Spiral grinding pump of continuous offshore fracturing fluid blending device

A fracturing fluid and spiral technology, applied in the field of grinding pumps, can solve problems such as the inability to realize continuous mixing of fracturing fluids, achieve rapid online grinding operations, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

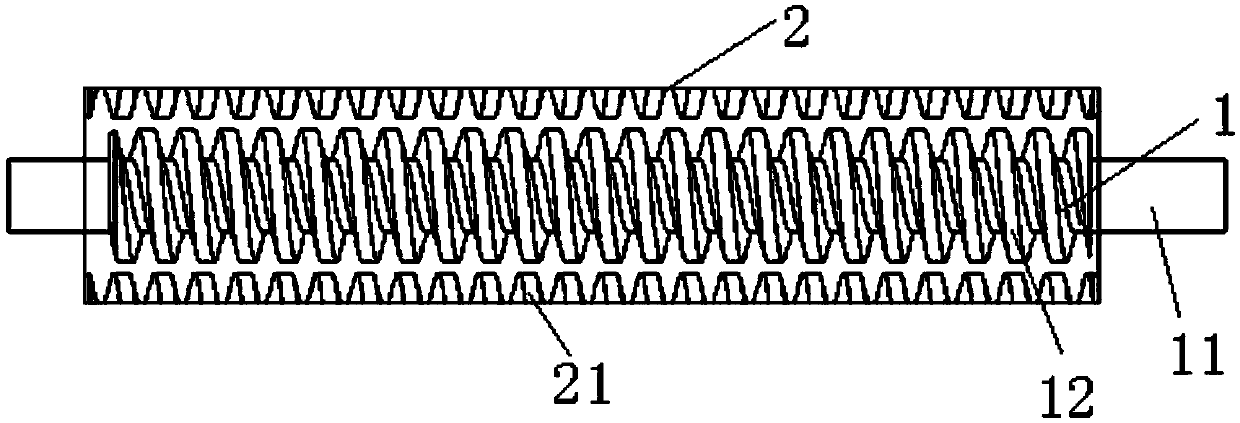

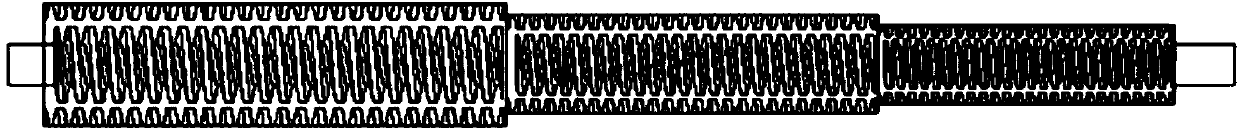

[0016] like figure 1 As shown, the screw grinding pump of the present invention includes a pump shaft 1 and a pump casing 2 set outside the pump shaft 1 . Both the pump spindle 1 and the pump housing 2 are connected to an external driving device (not shown in the figure). One end of the pump mandrel 1 and one end of the corresponding pump housing 2 form a pump inlet, and the other end of the pump mandrel 1 and the other end of the corresponding pump housing 2 form a pump outlet.

[0017] In the above embodiments, the pump spindle 1 includes a central shaft 11 and helical external threads 12 provided on the outer surface of the central shaft 11 at equal intervals or with gradually changing pitches. The inner surface of the pump housing 2 is provided with helical internal threads 21 at equal intervals or gradually changing pitches, the length of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com