Asphalt mixing and grinding equipment and grinding method thereof

A technology of mixing grinding and asphalt, applied in the direction of grain processing, etc., can solve the problems of damaged asphalt equipment, unable to self-clean asphalt operation, reduce work efficiency, etc., to ensure the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

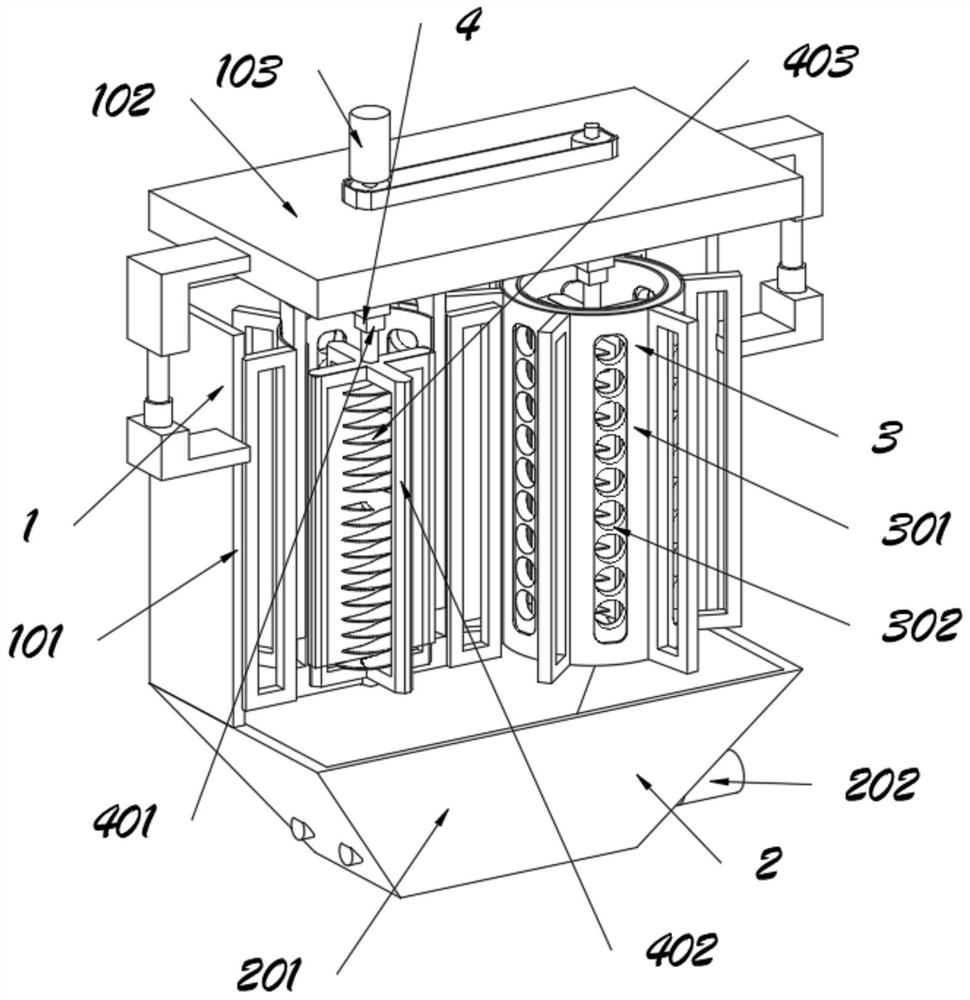

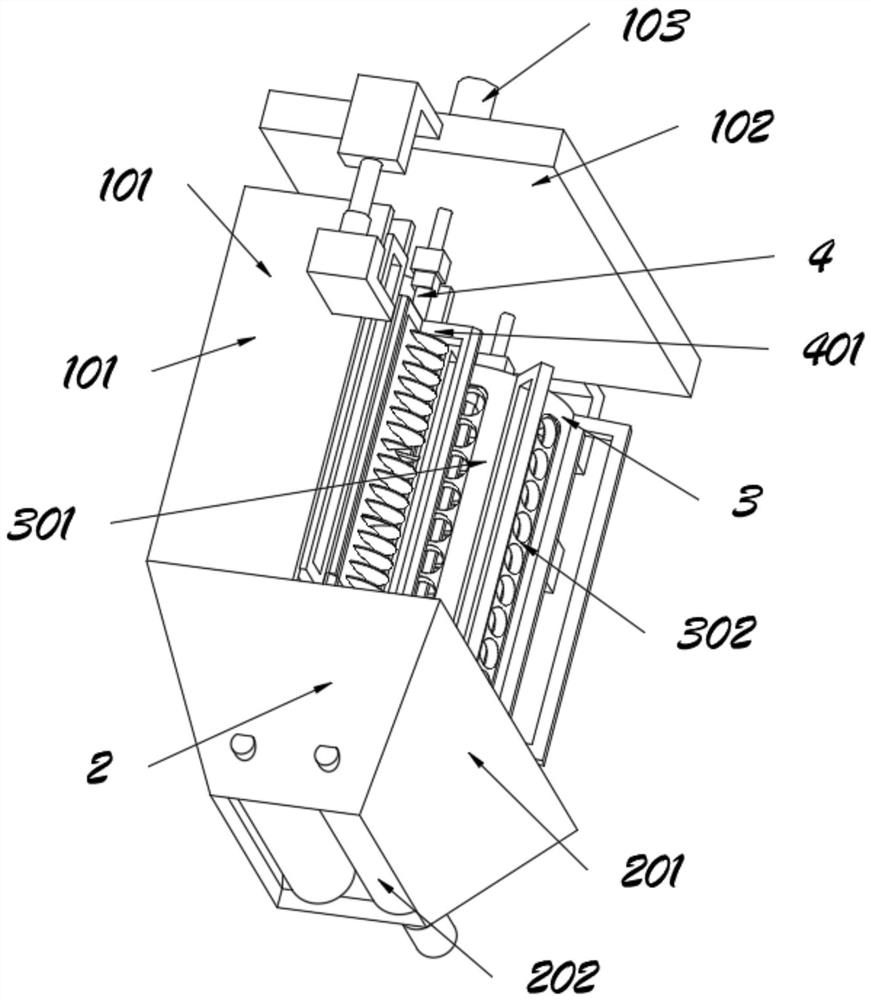

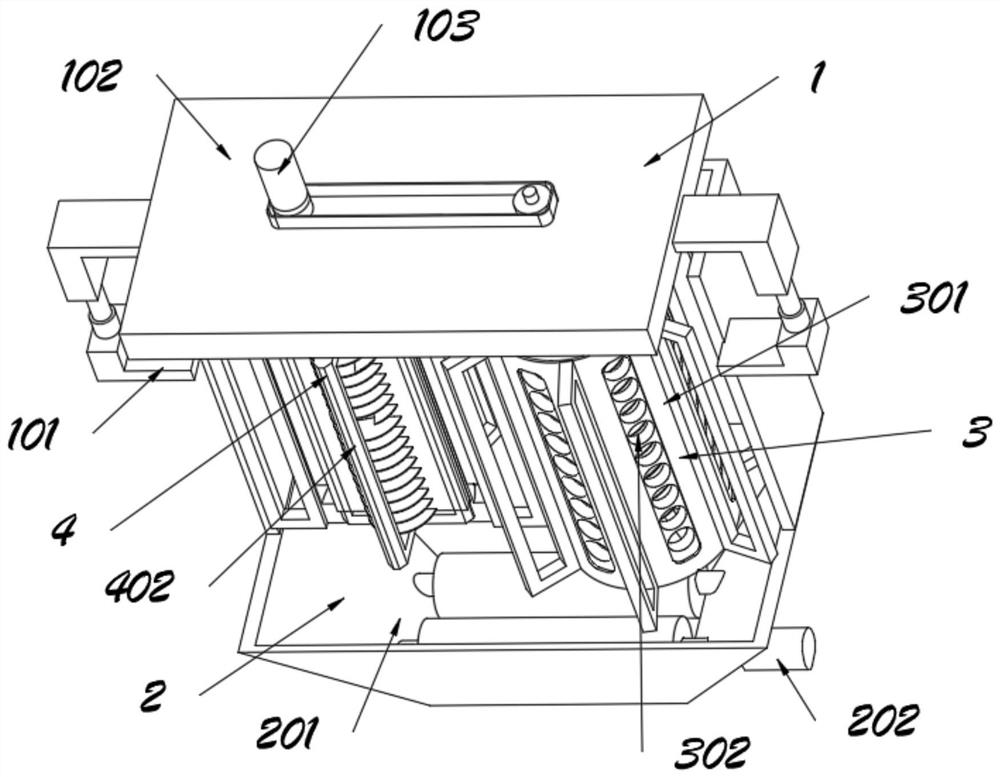

[0053] as attached figure 1 to the attached Figure 8 shown:

[0054] The present invention provides an asphalt mixing and grinding equipment and a grinding method thereof, comprising: a bearing mechanism 1;

[0055] The main body of the carrying mechanism 1 is designed with a hollow cuboid structure, and the bottom side of the carrying mechanism 1 is also equipped with a fine grinding mechanism 2, and above the fine grinding mechanism 2 are also provided with a secondary grinding mechanism 3 and a rough grinding mechanism 4. The main body of the component 403 is designed in a spiral structure, and the material guide component 403 is designed in a reverse segmented structure, and the material guide component 403 is installed at the outer position of the connecting component 401 to carry the component 101. The main body of the carrying component 101 is hollow inside The cuboid structure is designed, and the left and right sides of the carrying component 101 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com