Patents

Literature

30results about How to "Continuous grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

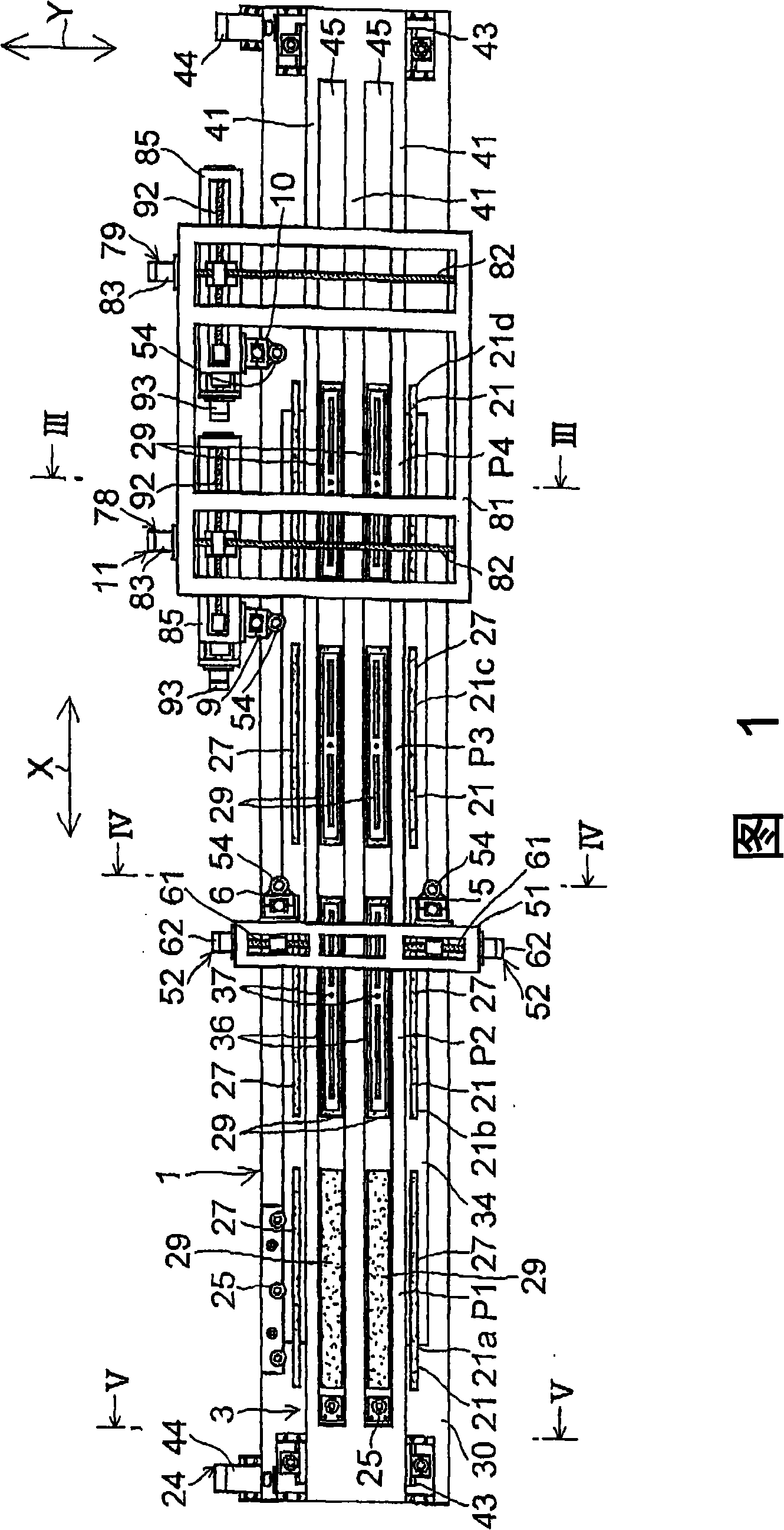

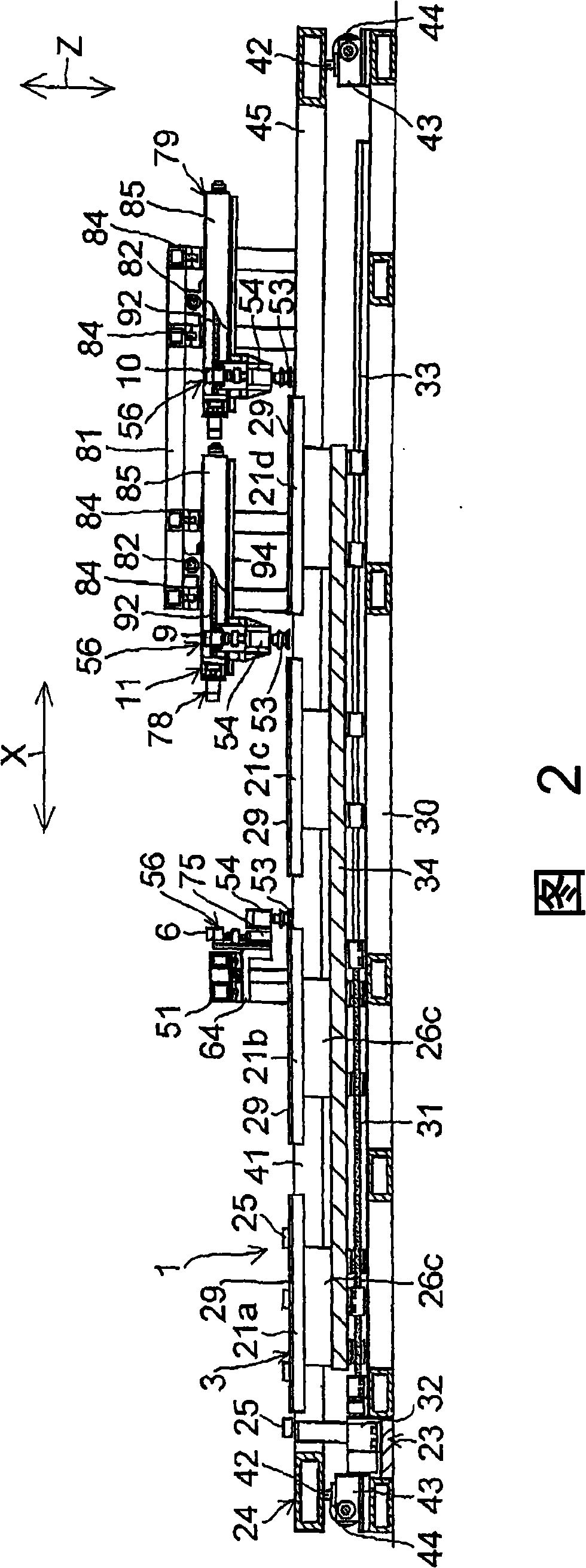

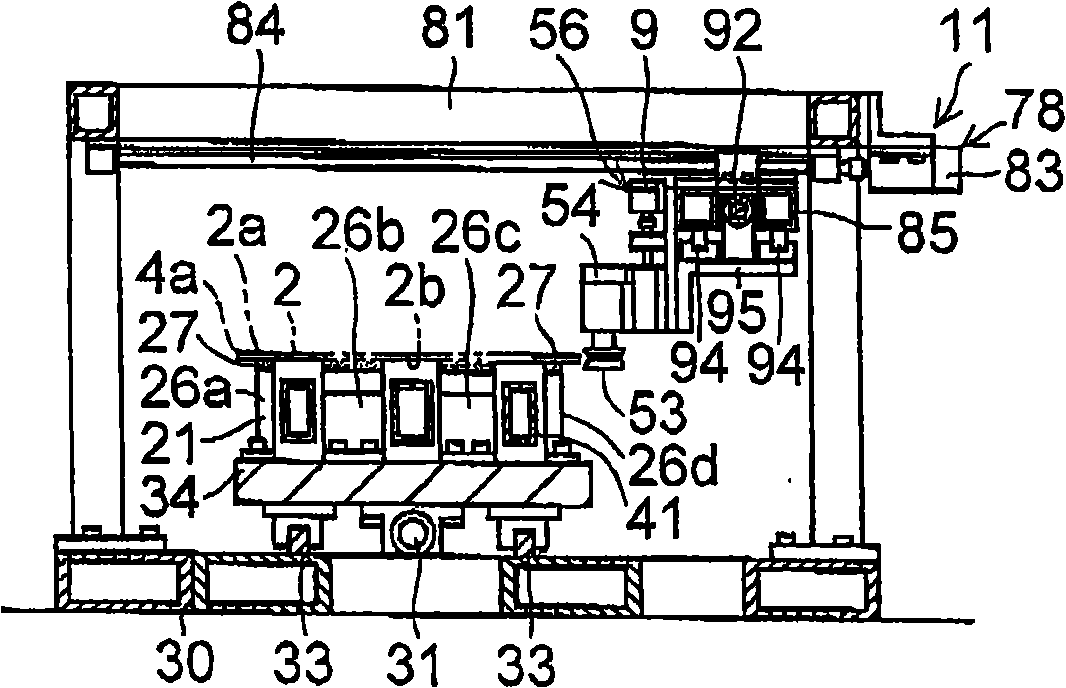

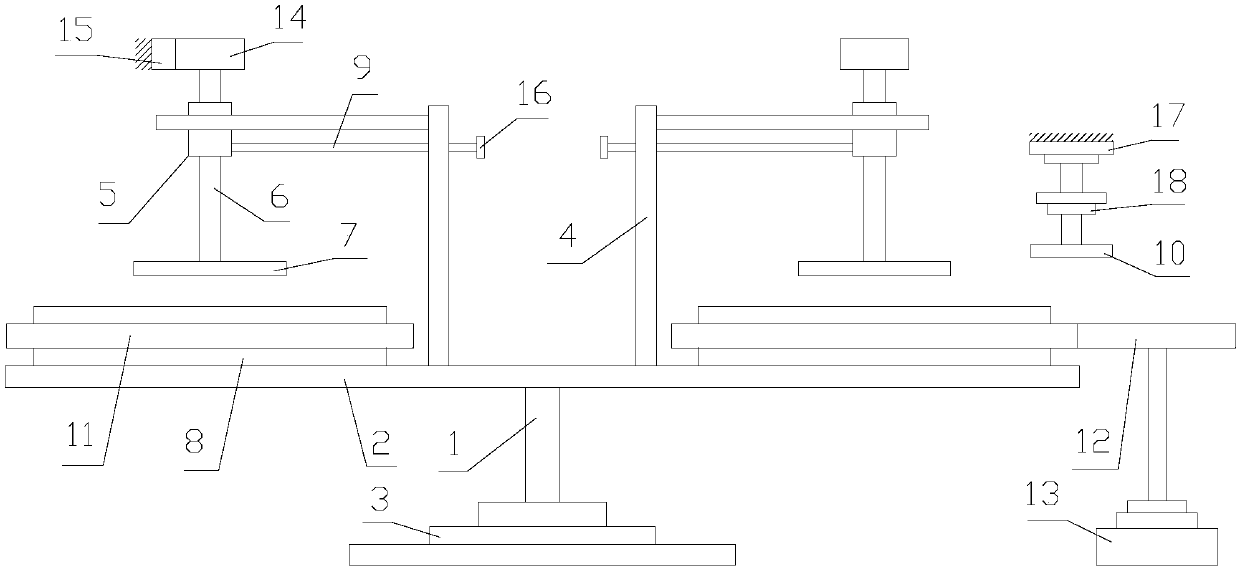

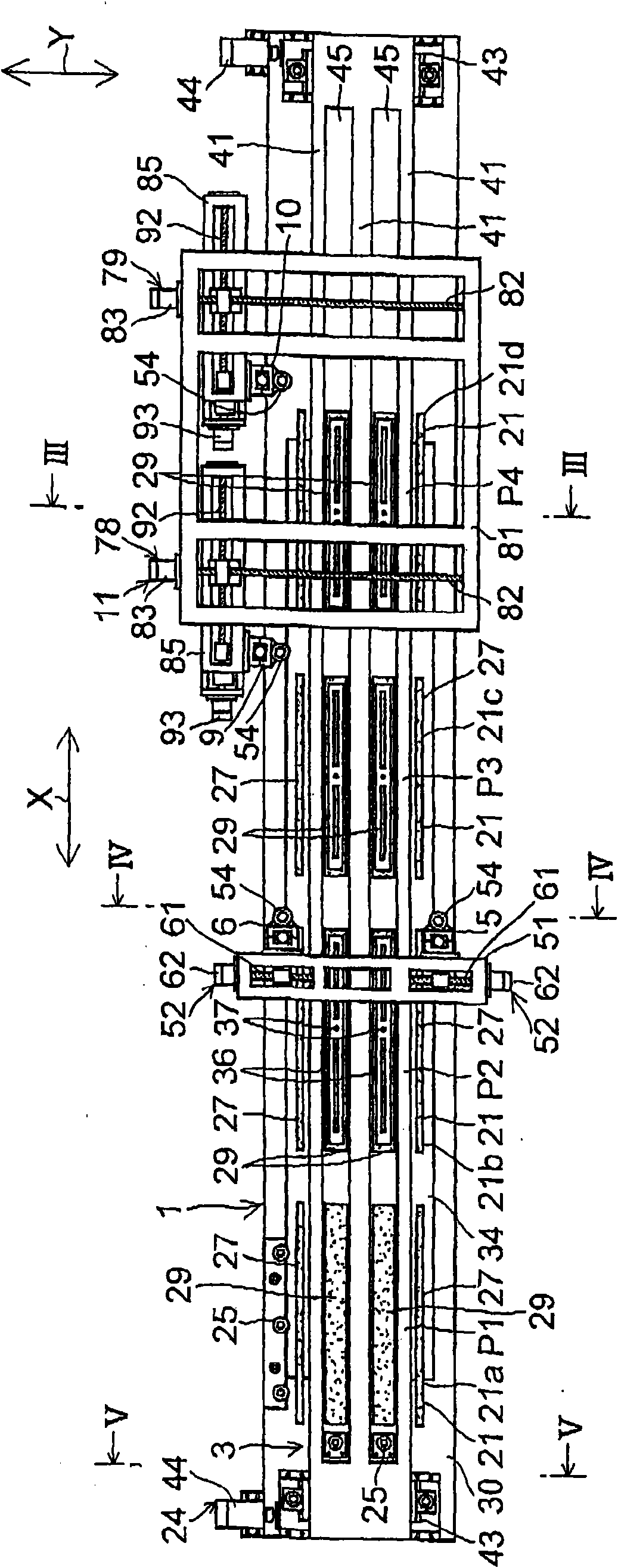

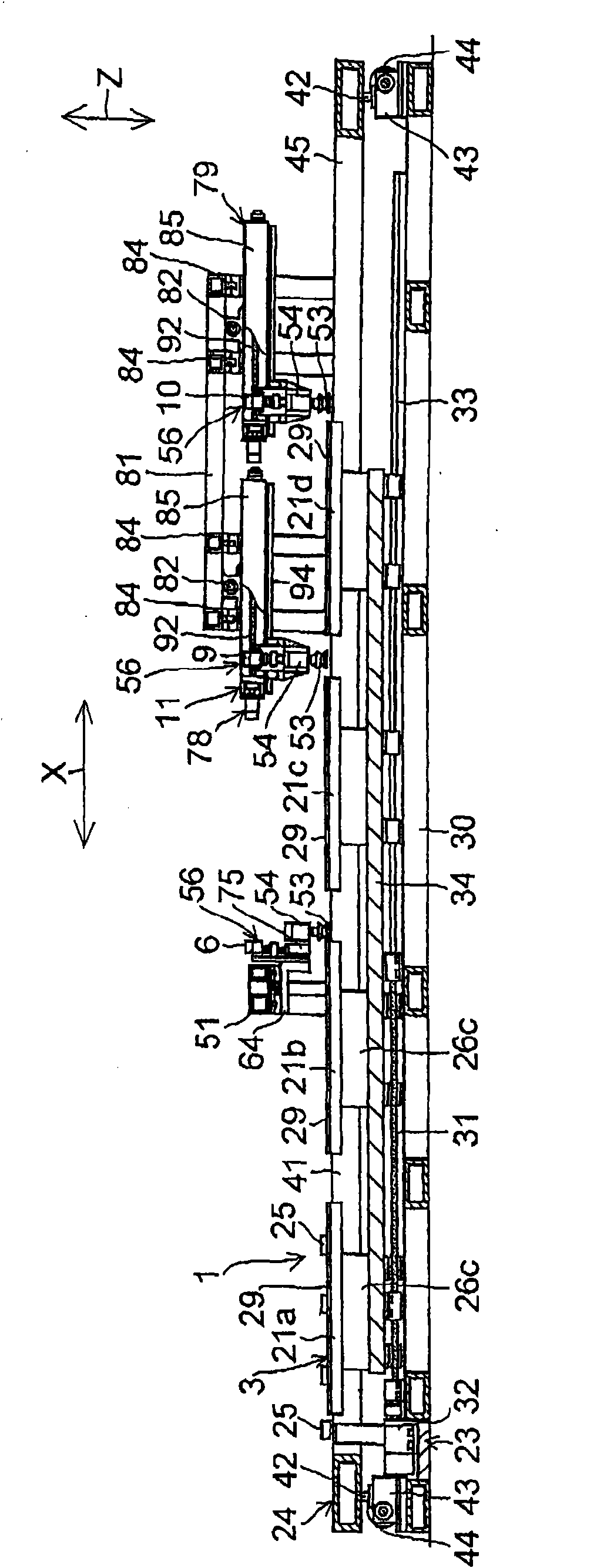

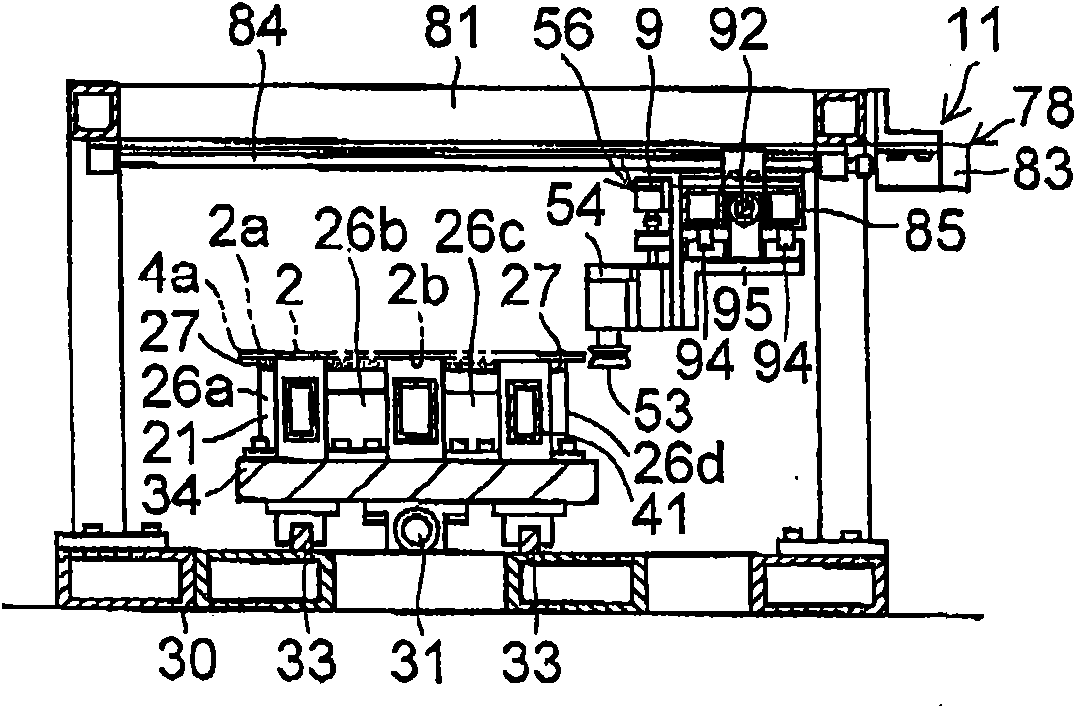

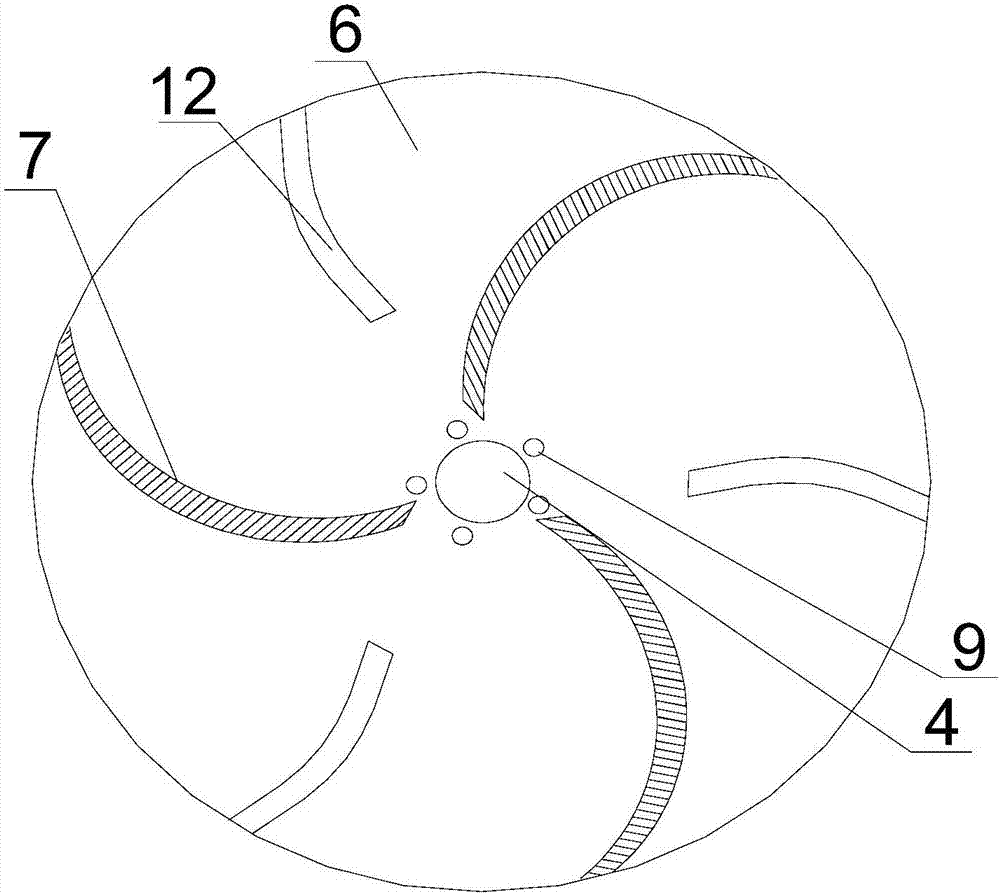

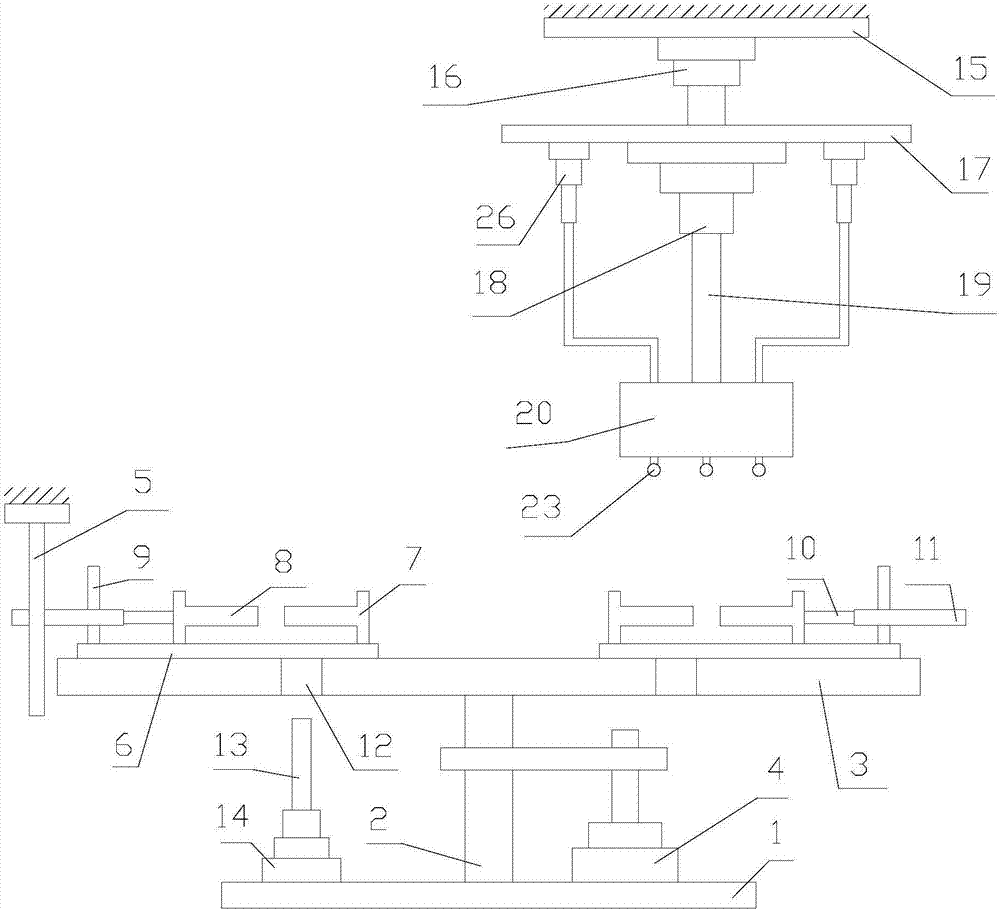

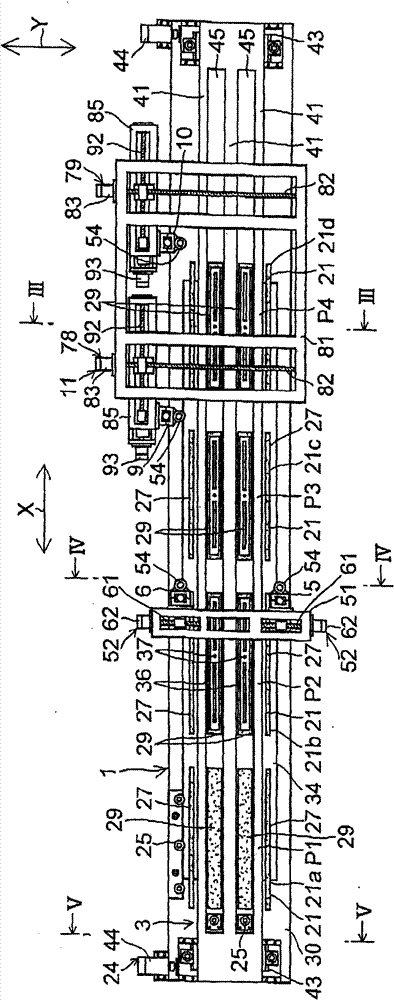

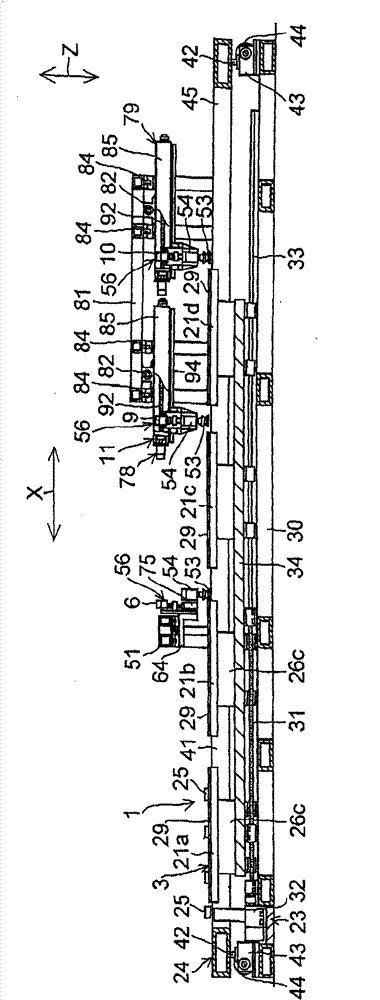

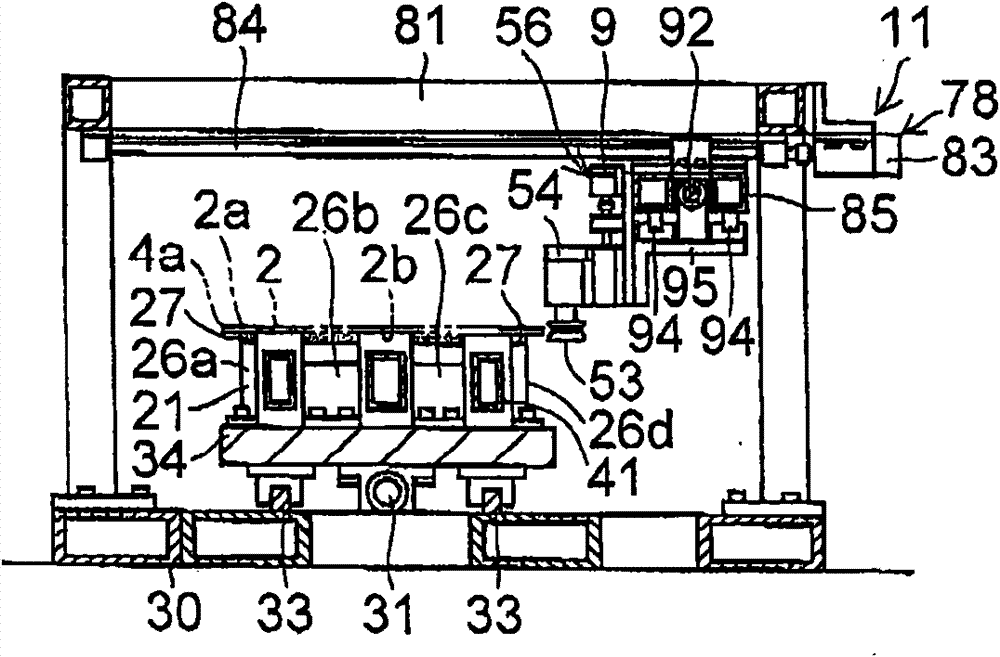

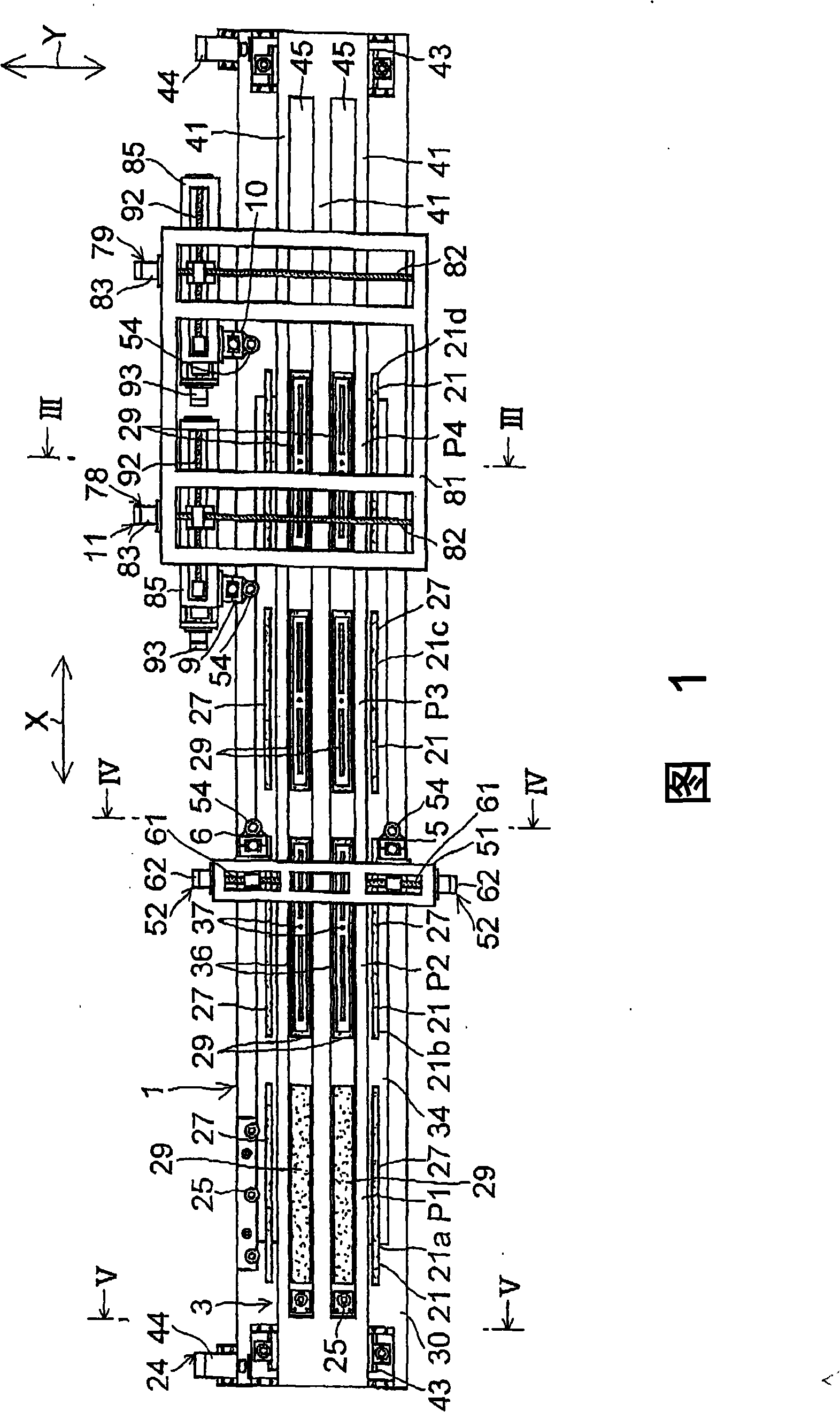

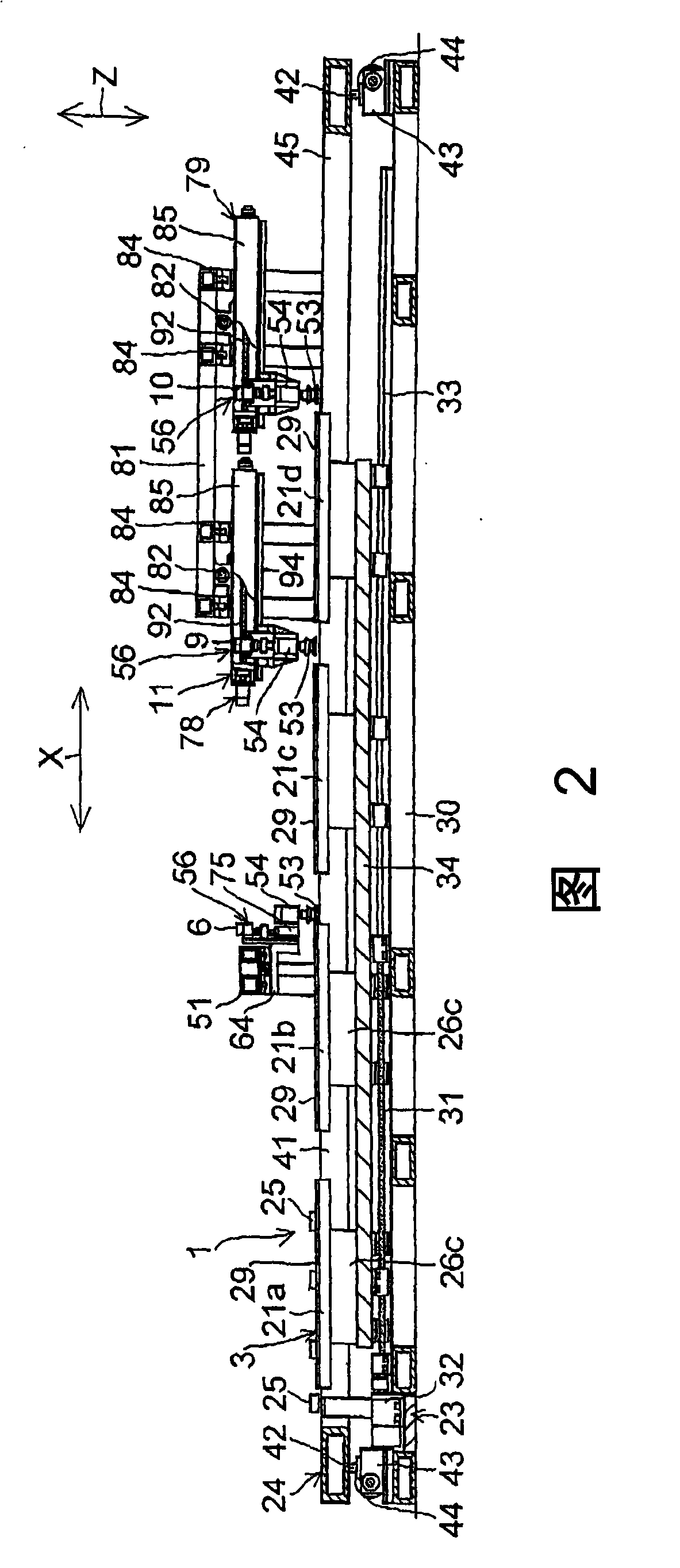

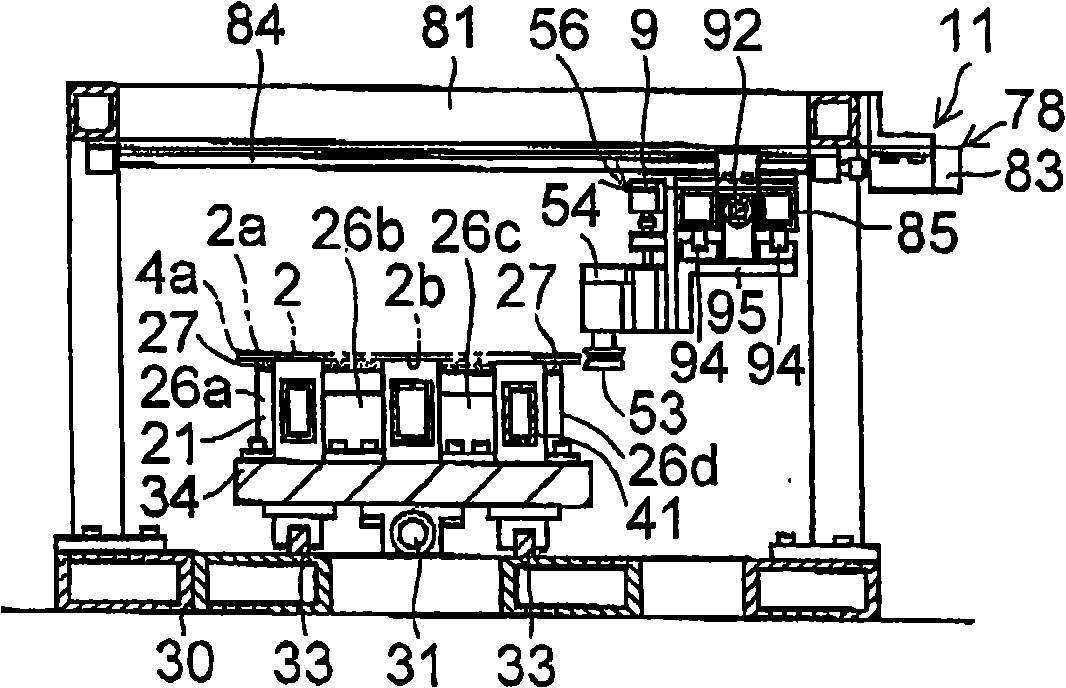

Grinding device of glass plate

InactiveCN101332578AContinuous grindingIncrease productionEdge grinding machinesEngineeringFront edge

A grinding device (1) of a glass plate comprises a linear conveyance unit (3) which linearly conveys the glass plate (2) along the X direction; a first grinding device is provided with grinding heads (5) and (6) for respectively grinding the two side edges (4a) and (4b) of the glass plate (2) linearly conveyed by the linear conveyance unit (3) extending along the X direction; and a second grinding device is adjacent to the first grinding device in the X direction and provided with movable grinding heads (9) and (10) for respectively grinding a front edge (7) and a rear edge (8) extending along the Y direction orthogonal with the X direction for the linear conveyance by the linear conveyance unit (3).

Owner:BANDO KIKO CO LTD

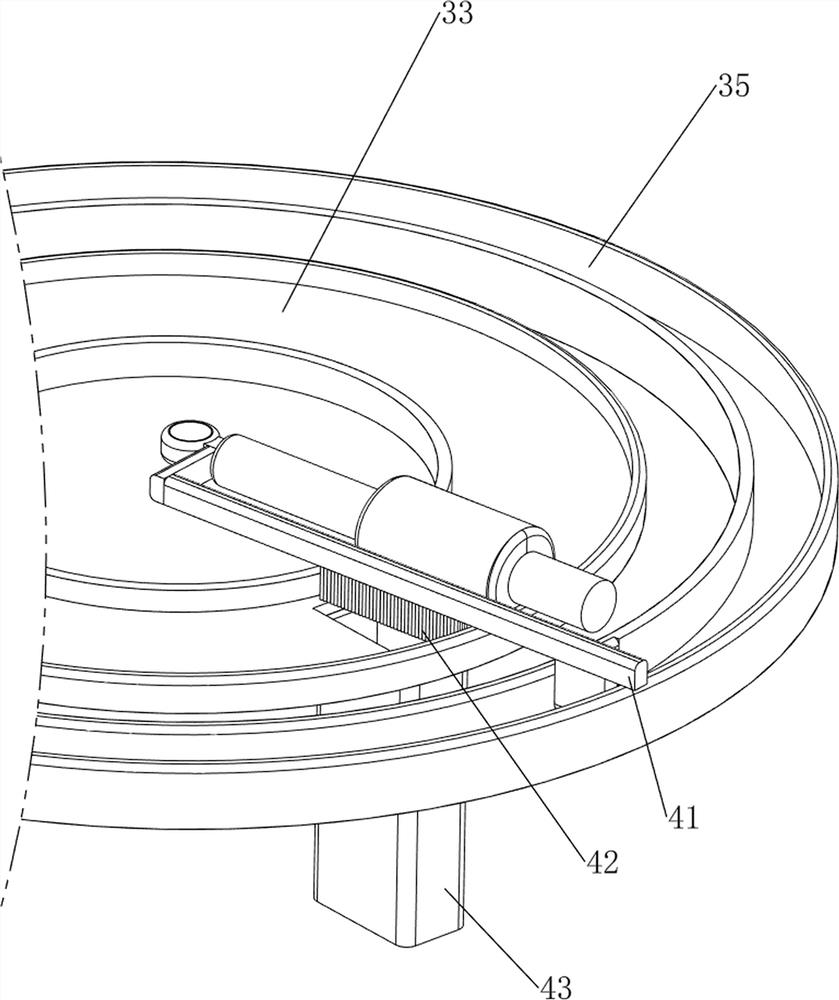

Wire surface rust removal polisher

ActiveCN104907907AAvoid dust pollutionReduce manufacturing costGrinding drivesBelt grinding machinesBelt grindingEngineering

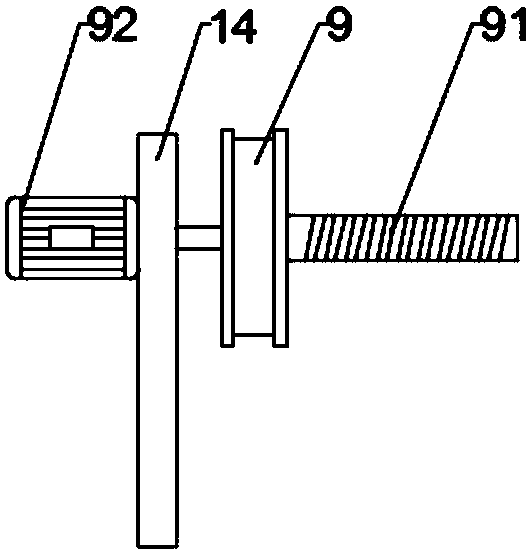

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

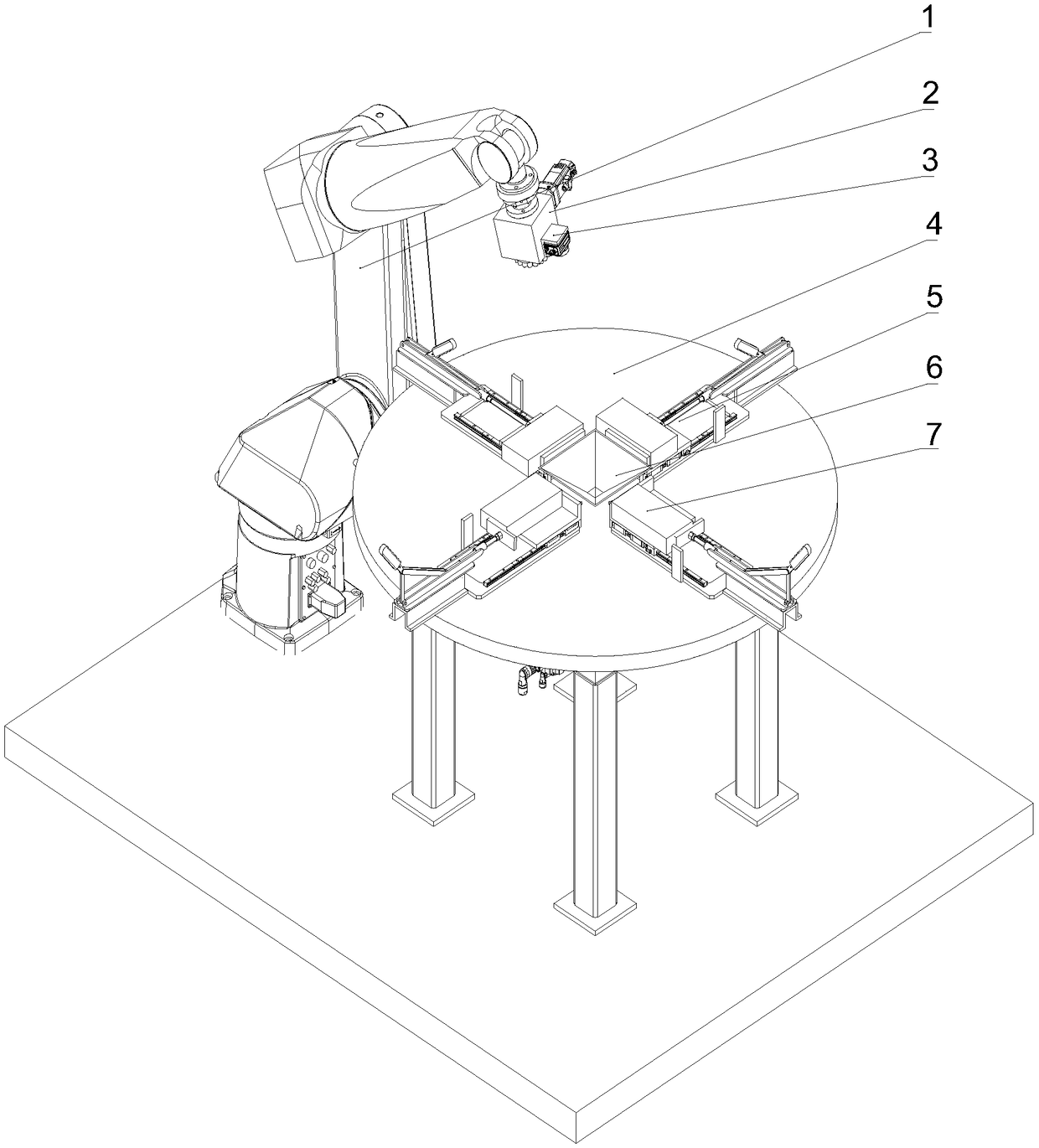

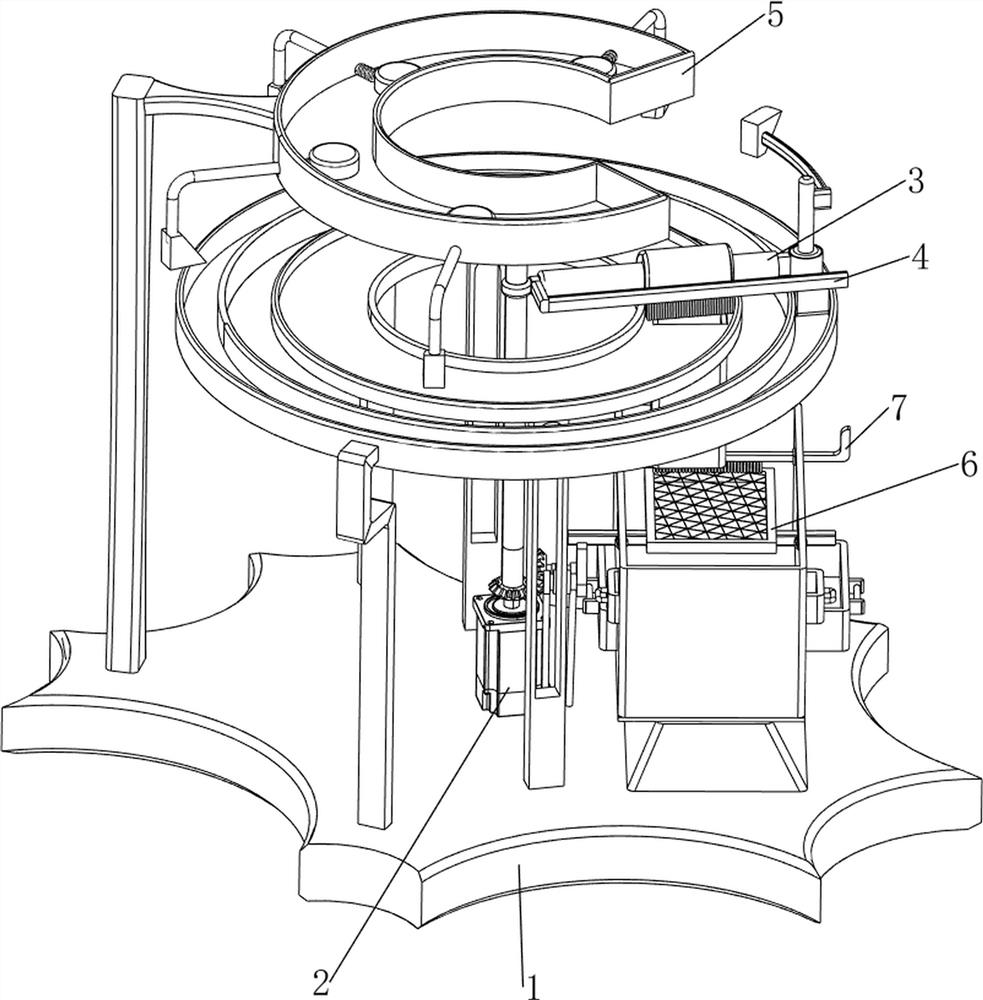

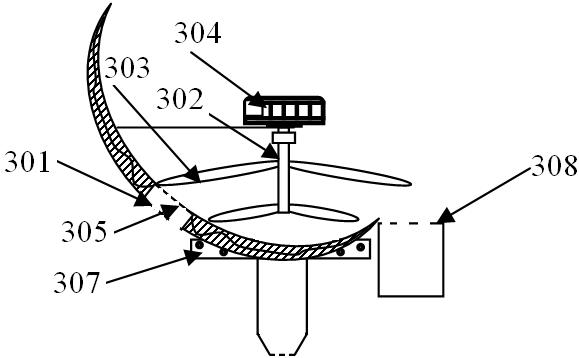

Robot automatic grinding equipment for ancient building bricks

PendingCN109048526AImprove sanding consistencyImprove grinding efficiencyGrinding feed controlManipulatorBrickEngineering

The invention relates to robot equipment for automatically and precisely grinding ancient building bricks. The robot equipment comprises a six-degree-of-freedom industrial robot, an electric servo grinding tool, a vision detecting and positioning device, a rotating disc type workbench, brick block positioning fixtures and a dust collector; the six-degree-of-freedom industrial robot is a movement mechanism for brick block grinding; the electric servo grinding tool is used for grinding the surfaces of a brick block to achieve grinding of all the surfaces of the brick block; the vision detectingand positioning device is used for detecting the initial geometric size of the brick block; the rotating disc type workbench is fixed to the ground through a support frame and driven by a servo motorto rotate and change the position, and then one-time feeding and in-turn grinding of multiple brick blocks are achieved; the brick block positioning fixture is installed on the rotating disc type workbench, the four groups of fixtures are evenly distributed at the periphery of a rotating disc to position the brick block, and grinding of the six surfaces of the brick block is completed through twotimes of clamping and position changing; and in the grinding process, the dust collector is used for collecting grinding dust, and environment pollution is avoided. According to the robot equipment, automatic grinding can be achieved, the efficient and the grinding consistency are improved, and the cost is reduced.

Owner:LIAONING BROADCASTING TELEVISION UNIV

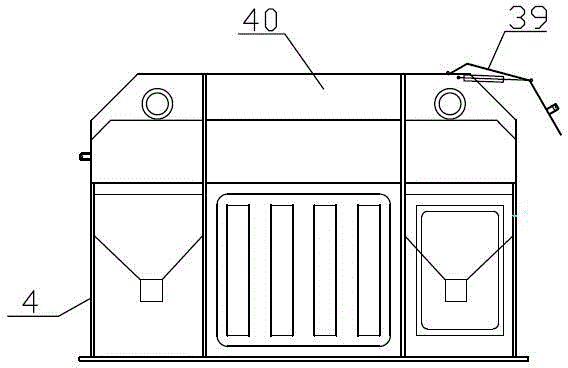

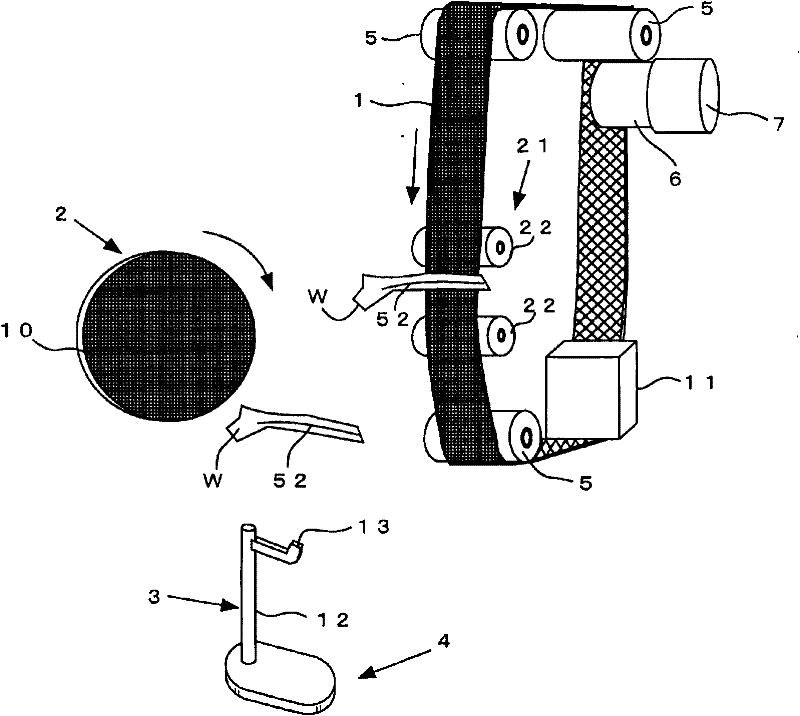

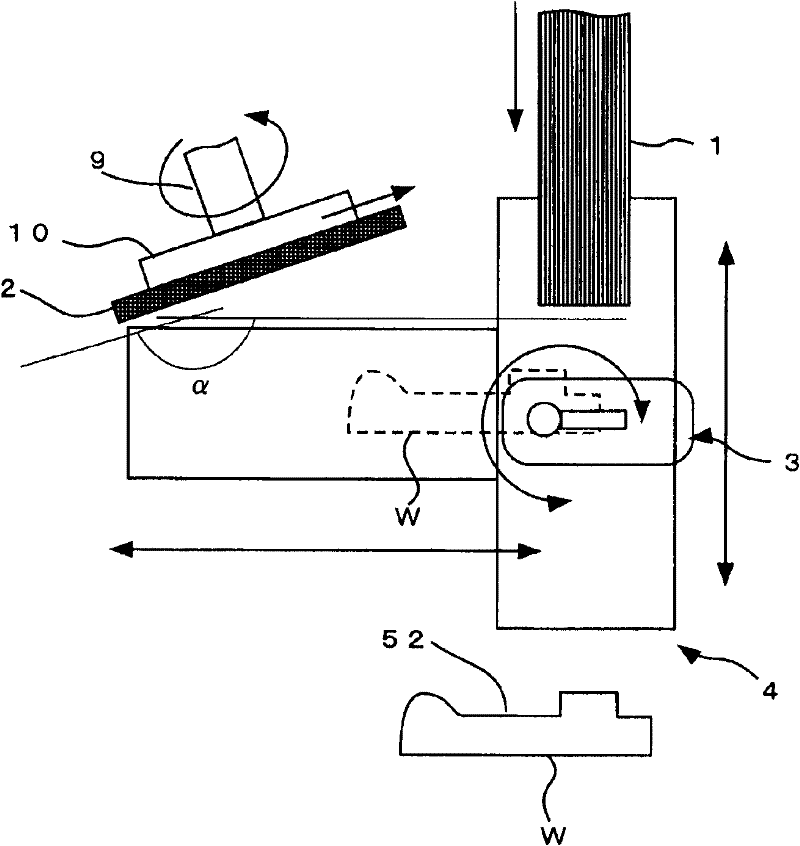

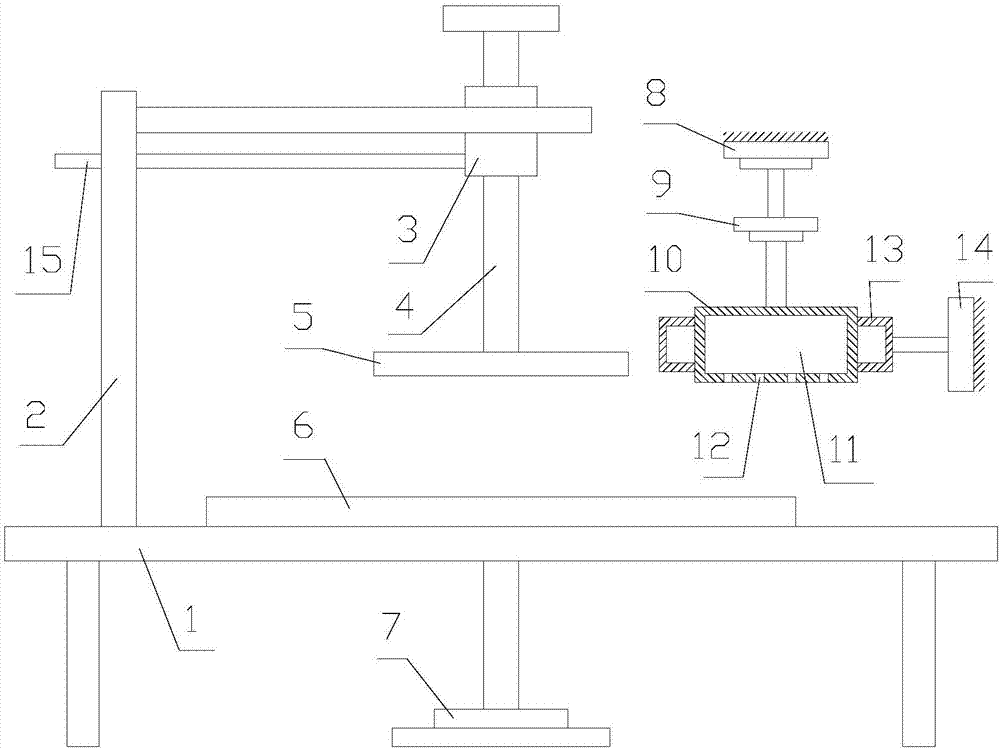

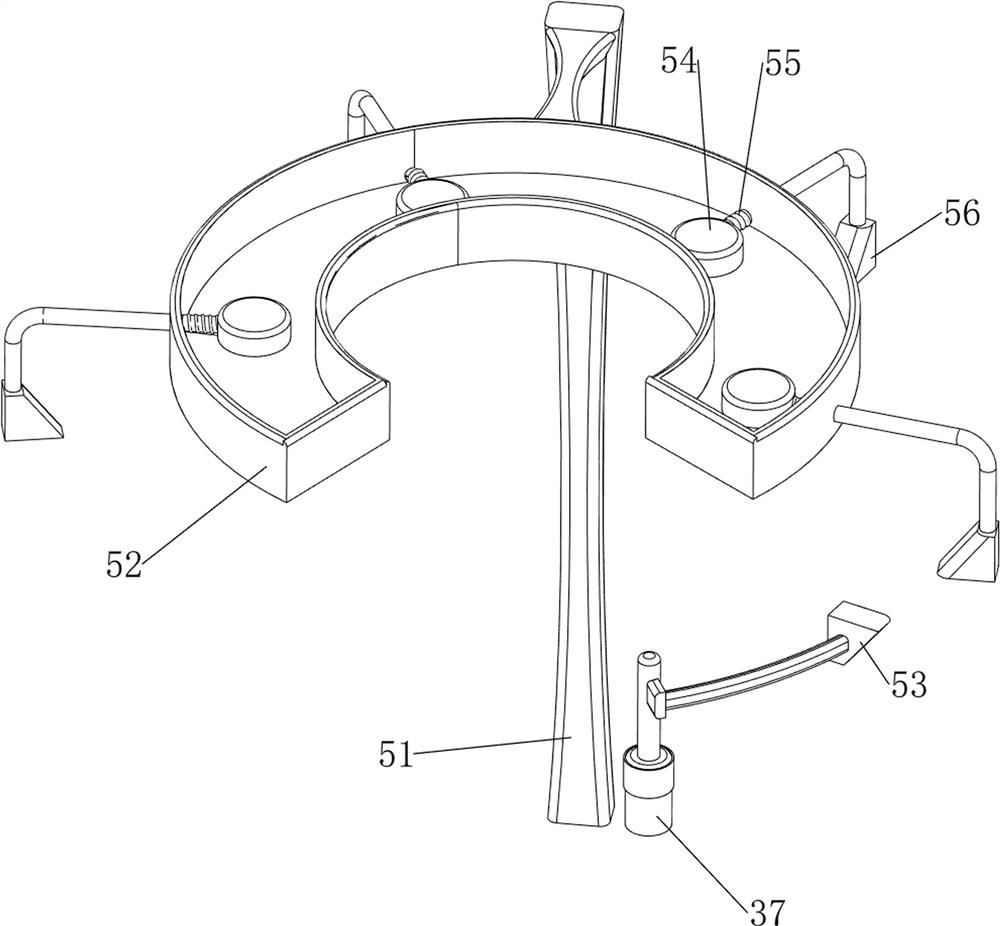

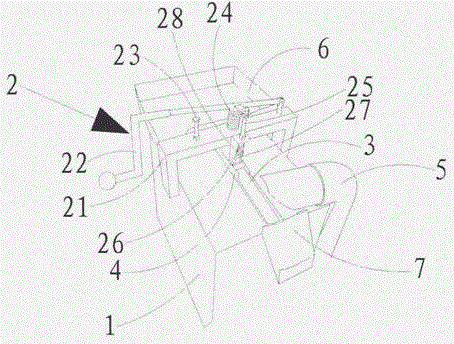

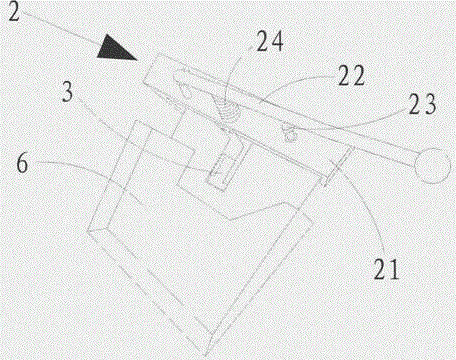

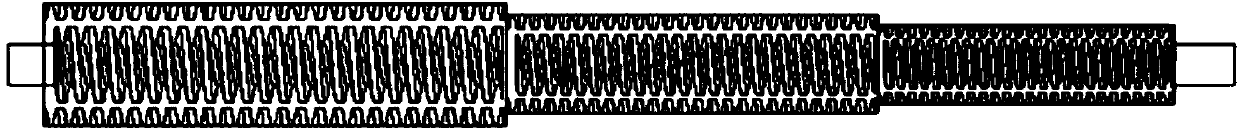

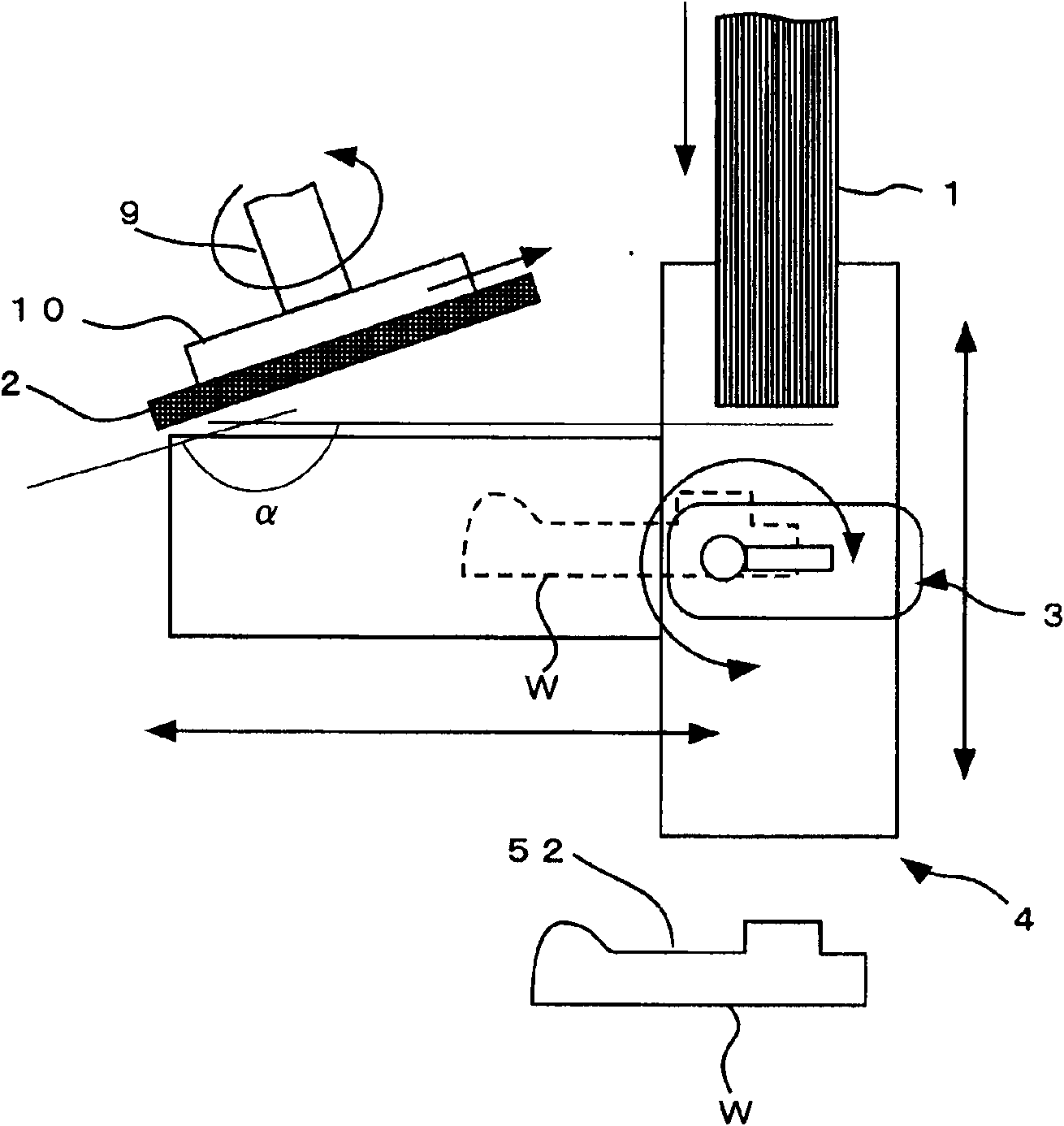

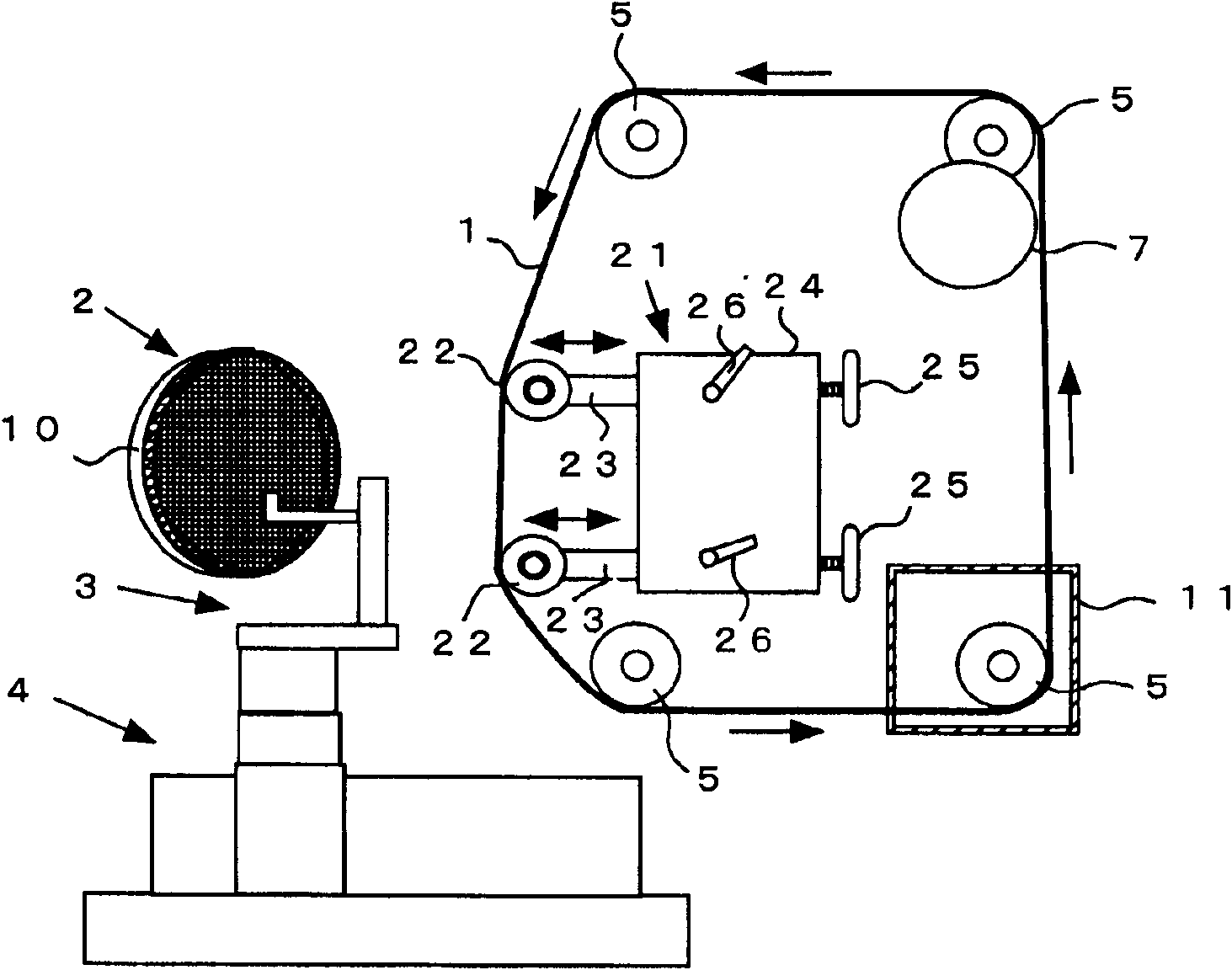

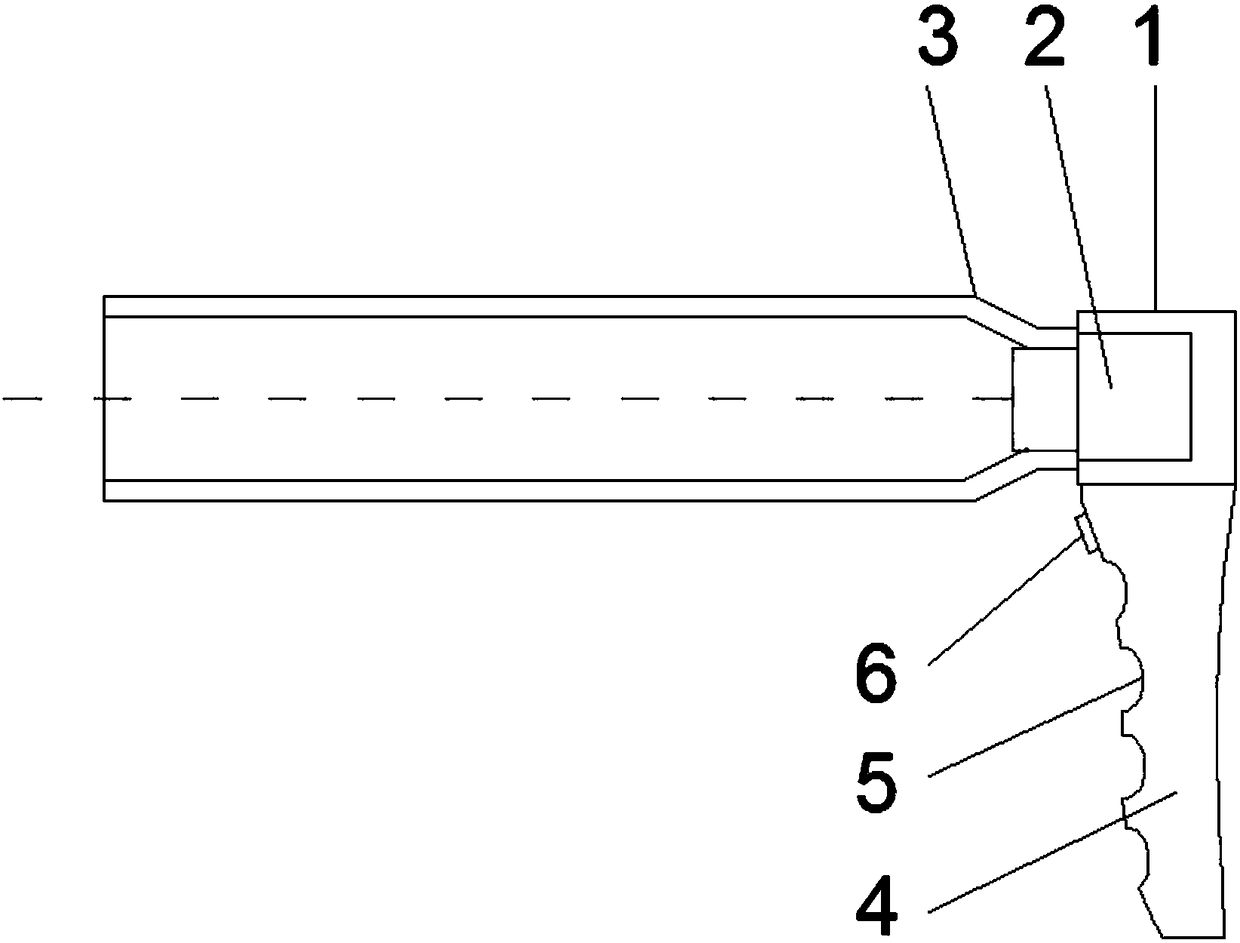

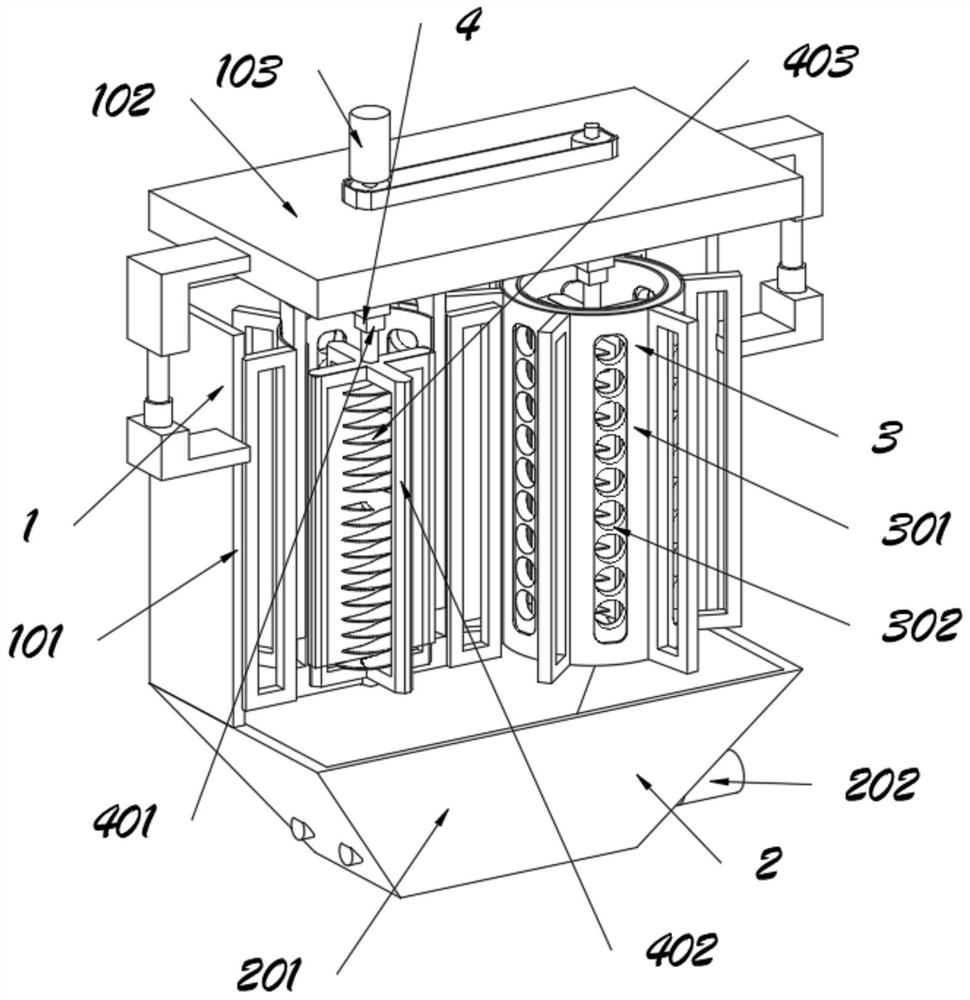

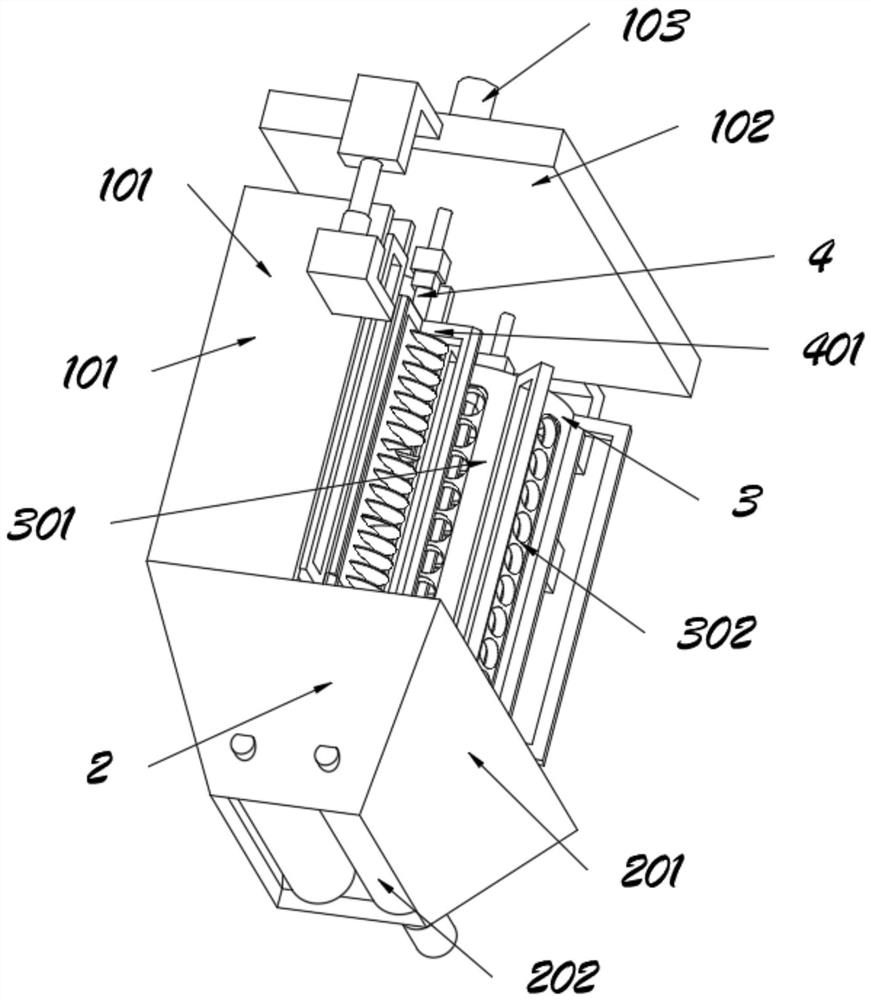

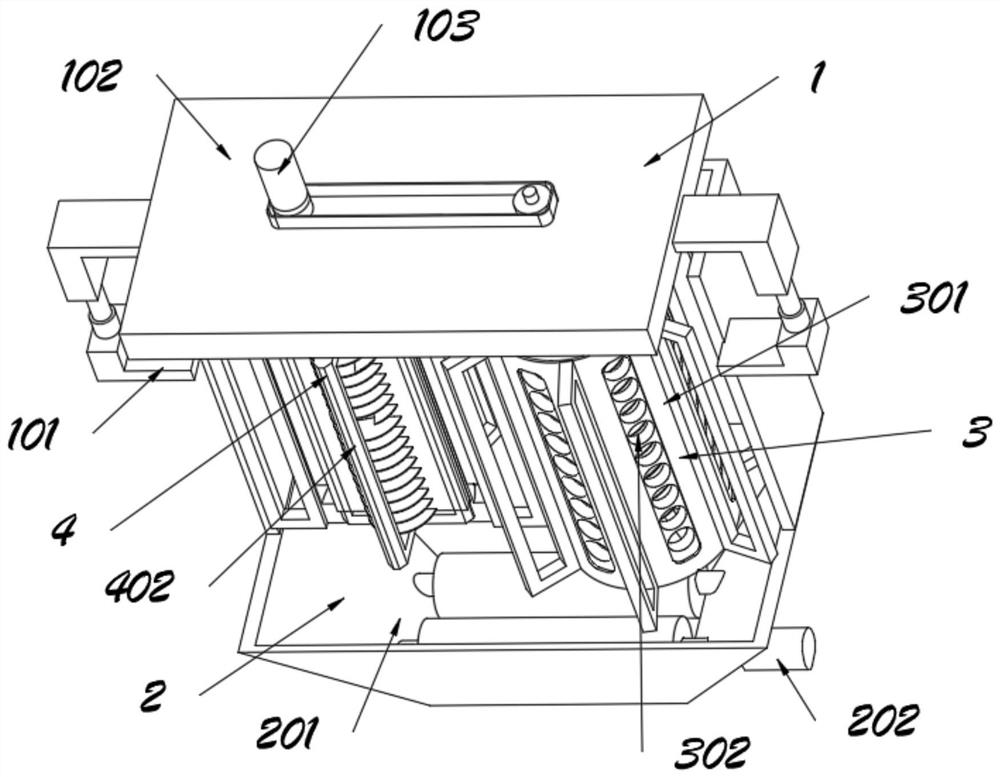

Grinding Device Of Parting Line Of Resin Molding And Grinding Method

ActiveCN102371523AGrinding fasterContinuous grindingBelt grinding machinesEngineeringPerpendicular direction

The invention provides a grinding device of a parting line of a resin molding and can grinding resin moldings having different shapes quickly. The grinding device of the parting line of the resin molding is composed of an annular grinding belt (1) rotating along a generally perpendicular direction and grinding burrs or jumps of the parting line (52) of the resin molding (W); a push and press pulley (21) capable of moving freely and provided with the grinding belt (1) on the back for pushing and pressing a part of the grinding belt and forming an inclining angle of an incline face of the grinding belt (1); a grinding plate (2) used for fine grinding and having a smaller thickness a low rigidity than the grinding belt (1); and a work piece holding tool (3) carrying the resin molding (W) in a dismountable manner to make the parting line (52) in a generally horizontal direction.

Owner:KAKIHARA KOGYO CO LTD

High-efficiency glass polishing equipment

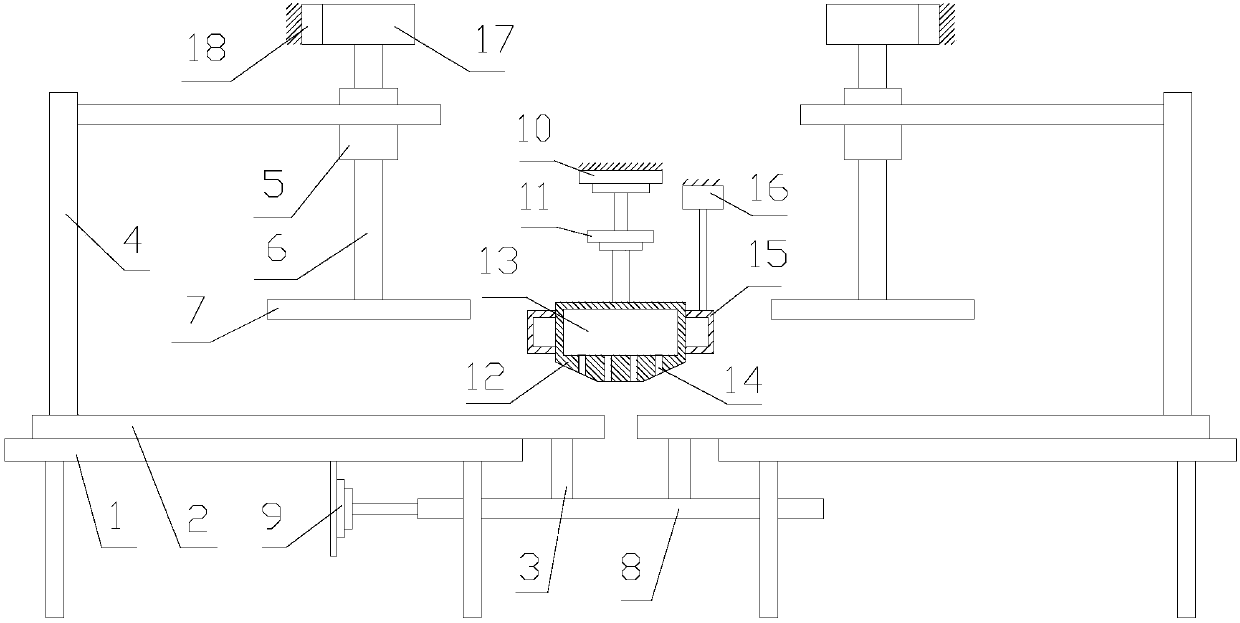

InactiveCN107932224AHigh degree of mechanizationGood effectGrinding drivesGrinding work supportsMachiningEngineering

The invention discloses high-efficiency glass polishing equipment. The high-efficiency glass polishing equipment comprises a polishing part, two clamping parts and a drive mechanism. The two clampingparts are distributed on the two sides of the polishing part correspondingly. Each clamping part comprises a machining platform, a machining plate, a first rack and a plurality of clamping units, wherein the machining platform is provided with a sliding groove, the machining plate is in sliding connection with the sliding groove, the first rack is arranged on the machining plate, the length direction of the first rack is parallel to the length direction of the sliding groove, and the multiple clamping units are sequentially distributed in the length direction of the sliding groove. Each clamping unit comprises an installation frame, a supporting block, a screw and a pressing plate, wherein the installation frame is arranged on the corresponding machining plate, the supporting block is arranged on the installation frame, the supporting block is provided with a threaded hole, the screw is arranged in the vertical direction, the screw is located in the threaded hole and is in threaded connection with the threaded hole, and the pressing plate is arranged at the bottom end of the screw. The drive mechanism comprises a gear shaft and a drive unit, wherein the gear shaft is rotationally connected with the machining platforms. The first racks in the two clamping parts are engaged with the gear shaft, and the drive unit is used for driving the gear shaft to rotate.

Owner:蚌埠承永玻璃制品有限公司

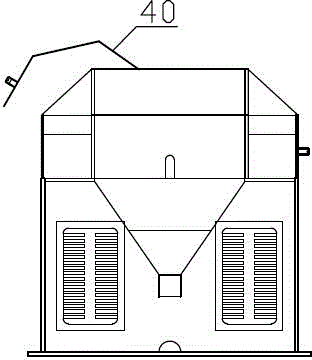

Chinese medicinal crop drying and grinding all-in-one machine

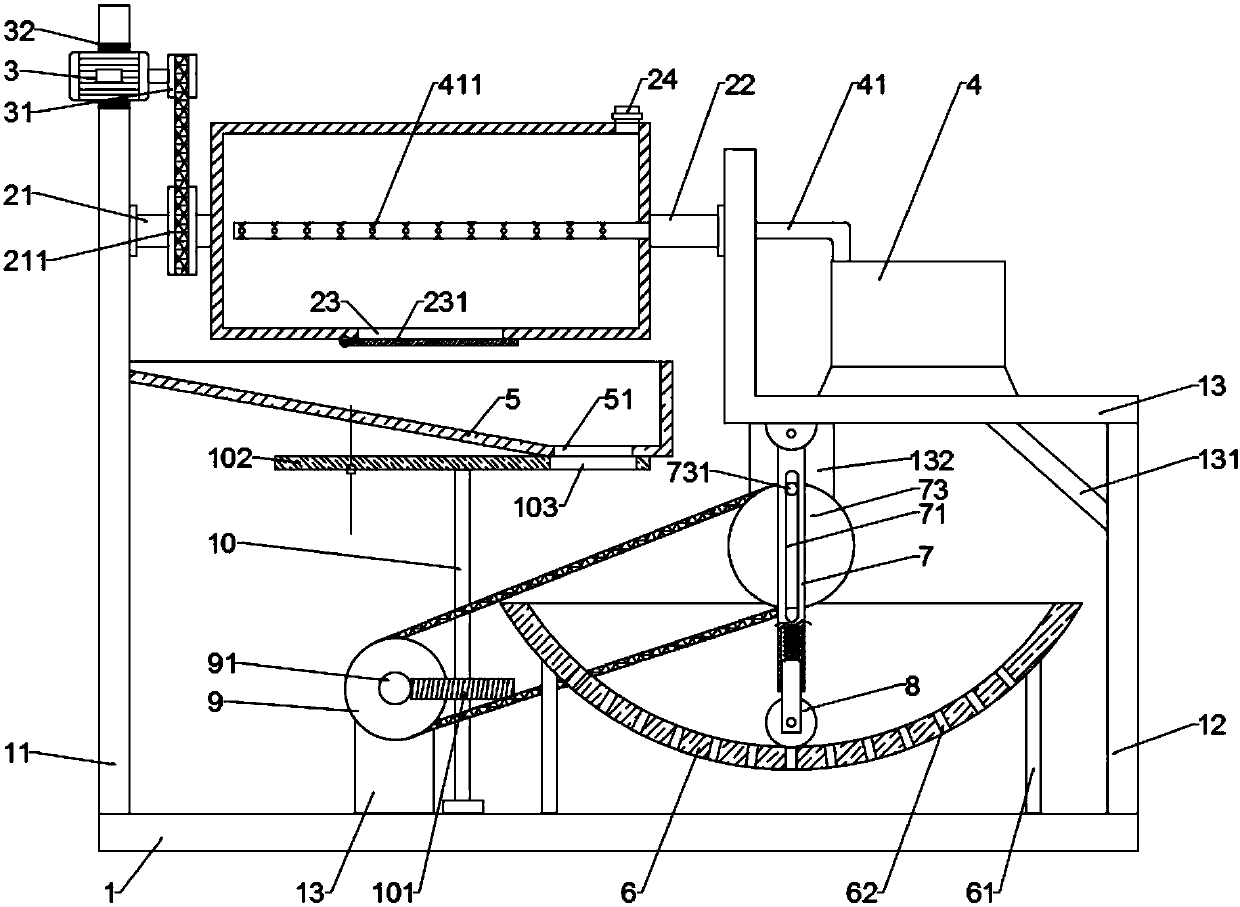

InactiveCN107597369AEvenly heatedGuaranteed drynessDrying gas arrangementsGrain treatmentsPulp and paper industryThrough transmission

The invention discloses a Chinese medicinal crop drying and grinding all-in-one machine which comprises a base, a drying barrel, a storing frame, a grinding bowl and a swinging rod. According to the Chinese medicinal crop drying and grinding all-in-one machine, drying and grinding of Chinese medicinal crop are integrated, so that working continuity is ensured, and the working efficiency is improved; a hot-blast air pipe is arranged in the center of the drying barrel, so that heat can be uniformly distributed in the drying barrel; along with rotation of the drying barrel, the Chinese medicinalcrop is uniformly heated, so that the drying effect is ensured; the swinging rod drives a grinding roller to roll back and forth along the inner cavity surface of the grinding bowl so as to grind theChinese medicinal crop in an all-around manner, so that grinding is more uniform; through elastic connection of a slippage rack and the swinging rod, the grinding roller and the Chinese medicinal cropon the inner cavity surface of the grinding bowl are in tight contact, so that the grinding effect is ensured; and through transmission of a worm wheel and a worm, discharging and grinding are carried out simultaneously, so that the entire grinding operation is more coherent.

Owner:WUHAN MATENG TECH DEV

Equipment for glass grinding

InactiveCN107932225AHigh degree of mechanizationImprove efficiencyGrinding drivesGrinding work supportsThreaded rodMachining

The invention discloses equipment for glass grinding. The equipment comprises a supporting shaft, a machining table, a driving mechanism, a plurality of clamping parts and a grinding part; the supporting shaft is arranged in the vertical direction; the machining table is arranged on the supporting shaft; the clamping parts are uniformly distributed around the supporting shaft; the holding parts comprise brackets, supporting blocks, first threaded rods, pressing plates and supporting plates; the brackets are arranged on the machining table; the supporting blocks are arranged on the brackets; first threaded holes are formed in the supporting blocks; the first threaded rods are arranged in the vertical direction; the first threaded rods are located in the first threaded holes and are in threaded connection with the first threaded holes; the pressing plates are arranged at the bottom ends of the first threaded rods; the supporting plates are located below the pressing plates and are mounted on the machining table; and the grinding part is used for grinding glass.

Owner:蚌埠承永玻璃制品有限公司

Glass production and machining device

InactiveCN107984329AImprove sanding effectImprove grinding efficiencyEdge grinding machinesGrinding drivesMachiningGlass production

The invention discloses a glass production and machining device comprising a machining table, a bracket, a supporting block, a first screw, a pressing holding plate, a supporting plate, a driving unit, and a grinding part; the bracket is mounted on the machining table; the supporting block is rotatably connected with the bracket, and a first screw hole is formed on the supporting block; the firstscrew is arranged in the vertical direction, the first screw is located in the first screw hole and is connected with the first screw hole in a threaded mode, and the pressing holding plate is installed at the bottom end of the first screw; the supporting plate is located below the pressing plate and is rotatably connected with the machining table; the driving unit is used to drive the supportingplate to rotate; and the grinding part is used for grinding the glass.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

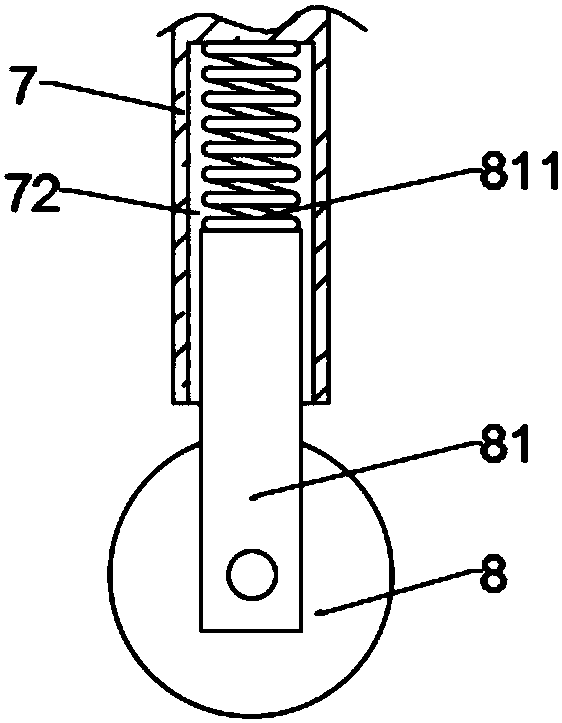

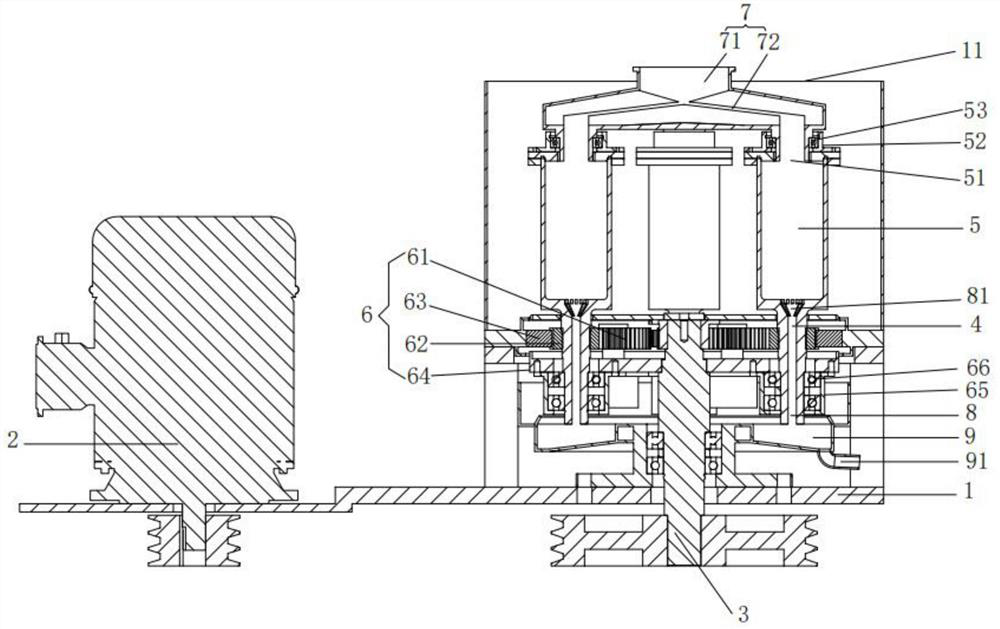

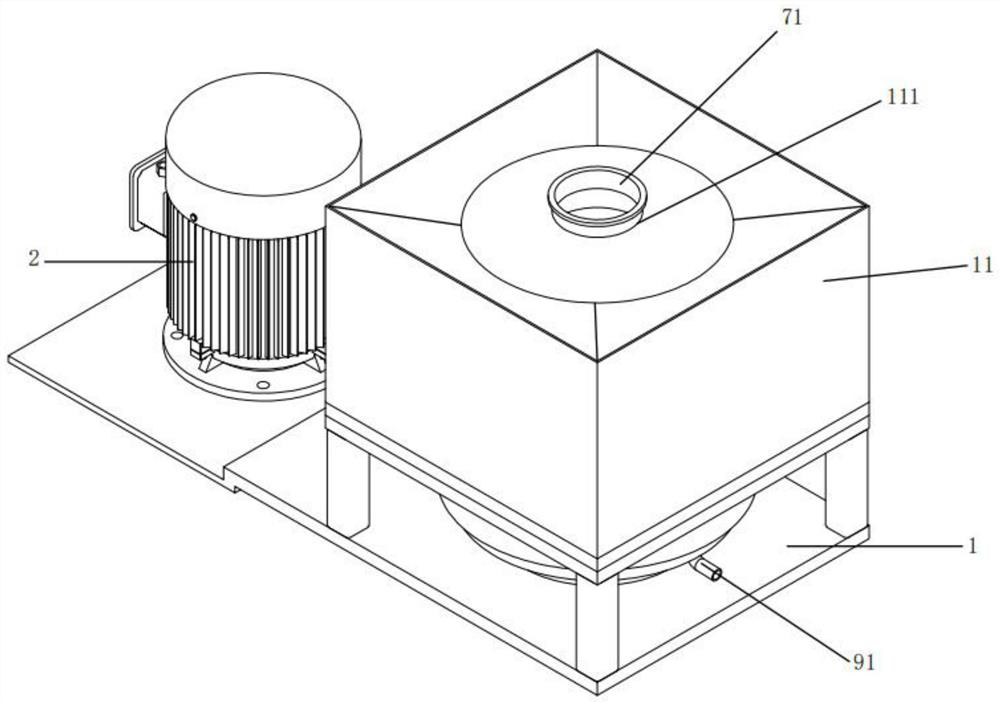

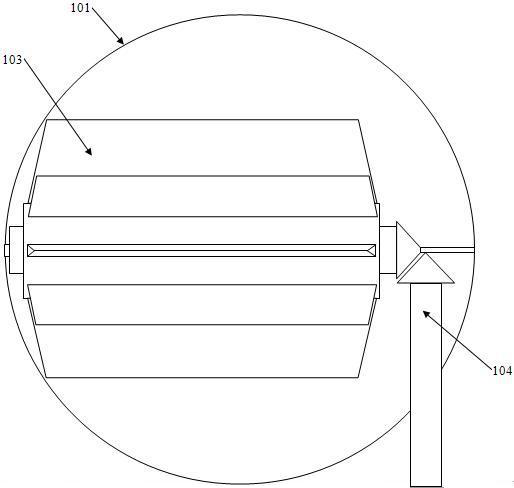

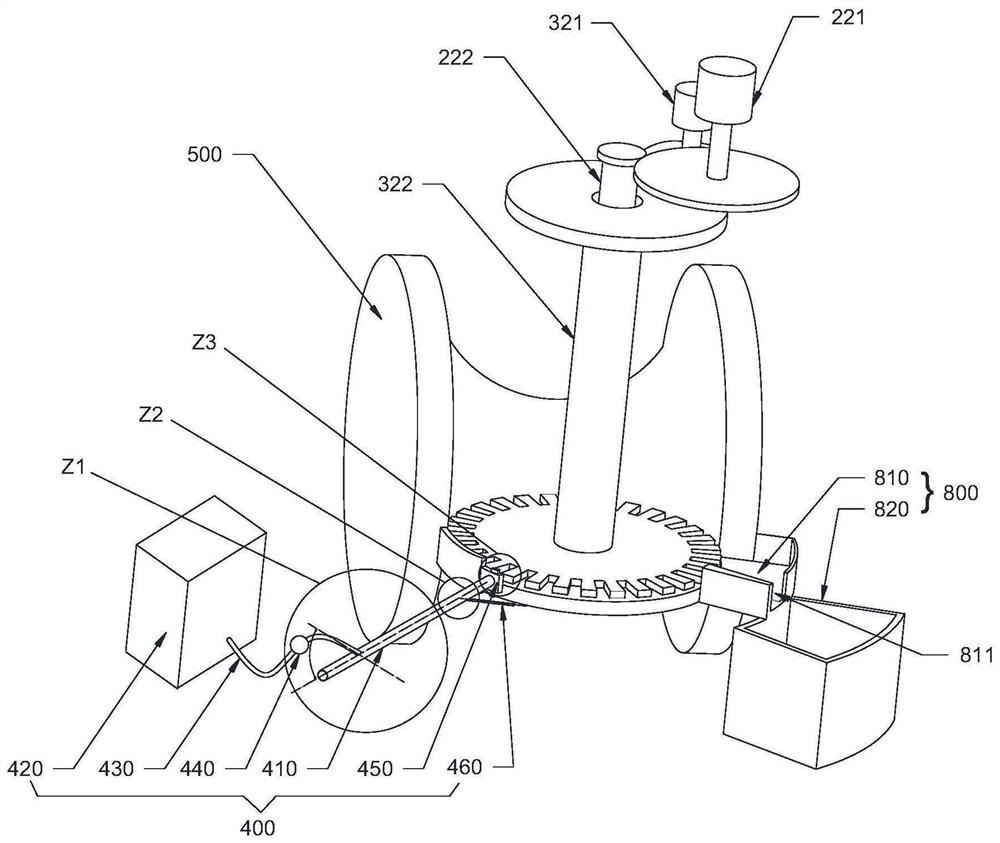

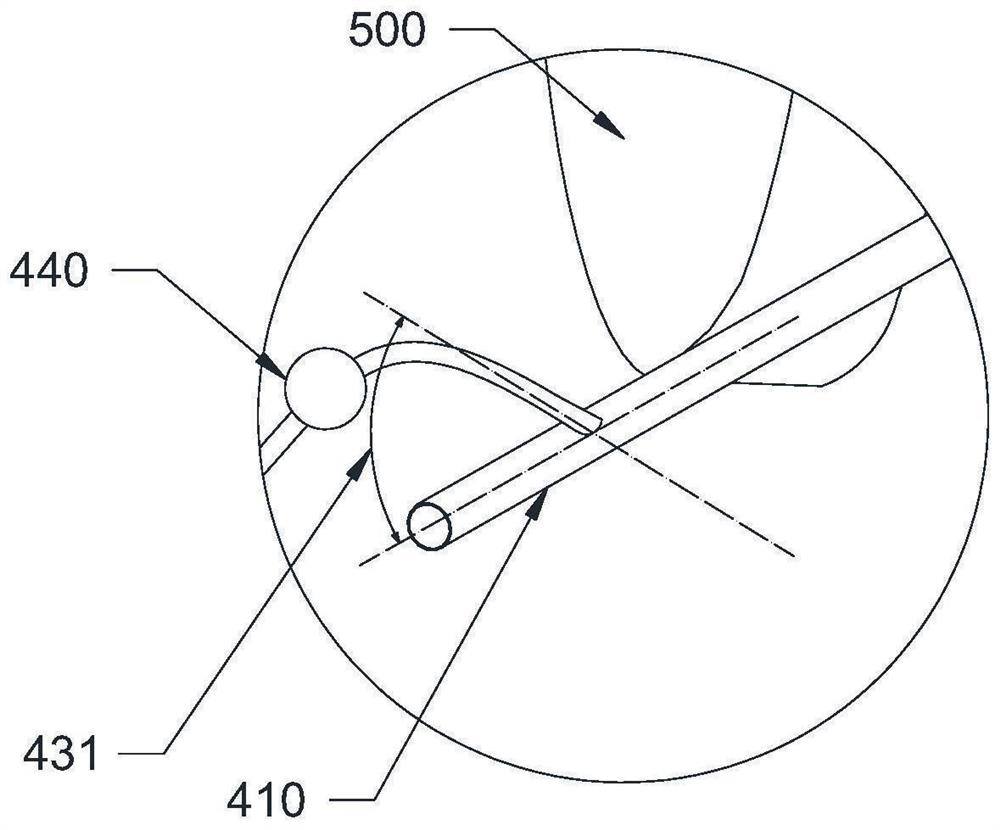

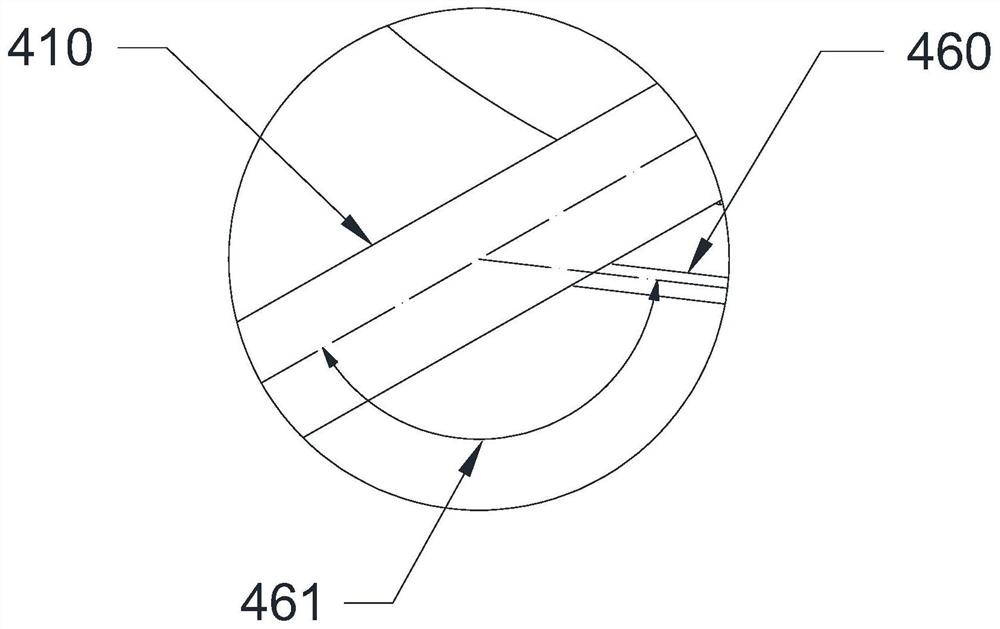

Automatic Chinese herbal medicine grinding device

InactiveCN113231151AContinuous grindingQuick preliminary filterCleaning using toolsGrain treatmentsHerb medicineEngineering

The invention relates to a grinding device, in particular to an automatic Chinese herbal medicine grinding device. According to the automatic Chinese herbal medicine grinding device, Chinese herbal medicine can be rapidly ground, and meanwhile, Chinese herbal medicine particles can be made to be similar, and the ground Chinese herbal medicine particles can be rapidly collected. The automatic Chinese herbal medicine grinding device comprises a bottom plate and a motor, wherein the motor is arranged in the middle of the top end of the bottom plate. The automatic Chinese herbal medicine grinding device is characterized by further comprising a grinding mechanism, and the grinding mechanism is arranged at the top of the bottom plate. According to the Chinese herbal medicine grinding device, the grinding mechanism is arranged, and the grinding mechanism is matched with a feeding mechanism, so that the Chinese herbal medicine can be continuously ground according to needs; through cooperation of a discharging mechanism and a shaking mechanism, the ground herbal medicine can be rapidly and preliminarily filtered; through cooperation of a shaking mechanism and a material sweeping mechanism, herbal medicine with large grinding particles can be collected; and through cooperation of the material sweeping mechanism and the grinding mechanism, the herbal medicine with the large particles can be ground again, so that the herbal medicine grinding efficiency can be effectively improved.

Owner:万一

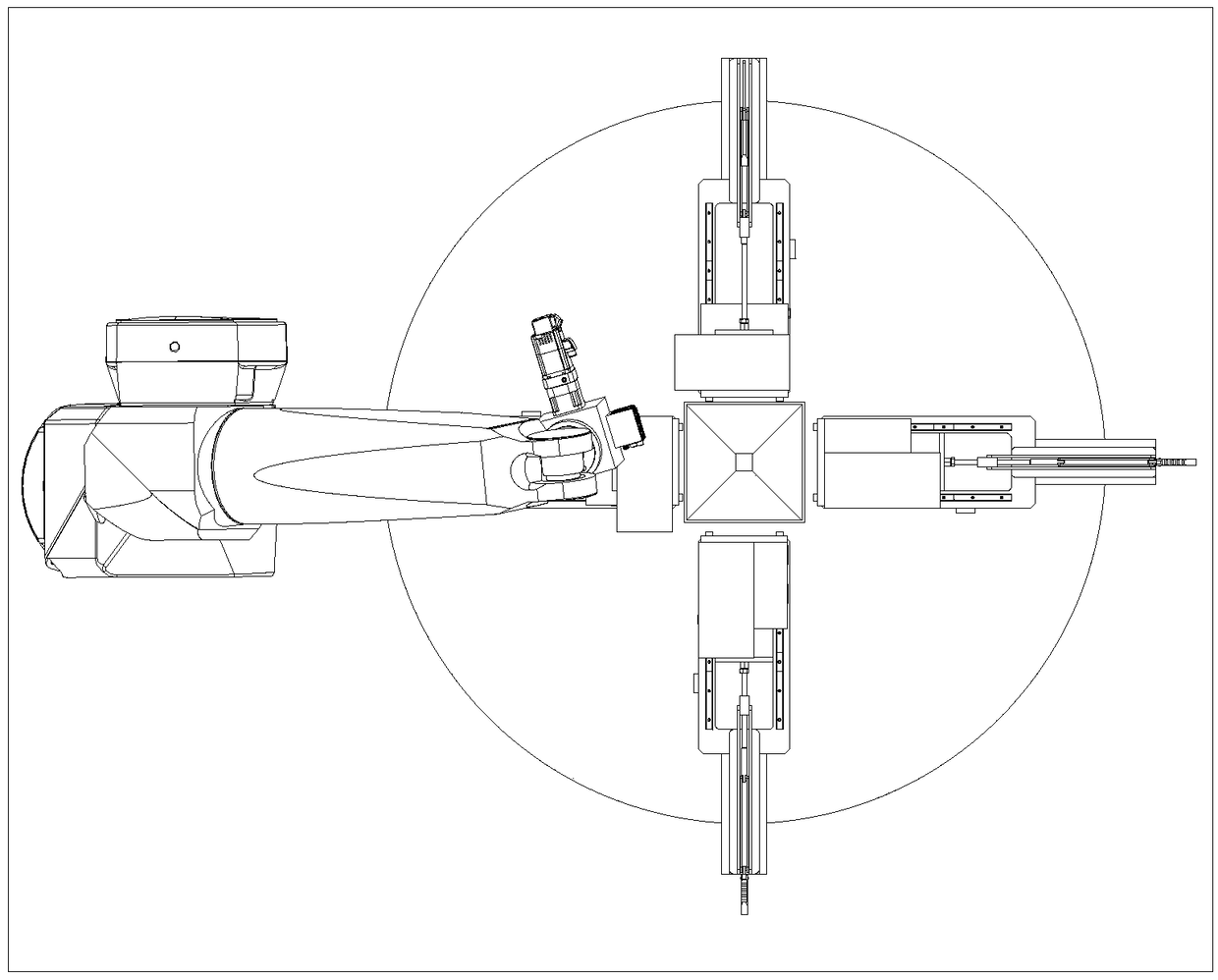

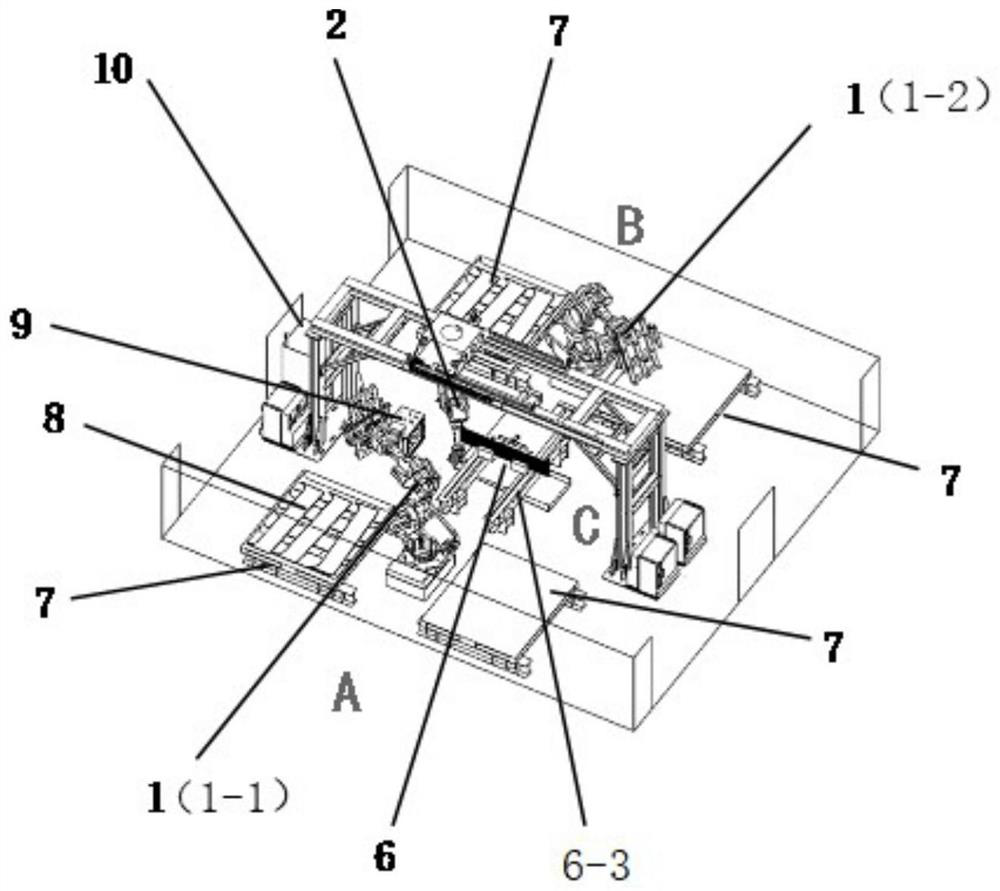

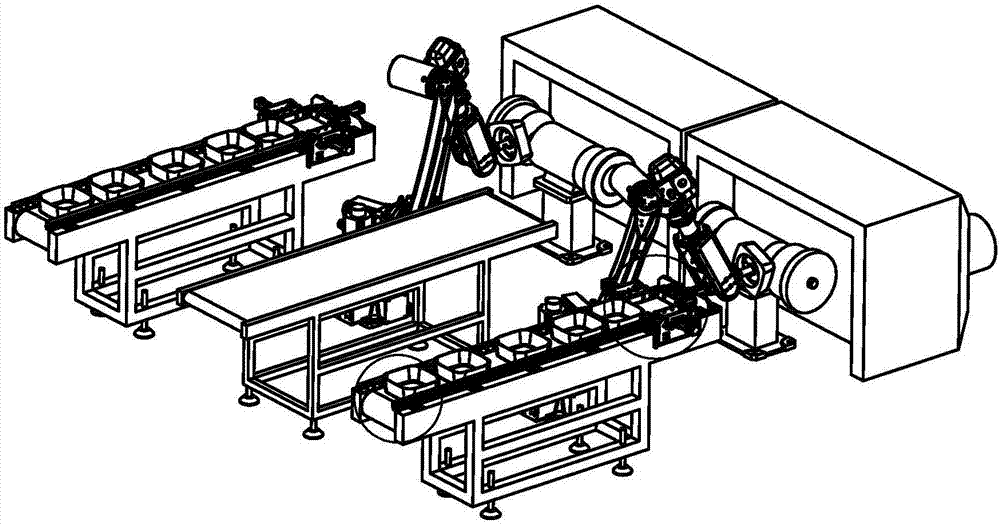

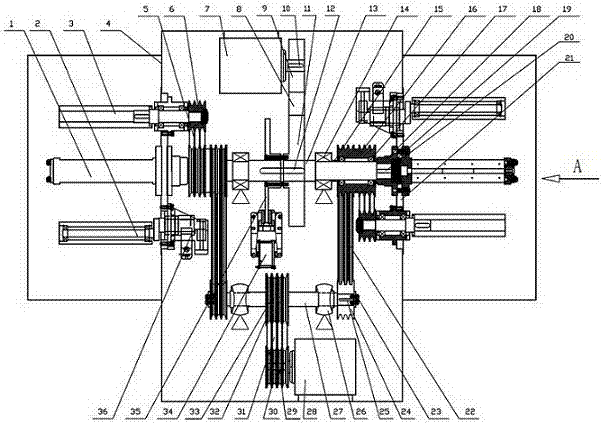

Equipment and method for continuous feeding and discharging and uninterrupted polishing of marine arc slab

PendingCN114193289ASolve the errorSolve many types of productsGrinding feed controlGrinding machinesVision sensorThree dimensional vision

The invention discloses equipment and method for continuous feeding and discharging and uninterrupted polishing of marine arc slabs, the size and center coordinates of the arc slabs are collected through a three-dimensional vision device on a feeding and discharging robot, the robot is guided to grab the arc slabs and flatly place the arc slabs on a tool clamp table, and then the clamp table adjusts the positions of the arc slabs according to size information and fixes the arc slabs; the tool clamp table enters a grinding station and turns over the arc plate to be vertical, a line laser vision sensor on a grinding robot detects the position of a free edge, the grinding robot is guided to move according to a track, and a six-dimensional force control device detects stress of a grinding tool and completes posture correction; and meanwhile, the feeding and discharging robot and the tool clamp table on the other side are prepared in the same mode, when the arc plate is polished and pushed out, the fed arc plate on the other side enters a polishing station, the same polishing operation is completed, flexible automatic polishing is achieved, the polishing application range is greatly widened, unmanned continuous polishing operation is achieved, and the production efficiency is improved. And the working efficiency is greatly improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

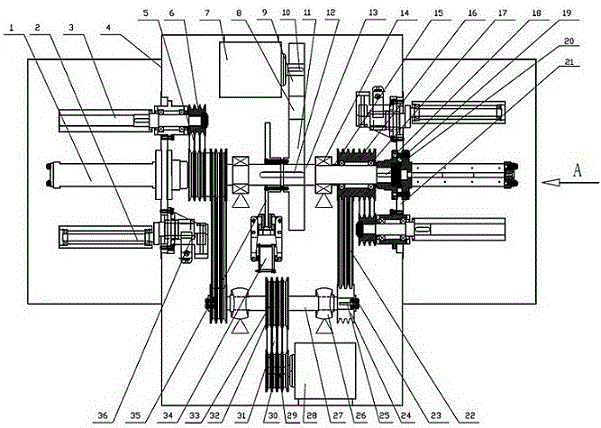

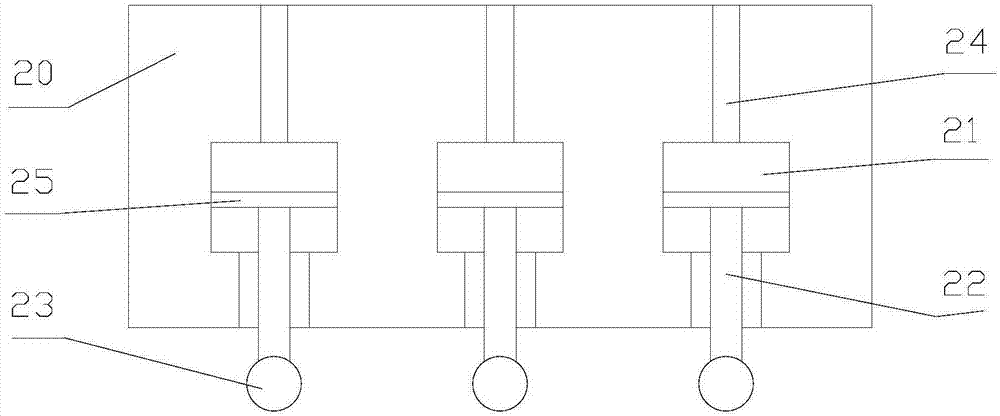

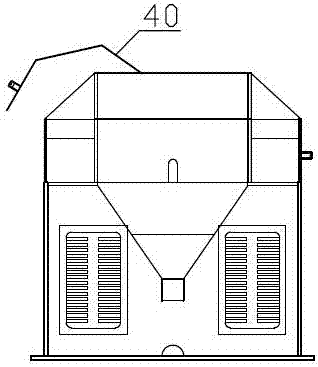

Continuous vertical planetary ball grinder

The invention discloses a continuous vertical planetary ball grinder which comprises a rack. A motor, a transmission spindle, a planetary gear mechanism, a ball grinding tank, a grinding tank shaft, acontinuous feeding hopper and a discharging opening arranged at the lower end of the ball grinding tank are arranged on the rack. The planetary gear mechanism comprises a gear ring, a sun gear, a planetary gear and a planetary carrier. The gear ring is fixed to the rack. The sun gear and the gear ring are engaged with the planetary gear. The planetary gear and the grinding tank shaft are fixedlyconnected and are coaxially and rotationally arranged on the planetary carrier. The sun gear and the planetary carrier are in transmission connection with the motor through the transmission spindle. The ball grinding tank is fixedly arranged at the upper end of the grinding tank shaft. A feed opening is arranged at the upper end of the ball grinding tank. The continuous feeding hopper comprises afeed opening and a feeding pipe, and the feeding pipe rotationally communicates with the feed opening. The grinding tanks shaft is provided with a discharging channel along the axis in a penetrating manner, wherein the discharging channel communicates with the discharging opening, and a discharging sieve is arranged in the discharging channel. The continuous feeding hopper can be combined with anautomatic assembly line to be used, the material feeding efficiency can be improved, and the rapid production requirement can be met.

Owner:长沙天创粉末技术有限公司

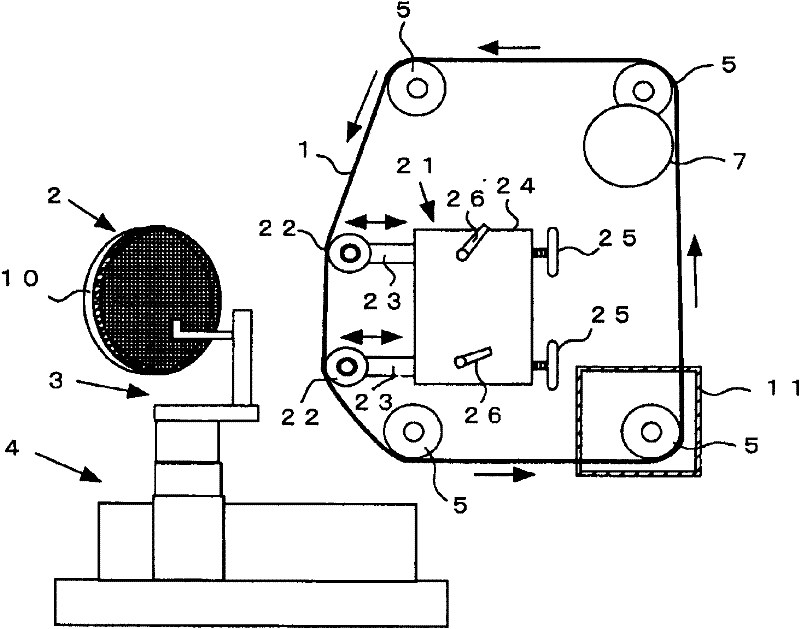

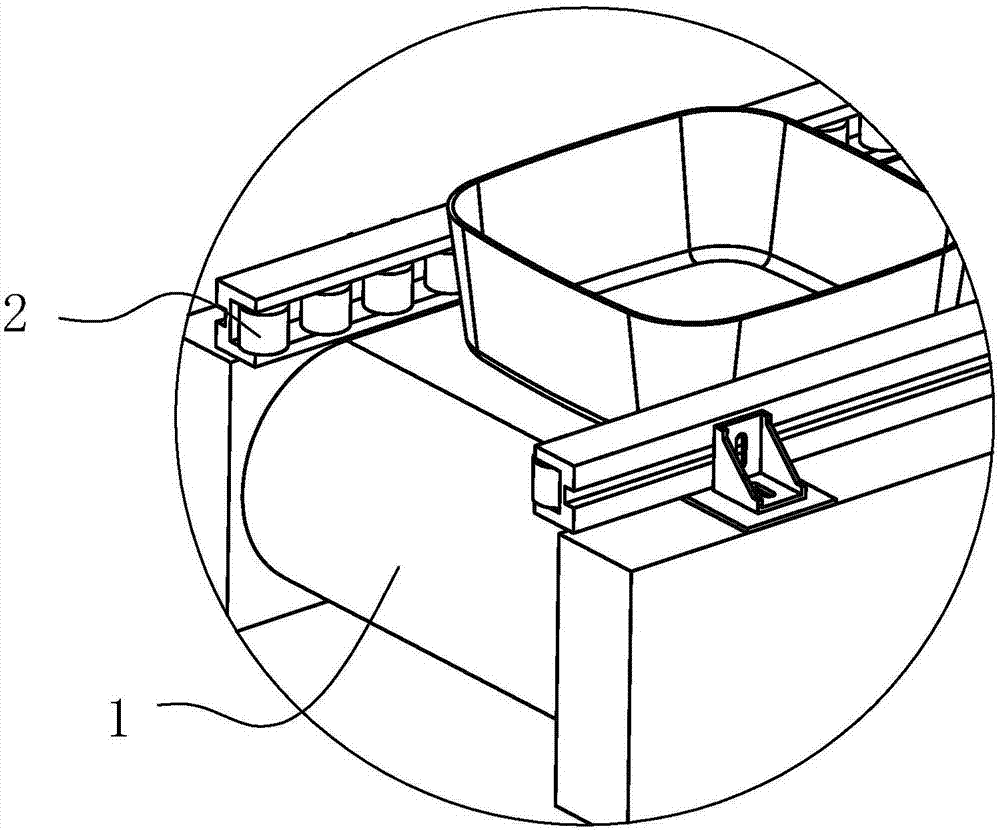

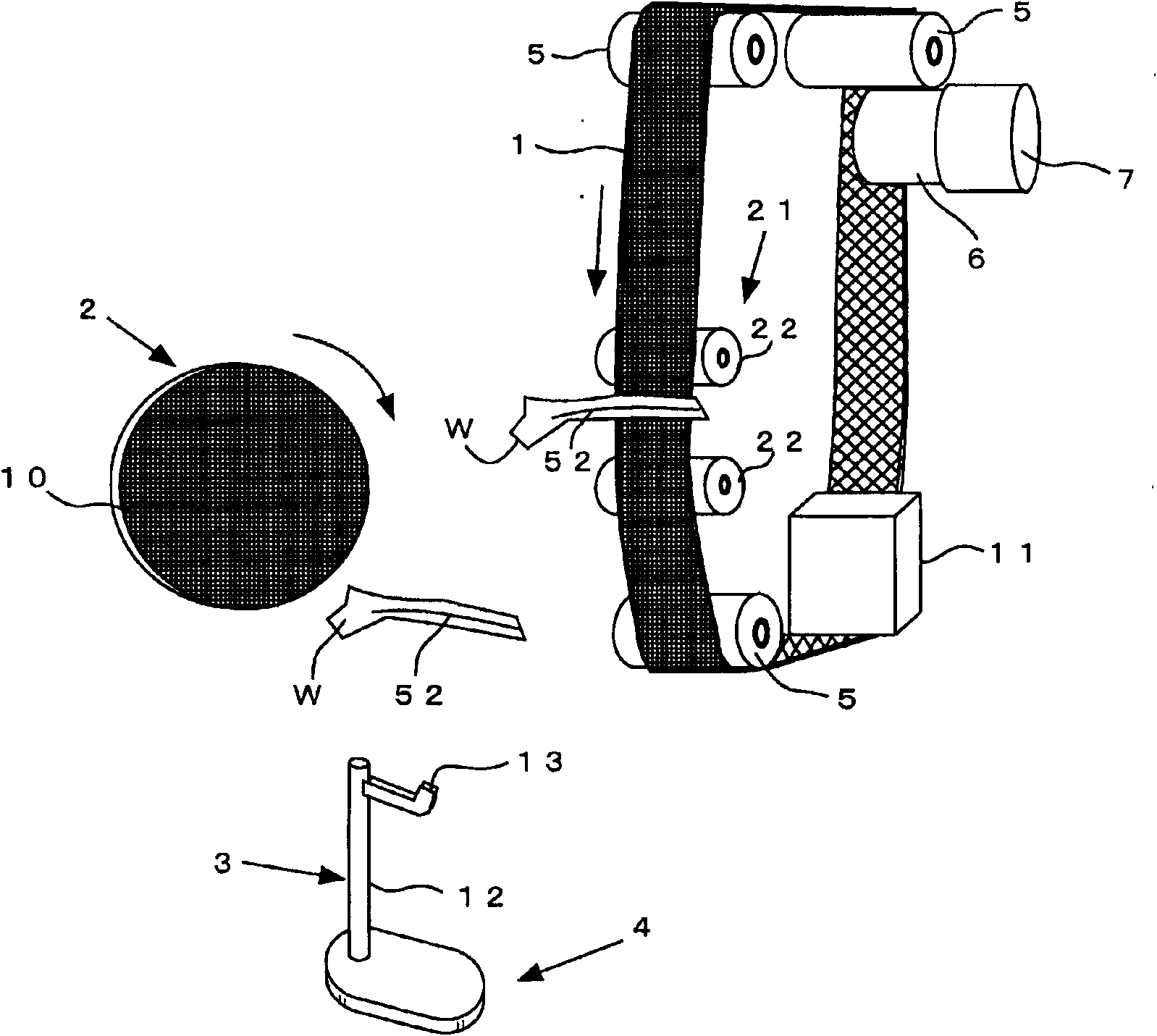

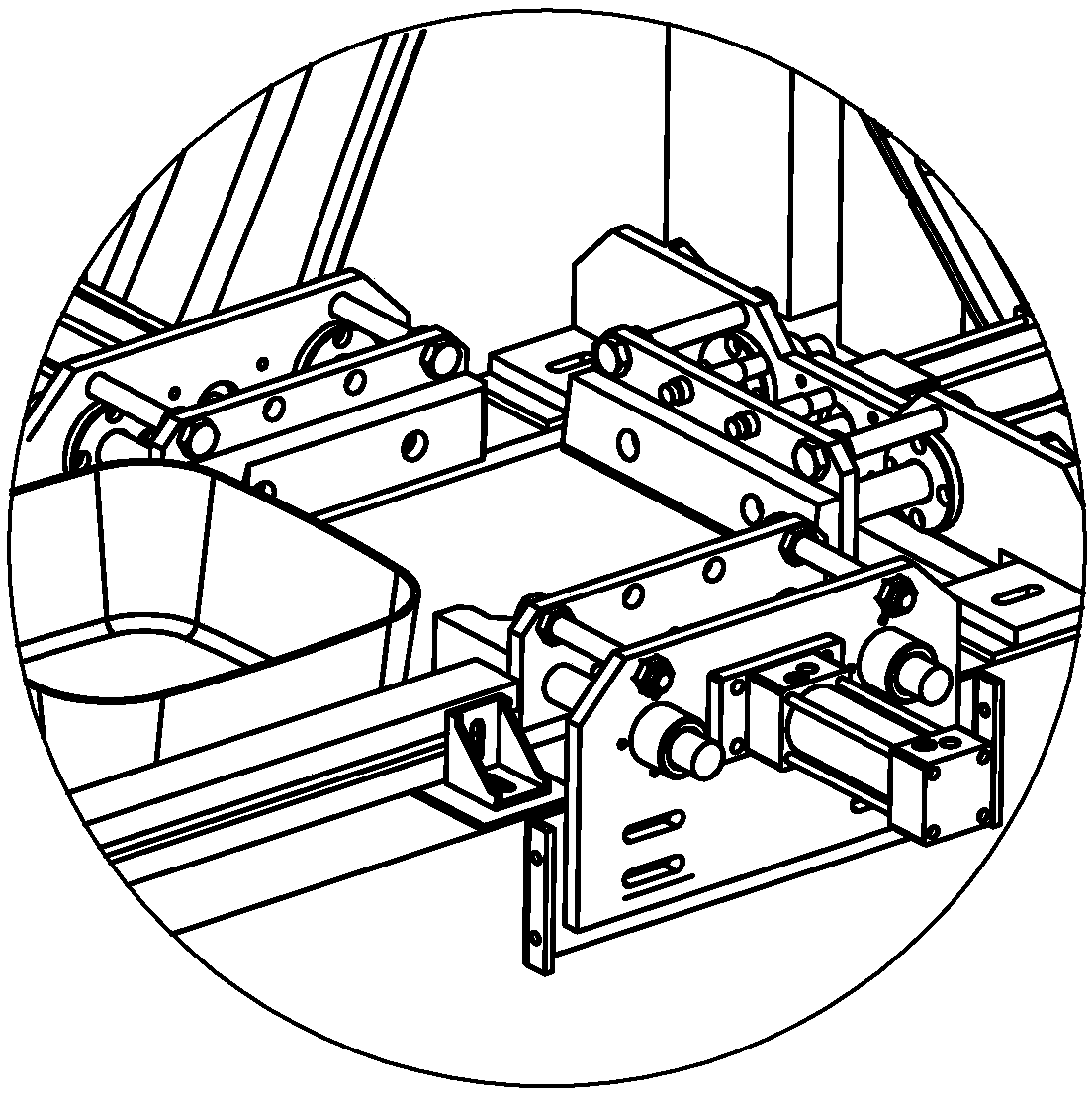

Grinding device of glass sheet

InactiveCN101837560AContinuous grindingIncrease productionEdge grinding machinesEngineeringFront edge

The invention relates to a grinding device (1) of a glass sheet, which is provided with a linear conveying unit (3), a first grinding device and a second grinding device. A glass sheet (2) is linearly conveyed by the linear conveying unit (3) along the X direction, the first grinding device is provided with grinding heads (5 and 6) for respectively grinding two lateral edges (4a and 4b) of the glass sheet (2) which is linearly conveyed by the linear conveying unit (3), and the second grinding device is adjacent to the first grinding device in the X direction and is provided with movable grinding heads (9 and 10) for respectively grinding a front edge (7) and a rear edge (8) extending along the Y direction orthogonal to the X direction in which the glass sheet (2) is linearly conveyed by the linear conveying unit (3).

Owner:BANDO KIKO CO LTD

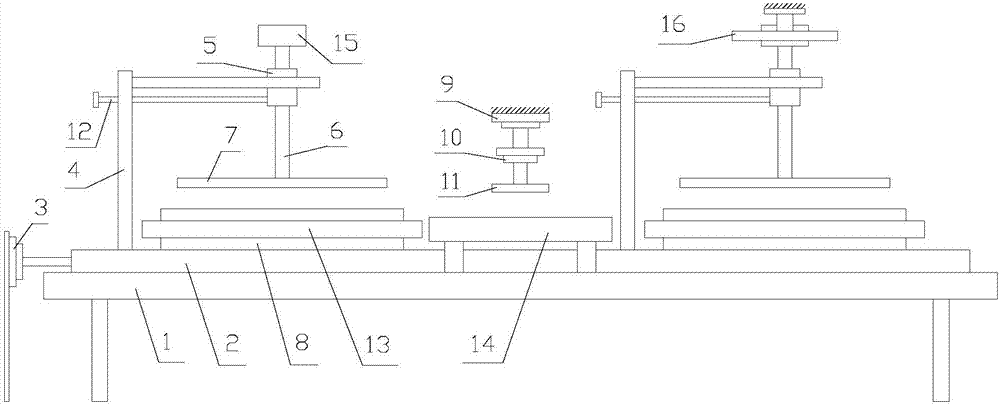

Polishing device for small side plates of table tennis bat handle

InactiveCN104149012AContinuous grindingImprove work efficiencyBelt grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention relates to a polishing device for small side plates of a table tennis bat handle. The polishing device comprises a base, a polishing assembly, a pressing assembly and a limiting plate assembly. The pressing assembly is mounted on the base and comprises a cross beam, a press rod, a first elastic piece, a limiting rod, a first vertical rod and a baffle, wherein the cross beam is fixed to the two side faces of the base and is higher than the upper surface of the base, one end of the press rod is hinged to end of the upper surface of the cross beam, the other end of the press rod extends along the cross beam, the first elastic piece is arranged on the cross beam and is connected with the press rod, the limiting rod is arranged on the cross beam and is located in the same plane with the press rod, the first vertical rod is connected with the press rod and is located on one side of the cross beam, and the baffle is connected with the lower end of the first vertical rod and is located above a polishing abrasive belt. The limiting plate assembly is located below the cross beam. On one hand, the limiting rod is used for limiting the travel of the press rod, and the polishing unevenness caused by overlarge force for pressing the press rod is avoided; on the other hand, the small side plates are limited to or separated from the limiting plate assembly by using the up-and-down movement of the baffle, in this way, the small side plates can be continuously polished, and working efficiency is improved.

Owner:YANCHENG AST SPORTING GOODS

Algae comprehensive integrated processing device

InactiveCN112024092AEfficient collectionImprove efficiencyGrain treatmentsAlgaeEnvironmental engineering

The invention relates to an algae comprehensive integrated processing device. The algae comprehensive integrated processing device comprises an algae suction component, a crushing component, a dryingcomponent and a grinding component. Through specific arrangement of all the components, algae in a water body can be crushed, dried and ground in real time after being collected in real time, so thatalgae decay and secondary pollution to the water body in the transfer process after collection in existing algae treatment are avoided, and through specific treatment of the algae, the algae can be more fully recycled.

Owner:申雪丽

Polishing treatment device for inner wall of bent pipe fitting

InactiveCN107020552ASave man hoursContinuous grindingRevolution surface grinding machinesPipe fittingEngineering

The invention discloses a polishing treatment device for the inner wall of a bent pipe fitting, which includes two semicircular spheres and a central shaft. There are grooves matching the protrusions on the top, and a wheel is installed on the outer peripheral wall of the sleeve. The main body is arranged on the sleeve, and a plurality of arc-shaped blades are arranged on both sides of the main body. A leaf groove is formed between them, and pulleys are installed at the ends of the upper and lower ends of the semicircular sphere. Aiming at the defects in the prior art that the inner surface of the oil pipeline is not properly treated before leaving the factory, which leads to a sharp decrease in its service life, the inventor designed a special grinding and polishing structure for the inner surface of the oil pipeline bend, through two semicircular The adjustment of the sphere and the roulette allows the polishing fluid to fully cover all parts of the elbow, reducing the probability of local protrusions on the inner wall of the elbow, so as to achieve the purpose of improving the service life of the oil pipeline.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

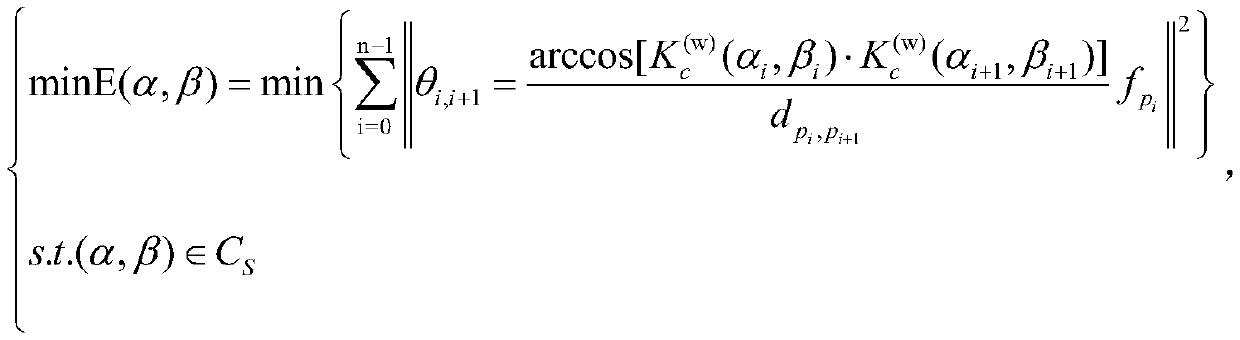

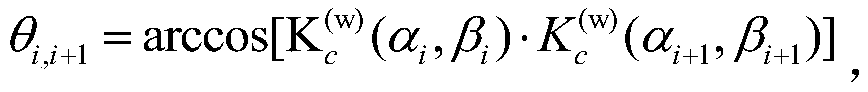

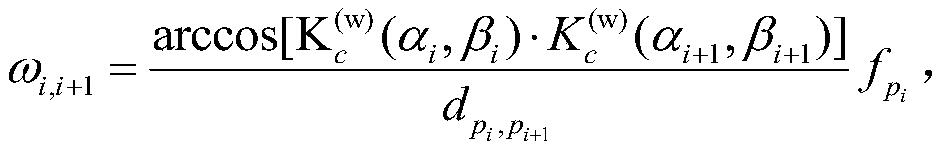

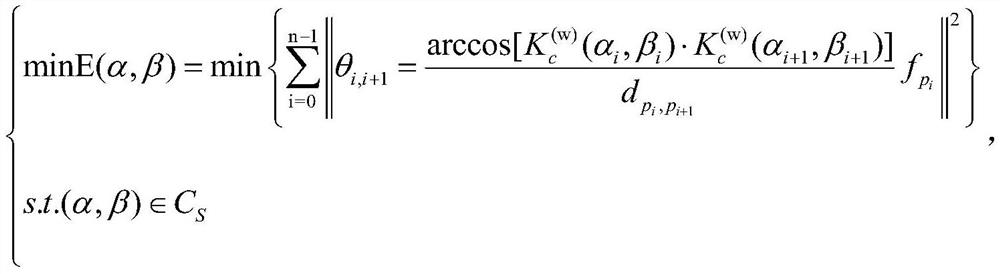

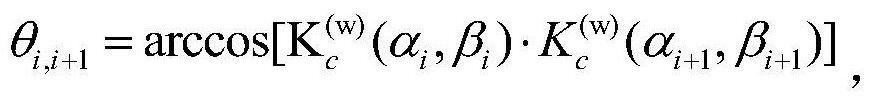

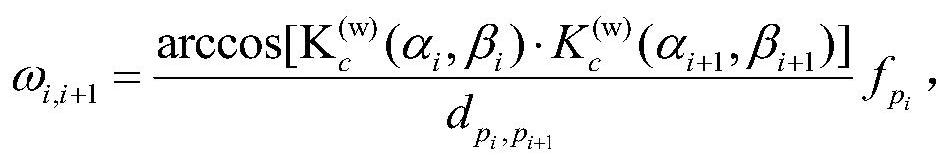

Method for adjusting position and posture of cutter shafts for grinding blade-type parts

ActiveCN109857060AAchieve smooth transitionEfficient and smoothNumerical controlNumerical controlEngineering

The invention discloses a method for adjusting the position and posture of cutter shafts for grinding blade-type parts. The method comprises the following steps: 1, a cutter contact coordinate systemxi (L) and a workpiece coordinate system xi (w) are established, and cutter shaft vectors are expressed in the workpiece coordinate system as in the specification, wherein in the formula, alpha is a heel angle of the contact face of a cutter and a workpiece, and beta is a slip angle of the contact face of the cutter and the workpiece; 2, cutter contacts are discretized, the included angle theta<i,i+1> between the cutter shaft vector of the i cutter contact and the cutter shaft vector of the <i+1> cutter contact is obtained, and the motion angular speed omega<i, i+1> between the icutter contact and the <i+1> cutter contact is calculated according to the formula; and 3, the optimization target function is established, according to the optimization target function, the cutter shaft vector position and posture meeting the minimum angular speed is solved, and the motion relationship of all the shafts of a numerical control grinder is solved. The cutter can conduct smooth machining in the grinding process, the phenomenon of overcutting or interference at curvature sudden change positions of the blade-type parts is avoided, and the surface machining quality is guaranteed.

Owner:CHONGQING UNIV OF TECH

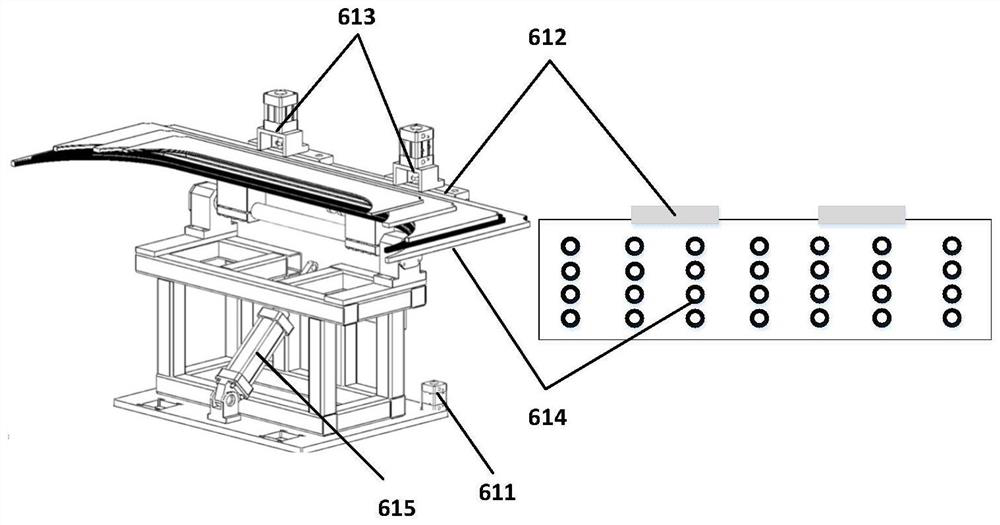

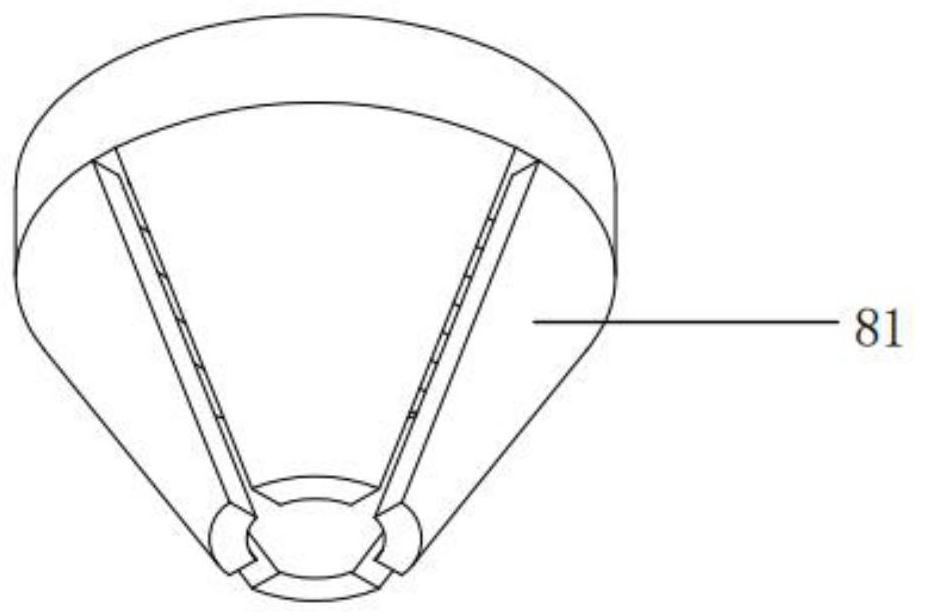

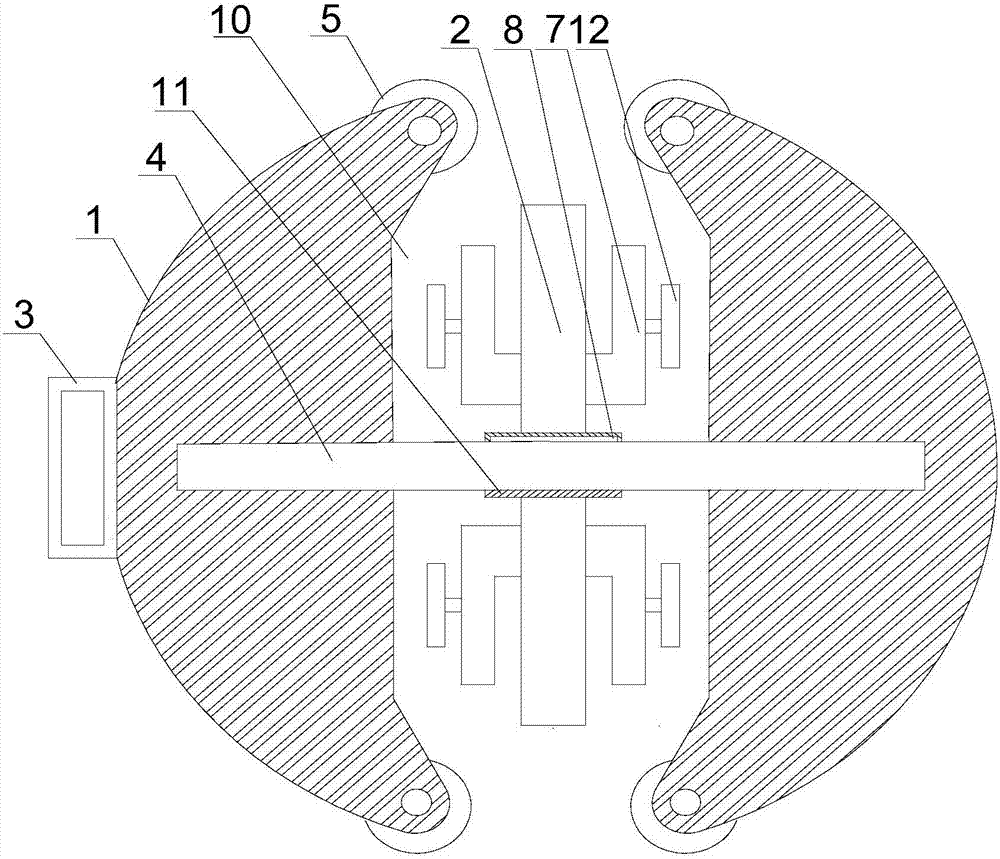

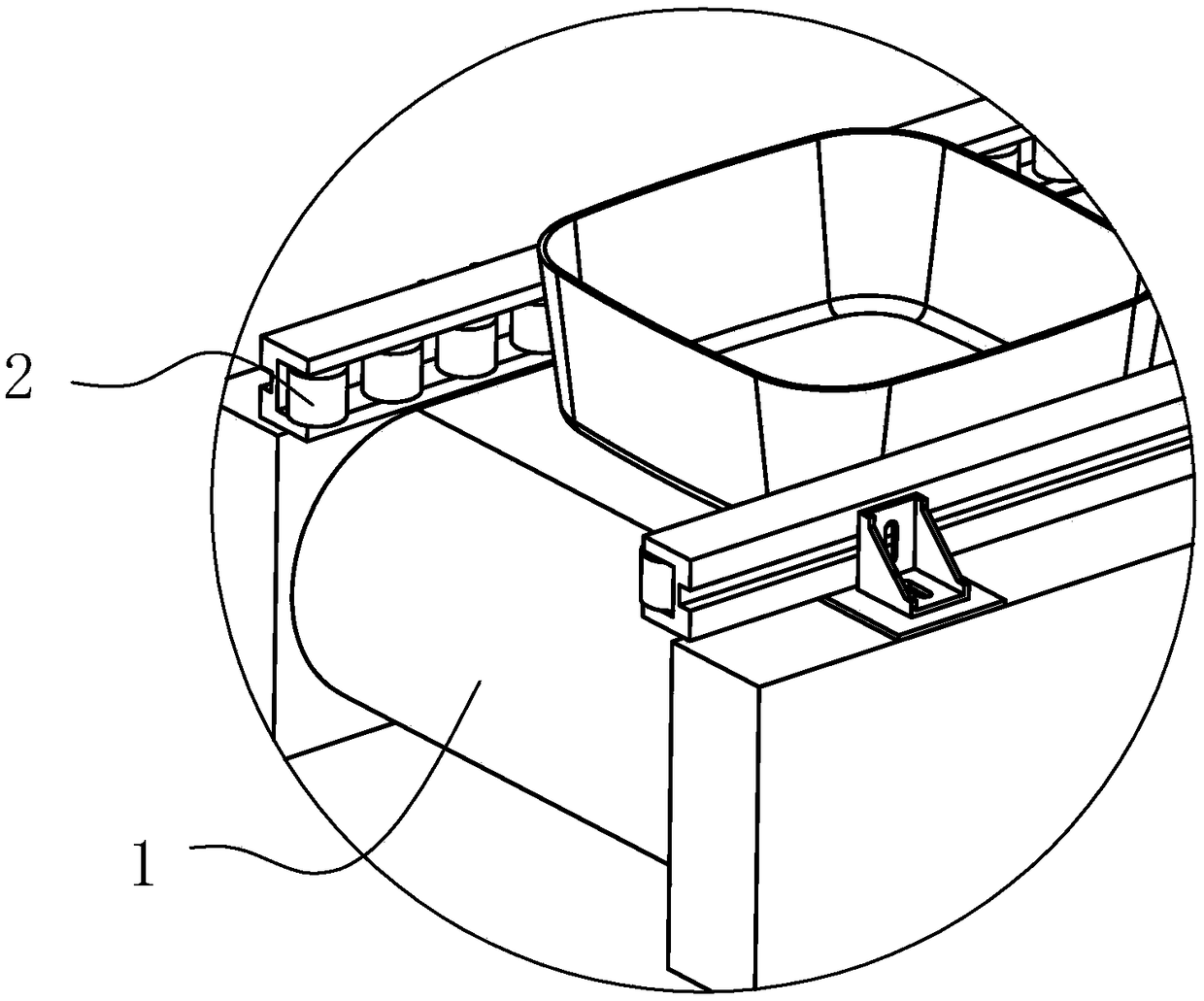

Partitioned grinding equipment for spherical base surfaces of bearing rollers

PendingCN112207708ASmall R angle deviationGood dimensional stabilityLapping machinesLapping toolsEngineeringCentrifugal force

The embodiment of the invention relates to the technical field of bearing roller machining, and specifically relates to partitioned grinding equipment for the spherical base surfaces of bearing rollers. The partitioned grinding equipment for the spherical base surfaces of the bearing rollers comprises a rack, as well as a revolution mechanism, an autorotation mechanism, a feeding mechanism and a grinding wheel which are all installed on the rack, wherein the bearing rollers are fed into accommodating grooves one by one according to a certain time interval through the feeding mechanism; and under the driving of a revolution disc and an autorotation disc, the bearing rollers in the accommodating grooves revolve around the axis of the revolution disc and rotate around the own axes of the bearing rollers, and therefore a centrifugal force is generated. The partitioned grinding equipment for the spherical base surfaces of the bearing rollers has the following beneficial effects: under the action of the centrifugal force, a pressure for always pressing the bearing rollers on the grinding wheel is constant, so that a constant grinding speed is ensured, and the machining precision for theangles R of the spherical base surfaces is ensured.

Owner:洛阳市人诚轴承配件有限责任公司

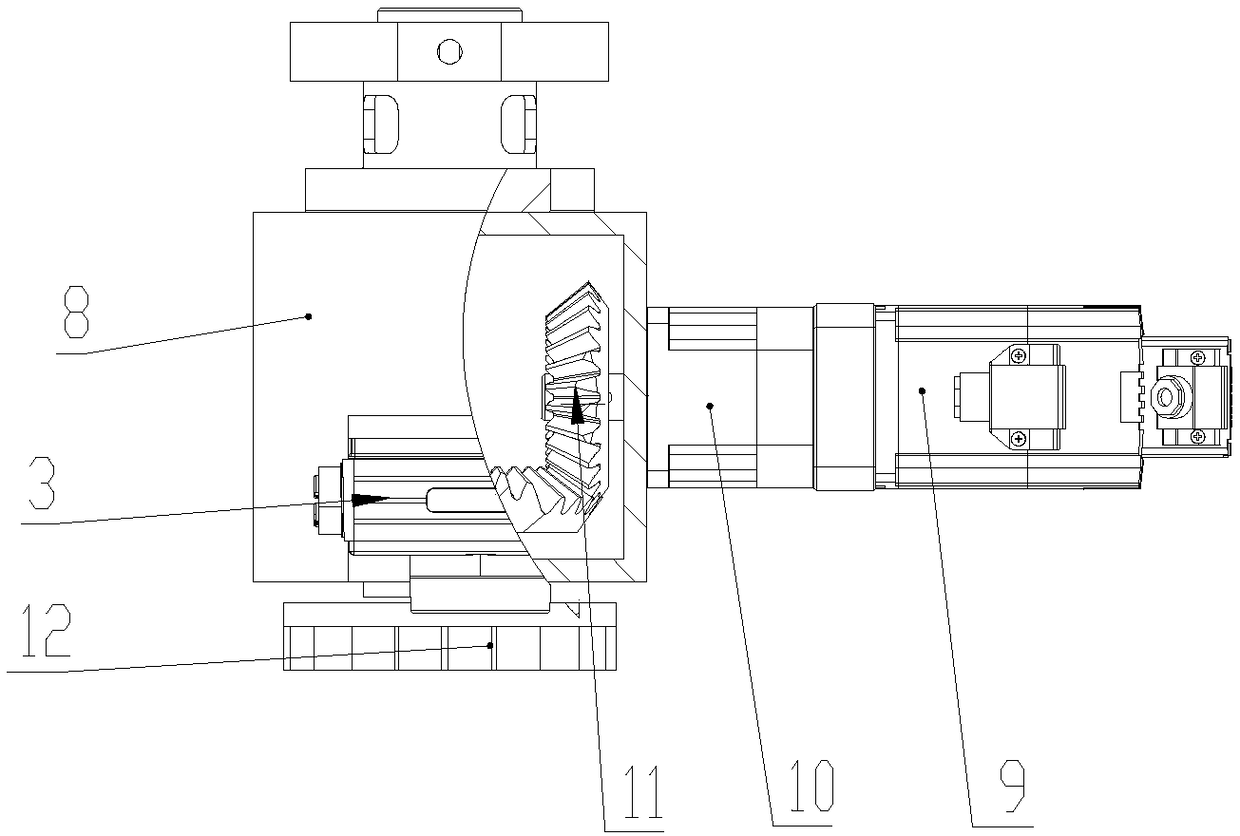

Device used for machining safety valve element

InactiveCN106965061ASimple structureGood effectGrinding machinesGrinding work supportsSpool valveEngineering

The invention discloses a device for processing the valve core of a safety valve, which comprises a base, a support shaft, a processing table, a driving mechanism, a plurality of clamping parts, a grinding part, and a limit rod; the support shaft is vertically rotated and installed on the base The processing table is installed on the support shaft; the driving mechanism is used to drive the support shaft to rotate; multiple clamping parts are evenly distributed around the support shaft, and the clamping parts include a bottom plate, a first clamping plate, a second clamping plate, a rotating The shaft, the first connecting piece, the second connecting piece, and the bottom plate are installed on the processing table, and guide rails are arranged on the bottom plate; the first clamping plate and the second clamping plate are distributed in sequence along the length direction of the guide rail, and the first clamping plate On the base plate; the second clamping plate is slidingly connected with the guide rail; the rotating shaft is vertically rotated and installed on the base plate; one end of the first connecting piece is hinged with the second clamping plate, and the other end of the first connecting piece is connected with the second connecting piece hinged.

Owner:WUHU RUNYU PRECISION MACHINERY

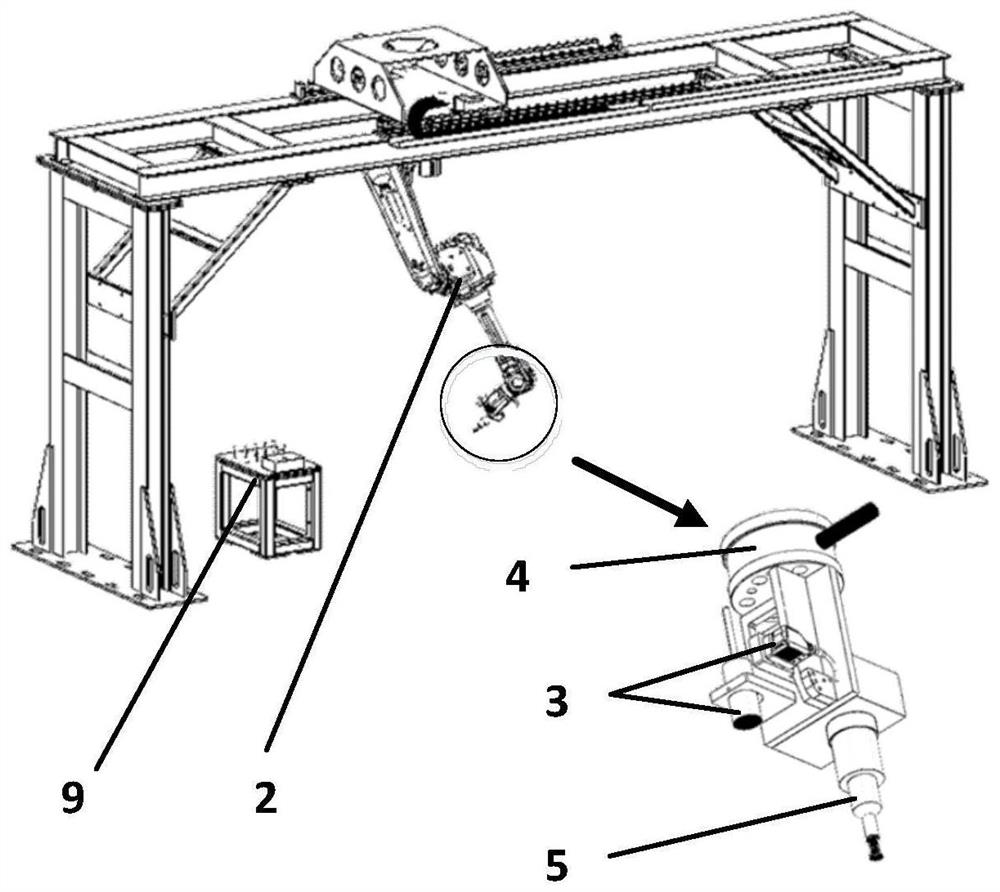

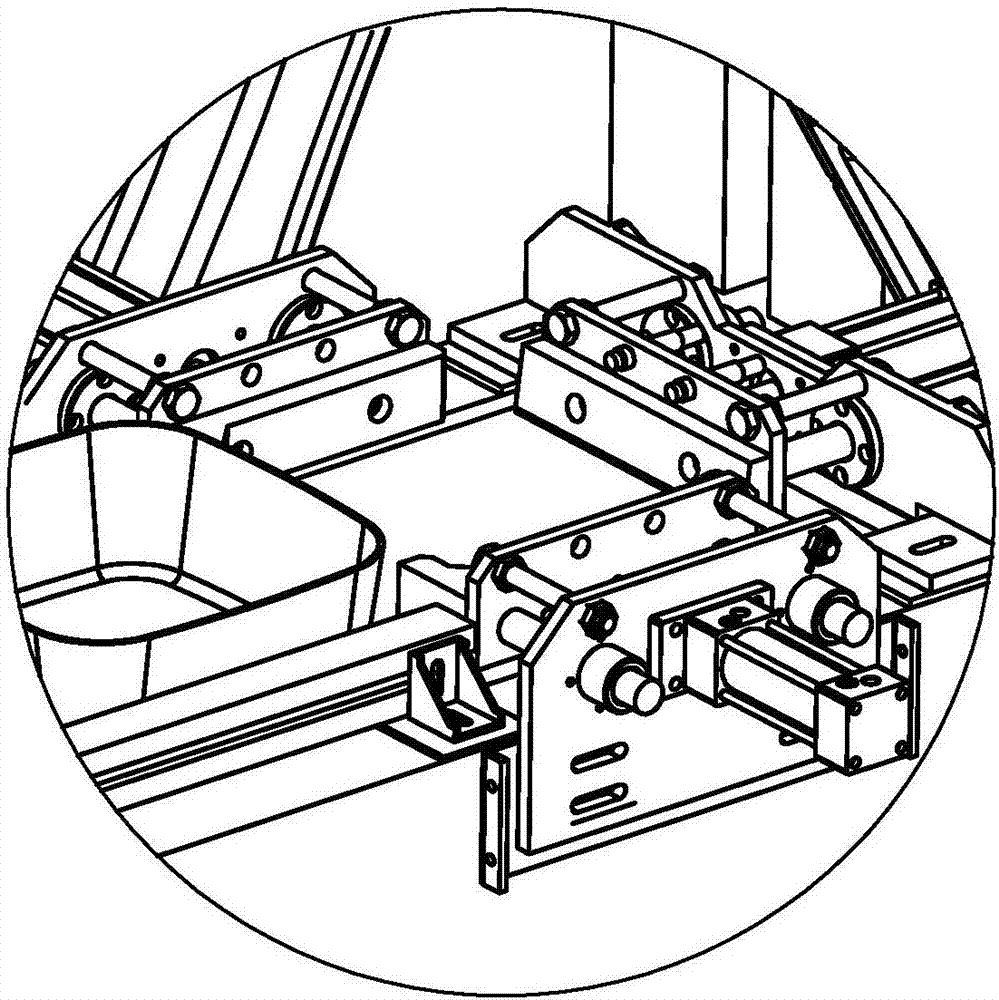

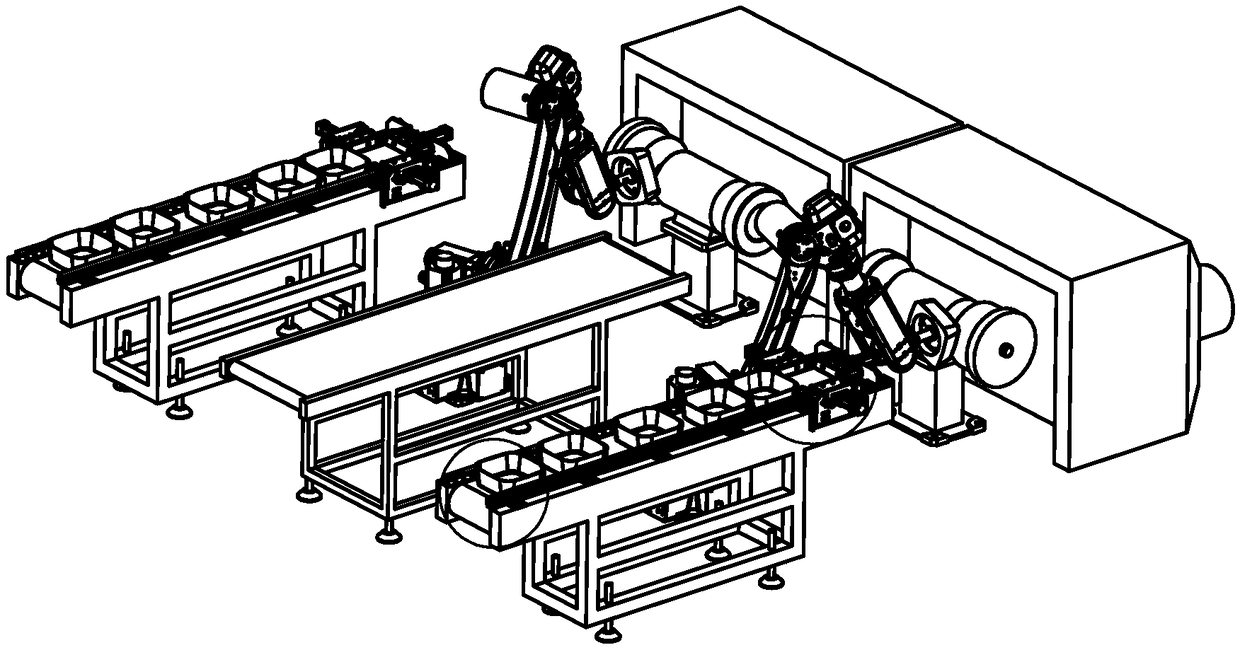

Robot-based automatic grinding system

ActiveCN106863124AContinuous grindingAutomatic grinding controlManipulatorGrinding wheelMechanical engineering

The invention discloses a robot-based automatic grinding system which comprises a grinder and a robot arranged behind the grinder. A feeding device is arranged beside the robot, a rotating shaft is arranged on the grinder, at least two profiling multi-leaf grinding wheels are arranged on the rotating shaft, and a profiling negative-suction clamp is arranged at the tail end of the robot. Since the profiling multi-leaf grinding wheels are arranged on the rotating shaft, each grinding wheel can be used for only a part of a product, the multi-leaf grinding wheel used for grinding corners is only used for grinding the corners, the multi-leaf grinding wheels used for grinding planes or large curved surfaces are specially used for grinding the planes and the large curved surfaces, and each grinding wheel can be abraded overall; and the multi-leaf grinding wheels become smaller overall while profiling shapes are not changed, and therefore the robot can achieve continuous grinding only through simple position compensation. The robot-based automatic grinding system is used for grinding products.

Owner:FOSHAN HUASHU ROBOTICS CO LTD

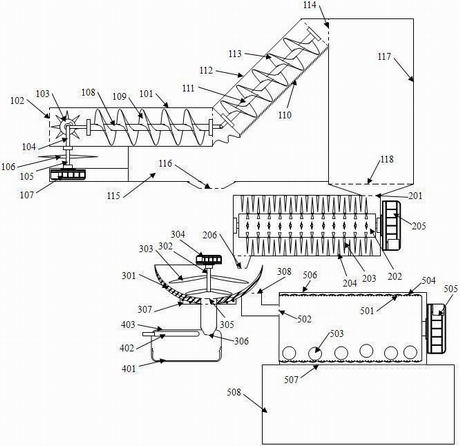

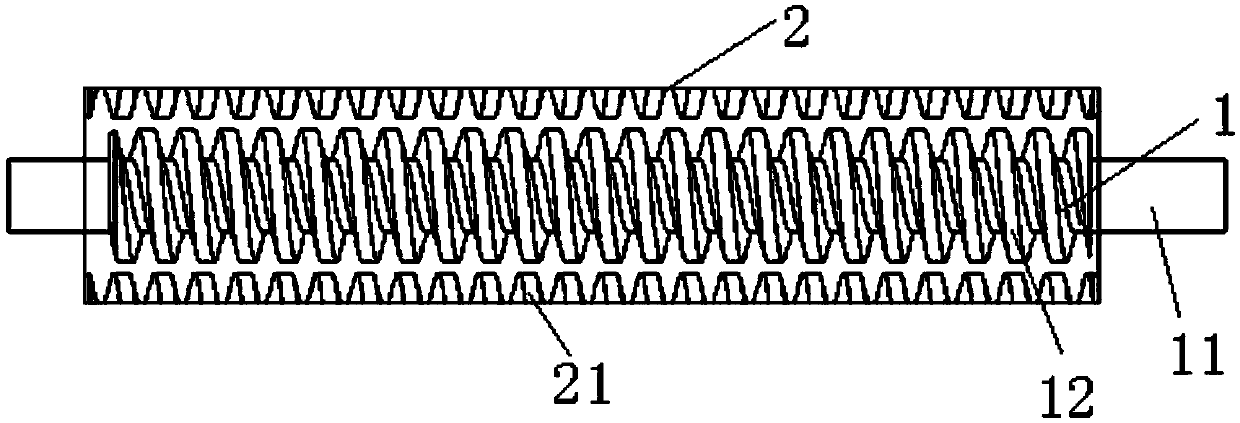

Spiral grinding pump of continuous offshore fracturing fluid blending device

InactiveCN103623906AContinuous grindingContinuous online grindingGrain treatmentsFracturing fluidEngineering

The invention relates to a spiral grinding pump of a continuous offshore fracturing fluid blending device. The spiral grinding pump is characterized by comprising a pump mandrel and an outer pump shell sleeved outside the pump mandrel, wherein a pump inlet is formed by one end of the pump mandrel and the corresponding end of the outer pump shell; a pump outlet is formed by the other end of the pump mandrel and the other corresponding end of the outer pump shell; the pump mandrel comprises a central shaft and outer spiral threads at equal intervals or gradient intervals in the outer surface of the central shaft; inner spiral threads at equal intervals or gradient intervals are formed in the inner surface of the outer pump shell; the length of each outer spiral thread is corresponding to that of each inner spiral thread; the rotational direction of the outer spiral threads is opposite to that of the inner spiral threads. According to practical working demands, multi-stage bidirectional spiral grinding pumps can be connected in parallel or in series, and fracturing fluid material grains can be ground in a bidirectional spiral mode, so that the spiral grinding pump can be widely applied to the process that a grain material is ground.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Grinding device of parting line of resin molding and grinding method

PROBLEM TO BE SOLVED: To perform polishing treatment on any resin molding having various part line shapes and also to polish them quickly.SOLUTION: An apparatus for polishing a part line of a resin molding comprises: a polishing belt 1 which has an endless belt-shape and polishes flashes or difference-in-level in the part line 52 of a resin molding W and which is arranged rotatably in a nearly vertical direction; a belt pressing pulley 21 which is provided on the rear face of the polishing belt 1 and is freely movable for the purpose of variably forming an inclined angle of a slope of the polishing belt 1 by pressing a part of the polishing belt 1 from the rear face; a planar polishing plate 2 which, for final polishing, has finer file teeth than the polishing belt 1, and has the teeth-hardness softer than the polishing belt 1; and a workpiece holder 3 which freely attachably / detachably carries the resin molding W in a manner making the part line 52 roughly horizontal.

Owner:KAKIHARA KOGYO CO LTD

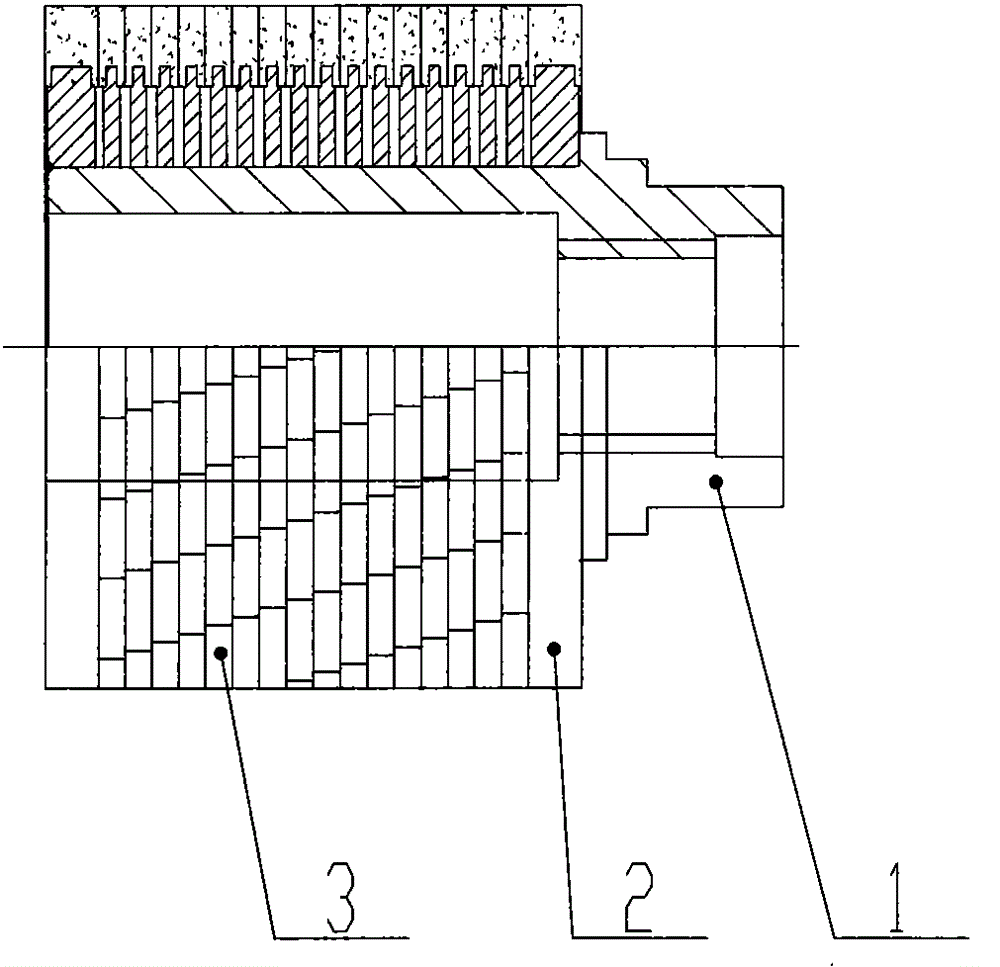

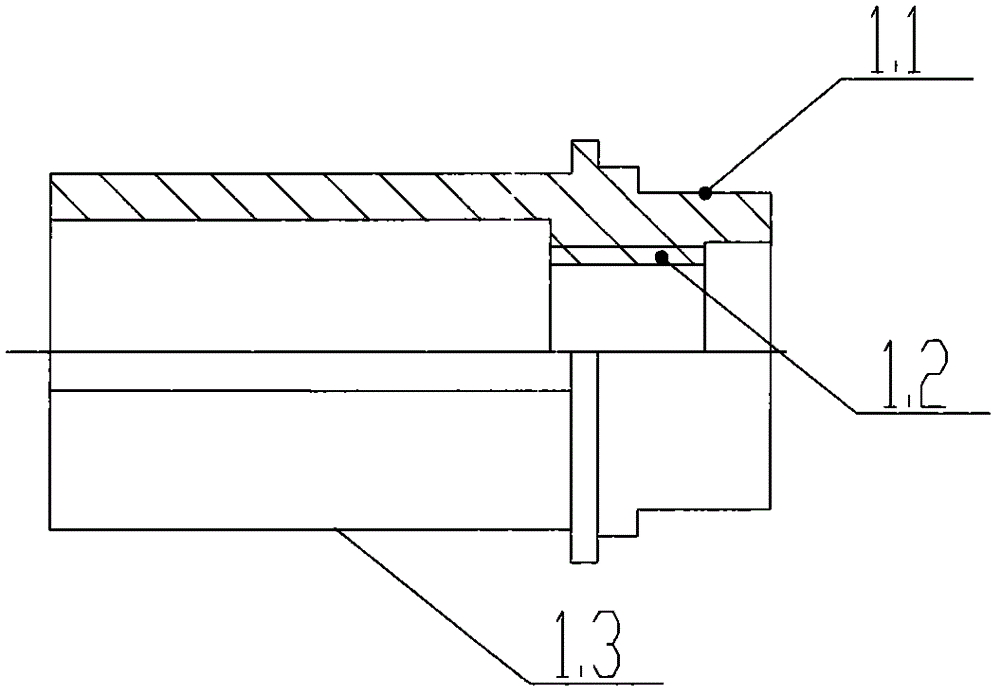

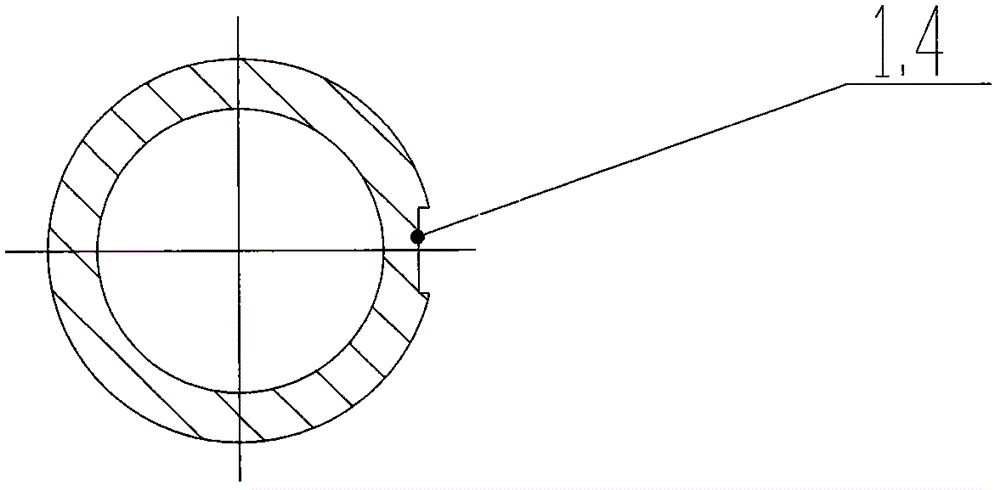

A kind of diamond grinding roller and its manufacturing method

ActiveCN104308756BEasy chip removalNo axial forceBonded abrasive wheelsGrinding devicesPulp and paper industryRadial surface

The invention provides a diamond grinding roller and a manufacturing method of the diamond grinding roller. The diamond grinding roller comprises a basic roller, a grinding bucket and a column type fixed part, wherein the basic roller comprises a connecting part used for being connected with using equipment, the column type fixed part is used for connecting a grinding ring in a sleeved mode, the surface of the fixed part is axially provided with at least one constant hump or one depression, and the grinding bucket is provided with a plurality of superimposed grinding rings. Two ends of the diamond grinding roller are designed into an integrated cutting head, the middle part of the diamond grinding roller is a discontinuous cutting head, so that the relative positions of middle pieces can be arbitrarily placed, and the integrated gap groove is a large helical angle. The radial surface of the cutting head is an arc-shaped surface or a surface with an angle is formed with the radius, the structure is better for chip removal, the cutting blade is broken line shaped of parallel axes, an axial component force cannot occur during working, and the grinding is more stable. The integrated cutting head end pieces are arranged on the two ends, so that the outer working surface of the whole grinding roller has the cutting head contact grinding at any time, and the impact due to the intermittent grinding is prevented.

Owner:石家庄泰威科技有限公司

Tea caddy internal polishing device

The present invention discloses a tea caddy internal polishing apparatus, belongs to the field of tea caddies, comprises a motor mount having a motor mounted therein, a main shaft of the motor is fixedly connected with a polishing barrel which is in a hollow structure. The present invention utilizes the motor and the polishing barrel connected with the motor to polish the inner surface of the teacaddy, the operation is convenient, the man power is saved, the working efficiency is improved, the polishing process is stable, speed-uniform, continuous, and controllable, the polishing quality isguaranteed and the damage to the interior of the tea caddy is prevented.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

Glass grinding processing device

InactiveCN107971868AHigh degree of mechanizationImprove efficiencyEdge grinding machinesEngineeringMechanical engineering

The invention discloses a glass grinding processing device which comprises a processing table, a processing plate, a driving mechanism, a plurality of clamping parts and a grinding part. A sliding groove is formed in the processing table, and the processing plate is slidably connected with the sliding groove. The driving mechanism is used for driving the processing plate to move in the length direction of the sliding groove. The multiple clamping parts are sequentially distributed in the length direction of the sliding groove, and the clamping parts comprise supports, supporting blocks, firstthreaded rods, pressing plates and supporting frames. The supports are mounted on the processing plate, and the supporting blocks are mounted on the supports. First threaded holes are formed in the supporting blocks in the vertical direction, and the first threaded rods are located in the first threaded holes and are in threaded connection with the first threaded holes. The pressing plates are mounted at the bottom ends of the first threaded rods, and the supporting plates are located below the pressing plates and mounted on the processing plate. The grinding part is used for grinding glass.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

Grinding device of glass sheet

InactiveCN101837560BContinuous grindingIncrease productionEdge grinding machinesEngineeringFront edge

The invention relates to a grinding device (1) of a glass sheet, which is provided with a linear conveying unit (3), a first grinding device and a second grinding device. A glass sheet (2) is linearly conveyed by the linear conveying unit (3) along the X direction, the first grinding device is provided with grinding heads (5 and 6) for respectively grinding two lateral edges (4a and 4b) of the glass sheet (2) which is linearly conveyed by the linear conveying unit (3), and the second grinding device is adjacent to the first grinding device in the X direction and is provided with movable grinding heads (9 and 10) for respectively grinding a front edge (7) and a rear edge (8) extending along the Y direction orthogonal to the X direction in which the glass sheet (2) is linearly conveyed by the linear conveying unit (3).

Owner:BANDO KIKO CO LTD

Grinding device of glass plate

InactiveCN101332578BContinuous grindingIncrease productionEdge grinding machinesEngineeringFront edge

A grinding device (1) of a glass plate comprises a linear conveyance unit (3) which linearly conveys the glass plate (2) along the X direction; a first grinding device is provided with grinding heads (5) and (6) for respectively grinding the two side edges (4a) and (4b) of the glass plate (2) linearly conveyed by the linear conveyance unit (3) extending along the X direction; and a second grinding device is adjacent to the first grinding device in the X direction and provided with movable grinding heads (9) and (10) for respectively grinding a front edge (7) and a rear edge (8) extending along the Y direction orthogonal with the X direction for the linear conveyance by the linear conveyance unit (3).

Owner:BANDO KIKO CO LTD

Asphalt mixing and grinding equipment and grinding method thereof

The invention provides asphalt mixing and grinding equipment and a grinding method thereof, relates to the technical field of asphalt mixing and grinding, and solves the problem that the working efficiency is reduced under the condition of sectional grinding as an existing asphalt grinding device cannot perform unified grinding and treatment on asphalt in different specifications. A main body of the bearing mechanism is designed to be of a cuboid structure with the hollow interior, due to the fact that the secondary grinding mechanism is arranged, a cavity formed in the scraping assembly can be filled with an adjusting assembly with the proper aperture, and then grinding adjustability is achieved; and after assembly is completed, the covering assembly can be put down to make contact with the bearing assembly so that a rough grinding mechanism in the scraping assembly can be started, and a connecting assembly can drive a cross-shaped bottom stirring assembly to continuously rotate.

Owner:王海英

A wire rod surface derusting polishing machine

ActiveCN104907907BContinuous grindingEffective sandingGrinding drivesBelt grinding machinesElectrolysisAir pollution

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

A robot-based automatic grinding system

The invention discloses a robot-based automatic grinding system which comprises a grinder and a robot arranged behind the grinder. A feeding device is arranged beside the robot, a rotating shaft is arranged on the grinder, at least two profiling multi-leaf grinding wheels are arranged on the rotating shaft, and a profiling negative-suction clamp is arranged at the tail end of the robot. Since the profiling multi-leaf grinding wheels are arranged on the rotating shaft, each grinding wheel can be used for only a part of a product, the multi-leaf grinding wheel used for grinding corners is only used for grinding the corners, the multi-leaf grinding wheels used for grinding planes or large curved surfaces are specially used for grinding the planes and the large curved surfaces, and each grinding wheel can be abraded overall; and the multi-leaf grinding wheels become smaller overall while profiling shapes are not changed, and therefore the robot can achieve continuous grinding only through simple position compensation. The robot-based automatic grinding system is used for grinding products.

Owner:FOSHAN HUASHU ROBOTICS CO LTD

A Method for Adjusting the Position and Posture of the Tool Axis in the Grinding Process of Blade Parts

ActiveCN109857060BAchieve smooth transitionRealize continuous grindingNumerical controlCnc grindingEngineering

The invention discloses a method for adjusting the position and posture of the blade-like parts grinding tool shaft, which includes the following steps: Step 1, establishing the tool contact coordinate system ξ (L) and workpiece coordinate system ξ (w) , the tool axis vector is expressed in the workpiece coordinate system as: where α is the heel angle of the contact surface between the tool and the workpiece, and β is the side slip angle of the contact surface between the tool and the workpiece; step 2, discretize the tool contact, and get Angle θ between the tool axis vector at the i-th tool contact point and the tool-axis vector at the i+1th tool contact point i,i+1 , according to the formula to calculate the angular velocity ω between knife contact i and knife contact i+1 i,i+1 ; Step 3, establish the optimization objective function, obtain the tool axis vector attitude satisfying the minimum angular velocity according to the optimization objective function, and solve the kinematic relationship of each axis of the CNC grinding machine. It can realize the smooth processing of the tool during the grinding process, avoid overcutting or interference at the abrupt curvature of the blade parts, and ensure the surface processing quality.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com