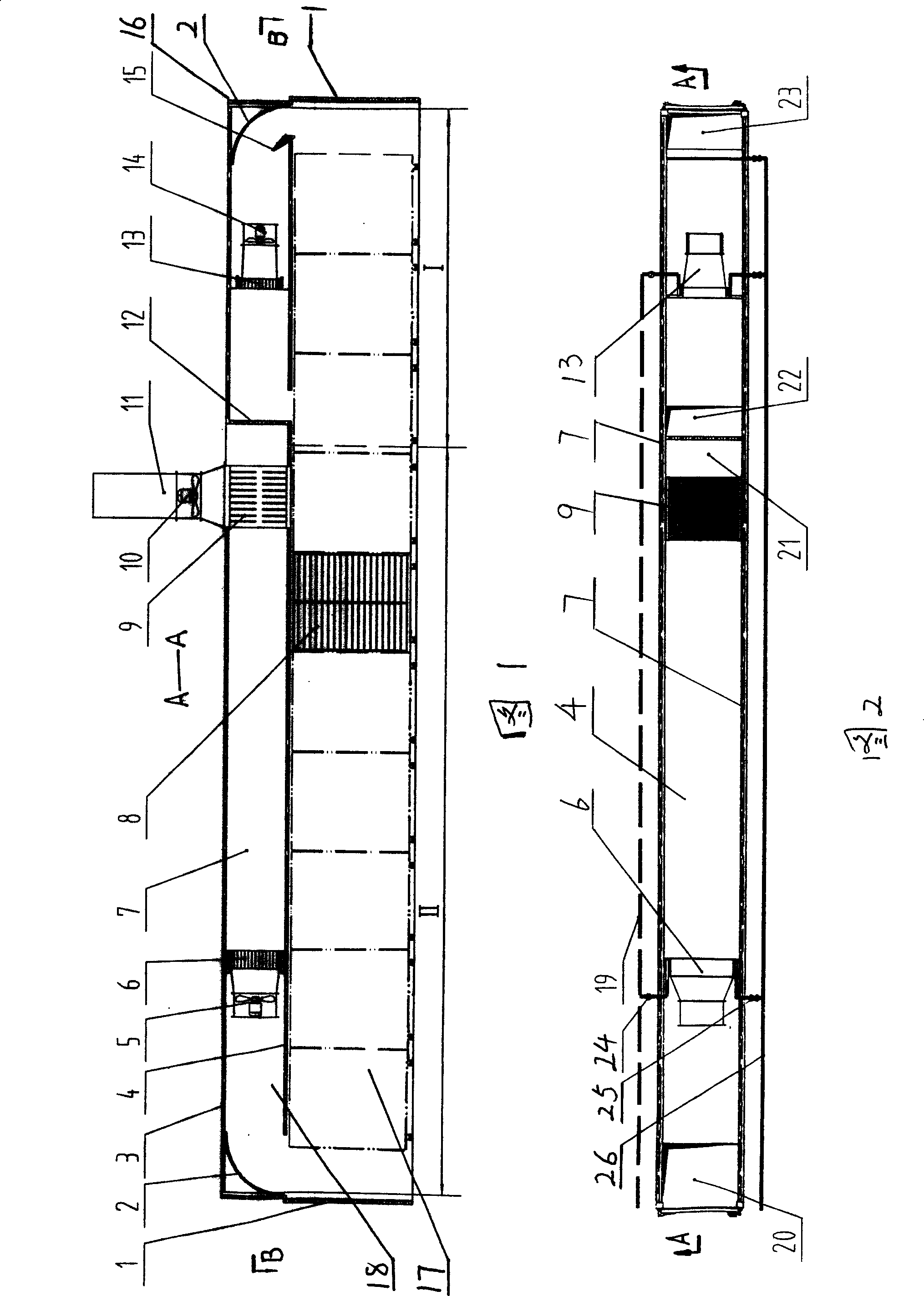

Tunnel chamber for drying

InactiveCN101216238AHeating up fastImprove drying efficiencyDrying machines with local agitationDrying machines with materials at restAir preheaterFresh air

The invention discloses a tunnel type drying chamber, which comprises an oven-drying room (16), a material carriage (8), a primary heat exchanger (6) and an air discharge tube (11). The invention is characterized in that a middle plate (4) is disposed inside the oven-drying room (16) and divides the drying room (16) into a drying room (17) and an air duct (18), a dry hot air port (20), a heating return air port (22) and a heating air outlet port (23) are disposed on the middle plate (4), a partitioning plate (12) is disposed in the air duct (18) close to the heating return air port (22) and divides the air duct (18) into a front air duct and a rear air duct, an air preheater (9), the primary heat exchanger (6) and a primary air blower (5) are disposed inside the front air duct, a secondary heat exchanger (13), a secondary air blower (14) and a steam nozzle (15) are disposed inside the rear air duct, a fresh air inlet port (21) is disposed at the front upper side of the partitioning plate (12), the air preheater (9) is disposed in the front of the fresh air inlet port (21), a moisture-removal blower (10) is disposed on the air preheater (9), and the air discharge tube (11) is disposed on the moisture-removal blower (10). The invention has the advantages of high drying efficiency and low energy consumption.

Owner:烟台一山机械有限公司

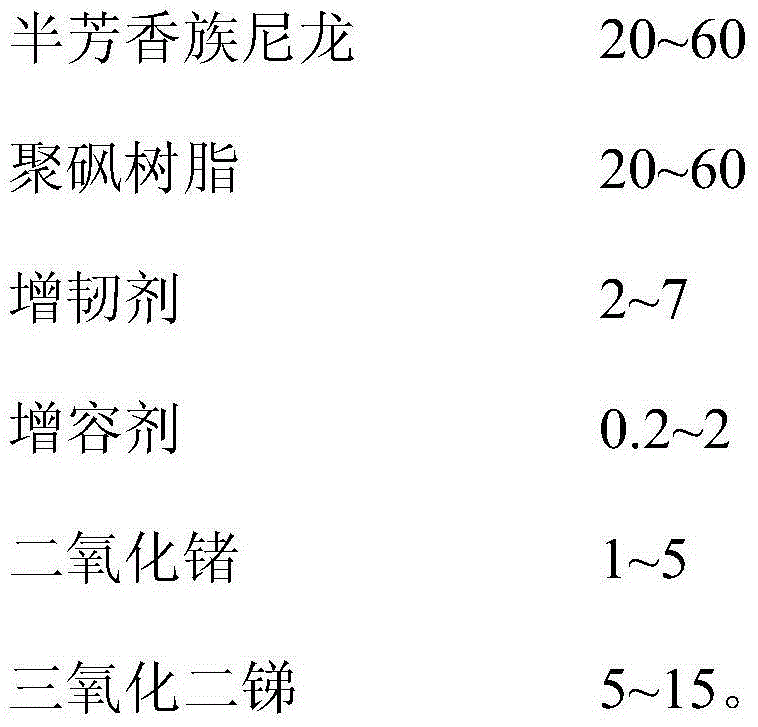

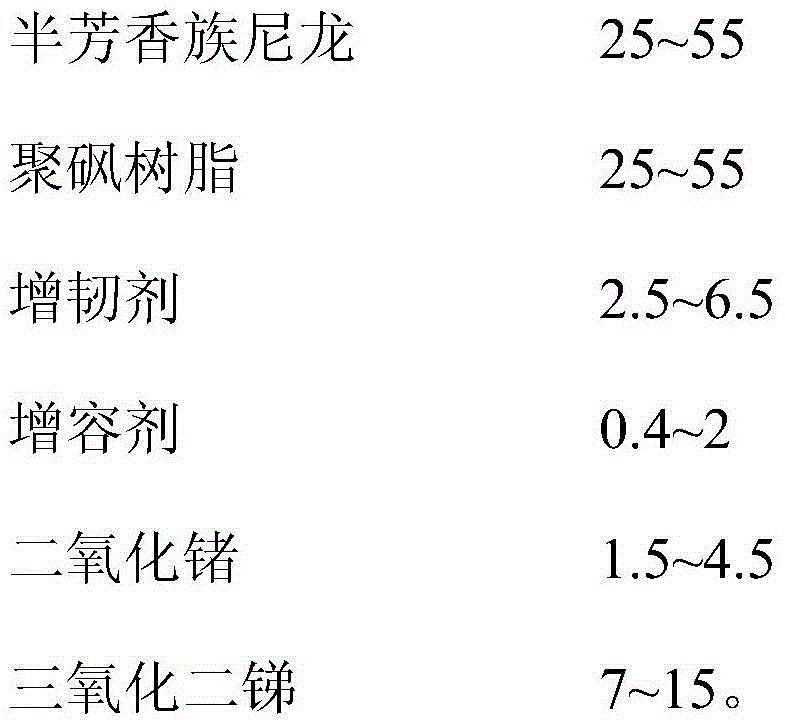

Polysulfone resin and semi-aromatic nylon alloy, and preparation method thereof

The present invention discloses a polysulfone resin and semi-aromatic nylon alloy, which is characterized in that the polysulfone resin and semi-aromatic nylon alloy is mainly prepared from the following raw materials by weight: 20-60 parts of semi-aromatic nylon, 20-60 parts of a polysulfone resin, 2-7 parts of a toughening agent, 0.2-2 parts of a compatibilizer, 1-5 parts of germanium dioxide, and 5-15 parts of diantimony trioxide. According to the present invention, the proper amount of the high-temperature-resistant semi-aromatic nylon is added to the polysulfone resin while the compatibilizer and the toughening agent are added to enhance the polysulfone resin and semi-aromatic nylon alloy, such that the high-temperature-resistant and high-mechanical strength alloy can be obtained; and the germanium dioxide and the diantimony trioxide are added so as to improve static electricity resistance and flame retardant property.

Owner:无锡市万士达羽绒制品有限公司

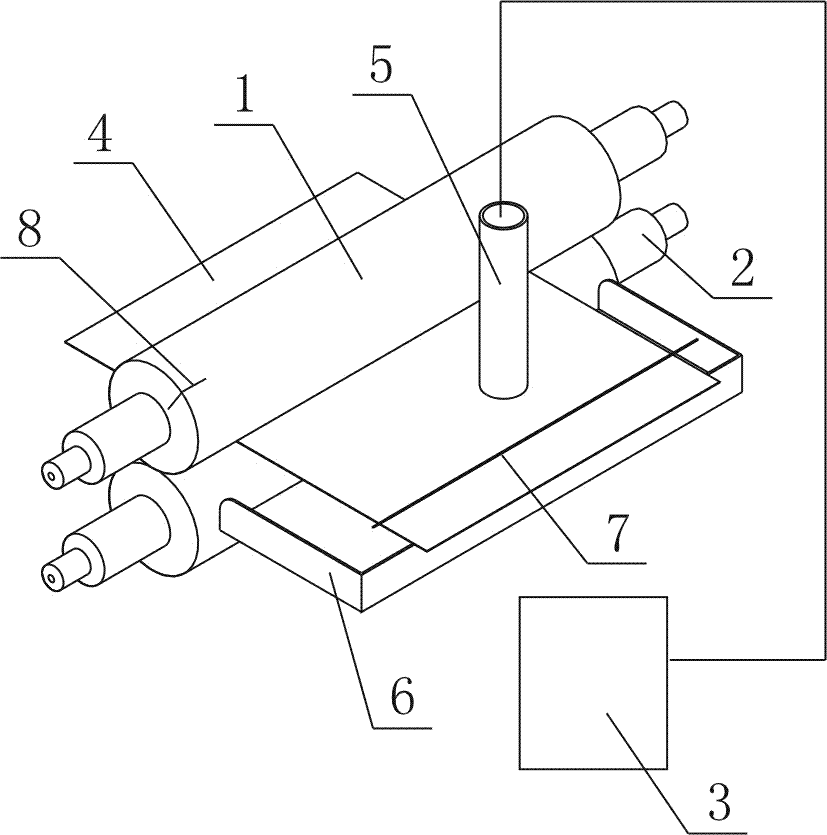

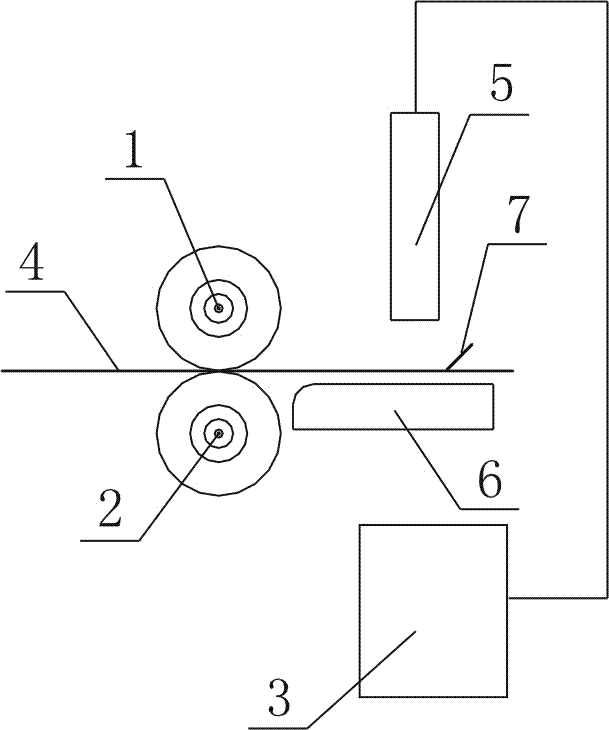

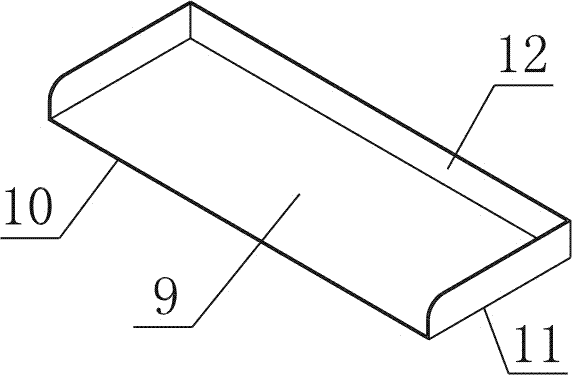

Coating machine for coating silicon-steel magnesium oxide coating liquid

InactiveCN103480535ADisappear wearDisappearing qualityLiquid surface applicatorsCoatingsStrip steelOxide coating

The invention discloses a coating machine for coating silicon-steel magnesium oxide coating liquid. The coating machine comprises a frame, an upper coating roll, a lower coating roll, a magnesium oxide coating liquid circulating device and a nozzle pipe, and also comprises a coating liquid drainage apparatus and a baffle, wherein the coating liquid drainage apparatus is arranged on one side of the lower coating roll and installed on the frame; the coating liquid drainage apparatus at least comprises one bottom plate; the side of the bottom plate, which is towards the lower coating roll, adopts a drainage side; the other sides of the bottom plate adopt collecting sides; the width of the bottom plate of the coating liquid drainage apparatus is larger than the width of strip steel arranged between the upper coating roll and the lower coating roll; the drainage side of the liquid drainage apparatus is used for draining magnesium oxide coating liquid overflowing from the upper surface of the strip steel to the lower coating roll; and the baffle is arranged below the nozzle pipe and arranged on the upper surface of the strip steel in an inclined way. The coating machine has the benefits that the magnesium oxide coating liquid overflowing from the surface of the strip steel is directly drained to the lower coating roll through the coating liquid drainage apparatus, the flowability of the coating liquid is good, the leveling of the coating liquid coating the surface of the strip steel is uniform, and the continuous production efficiency and the material yield of oriented silicon steel are improved.

Owner:武汉钢铁有限公司

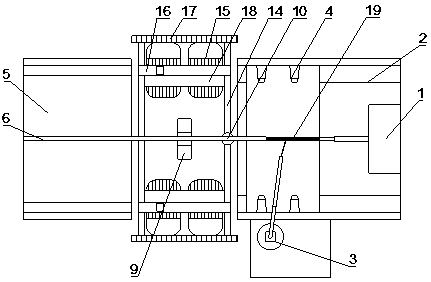

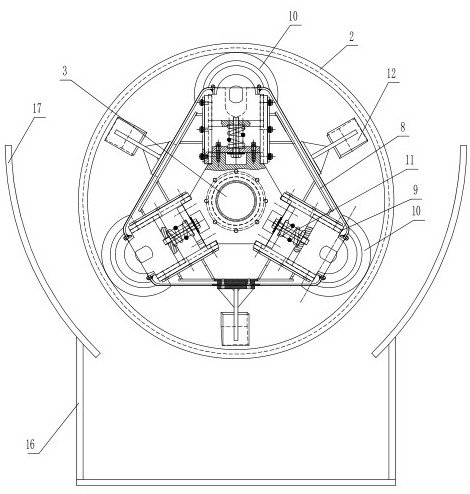

Carrier for sheet wafer processing

ActiveCN108436683AReduce intensityLower requirementGrinding machinesFine working devicesMagnetorheological fluidEngineering

The invention discloses a carrier for sheet wafer processing. The carrier comprises a shell with an upward opening, and adjusting mechanisms used for adjusting the horizontal inclination angle of a product is arranged in the shell; magnetorheological fluid is poured into the shell, so that the adjusting mechanisms are immersed in the magnetorheological fluid, and when the lower part of the productis connected to the adjusting mechanisms, the adjusting mechanisms drive the product to swing to a set position for standing, and a to-be-processed part of the product is located above the magnetorheological fluid level; and a magnetic field generator is arranged on the shell and is used for driving the magnetorheological fluid in the shell to be solidified or reset to be in a fluid state. According to the carrier for sheet wafer processing, the performance requirement of the slide wafer is low, so that the consumable cost is low, meanwhile, the fragment rate of the functional wafer is low onthe basis of firm clamping, and the qualified rate of the whole product is high.

Owner:抚州市东乡区东红光学科技有限公司

Wear-resistant and high-temperature-resistant nylon composite material and preparation method thereof

The invention provides a wear-resistant and high-temperature-resistant nylon composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 65-95 parts of high-temperature-resistant nylon, 5-35 parts of nylon66, 1-15 parts of wear-resistant agent, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricating agent, and is prepared by virtue of a double-screw melt blending extrusion process after mixing. According to the wear-resistant and high-temperature-resistant nylon composite material, nylon66 and the wear-resistant agent are firstly premixed so as to greatly improve the dispersibility of the wear-resistant agent in the composite material and regulate the viscosity of the composite material, thus improving the wear-resistance performance and heat-resistant performance of the composite material, ensuring that the composite material has higher application values, and broadening the application range; the composite material can be widely applied to the field of electronic and electrical appliances, automobiles, military industries and the like, and can be used for promoting the smooth processing of extruding machines.

Owner:HEFEI GENIUS NEW MATERIALS

Defect cutting device for capacitor-used metalized film

InactiveCN106252106AIncrease flexibilityGuaranteed continuityCapacitor manufactureLaser cuttingLight emitting device

The invention relates to a defect cutting device for a capacitor-used metalized film, which belongs to the technical field of capacitor detection devices. The device comprises a light transmitting plate; a light emitting device is arranged below the light transmitting plate; a metalized thin film is laid on the light transmitting plate; light emitted by the light emitting device sequentially passes through the light transmitting plate to irradiate on the back surface of the metalized thin film; the position, located behind the light transmitting plate, on the stroke of the metalized thin film is provided with a laser cutting device; the laser cutting device comprises a supporting frame; the supporting frame is provided with a movable arm; and a laser is arranged on the movable arm. According to the technical scheme of the invention, the laser cutting device carries out cutting processing on defects of the thin film, the laser can selectively cut off an area of the capacitor film electrode with the defect, the overall continuity of the metalized film is ensured, and the continuous production efficiency is improved.

Owner:铜陵市铜创电子科技有限公司

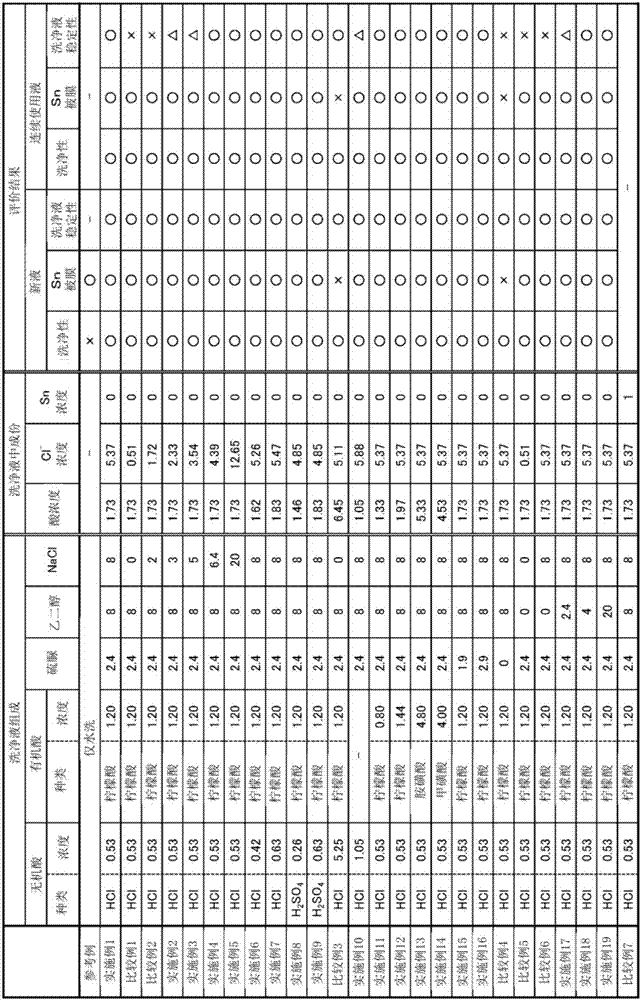

Washing solution for surface of electroless tin plating film, replenishing solution for said washing solution, and method for forming tin plating layer

InactiveCN107109651AExcellent stability over timeReduce replacement frequencyLiquid/solution decomposition chemical coatingConductive pattern reinforcementElectrolysisTin plating

The present invention relates to: a washing solution for a tin plating film, which can be used for washing in advance of the washing with water after electroless tin plating; and a method for forming a tin plating layer, which includes a step of washing with the washing solution. The washing solution according to the present invention is an acidic aqueous solution containing an acid, a complexing agent, a stabilizer and a chloride ion. The washing solution contains the chloride ion at a concentration of 2% by weight or more, and also contains tin at a concentration of 0.5% by weight or less. The washing solution according to the present invention has good washing performance against the surface of a tin plating film, can maintain the properties of the tin plating film readily, has a small influence on the surface of the plating film even when used continuously, and has excellent long-term stability.

Owner:MEC CO LTD

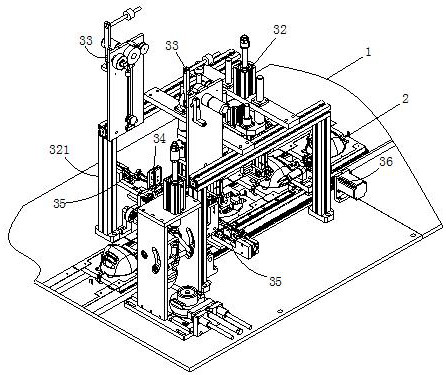

Grinding device for welding operation

ActiveCN109159005APrevent fallingImprove securityGrinding machine componentsGrinding machinesPropellerManipulator

The invention discloses a grinding device for welding operation, and belongs to the technical field of welding and grinding equipment. The grinding device comprises a plate turning machine, a weldingmachine is arranged on one side of the plate turning machine, and a grinding machine is arranged on the other side of the plate turning machine; a welding manipulator is arranged on one side of the welding machine, a plate rail is arranged at the top of the welding machine, a propeller is arranged at one end, away from the plate turning machine, of the plate rail, and fixing clamps are arranged onthe two sides of the other end of the plate rail; the plate turning machine comprises two opposite arranged turnover discs, a chain groove is formed in the peripheral surface of each turnover disc, turnover motors are arranged at the bottoms of the turnover discs, a frame beam is connected between the two turnover discs through the frame beam, and two load plates are fixed on the frame beam; andvertical columns which are vertically upward are fixed on the frame beam, two fixed beams are fixed above the vertical columns, a movable plate is fixed below the vertical columns through telescopic devices, the two ends of the movable plate are arranged in the vertical columns in a sliding mode. According to the device, the operation is simple, and welding, grinding, turning plates, polishing andcontinuous double-sided grinding operation can be realized, manual turning is not needed, manpower is saved, and the working efficiency is high.

Owner:徐州智能自动化设备有限公司

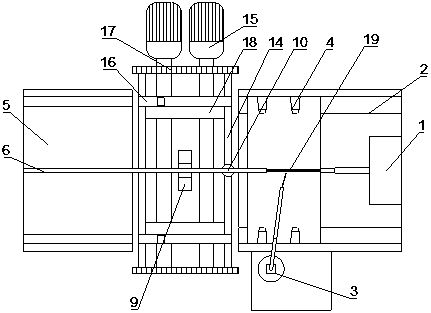

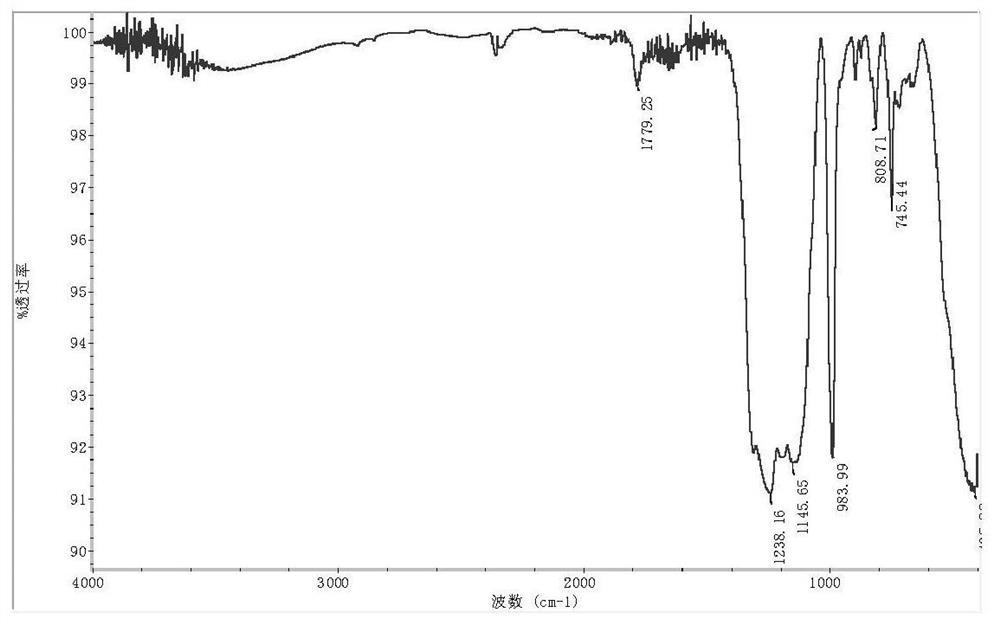

End capping method of perfluoropolyether

ActiveCN113150262AImprove conversion rateImprove efficiencyOrganic chemistryOrganic compound preparationChemical industryEndcapping

The invention discloses an end capping method of perfluoropolyether, and relates to the technical field of fluorine chemical industry. The end capping method comprises the following steps: carrying out end capping reaction on a perfluoropolyether raw material with an unsaturated group as an end group in the presence of an auxiliary agent and reaction medium steam to obtain saturated perfluoropolyether, the auxiliary agent is an organic amine compound or a mixture of the organic amine compound and inorganic base. The method solves the problems that an existing blocking method is low in reaction efficiency, high in energy consumption and not suitable for industrial production, the yield and production efficiency of saturated perfluoropolyether are improved, energy consumption is reduced, and the method is suitable for industrial production.

Owner:JUHUA GROUP TECH CENT

Wear-resistant and high-temperature resistant nylon composite material and preparation method therefor

The invention discloses a wear-resistant and high-temperature resistant nylon composite material. The wear-resistant and high-temperature resistant nylon composite material is prepared from the following ingredients in parts by weight: 65-95 parts of high-temperature resistant nylon, 1-15 parts of pretreated molybdenum disulfide, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricant. The invention also discloses a preparation method for the wear-resistant and high-temperature resistant nylon composite material. According to the wear-resistant and high-temperature resistant nylon composite material and the preparation method therefor, the pretreated molybdenum disulfide is added as a wear resistance modifier, and proper processing aids are added, so that the wear resistance and heat resistance of high-temperature nylon are improved, the use value is higher, the field of employment is widened, and the wear-resistant and high-temperature resistant nylon composite material can be extensively applied to the fields of electronic electrical appliances, automobiles, war industry and the like; the composite material disclosed by the invention is simple in extruded preparation process, high in continuous production efficiency and stable in product quality; and the high-temperature nylon and the pretreated molybdenum disulfide are pre-mixed firstly, so that the dispersity of the pretreated molybdenum disulfide in the composite material is greatly improved, and the wear resistance of the composite material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

Cable winding device

InactiveCN108557567AHigh continuous production efficiencyFilament handlingContinuous productionEngineering

The invention discloses a cable winding device, and relates to the technical field of cable processing equipment. The problems that when an existing cable winding device winder is assembled and disassembled, a winding device stops and cannot work, so that the continuous production capacity is poor, and the production efficiency is lowered are solved. The device comprises a support and winders arranged on the support, each winder comprises a support rod and baffles sleeving the two ends of the support rod, the support comprises a vertically arranged hollow supporting column, a horizontal supporting plate is arranged on the outer wall of the bottom of the hollow supporting column, the winders are arranged on the portions, on the two sides of the hollow supporting column, of the supporting plate, a through hole which can contain the tail end of the support rod is formed in the support plate, a driving mechanism which can be in contact cooperation with the tail end of the support rod is arranged on the lower portion of the supporting plate, a cable is arranged in the hollow supporting column, an opening allowing the cable to go through is vertically formed in the hollow supporting column, and a cable leading mechanism capable of moving vertically sleeves the hollow supporting column.

Owner:德阳市德东电工机械制造有限公司

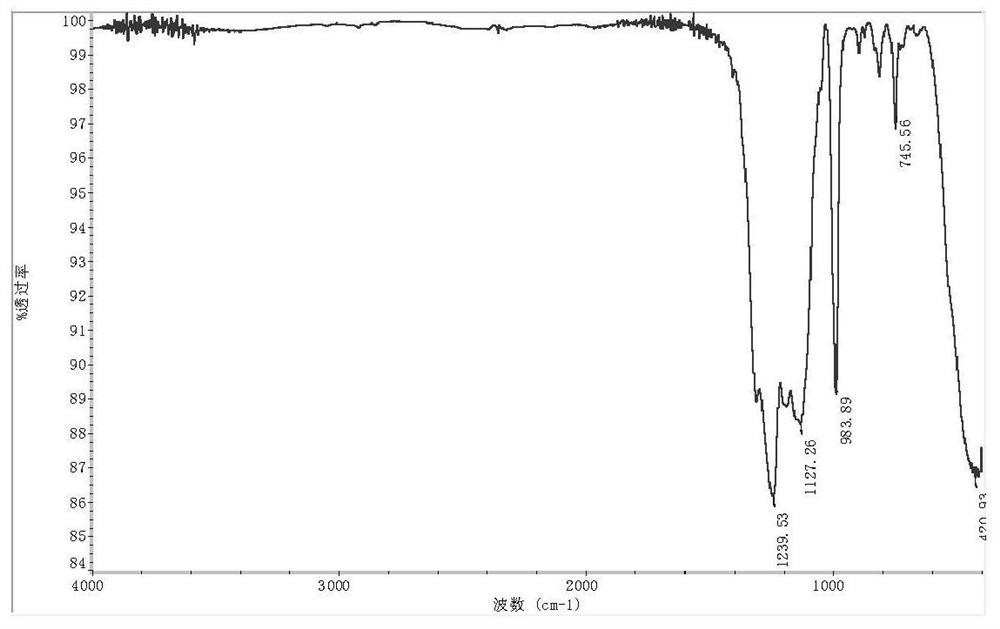

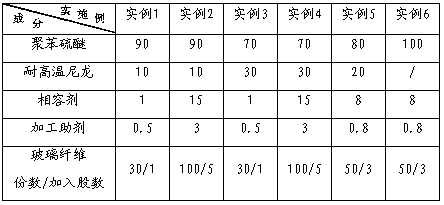

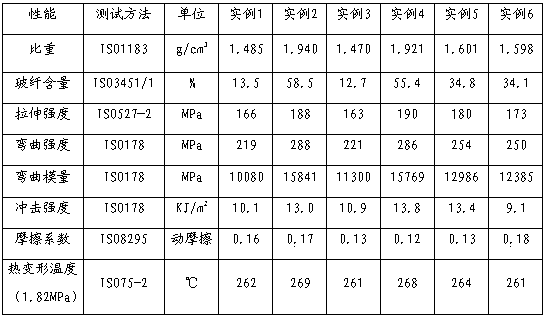

Polyphenylene sulfide and high-temperature-resistant nylon complex and preparation method thereof

The invention provides a polyphenylene sulfide and high-temperature-resistant nylon complex and a preparation method thereof. The complex is prepared by mixing polyphenylene sulfide, high-temperature-resistant nylon, a compatibilizer, a processing aid and other components and then carrying out twin-screw melt blending extrusion on the mixture and glass fiber. The complex provided by the invention has excellent heat resistance and mechanical properties, the complex can be widely used in electronic appliances, automobiles, military industries and other fields, the complex is prepared by twin-screw extrusion, and the preparation method has the advantages of simple process, high continuous production efficiency and stable product quality.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

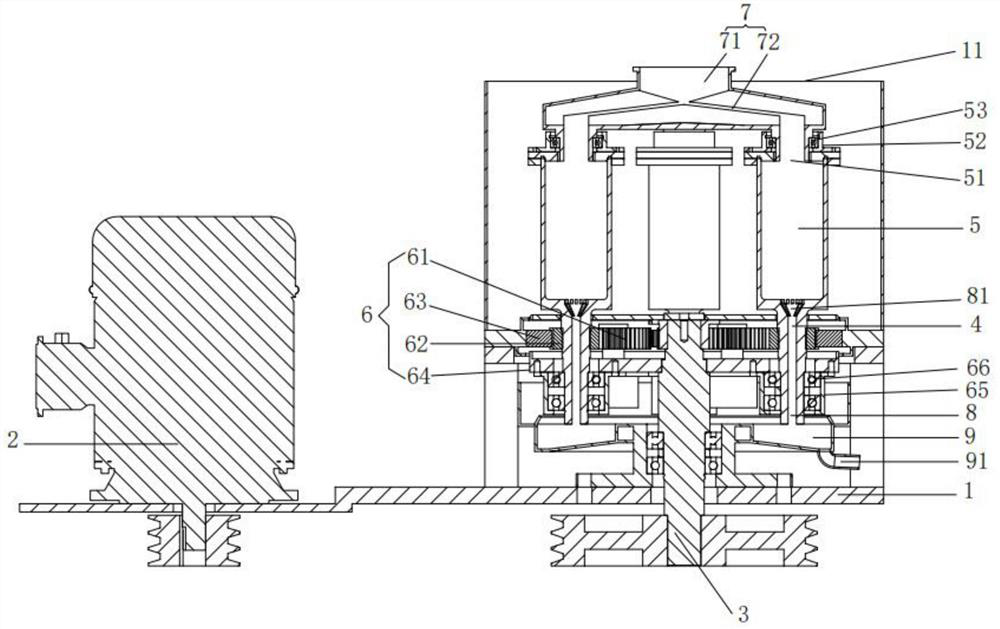

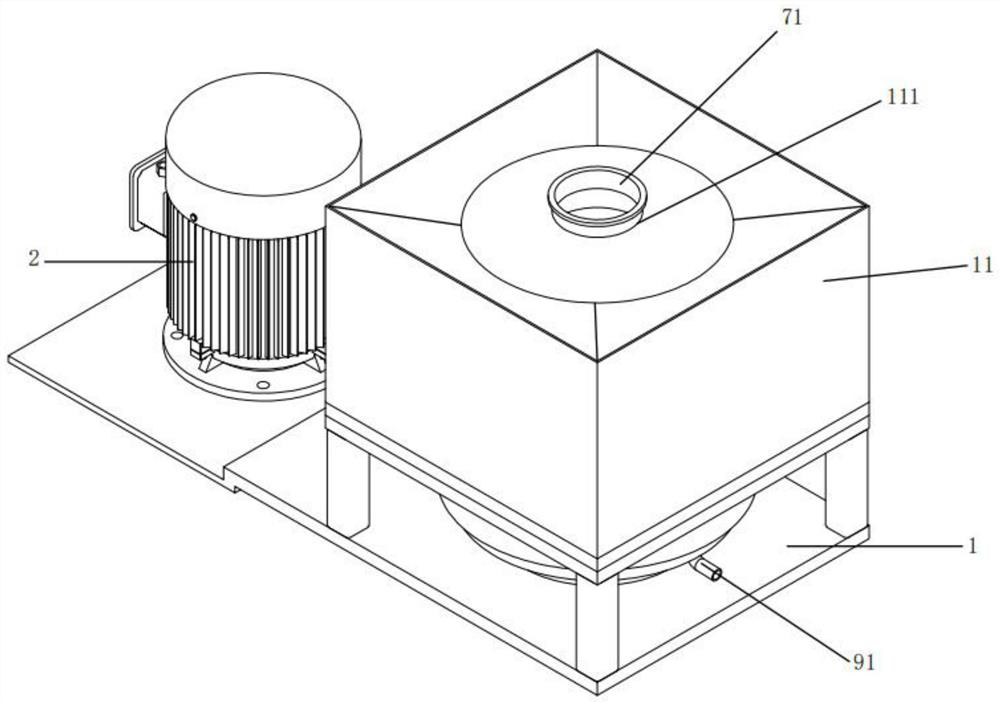

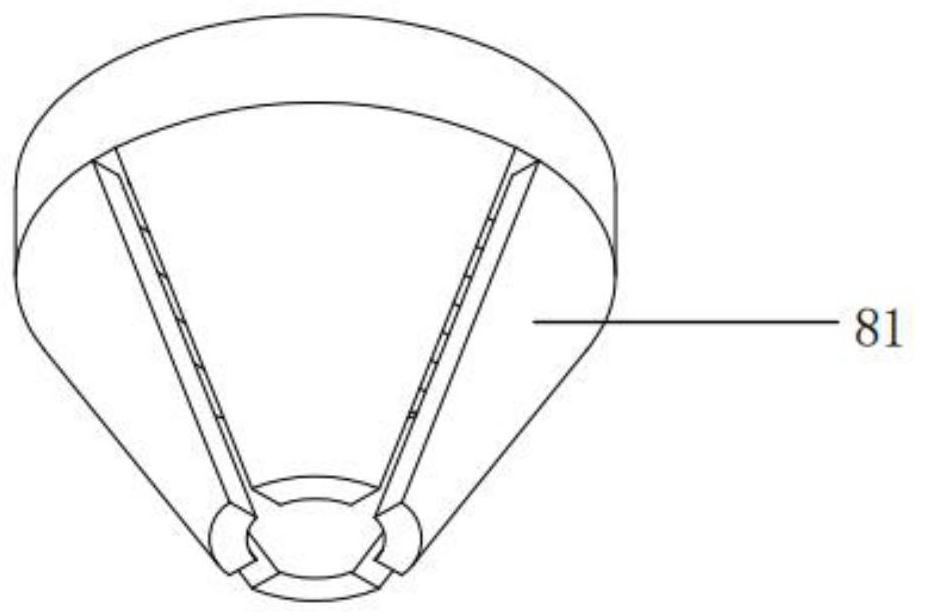

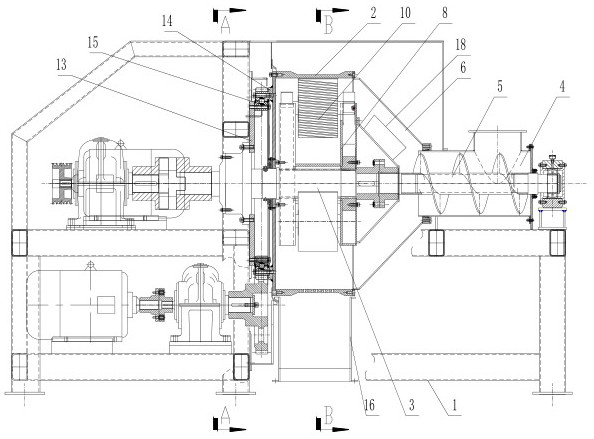

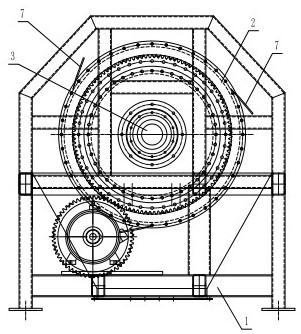

Continuous vertical planetary ball grinder

The invention discloses a continuous vertical planetary ball grinder which comprises a rack. A motor, a transmission spindle, a planetary gear mechanism, a ball grinding tank, a grinding tank shaft, acontinuous feeding hopper and a discharging opening arranged at the lower end of the ball grinding tank are arranged on the rack. The planetary gear mechanism comprises a gear ring, a sun gear, a planetary gear and a planetary carrier. The gear ring is fixed to the rack. The sun gear and the gear ring are engaged with the planetary gear. The planetary gear and the grinding tank shaft are fixedlyconnected and are coaxially and rotationally arranged on the planetary carrier. The sun gear and the planetary carrier are in transmission connection with the motor through the transmission spindle. The ball grinding tank is fixedly arranged at the upper end of the grinding tank shaft. A feed opening is arranged at the upper end of the ball grinding tank. The continuous feeding hopper comprises afeed opening and a feeding pipe, and the feeding pipe rotationally communicates with the feed opening. The grinding tanks shaft is provided with a discharging channel along the axis in a penetrating manner, wherein the discharging channel communicates with the discharging opening, and a discharging sieve is arranged in the discharging channel. The continuous feeding hopper can be combined with anautomatic assembly line to be used, the material feeding efficiency can be improved, and the rapid production requirement can be met.

Owner:长沙天创粉末技术有限公司

A kind of method utilizing organosilicon azeotrope to produce hexamethyldisiloxane

The invention discloses a method for producing hexamethyldisiloxane by the utilization of organosilicon azeotrope, comprising the following steps: (1) carrying out heating distillation on the organosilicon azeotrope, and removing fractions with boiling point being lower than 40 DEG C to obtain an intermediate mixture; (2) mixing the intermediate mixture and ethanol to carry out an intermittence esterification reaction, carrying out heating distillation on the reaction solution, and collecting fractions with the boiling point being lower than 80 DEG C to obtain a trimethylchlorosilane crude product; and (3) hydrolyzing the trimethylchlorosilane crude product, and separating from the hydrolysate so as to obtain hexamethyldisiloxane. According to the method provided by the invention, price of the raw materials is cheap, supply is sufficient, condition during the reaction process is mild, the technology is stable, continuous production efficiency is high, there is no by-product, and it is not necessary to use other poisonous and harmful organic solvents. Purity of the obtained hexamethyldisiloxane finished product is more than 99%, and the content of chloride ions is less than 100ppm.

Owner:HOSHINE SILICON IND CO LTD

Sword blank hot-rolling former and hot-rolling manufacturing method using same

The invention relates to a hot-rolling sword blank manufacturing device and a hot-rolling manufacturing method thereof, in particular to a sword blank hot-rolling former and a hot-rolling manufacturing method using the same. The sword blank hot-rolling former comprises a feed mechanism, a high-frequency heating system, and a rolling machine. The high-frequency heating system is disposed between the feed mechanism and the rolling machine and comprises an induction coil pipe, a cooling water circuit system, a high-temperature cement block, a transformer, and an ultrasonic frequency induction heating device connected with the transformer. The high-temperature cement block is provided with a heating passage. A main part of the induction coil pipe is embedded into the high-temperature cement block. The induction coil pipe extends out of two ends of metal pipes in the high-temperature cement block and respectively electrically connected with the transformer; the interiors of hollow pipes of the metal pipes at two ends are further communicated with the cooling water circuit system. High-temperature cement material for the high-temperature cement block is made from cement, water, tricalcium aluminate, polyester fiber, retarder, and polypropylene fiber. The sword blank hot-rolling former heats up by high frequency, is high in production efficiency and good in safety, causes low pollution, and is good in machining quality.

Owner:浙江精龙刀剑有限公司

Calibrating device for soft magnetic stripe

The invention discloses a calibrating device for a soft magnetic stripe. The device is characterized by comprising a base supporting device, three groups of longitudinal levelling devices, twelve transverse calibrating assemblies which form six groups, a transitional horizontal support and a sensing calibrator, wherein the base supporting device comprises a side surface supporting plate, a trapezoidal supporting plate and a horizontal base; each longitudinal levelling device comprises an upright supporting plate, a lower roller, an upper roller, a pin shaft and a pressure spring adjusting assembly; each transverse calibrating assembly comprises a supporting column, a roller, a gasket and a bolt; the transitional horizontal support comprises a positioning seat, a fixing bolt, a horizontal support and a pin; the sensing calibrator is fixedly mounted on the lower surface of the horizontal base, and a center line of the sensing calibrator is on the same vertical plane with the center line of the transitional horizontal support. With the adoption of the calibrating device, the problems of calibrating and levelling of a bent and deformed magnetic stripe can be solved; the specification of the magnetic stripe can be kept the same. Therefore, the magnetic stripe can smoothly pass through a magnetic engine to enter a door sealing rubber sleeve. The calibrating device is suitable for being popularized and used in a refrigerator door gasket industry.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Circular mold granulator

PendingCN113908768AGuarantee molding qualityQuality assuranceGranulation by pressingCouplingEngineering

The invention discloses a circular mold granulator which comprises a rack and a forming roller. Forming holes penetrating through the inside and the outside are densely distributed in the forming roller. A compression roller spindle driven by power of a compression roller driving device is installed in the forming roller. A compression roller set matched with the forming roller to conduct ceramsite forming is installed on the compression roller spindle. A scraping knife capable of being attached to the outer wall of the forming roller is connected to the rack. The forming roller and the compression roller spindle rotate reversely. An annular material inlet is formed in the front side of the forming roller. A feeding barrel located on one side of the forming roller is installed on the rack, a feeding opening is formed in the feeding barrel, and a feeding screw is installed in the feeding barrel. A main shaft of the feeding screw and the compression roller spindle are coaxially arranged and connected through a coupler. A conical material guiding barrel is installed between the discharging end of the feeding barrel and the material inlet, the material guiding barrel is fixedly connected with the outer wall of the forming roller, and the material guiding barrel and the feeding barrel are connected in a rotating and sealing mode. The circular mold granulator has the advantages that the ceramsite forming quality is high, the continuous production efficiency is high, and the ceramsite forming quality is improved.

Owner:山东恒远利废技术股份有限公司

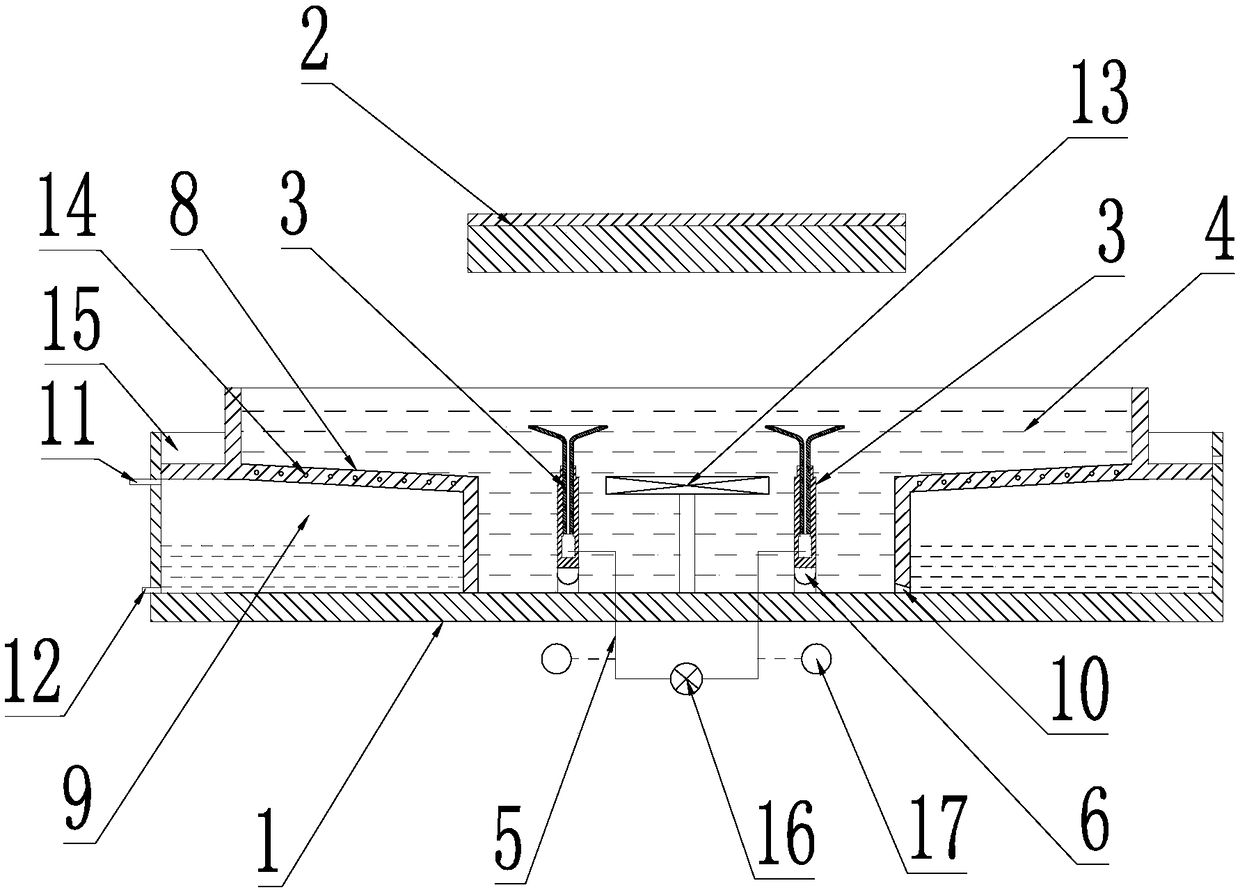

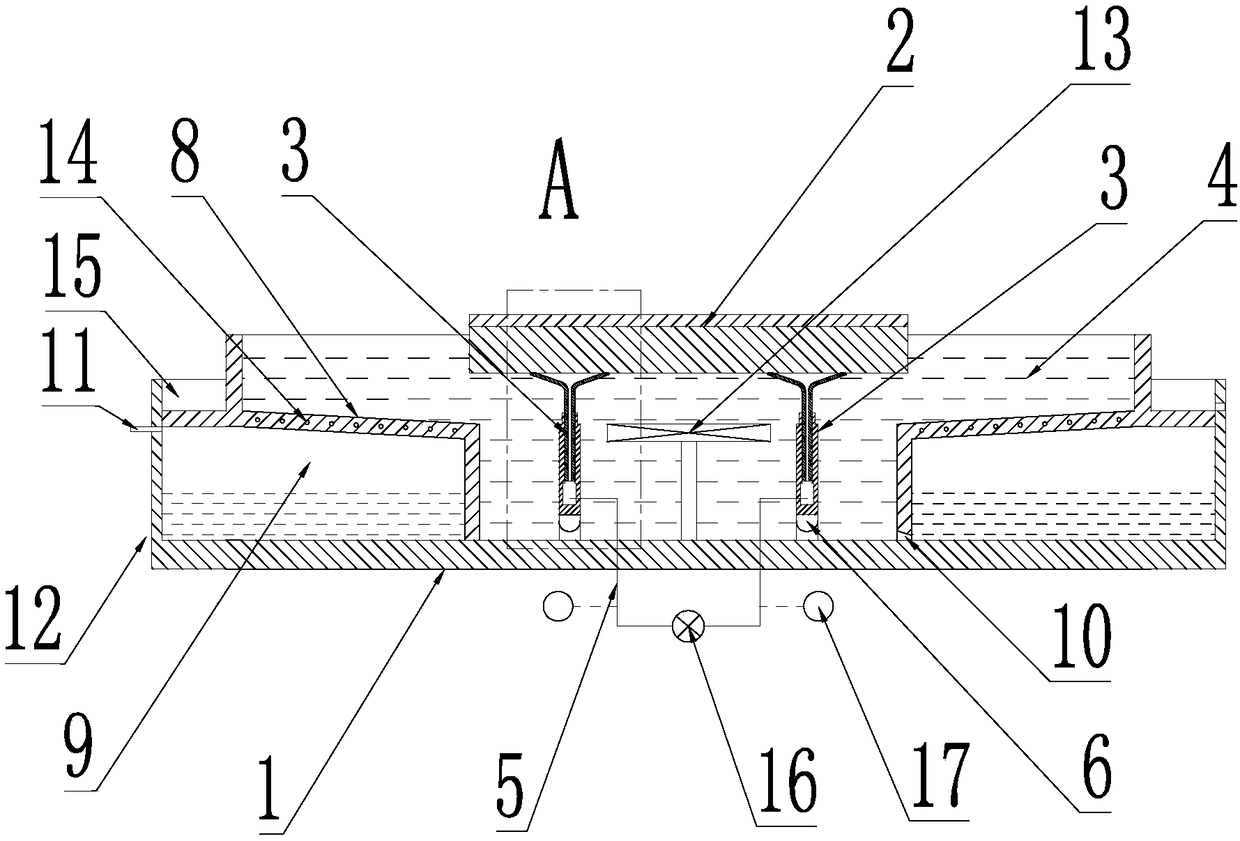

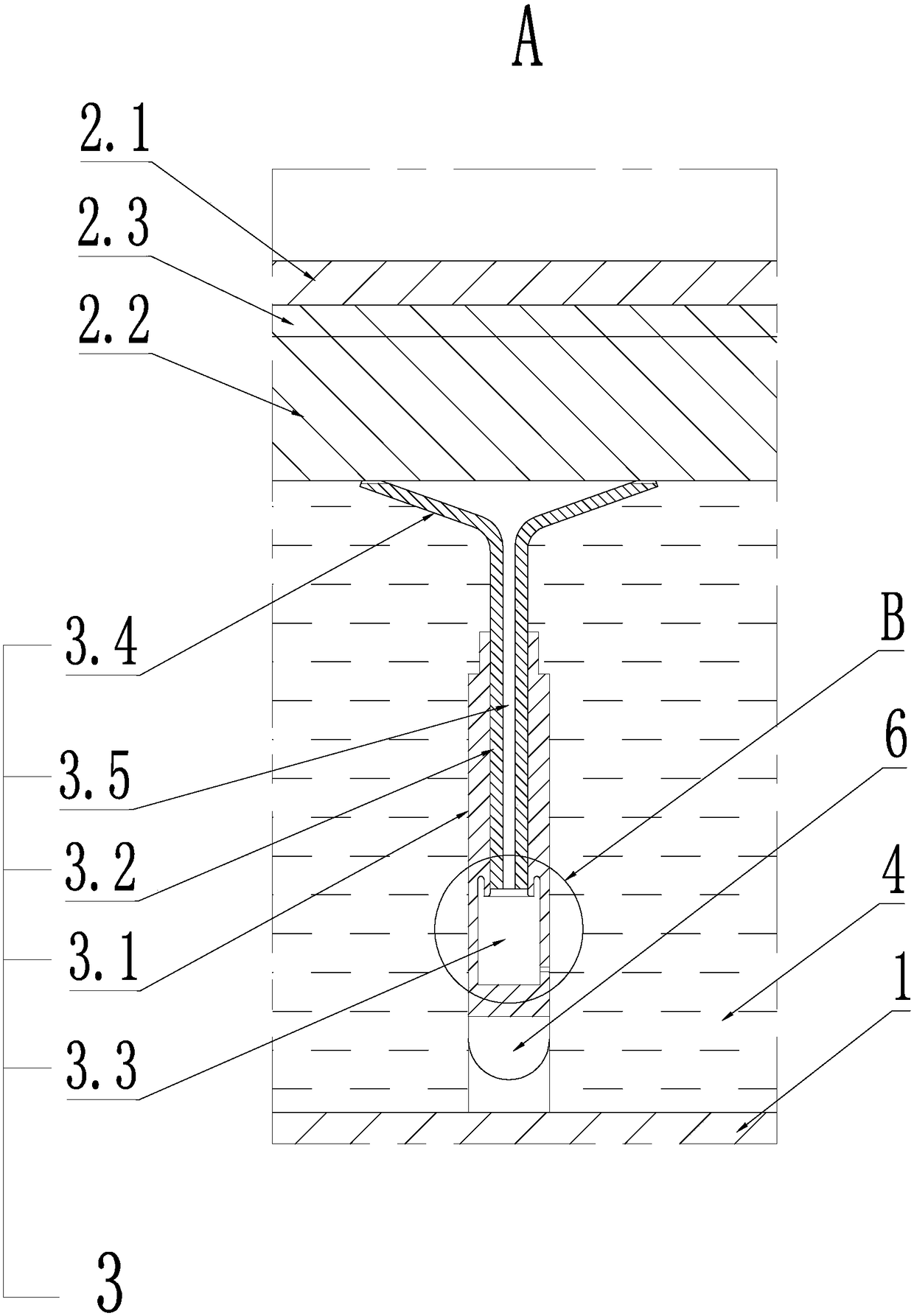

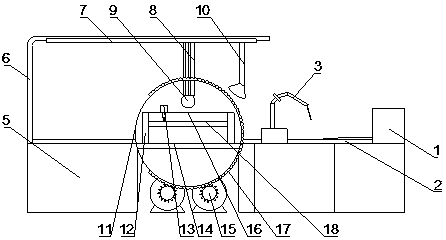

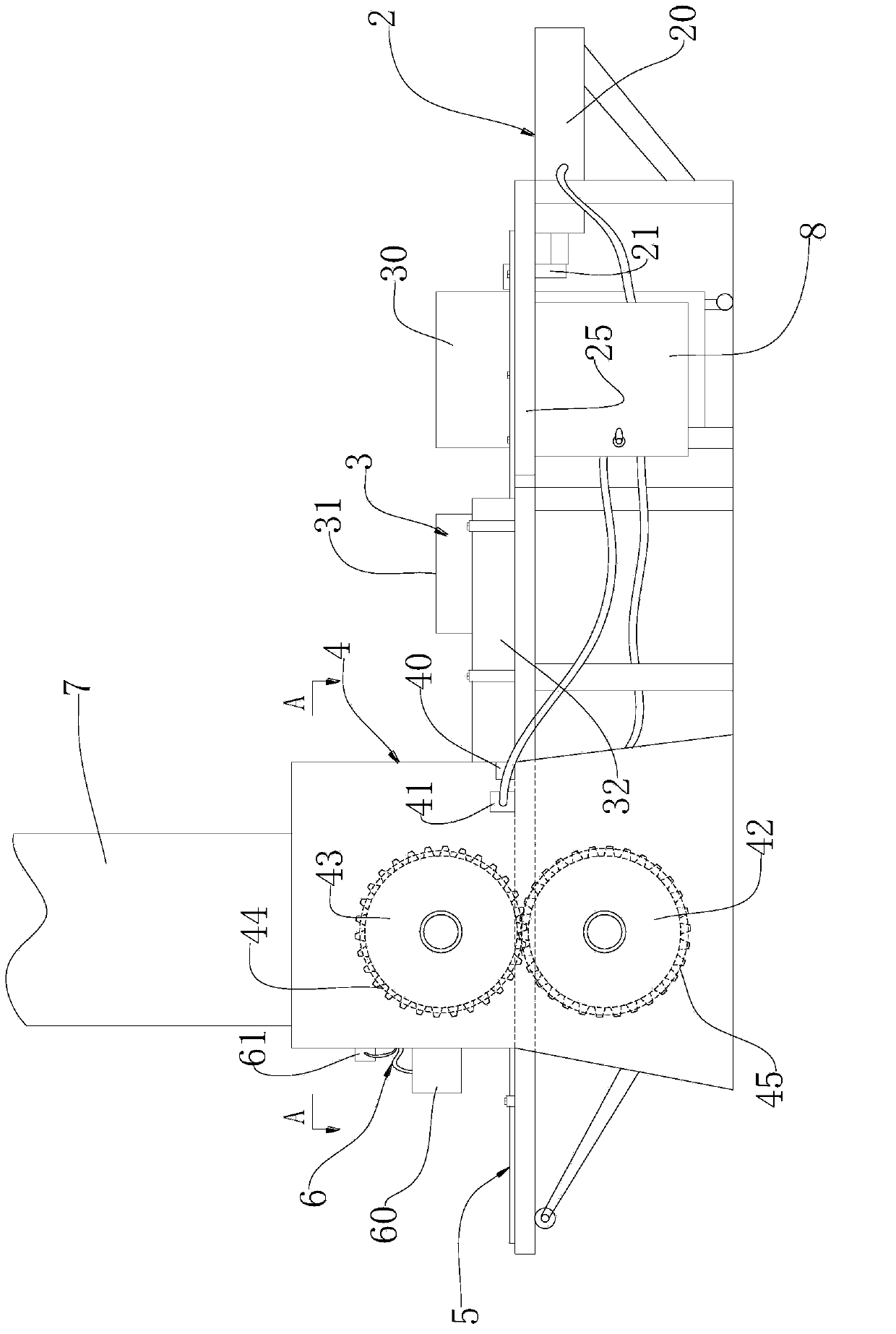

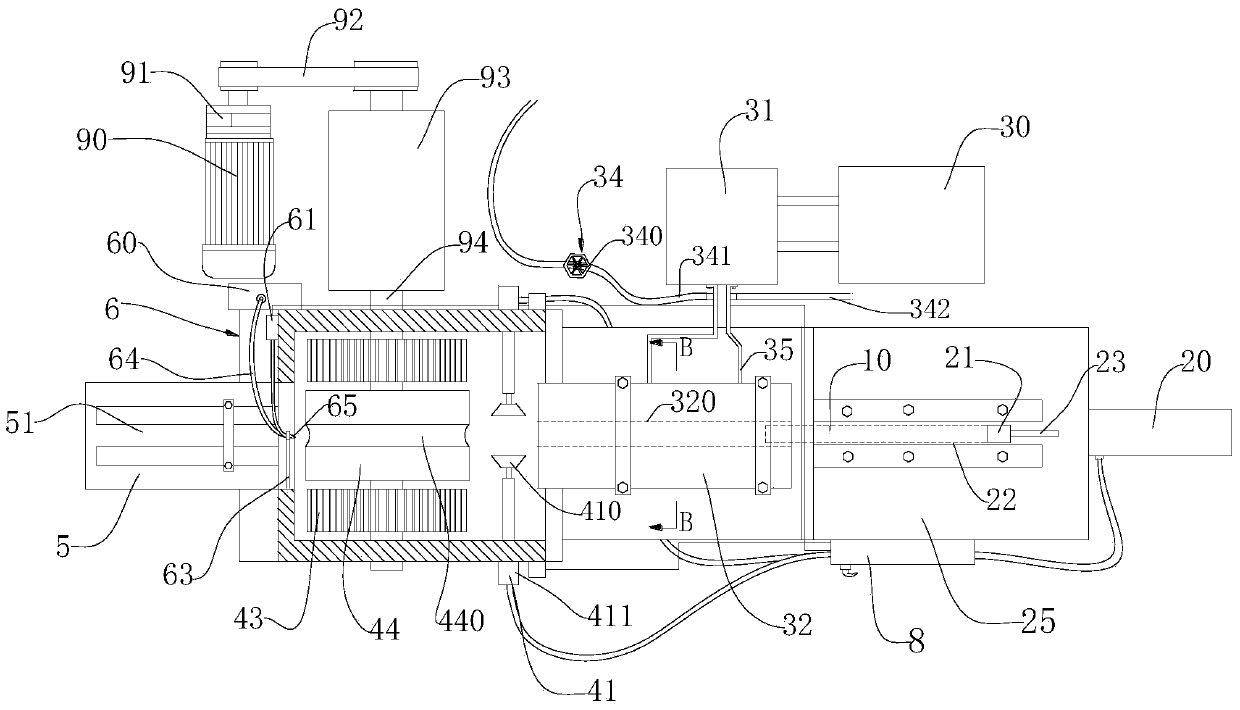

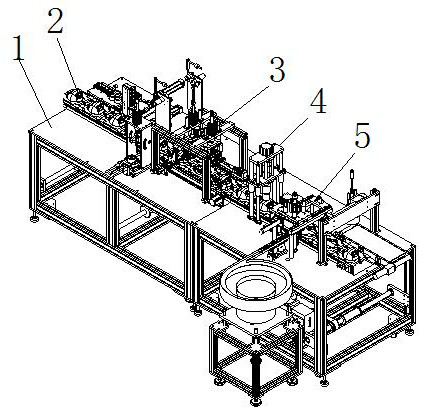

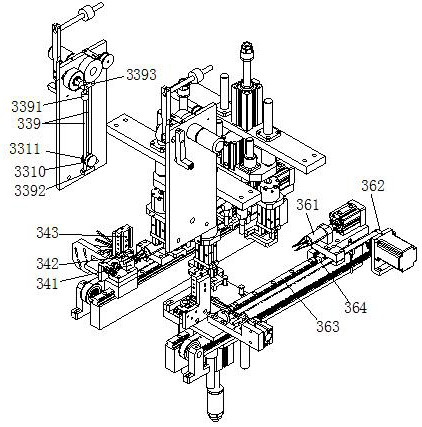

Full-automatic production line of breathing mask

ActiveCN112277322AHigh continuous production efficiencyDomestic articlesProtective garmentProduction lineMedicine

The invention discloses a full-automatic production line of a breathing mask, and belongs to the field of manufacturing of breathing masks. The full-automatic production line of the breathing mask comprises a machine frame, a breathing mask conveyor, an ear band welding device, a breathing valve hole punching device and a breathing valve welding device, wherein the breathing mask conveyor, the earband welding devices, the breathing valve hole punching device and the breathing valve welding device are arranged on the machine frame; the ear band welding device comprises a breathing mask supporting mechanism, an ear band welding assembly containing the two ear band welding mechanisms and two sets of ear band feeding devices; each set of ear band feeding device comprises an ear band conveyingmechanism, an ear band pressing mechanism, an ear band cutting mechanism and an ear band traction mechanism; each of the ear band welding mechanisms comprises an ear band welding support, a first lifting driving mechanism, an abutment, a rotation driving mechanism, a clamping mechanism, a second lifting driving mechanism and an ear band welding gun; each of the clamping mechanism comprises two output ends with clamping parts; each of the clamping parts comprises bodies of two clamping faces; and when two output ends of the each clamping mechanism approach mutually, the two clamping faces of the two clamping parts separately form an ear band clamping point in the two directions of the clamping mechanisms. The full-automatic production line of the breathing mask disclosed by the invention is reasonable in design, and can effectively provide ear bands for welding.

Owner:湖南众焰自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com