Groove broaching machining equipment for custom-made furniture boards

A processing equipment and grooving technology, which is applied in the field of customized furniture sheet grooving processing equipment, can solve the problems of low sheet processing accuracy, uncontrollable operation error, high sheet scrap rate, etc., achieve stable and reliable vacuum adsorption force, and reduce sheet size range restrictions, the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

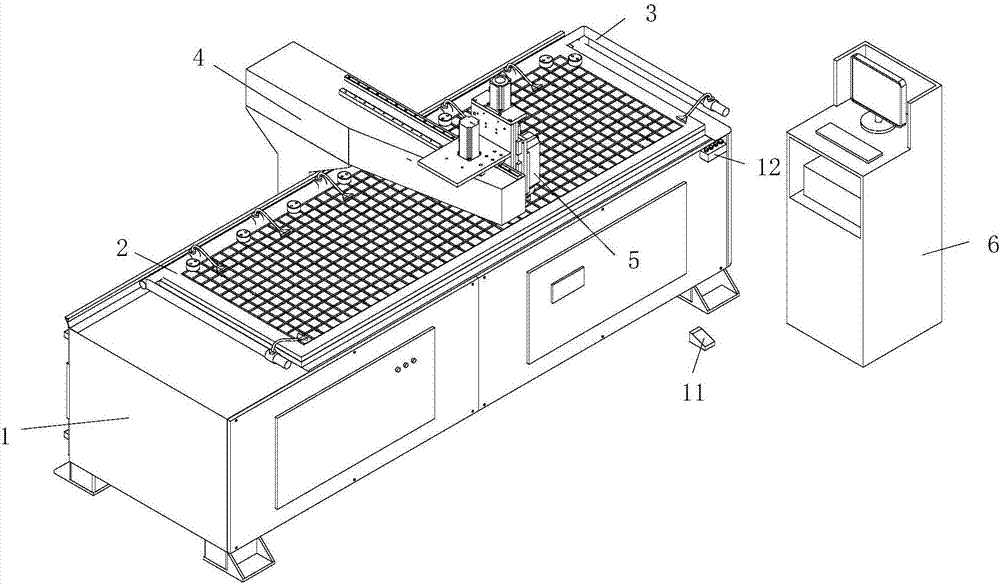

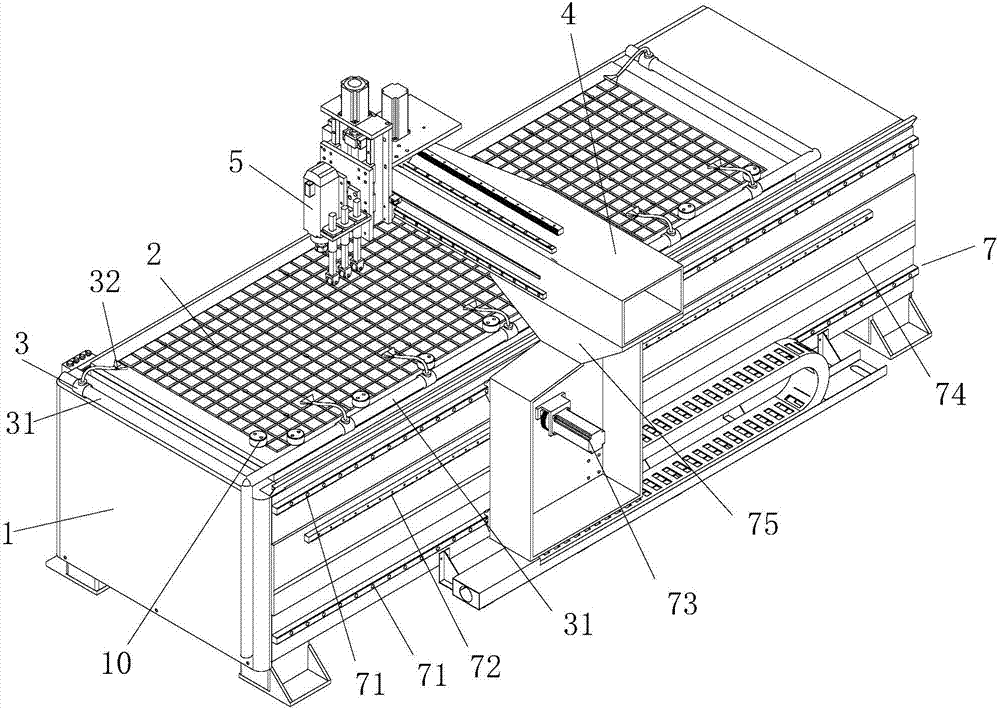

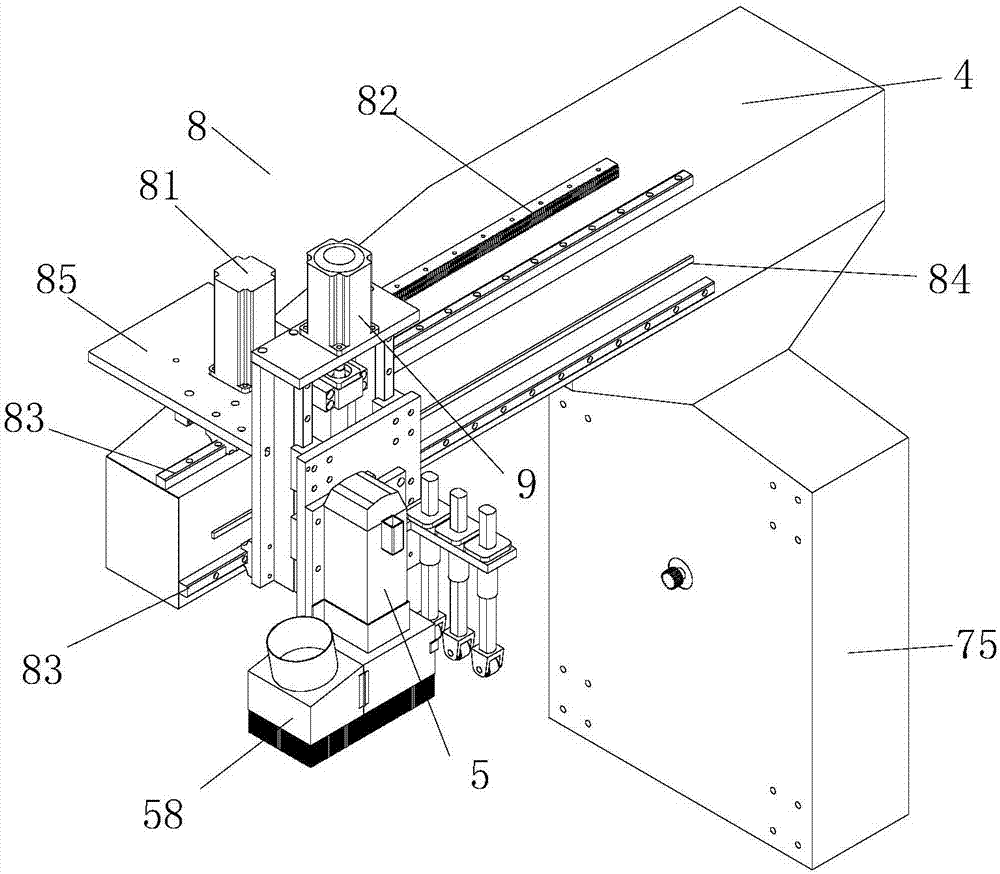

[0040] Such as Figure 1 to Figure 6 As shown, a kind of custom-made furniture sheet groove processing equipment of the present invention comprises:

[0041] A frame 1 provided with a processing platform;

[0042] Vacuum adsorption platform 2 for vacuum adsorption and fixing plates;

[0043] A chip blowing mechanism 3 used for jetting to remove waste chips on the vacuum adsorption platform 2;

[0044] A groove head 5 for realizing groove processing;

[0045] The cantilever beam 4 that is used to hang the slotting head 5;

[0046] and the control device 6;

[0047] There is a processing area on the processing platform of the frame 1; the vacuum adsorption platform 2 is located on the processing area; the chip blowing mechanism 3 is located on the side of the processing area; the groove head 5 is located above the processing area; the cantilever beam 4 moves through the X axis The mechanism 7 is movably arranged on the frame 1, and the control device 6 is signal-connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com