A kind of diamond grinding roller and its manufacturing method

A manufacturing method and diamond technology, applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of low grinding speed, reduced surface quality of the grinding surface, and low roundness of the grinding roller, so as to improve the precision of processed products , Save production costs, cancel the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

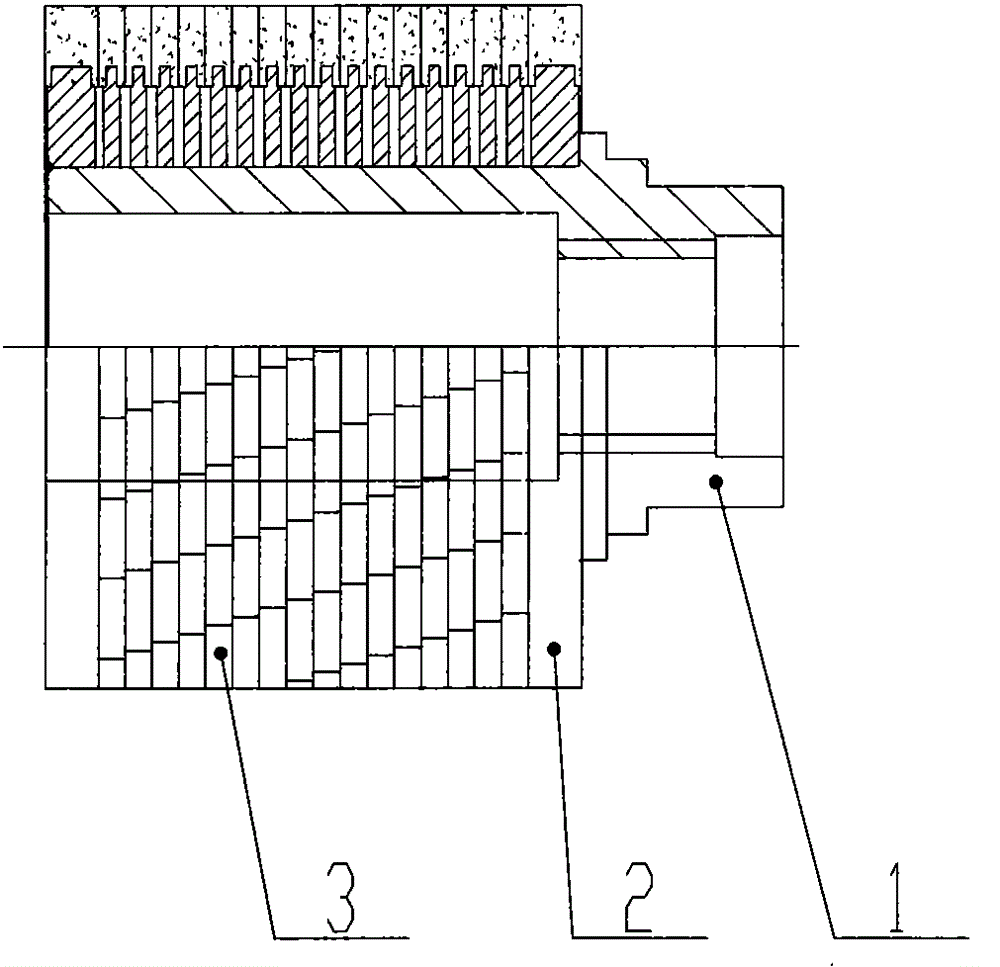

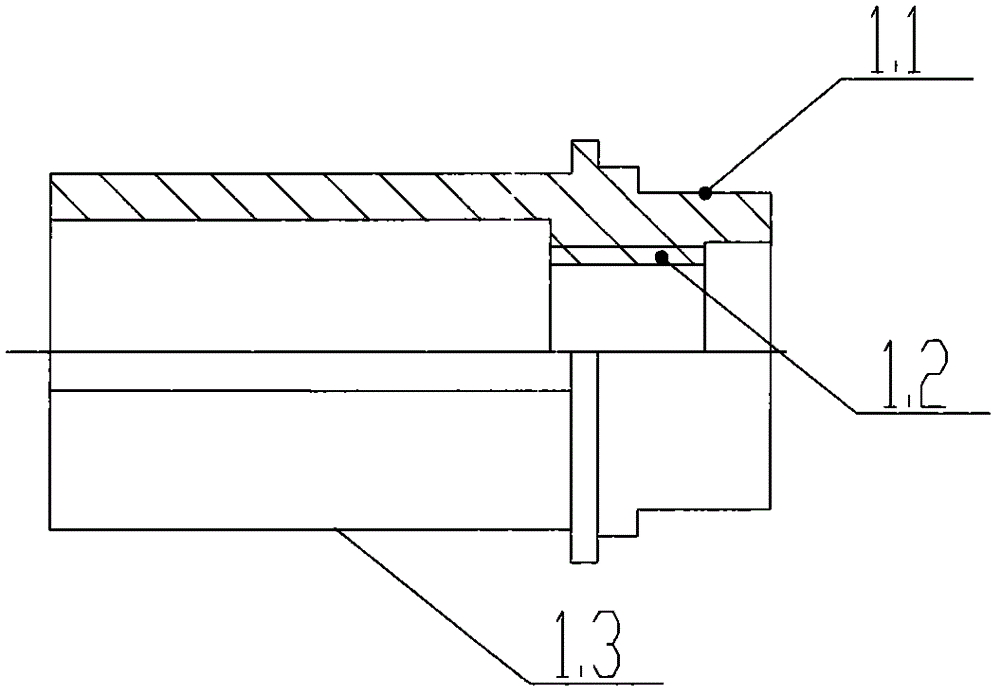

[0043] The present invention proposes a diamond grinding roller, such as figure 1 , figure 2 , image 3 As shown, including the base roller 1 and the grinding barrel,

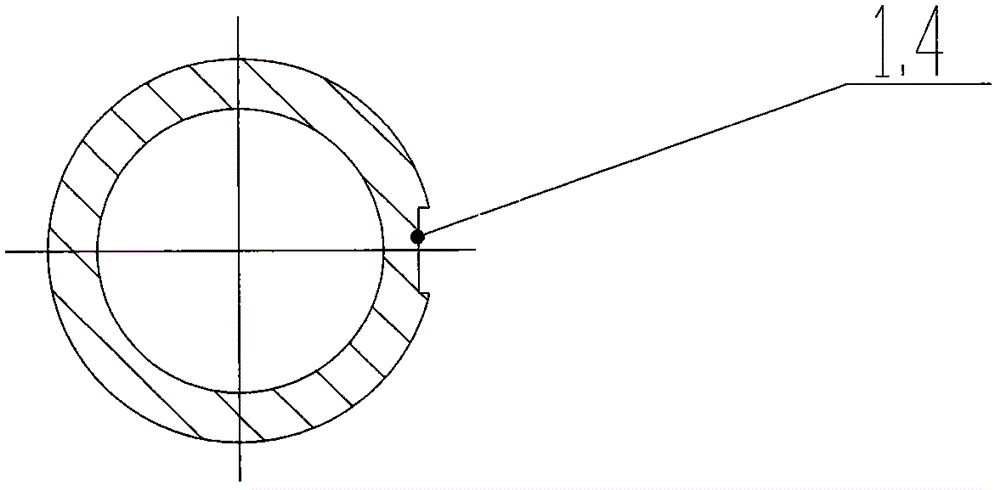

[0044]The base roll 1 includes a connecting portion 1.1 for connecting the equipment used, the connecting portion has a connecting thread 1.2, and also includes a cylindrical fixing portion 1.3 for fitting the grinding ring, and the surface of the fixing portion has at least A continuous depression 1.4, which can also be a protrusion;

[0045] The grinding barrel is formed by superimposing several grinding rings 2 and 3 with the same diameter, and the grinding ring is composed of a disc-shaped base body and a diamond cutter head arranged on the peripheral edge of the base body;

[0046] Such as figure 1 , Figure 4 , Figure 5 As shown, the grinding ring 2 located at both ends of the grinding bucket includes a base body 2.1, and its diamond cutter head is a continuous cutter head 2.2;

[0047] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com